Anti-corrosion and anti-shrinkage pavement bricks

An anti-shrinkage, pavement brick technology, applied in the direction of paving, roads, roads, etc. paved with prefabricated blocks, can solve the problems of inability to reuse waste, poor corrosion resistance, low compressive strength, etc., to achieve good product stability, Low cost and low concrete shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

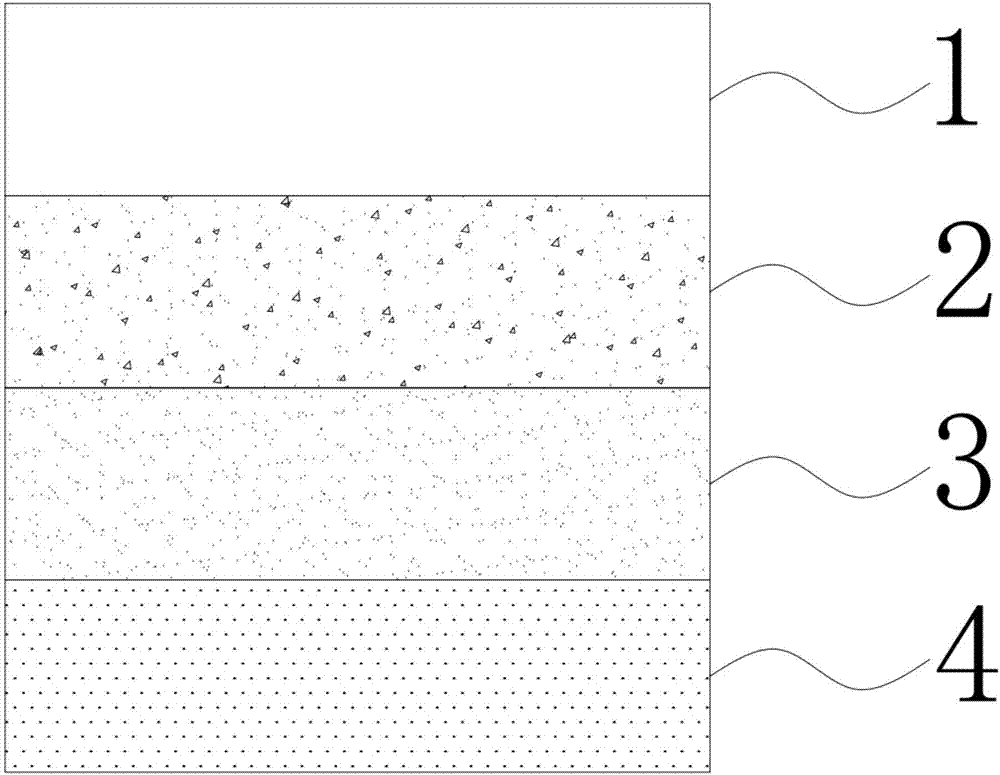

[0039] A corrosion-resistant and shrinkage-resistant pavement brick comprises a surface layer 1 , a first middle layer 2 , a second middle layer 3 and a bottom layer 4 .

[0040] The surface layer 1 includes the following raw materials in parts by weight: 12.5 parts of cement, 27.5 parts of yellow sand, 12 parts of pebbles, 3.5 parts of silicon dioxide, 4.5 parts of fly ash, 2.6 parts of redispersible latex powder, 0.4 parts of expansion agent, retarder 0.5 parts, 0.3 parts of water reducing agent, 0.4 parts of pigment powder and 2.5 parts of water;

[0041] The first intermediate layer 2 comprises the following raw materials in parts by weight: 13 parts of cement, 28 parts of sand, 12 parts of discarded granular ceramics, 0.4 part of expansion agent, 0.75 part of polyester fiber, 2.6 parts of polypropylene fiber, 0.5 part of glass fiber and water 3 copies;

[0042] The second intermediate layer 3 comprises the following raw materials in parts by weight: 13 parts of cement, 2...

Embodiment 2

[0057] A corrosion-resistant and shrinkage-resistant pavement brick comprises a surface layer 1 , a first middle layer 2 , a second middle layer 3 and a bottom layer 4 .

[0058] Surface layer 1 includes the following raw materials in parts by weight: 10 parts of cement, 25 parts of yellow sand, 10 parts of pebbles, 2 parts of silicon dioxide, 3 parts of fly ash, 2 parts of redispersible latex powder, 0.3 parts of expansion agent, retarder 0.4 parts, 0.2 parts of water reducing agent, 0.3 parts of pigment powder and 2 parts of water;

[0059] The first intermediate layer 2 comprises the following raw materials in parts by weight: 12 parts of cement, 21 parts of sand, 10 parts of discarded granular ceramics, 0.3 part of expansion agent, 0.5 part of polyester fiber, 2 parts of polypropylene fiber, 0.4 part of glass fiber and water 2 copies;

[0060] The second intermediate layer 3 comprises the following raw materials in parts by weight: 12 parts of cement, 21 parts of sand, 10...

Embodiment 3

[0075] A corrosion-resistant and shrinkage-resistant pavement brick comprises a surface layer 1 , a first middle layer 2 , a second middle layer 3 and a bottom layer 4 .

[0076] The surface layer 1 includes the following raw materials in parts by weight: 15 parts of cement, 30 parts of yellow sand, 14 parts of pebbles, 5 parts of silicon dioxide, 6 parts of fly ash, 3.2 parts of redispersible latex powder, 0.5 parts of expansion agent, retarder 0.6 parts, 0.4 parts of water reducer, 0.5 parts of pigment powder and 3 parts of water;

[0077] The first intermediate layer 2 comprises the following raw materials in parts by weight: 14 parts of cement, 35 parts of sand, 14 parts of discarded granular ceramics, 0.5 part of expansion agent, 1 part of polyester fiber, 3.2 parts of polypropylene fiber, 0.6 part of glass fiber and water 4 parts;

[0078] The second intermediate layer 3 comprises the following raw materials in parts by weight: 14 parts of cement, 35 parts of sand, 14 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com