Burning explosion mechanism capable of preventing reverse fire moving

A kind of explosion and reverse technology, which is applied in the direction of blasting cylinders, mechanical equipment, functional valve types, etc., can solve the problems of gas reverse fire, high system pressure, system damage, etc., and achieve the effect of preventing cross fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

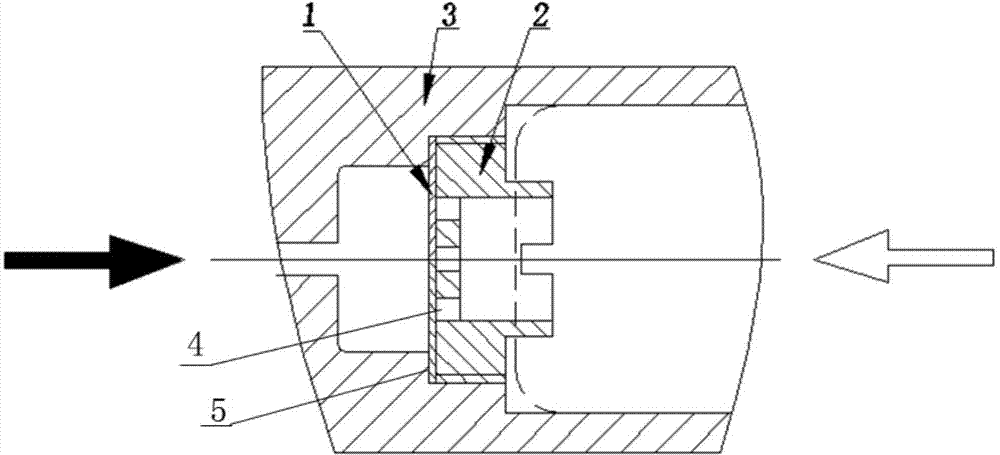

[0015] Such as figure 1 The shown embodiment of the combustion and explosion mechanism of the present invention that can prevent reverse crossfire includes a gas channel 3, a throttling plate 2 is arranged in the gas channel 3, and a plurality of through holes 4 are opened on the throttle plate 2; throttling A blocking piece 1 is provided between the plate 2 and the channel outlet, and the blocking piece 1 closely covers the side of the throttling plate 2 .

[0016] The cross-sections of the gas channel 3 and the throttling plate 2 are circular, and the inner diameter of the gas channel between the throttling plate 2 and the channel outlet is reduced, and the throttling plate 2 presses the blocking piece 1 on the stepped surface of the gas channel 3 .

[0017] A screw port is provided on the contact surface between the inner wall of the gas channel and the throttling plate 2, and the arc surface of the throttle plate 2 is provided with a screw port matching the inner wall of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com