Wall building material and preparing method thereof

A technology for building materials and walls, applied in the field of building materials, can solve the problems of poor thermal insulation effect, low waste recycling rate, poor sound absorption effect, etc. , Good sound absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

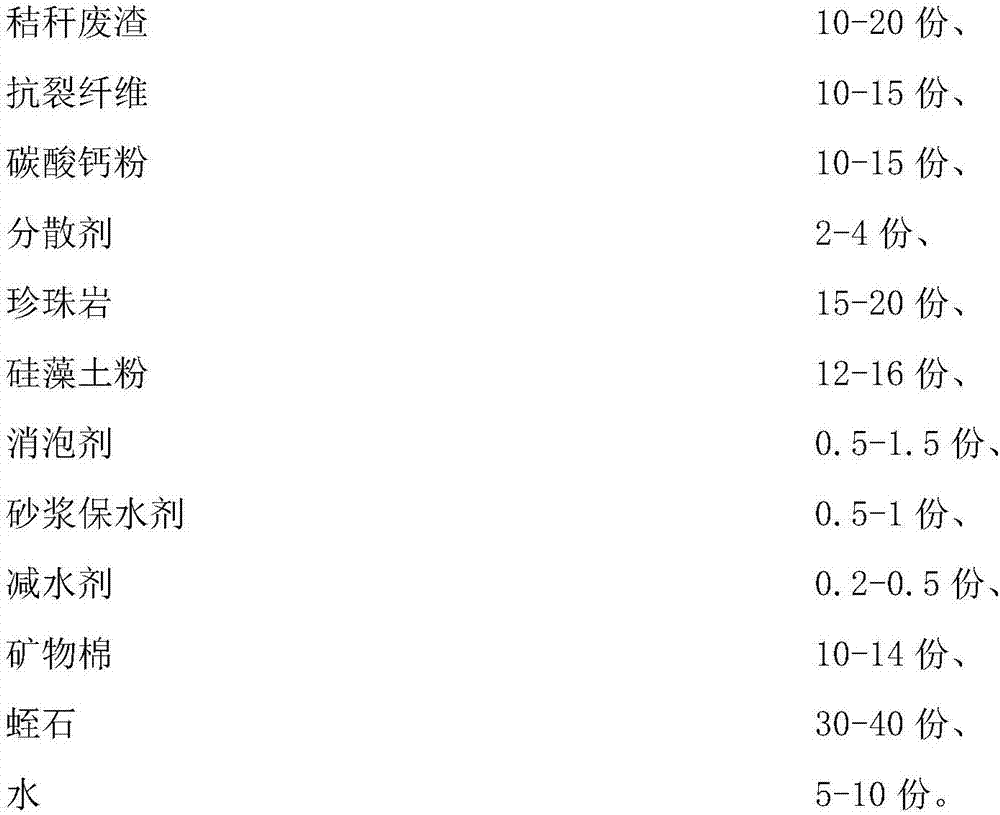

[0034] A wall construction material, which is made of the following raw materials in parts by weight:

[0035]

[0036]

[0037] Mineral wool is glass wool, and glass wool has the advantages of good molding, low bulk density, low thermal conductivity, thermal insulation, good sound absorption effect, and good corrosion resistance.

[0038] A method for preparing a wall building material, comprising the steps of:

[0039] (1) Weigh 65 parts of waste ceramic material, 55 parts of rock wool board waste, 18 parts of straw waste residue, 14 parts of anti-crack fiber, 13 parts of calcium carbonate powder, 18 parts of perlite, and 15 parts of diatomite powder according to parts by weight , 1 part of defoamer, 0.8 part of mortar water-retaining agent, 0.4 part of water-reducing agent, 12 parts of mineral wool, and 35 parts of vermiculite are put into the mixer, and the rotation speed is controlled at 160r / min, stirred for 40min, and mixed evenly to obtain a solid mixture ;

[...

Embodiment 2

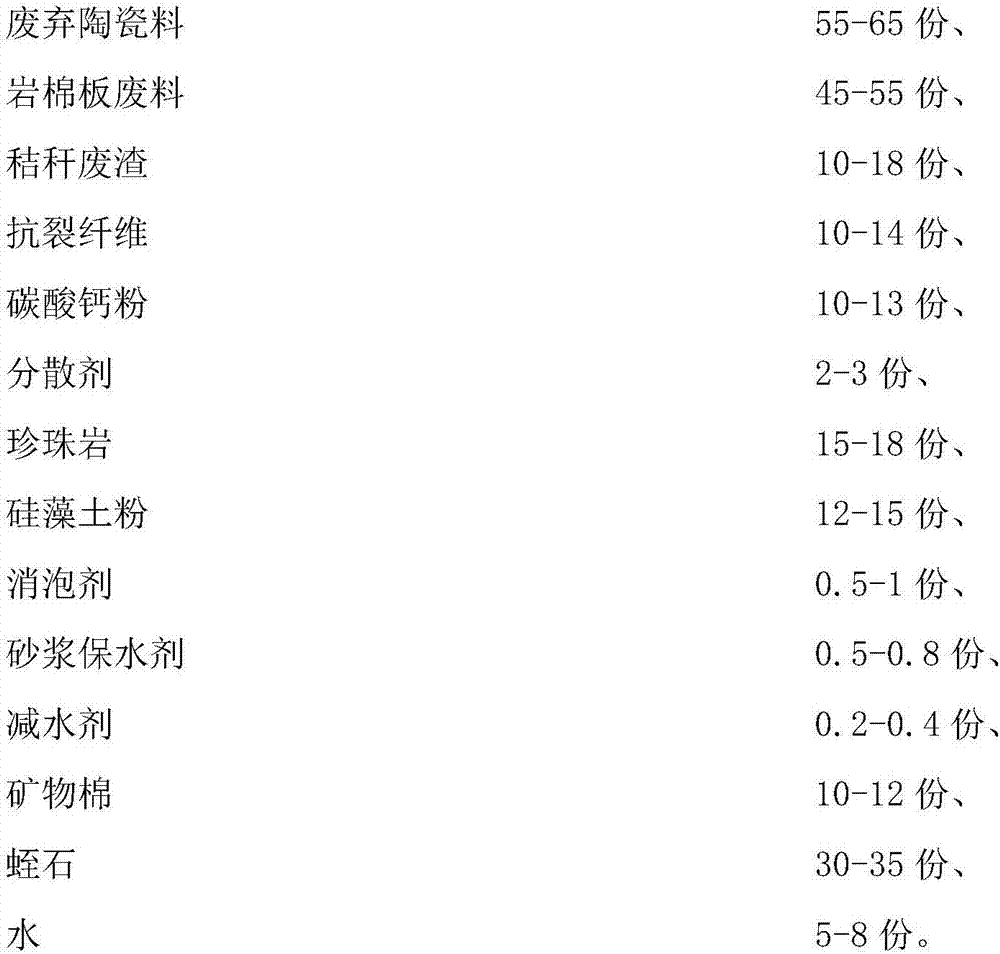

[0046] A wall construction material, which is made of the following raw materials in parts by weight:

[0047]

[0048] Mineral wool is glass wool, and glass wool has the advantages of good molding, low bulk density, low thermal conductivity, thermal insulation, good sound absorption effect, and good corrosion resistance.

[0049] A method for preparing a wall building material, comprising the steps of:

[0050] (1) Weigh 60 parts of waste ceramic material, 50 parts of rock wool board waste, 15 parts of straw waste residue, 12 parts of anti-crack fiber, 12 parts of calcium carbonate powder, 16 parts of perlite, and 14 parts of diatomite powder according to parts by weight , 0.8 parts of defoamer, 0.6 parts of mortar water-retaining agent, 0.3 parts of water-reducing agent, 11 parts of mineral wool, and 32 parts of vermiculite are put into the mixer, and the rotation speed is controlled at 160r / min, stirred for 40min, and mixed evenly to obtain a solid mixture ;

[0051] (...

Embodiment 3

[0057] A wall construction material, which is made of the following raw materials in parts by weight:

[0058]

[0059]Mineral wool is glass wool, and glass wool has the advantages of good molding, low bulk density, low thermal conductivity, thermal insulation, good sound absorption effect, and good corrosion resistance.

[0060] A method for preparing a wall building material, comprising the steps of:

[0061] (1) Weigh 55 parts of waste ceramic material, 45 parts of rock wool board waste, 10 parts of straw waste residue, 10 parts of anti-cracking fiber, 10 parts of calcium carbonate powder, 15 parts of perlite, and 12 parts of diatomite powder according to parts by weight , 0.5 parts of defoamer, 0.5 parts of mortar water-retaining agent, 0.2 parts of water-reducing agent, 10 parts of mineral wool, and 30 parts of vermiculite are put into the mixer, and the rotation speed is controlled at 160r / min, stirred for 40min, and mixed evenly to obtain a solid mixture ;

[0062]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com