Thermosetting composite polystyrene exterior wall thermal insulation system thermal insulation board coating preparation system and method

A polystyrene and exterior wall insulation technology, which is applied in the direction of mixing methods, chemical instruments and methods, mixers, etc., can solve the problems of uneven distribution of aggregates, low mixing efficiency, and affecting the insulation effect of coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

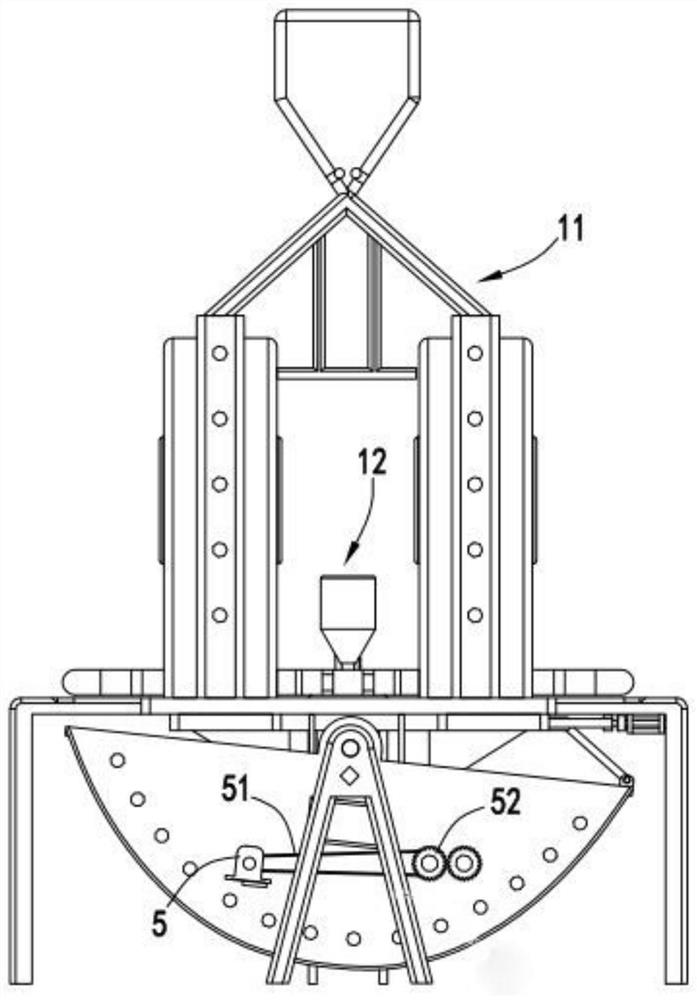

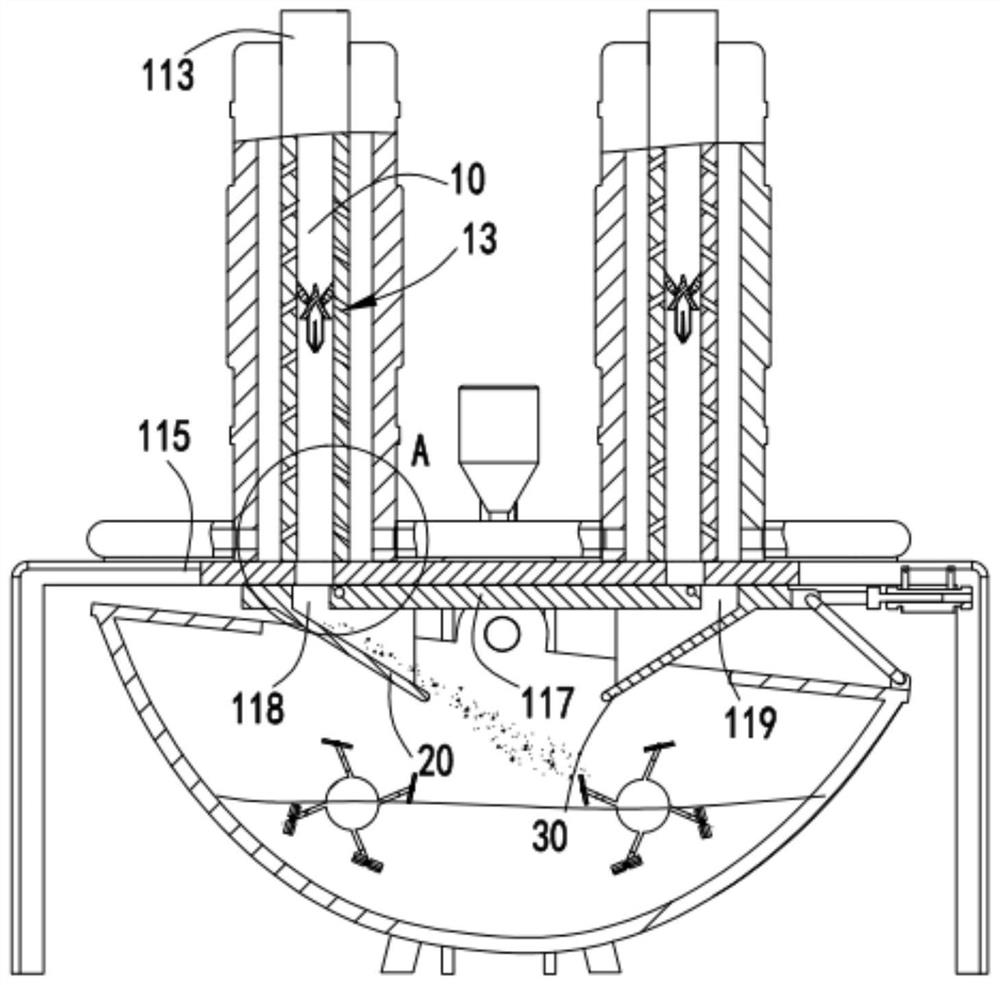

[0063] Such as Figure 1 to Figure 15 As shown, the thermosetting composite polystyrene exterior wall insulation system insulation board coating preparation system includes a mixing device 1 and a mixing device 2 arranged below the mixing device 1;

[0064] The mixing device 1 includes an aggregate conveying mechanism 11, a powder blowing mechanism 12 arranged on both sides of the aggregate conveying mechanism 11, and a transposition mechanism 13 arranged inside the aggregate conveying mechanism 11. The aggregate conveying mechan...

Embodiment 2

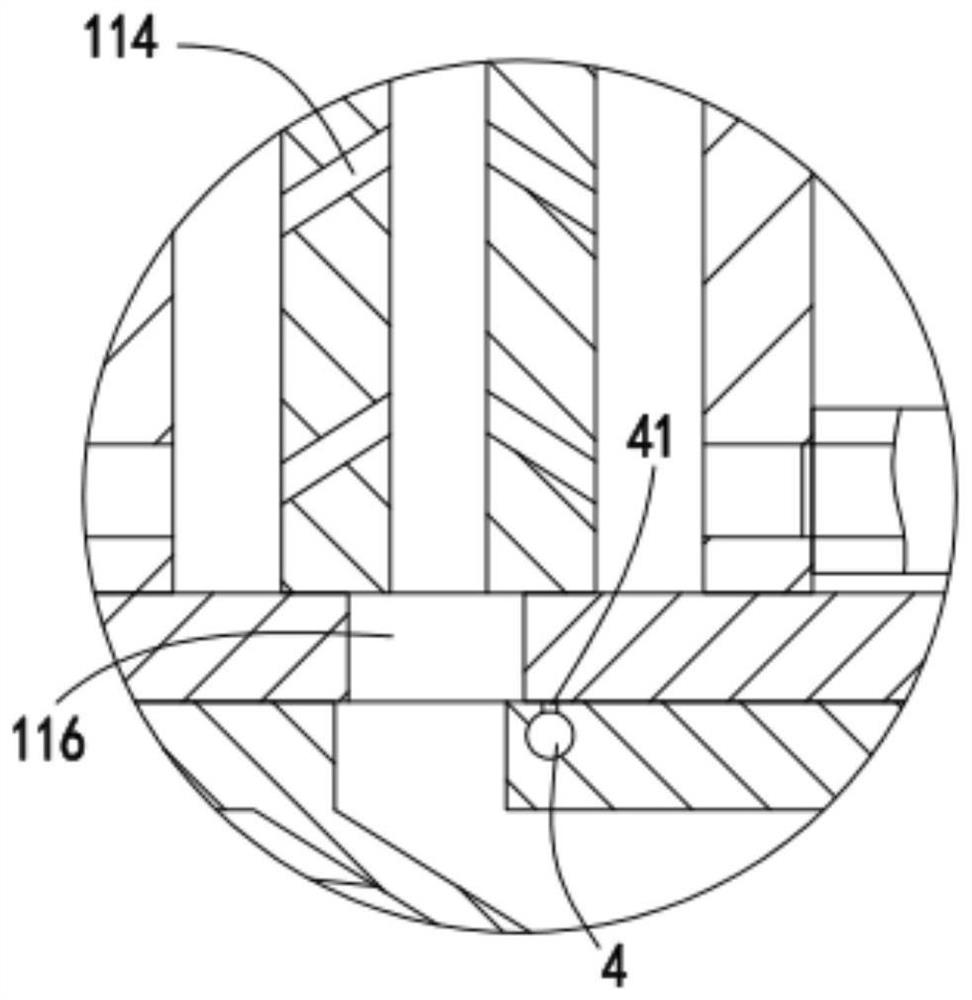

[0083] Such as image 3 with Figure 14 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The advantage is that: further, the sides of the discharge port b118 and the discharge port c119 are provided with long strip-shaped channels 4, and the upper surface of the switching plate 117 is provided with several communication channels along the length direction of the channel 4 4, the channel 4 is connected to the air blower 125 through a hose 42.

[0084] In this embodiment, by opening a strip-shaped channel 4 on the side of the discharge port b118 and the discharge port c119, the upper surface of the switching plate 117 is provided with a number of air holes 41 communicating with the channel 4 along the length direction of the c...

Embodiment 3

[0086] Such as Figure 16 Shown, the preparation method of thermosetting composite polystyrene exterior wall insulation system thermal insulation board coating includes the following production steps:

[0087] Step 1, the aggregate conveying process, the aggregate in the hopper 111 falls evenly along the mixing channel 10 after passing through the material distribution channel 112;

[0088] Step 2, a mixing process, the powder blowing mechanism 12 blows the powder into the mixing channel 10 during the falling of the aggregate in the step 1, and mixes with the aggregate in the mixing channel 10;

[0089] Step 3, the transposition process, the material that has been mixed once in step 2 continues to fall to the transposition mechanism 13, and the material close to the side wall of the mixing channel 10 is transferred to the middle of the mixing channel 10 under the action of the transposition mechanism 13 The position continues to fall, and the material in the middle position i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com