Color steel slag road pavement brick and preparation method thereof

A technology of pavement bricks and steel slag, which is applied in the field of colored steel slag pavement bricks and its preparation, can solve the problems of waste reuse, pan-alkali and discoloration, and low compressive strength, so as to improve the early strength, accelerate the coagulation progress, and avoid extrusion The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

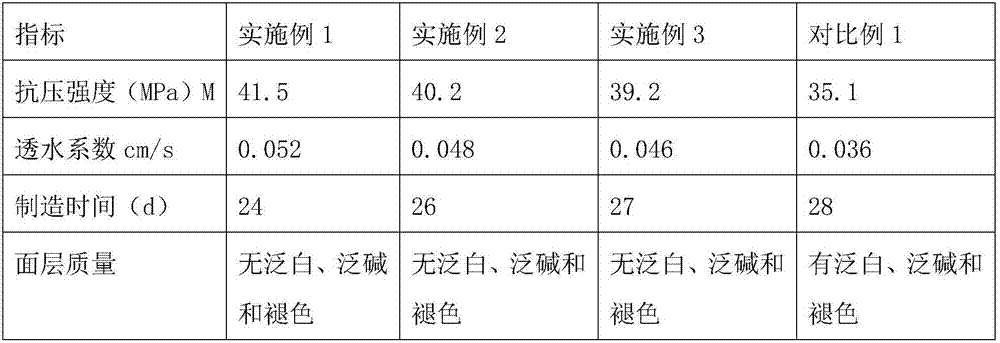

Examples

Embodiment 1

[0035] A colored steel slag pavement brick, including a surface layer and a bottom layer:

[0036] The surface layer includes the following raw materials in parts by weight: 21 parts of cement, 27.5 parts of steel slag sand, 19 parts of quartz sand, 7.5 parts of gravel, 4.5 parts of pozzolan, 4 parts of zeolite, 4.5 parts of red mud, 5 parts of admixture, accelerator 2.2 parts, 1.8 parts of early strength agent, 1 part of anti-efflorescence agent, 0.4 parts of pigment powder, 1.4 parts of water reducing agent and 2 parts of water;

[0037] The bottom layer includes the following raw materials in parts by weight: 20.5 parts of cement, 25 parts of steel slag molding sand, 22 parts of gravel and 2.5 parts of water.

[0038] The pavement bricks prepared with this raw material formula are optimal in terms of energy saving, environmental protection, water permeability, compressive strength, manufacturing time and surface quality.

[0039] The particle size of steel slag molding san...

Embodiment 2

[0051] A colored steel slag pavement brick, including a surface layer and a bottom layer:

[0052]The surface layer includes the following raw materials in parts by weight: 17 parts of cement, 25 parts of steel slag sand, 18 parts of quartz sand, 5 parts of gravel, 3 parts of pozzolan, 3 parts of zeolite, 3 parts of red mud, 4 parts of admixture, accelerator 1.2 parts, 1.3 parts of early strength agent, 0.5 parts of anti-efflorescence agent, 0.3 parts of pigment powder, 1.2 parts of water reducing agent and 1 part of water;

[0053] The bottom layer includes the following raw materials in parts by weight: 16 parts of cement, 22 parts of steel slag molding sand, 19 parts of gravel and 2 parts of water.

[0054] The particle size of steel slag molding sand is 1-4mm. Steel slag molding sand itself has the characteristics of high hardness. Now the particle size is controlled at 1-4mm to effectively mix steel slag molding sand with other raw materials of pavement bricks to improve ...

Embodiment 3

[0066] A colored steel slag pavement brick, including a surface layer and a bottom layer:

[0067] The surface layer includes the following raw materials in parts by weight: 25 parts of cement, 30 parts of steel slag sand, 20 parts of quartz sand, 10 parts of crushed stone, 6 parts of pozzolan, 5 parts of zeolite, 6 parts of red mud, 6 parts of admixture, accelerator 3.2 parts, 2.3 parts of early strength agent, 1.5 parts of anti-efflorescence agent, 0.5 parts of pigment powder, 1.6 parts of water reducing agent and 3 parts of water;

[0068] The bottom layer includes the following raw materials in parts by weight: 25 parts of cement, 28 parts of steel slag molding sand, 25 parts of gravel and 3 parts of water.

[0069] The particle size of steel slag molding sand is 1-4mm. Steel slag molding sand itself has the characteristics of high hardness. Now the particle size is controlled at 1-4mm to effectively mix steel slag molding sand with other raw materials of pavement bricks t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com