Carbon fiber composite material for high-temperature environment and preparation thereof

A composite material and carbon fiber technology, which is applied in the field of reinforced heat-resistant carbon fiber composite materials and its preparation, can solve problems such as poor thermal conductivity, low heat distortion temperature, and insufficient thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

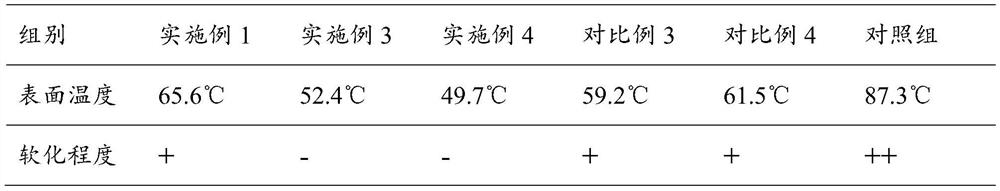

Examples

preparation example 1

[0097] Preparation of multi-component composite thermally conductive fillers with resin-coated thermally conductive components

[0098] 100g graphene nanosheets (thickness 2-3nm, average diameter 8-10μm), 50g spherical boron nitride (average particle size 10μm), 30g alumina particles (average particle size 15μm), 420g vinyl epoxy resin and 32g Diethylenetriamine, 18g hexamethylenetetramine mixed curing agent, stir and mix evenly, then centrifuge the mixture at 3000rpm for 10 minutes, pour off the upper liquid in the centrifuge tube, put the precipitate in an oven and preheat at 60°C for 1.5h , cured at 120°C for 2 hours, pulverized and granulated after complete curing, and the particle size was controlled within 100 μm to obtain a multi-component composite thermally conductive filler with resin-coated thermally conductive components; the thermal conductivity of the sample was 12.4W / mK (tested by steady-state heat flow method) .

preparation example 2

[0100] Preparation of Toughened Resin Composite

[0101] 1) Mix 100 parts by weight of bismaleimide resin and 20 parts by weight of polyethersulfone resin (hydroxyl-terminated reactive polyethersulfone PESU), heat to 158-160 ° C, stir and mix until the resin is completely dissolved, and then Cool down to 100-110°C in a vacuum oven, pour into a mold at 120°C after vacuum defoaming treatment, then perform curing treatment, and finally cool naturally to room temperature to obtain a toughened resin matrix; among them, the curing process is: first at 130°C Incubate for 1h; then maintain at 160°C for 1h; finally maintain at 200°C for 4h.

[0102] 2) Grind the toughening resin matrix raw material in a mixer and mix it with 20 parts by weight of auxiliary toughening agent maleic anhydride grafted EPDM, and melt the mixture in a screw extruder at 270-280°C. After cooling, pelletizing, drying and other post-treatments, the toughened resin composite can be obtained.

preparation example 3

[0104] Preparation of the first composite resin composition

[0105] 1) Weigh the materials according to the following proportions by weight: 60 parts of polybutylene adipamide resin, 18 parts of polyetherimide resin (PEI), 5 parts of polybismaleimide, 12 parts of toughened resin Composite, 10 parts of composite thermally conductive filler, wherein the resin raw material is pre-dried at 110-120°C for 4 hours;

[0106] 2) Put the above materials, 0.5 parts by weight of silicone lubricant, and 0.5 parts of calcium silicate into a high-speed mixer, and stir for 5-10 minutes to obtain a premix;

[0107] 3) After mixing, feed the above-mentioned premixed material from the main feeding port of the twin-screw extruder, and feed 15 parts by weight of chopped carbon fibers (5-10 microns in diameter and 0.2-0.3 mm in length) from the side feeding port added, blended for 45 seconds, melted and extruded, cooled, pelletized and dried to obtain the first composite resin composition.

[0108...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com