Frameless composite heat-insulation fireproof glass splicing structure

A fireproof glass and fireproof glue layer technology, which is applied to glass/slag layered products, building components, building structures, etc. Aesthetics, strength and safety, flame and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

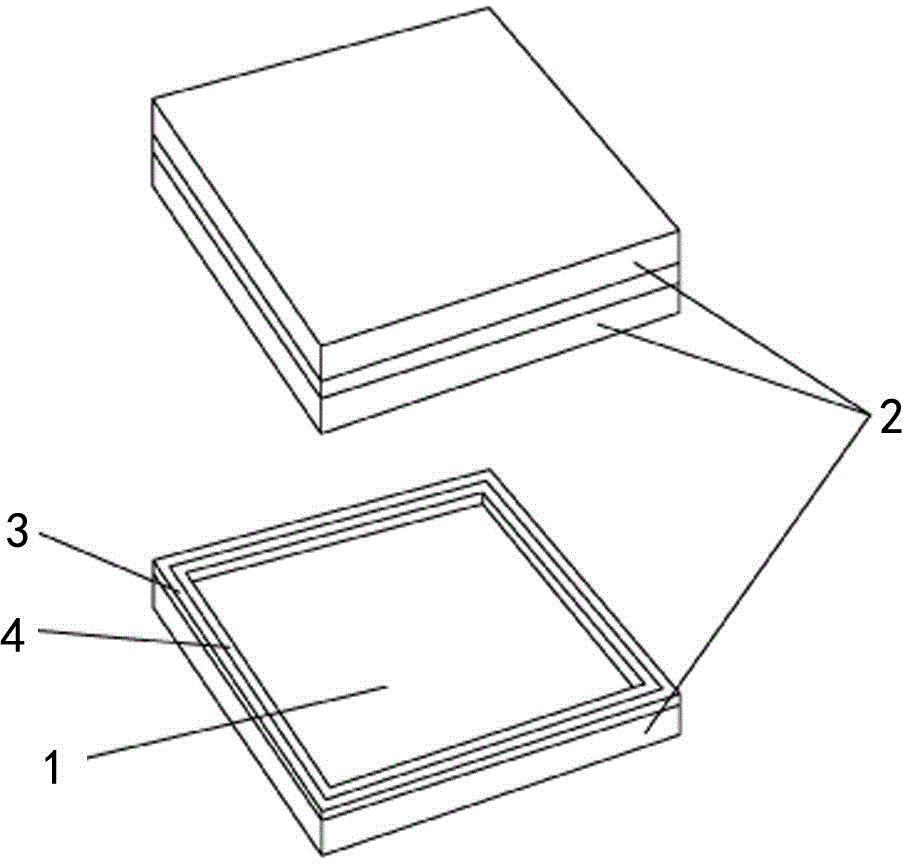

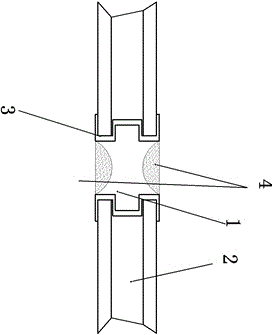

[0018] see Figure 1-2 As shown, the present invention relates to a frameless composite heat-insulating fireproof glass splicing structure, which includes two pieces of fireproof glass substrates 2, and the fireproof glass substrates 2 are arranged in parallel with each other. There is a PVC bead 3, and the heat-insulating bead 3 and the adjacent fireproof glass substrate 2 form a sealed accommodation chamber, and two layers of silicone rubber layer 4 and a layer of transparent fireproof glue layer 1 are poured into the chamber, so that The above-mentioned transparent fireproof adhesive layer 1 is arranged between two silicone adhesive layers 4 .

[0019] A method for manufacturing a frameless composite heat-insulating fireproof glass splicing structure, the steps comprising:

[0020] (1) First set and fix the two fire-resistant glass substrates in parallel up and down to make the facade smooth;

[0021] (2) Adjust the distance between the two fire-resistant glass substrates...

Embodiment 2

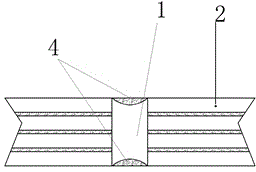

[0026] see figure 1 and 3 As shown, the present invention relates to a frameless composite heat-insulating fireproof glass splicing structure, including four pieces of fireproof glass substrates 2, the fireproof glass substrates 2 are arranged parallel to each other, and the gaps between each adjacent fireproof glass substrates form a container Two layers of silicone rubber layers 4 are poured on both sides of the cavity, and a layer of transparent fireproof glue layer 1 is poured in the middle, and the transparent fireproof glue layer 1 is arranged between the two silicone rubber layers 4 .

[0027] A method for manufacturing a frameless composite heat-insulating fireproof glass splicing structure, the steps comprising:

[0028] (1) First set and fix the two fire-resistant glass substrates in parallel up and down to make the facade smooth;

[0029] (2) Adjust the distance between the two fire-resistant glass substrates as small as possible, and form an accommodation cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com