A kind of composite foam paper product and its preparation method and application

A technology for composite foaming and paper products, applied in papermaking, patterned paper, paper coatings, etc., can solve the problems of inability to meet the printing effect of enterprises or individuals, the effect is not obvious, and the printing of foamed materials is rough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

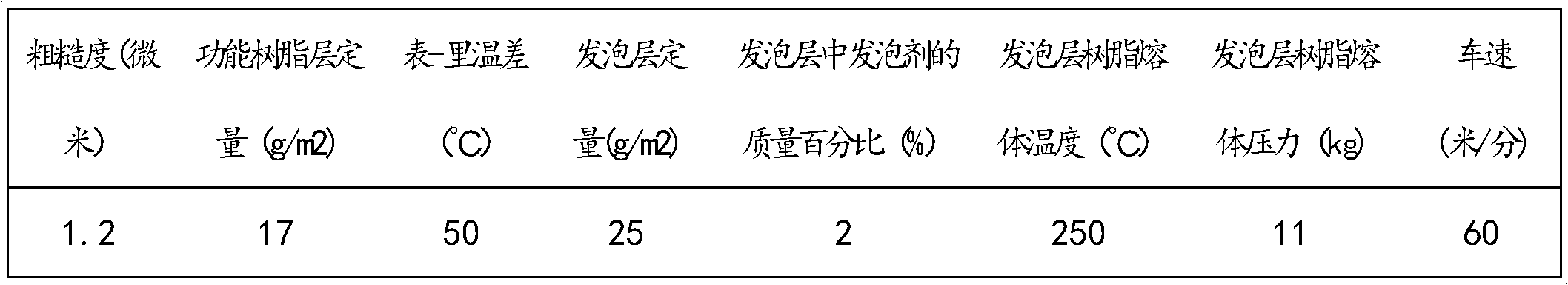

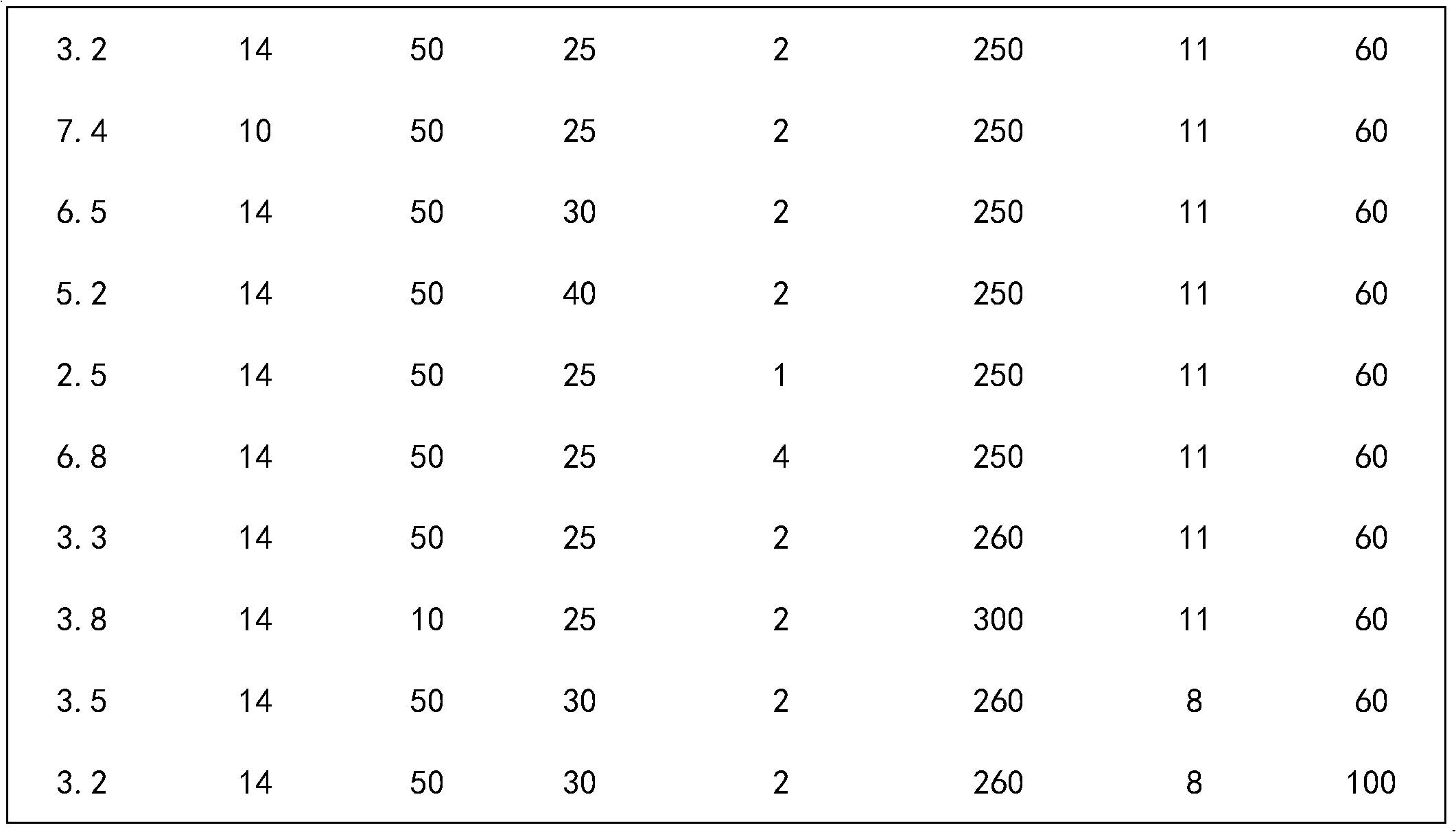

Examples

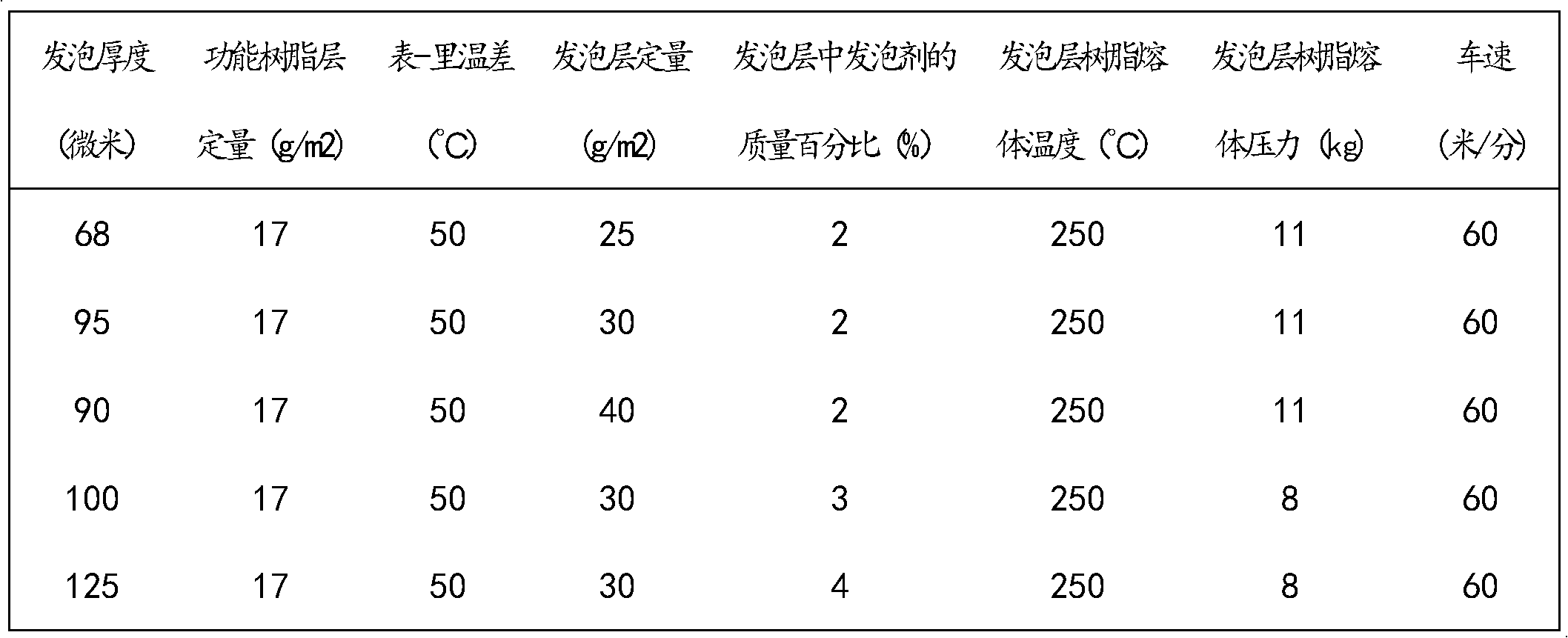

Embodiment 1

[0064] A composite foamed paper product is composed of a first functional resin layer, a foam layer, a paper cup base paper and a second functional resin layer, which are sequentially extruded and fixed. The specific preparation method is as follows: take 230 g / m2 of paper cup base paper as the base material, and on one side of the paper cup base paper, use 14 g / m2 of LDPE as the first functional resin layer (playing the role of printing layer), LDPE The melt temperature is 310 degrees Celsius, and the resin melt pressure is 4KG; 30 grams / square meter of composite resin is used as a foam layer, wherein the composite resin is made of 96% (w / w) of LDPE and 4% (w / w) of absorbent Composed of thermal foaming agent HYDROCEROL.BIH (Dongguan Kejia Plastic Chemical Co., Ltd.), the melt temperature of the composite resin is 260 degrees Celsius, and the resin melt pressure is 8KG; on the other side of the paper cup base paper, according to 18 g / The LDPE of square meter is made the secon...

Embodiment 2

[0066] A composite foamed paper product is composed of a functional resin layer, a foamed layer and paper cup base paper which are sequentially extruded and fixed. The specific preparation method is as follows: take 230 g / m2 of paper cup base paper as the base material, and on one side of the paper cup base paper, use 14 g / m2 of LDPE as the first functional resin layer (playing the role of printing layer), LDPE The melt temperature is 300 degrees Celsius, and the resin melt pressure is 6KG; 30 grams / square meter of composite resin is used as the foam layer, and the composite resin is made of 98% (w / w) LDPE and 2% (w / w) of environmental protection Type PE foaming agent HYDROCEROL.BIH (Dongguan Kejia Plastic Chemical Co., Ltd.), the melt temperature of the composite resin is 260 degrees Celsius, and the resin melt pressure is 8KG; according to the proportional relationship and processing conditions, through multi-layer composite Casting extrusion production line (equipment purch...

Embodiment 3

[0068] A compound foamed paper product is composed of a first foam layer, a cardboard and a second foam layer through extrusion compounding and fixing. Its specific preparation method is: take 450 grams / square meter of cardboard as the base material, on one side of the cardboard, make the first foaming layer according to the composite resin of 40 grams per square meter, wherein the composite resin is made of 99% (w / w) composed of PP and 1% (w / w) blowing agent, the melt temperature of the composite resin is at 300 degrees Celsius, and the resin melt pressure is at 7KG; Composite resin is used as the second foam layer, wherein the composite resin is composed of 93% (w / w) PE and 7% (w / w) foaming agent HYDROCEROL.BIH, the melting temperature of the composite resin is 240 degrees Celsius, and the resin The melt pressure is 11KG. According to the proportional relationship and processing conditions, through the multi-layer composite casting extrusion production line (the equipment i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com