Eco-friendly pavior brick and preparation method thereof

A kind of pavement brick and environmental protection technology, applied in the direction of roads, roads, paving surfaces paved with prefabricated blocks, etc., can solve the problems of inability to reuse waste, poor water reduction effect, low compressive strength, etc., and achieve fast condensation and hardening speed, Structural stability and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

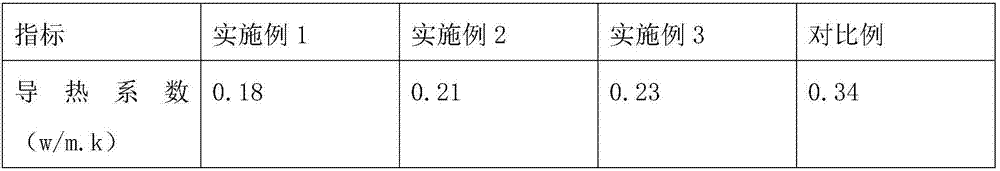

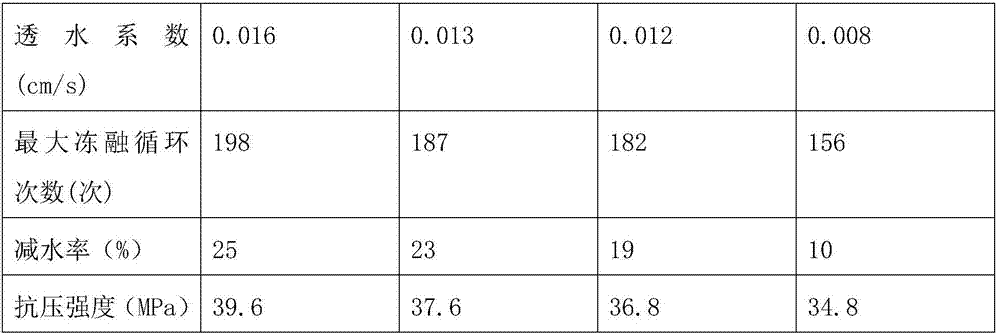

Embodiment 1

[0036] An environmentally friendly pavement brick, including a surface layer and a base layer:

[0037] The surface layer includes the following raw materials in parts by weight: 21 parts of cement, 22.5 parts of sand, 6 parts of gravel, 35 parts of industrial waste slag particles, 14 parts of waste ceramic particles, 4.5 parts of silica fume, 7.5 parts of fly ash, 6.5 parts of lime, 3 parts of air entraining agent, 2 parts of water repellent, 0.4 part of antifreeze, 0.5 part of water reducing agent, 0.4 part of pigment powder and 2 parts of water;

[0038] The base layer includes the following raw materials in parts by weight: 17 parts of cement, 20 parts of sand, 21 parts of gravel and 2.5 parts of water.

[0039] The energy saving and environmental protection, water permeability, antifreeze performance, water reducing effect and compressive strength of pavement bricks prepared under the raw material formula have all reached the best performance.

[0040] Industrial waste s...

Embodiment 2

[0052] An environmentally friendly pavement brick, including a surface layer and a base layer:

[0053] The surface layer includes the following raw materials in parts by weight: 15 parts of cement, 15 parts of sand, 5 parts of gravel, 30 parts of industrial waste slag particles, 12 parts of waste ceramic particles, 3 parts of silica fume, 5 parts of fly ash, and 3 parts of lime , 2 parts of air-entraining agent, 1.5 parts of waterproofing agent, 0.3 part of antifreeze, 0.4 part of water reducing agent, 0.3 part of pigment powder and 1 part of water;

[0054] The base layer includes the following raw materials in parts by weight: 16 parts of cement, 18 parts of sand, 17 parts of gravel and 2 parts of water.

[0055] Industrial waste slag particles, waste ceramic particles and fly ash are added to the raw materials. As construction waste and industrial waste, the annual output is huge, and the long-term disposal is different. It not only affects the limited urban land, but also...

Embodiment 3

[0067] An environmentally friendly pavement brick, including a surface layer and a base layer:

[0068] The surface layer includes the following raw materials in parts by weight: 27 parts of cement, 30 parts of sand, 7 parts of gravel, 40 parts of industrial waste slag particles, 16 parts of waste ceramic particles, 6 parts of silica fume, 10 parts of fly ash, 10 parts of lime, 4 parts of air entraining agent, 2.5 parts of water repellent, 0.5 part of antifreeze, 0.6 part of water reducer, 0.5 part of pigment powder and 3 parts of water;

[0069] The base layer includes the following raw materials in parts by weight: 18 parts of cement, 22 parts of sand, 25 parts of gravel and 3 parts of water.

[0070] Industrial waste slag particles, waste ceramic particles and fly ash are added to the raw materials. As construction waste and industrial waste, the annual output is huge, and the long-term disposal is different. It not only affects the limited urban land, but also affects the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com