Spaced special-shaped combined firework and preparation method thereof

A technology for combining fireworks and fireworks, applied in the directions of fireworks, offensive equipment, weapon types, etc., can solve the problems of low production work efficiency, high labor intensity, difficult to guarantee production quality, etc., and achieve simplified production process, high structural strength, and improved safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

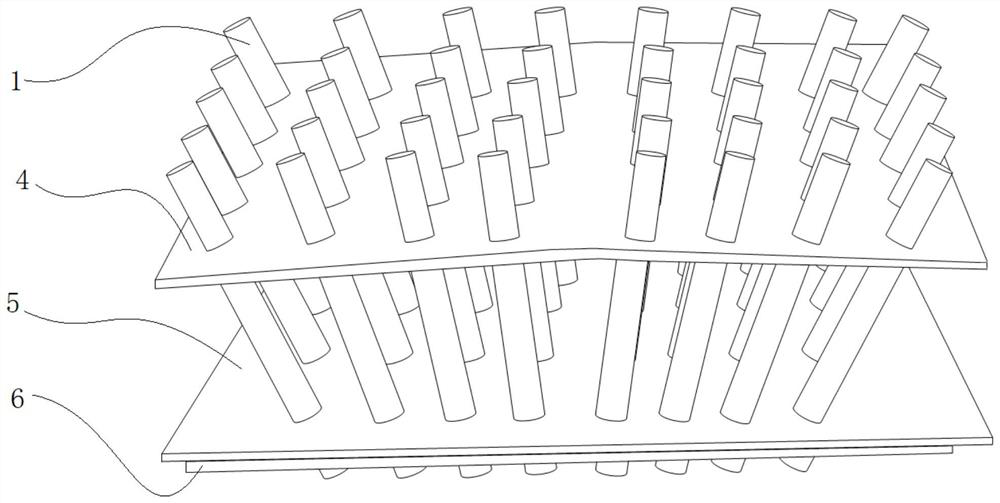

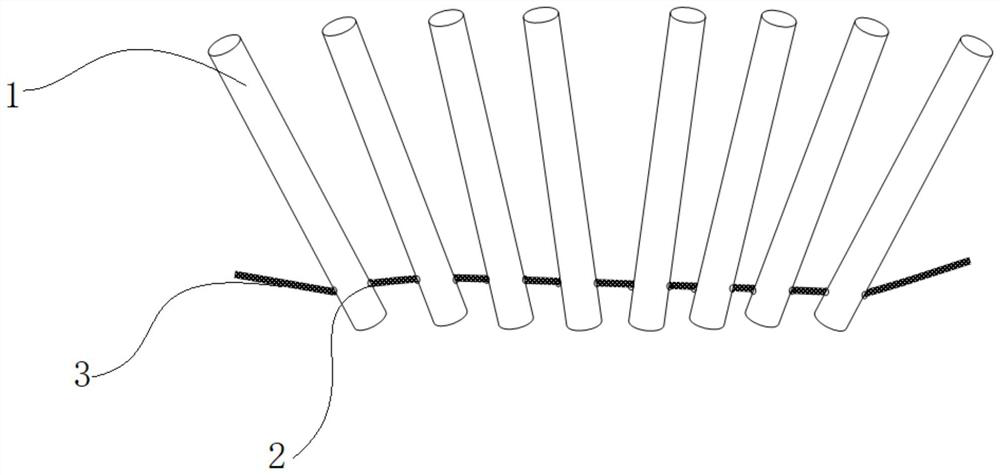

[0045] Embodiment 1: see attached Figure 1-6 , reflecting a specific structure of the present invention, the spaced special-shaped combined fireworks, forty (fat) fireworks paper tubes 1 are distributed in a manner of 5 rows × (8 pieces / row), and the firework paper tubes 1 are near the bottom A lead wire hole 2 is provided, and a fire transmission lead wire 3 is sequentially connected in series with each row of fireworks paper tubes 1 .

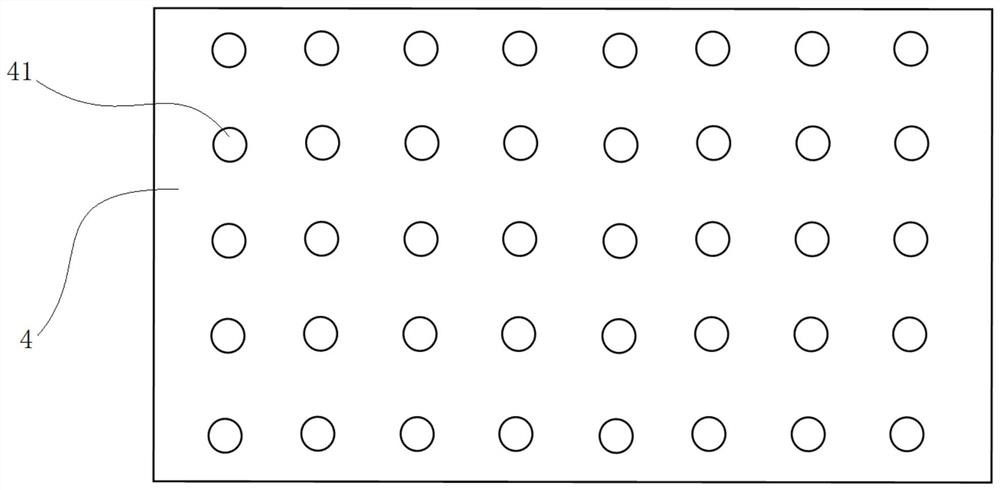

[0046] The combined firework includes positioning upper cardboard 4 and lower positioning cardboard 5 distributed up and down, forty upper positioning holes 41 are distributed on the upper positioning cardboard 4, forty lower positioning holes 51 are distributed on the lower positioning cardboard 5, and the upper positioning holes 41 and the lower positioning hole 51 are set correspondingly: in this example, compared with the corresponding upper positioning hole 41, the hole spacing of the lower positioning hole 51 is smaller and close to th...

Embodiment 7

[0059] Embodiment 7: see attached Figure 7 , and the difference from Example 1 is that the setting of the glue guide groove is not to use a whole piece of glue guide cardboard to punch out the glue guide groove. Instead, six paper strips 103 are used to stick on the lower side of the positioning lower cardboard 101 , and the concave area between the six paper strips 103 constitutes the glue guide groove 104 . When sticking, the bottom ports of each row of lower positioning holes 102 are located in the same glue guide groove 104 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com