Addition-type room temperature vulcanized silicone rubber external heat-resistant material for engine and preparation method thereof

A technology of room temperature vulcanization and heat-resistant materials, which is applied in the field of addition-type room-temperature-vulcanized silicone rubber heat-resistant materials for engines and addition-type room-temperature vulcanized silicone rubber materials. It can solve the problems affecting material properties, deep vulcanization, and unreported processes problems, to achieve good results in mechanical and ablation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The rubber material produced by this formula can be vulcanized at room temperature and deep, and can be prepared by kneading and mixing. Due to the reasonable combination of ablation-resistant fiber and ablation-resistant powder in the formula, the outer heat-resistant layer of the engine made of this material has a smooth surface, is suitable for engine patch molding, and has good mechanical and ablation properties. It has been tested on missile engines many times. Verification performance is reliable.

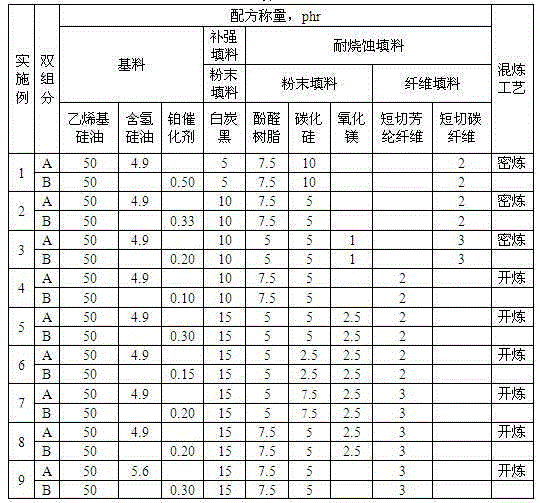

[0034] The present invention is calculated in parts by weight, weighs the components corresponding to A and B components according to the formula ratio, and respectively mixes A and B components according to 1) base material, 2) powder filler, 3) The order of the fiber filler is evenly mixed, and the A and B components can be mixed evenly when used, as shown in the following table 2:

[0035] Table 2

[0036]

[0037] Illustrate the milling mixing process of this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com