High temperature-resistant electromagnetic wave-absorbing coating and use thereof

A wave-absorbing coating, high-temperature resistant technology, applied in coatings, radiation-absorbing coatings, fire-retardant coatings, etc., can solve the problems of maintaining wave-absorbing performance, but cannot completely solve the problem of anti-oxidation and large specific surface area of wave-absorbing coatings , to achieve the effect of ensuring temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Preparation of high temperature resistant wave-absorbing coating

[0021] Using ammonia water and tetraethyl orthosilicate as raw materials, the surface-coated SiO 2 Membrane of carbonyl iron powder absorbent.

[0022] Silicone modified epoxy resin was prepared according to the method described in patent CN201010233875.8.

[0023] In terms of mass, according to the surface coated SiO 2 Film carbonyl iron powder absorbent 10-60 parts; pigments and fillers 2-40 parts; silicone modified epoxy resin 15-45 parts; high temperature resistant phenolic resin curing agent 1-10 parts; coupling agent (KH560) 0.5- 5 parts; the proportion range of 10-50 parts of the mixed solvent, weighing each raw material, fully mixing the above raw materials, and ball milling in a ball mill for 4 hours to obtain a wave-absorbing coating.

[0024] In terms of mass, 6-60 parts of pigments and fillers; 15-45 parts of silicone modified epoxy resin; 1-10 parts of high temperature resistan...

Embodiment 2

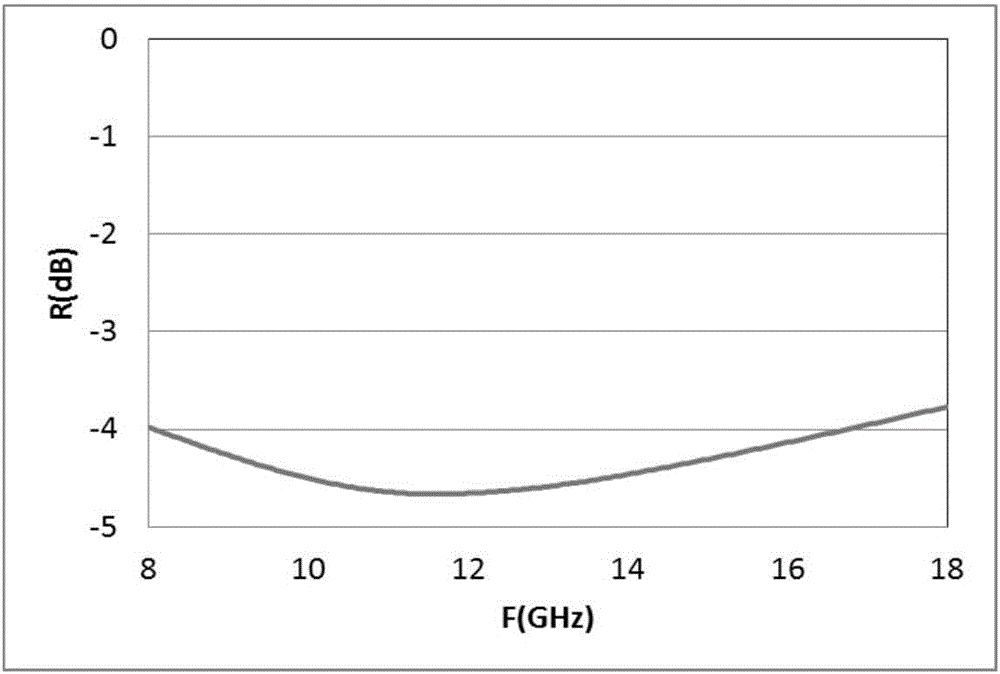

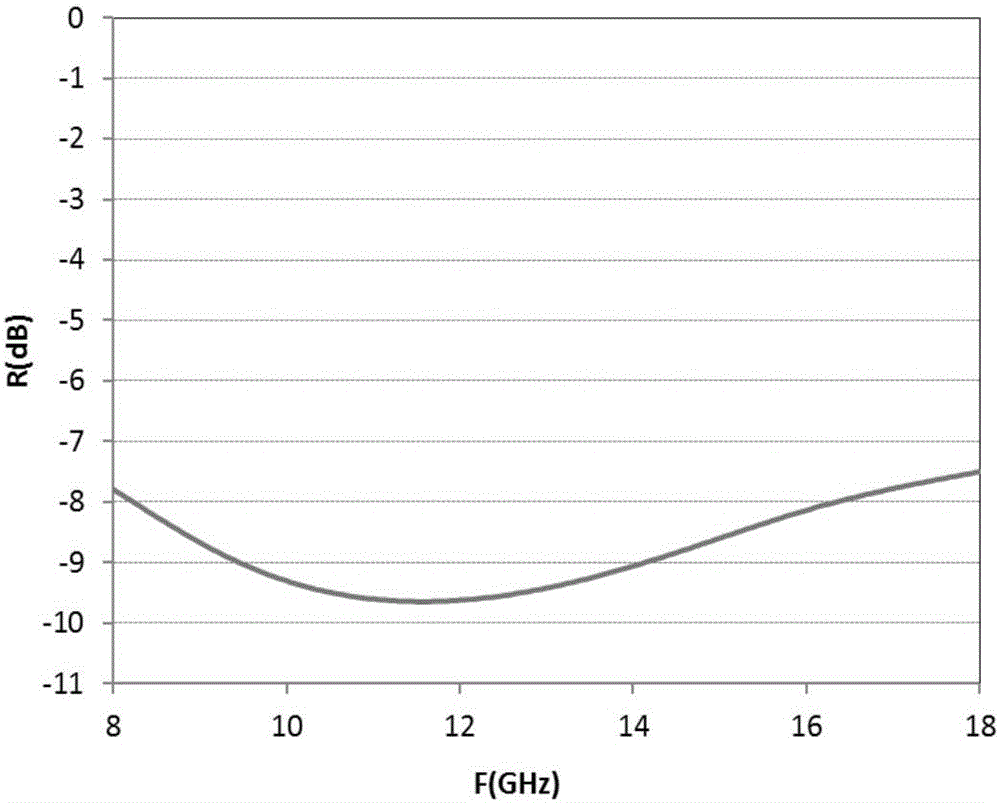

[0029] Example 2: Test of reflectivity curve of high temperature resistant wave-absorbing coating

[0030] Taking coated plates 1, 2, 3, and 4 as objects, the reflectivity curve of the coating at 8-18 GHz was tested. attached figure 2 is the real-time reflectance of coating plate 1 tested at 350°C high temperature, attached image 3 is the real-time reflectance of coating plate 2 tested at 300°C high temperature, attached Figure 4 is the real-time reflectance of coating plate 3 tested at 300°C high temperature, attached Figure 5 is the real-time test reflectance of the coated plate 4 at room temperature and 350°C high temperature respectively. The test method adopts the bow frame method described in GJB 5022-2011; the high temperature real-time test adopts the flat furnace heating, and reaches the bow frame method test.

Embodiment 3

[0031] Example 3: Reflectivity test of high temperature resistant wave-absorbing coating

[0032] Taking coated panels 1, 2, 3, and 4 as objects, test the adhesion, flexibility, and impact strength of the coating. See Table 2 for the test content, achieved indicators and reference test methods.

[0033] Table 2 Conventional performance tests of high temperature resistant wave-absorbing coatings

[0034]

[0035] Note: High temperature (300°C) adhesion is the coating adhesion measured after the coated plate is kept in a muffle furnace at 300°C for 2 hours and cooled to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com