A kind of high-strength, high heat insulation silica airgel and preparation method thereof

A silica, high-strength technology, applied in ceramic products, other household appliances, applications, etc., can solve the problem of airgel thermal insulation performance decline, affect super thermal insulation performance, increase the porosity of silica airgel, etc. problems, to achieve the effect of solving reinforcement and heat insulation and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

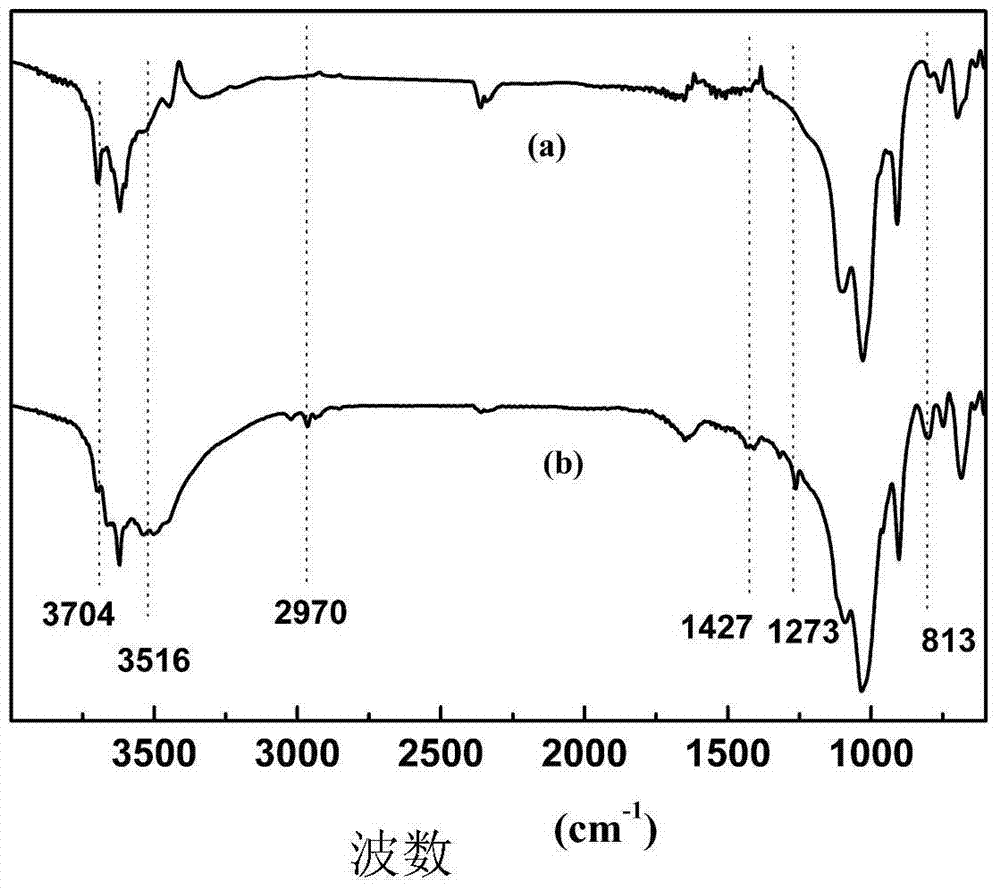

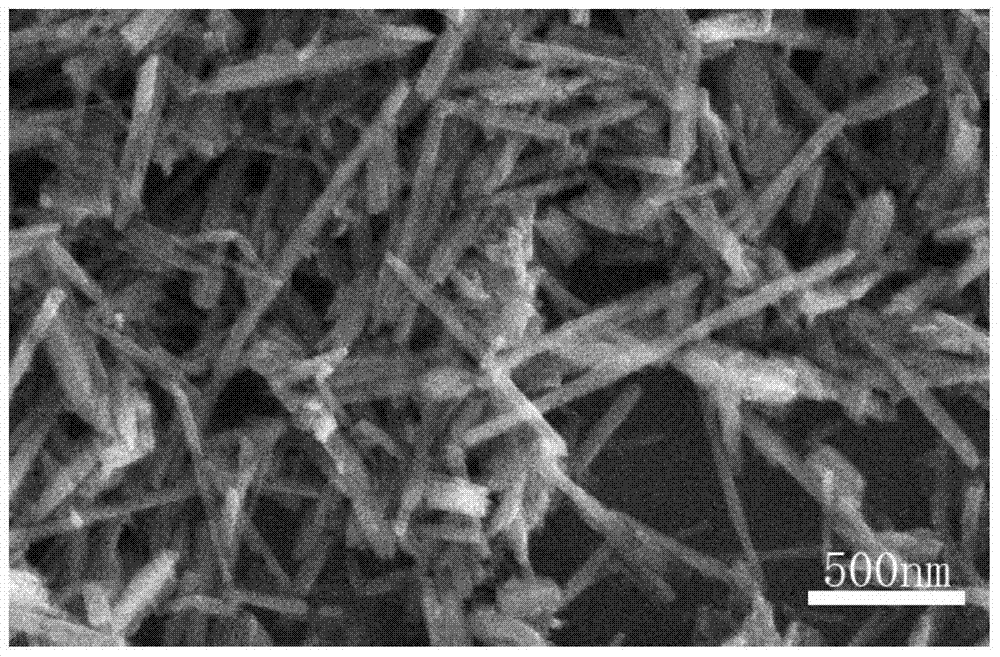

[0030] Step (1) Ultrasonically disperse 10 g of halloysite in 200 mL of dimethyl sulfoxide, then add 0.1 g of N, N-carbonyldiimidazole, continue stirring at 70 ° C for 2 h, and then add 1 g of Amino mono-terminated polydimethylsiloxane, after reacting at 55°C for 6h, filter the product, wash the product with distilled water until it is neutral, and dry it in a blast drying oven at 100°C for 24h.

[0031] Step (2) Mix and stir 20g of tetraethylorthosilicate and 90g of absolute ethanol for 20min, add dropwise 6g of distilled water and 2g of hydrochloric acid, continue stirring for 55min, add 20g of the halloysite product obtained in step (1), ultrasonically disperse for 40min, and Stand still at 45°C for 7 hours for full acid hydrolysis, then add 0.5g of dimethylformamide and 2g of ammonia water, let stand for 24 hours to obtain a wet gel and allow the unstable structure in the gel to continue to react and solidify, add Mixture of 80g water and 15g absolute ethanol, let it stand...

Embodiment 2

[0033] Step (1) Ultrasonically disperse 5g of halloysite in 500mL of dimethyl sulfoxide, then add 0.1g of N,N-carbonyldiimidazole, keep stirring at 50°C for 5h, then add 1g of ethylene with a number average molecular weight of 2000 Amino double-terminated polydimethyldivinylsiloxane with a molar percentage of 4%, after reacting at 50°C for 3h, filter the product, wash the product with distilled water until neutral, and place it in a blast drying oven at 100°C Dry within 48 hours.

[0034] Step (2) Mix and stir 30 g of tetraethyl orthosilicate and 100 g of absolute ethanol for 20 min, add dropwise 10 g of distilled water and 3 g of hydrochloric acid, continue stirring for 30 min, add 5 g of the halloysite product obtained in step (1), and ultrasonically disperse for 30 min. Stand still at 50°C for 10 hours for full acid hydrolysis, then add 2g of dimethylformamide and 1g of ammonia water, let stand for 48 hours to obtain a wet gel and allow the unstable structure in the gel to ...

Embodiment 3

[0036] Step (1) Ultrasonically disperse 15g of halloysite in 250mL of dimethyl sulfoxide, then add 0.6g of N,N-carbonyldiimidazole, keep stirring at 55°C for 4h, then add 2g of ethylene with a number average molecular weight of 3000 Amino double-terminated polydimethyldivinyldiphenylsiloxane with a molar percentage of 2% phenyl content of 1% molar content, reacted at 60°C for 7h, filtered the product, and washed the product with distilled water until Neutral, dry in a 100°C blast oven for 36 hours.

[0037] Step (2) Mix 10 g of tetraethyl orthosilicate and 80 g of absolute ethanol and stir for 20 min, add dropwise 6 g of distilled water and 2.5 g of hydrochloric acid, continue stirring for 45 min, add 25 g of the halloysite product obtained in step (1), and ultrasonically disperse for 45 min. Stand still at 45°C for 7 hours to carry out sufficient acid hydrolysis, then add 1.2g dimethylformamide and 1.6g ammonia water, let stand for 36 hours to obtain a wet gel and allow the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com