Patents

Literature

113results about How to "Affect appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

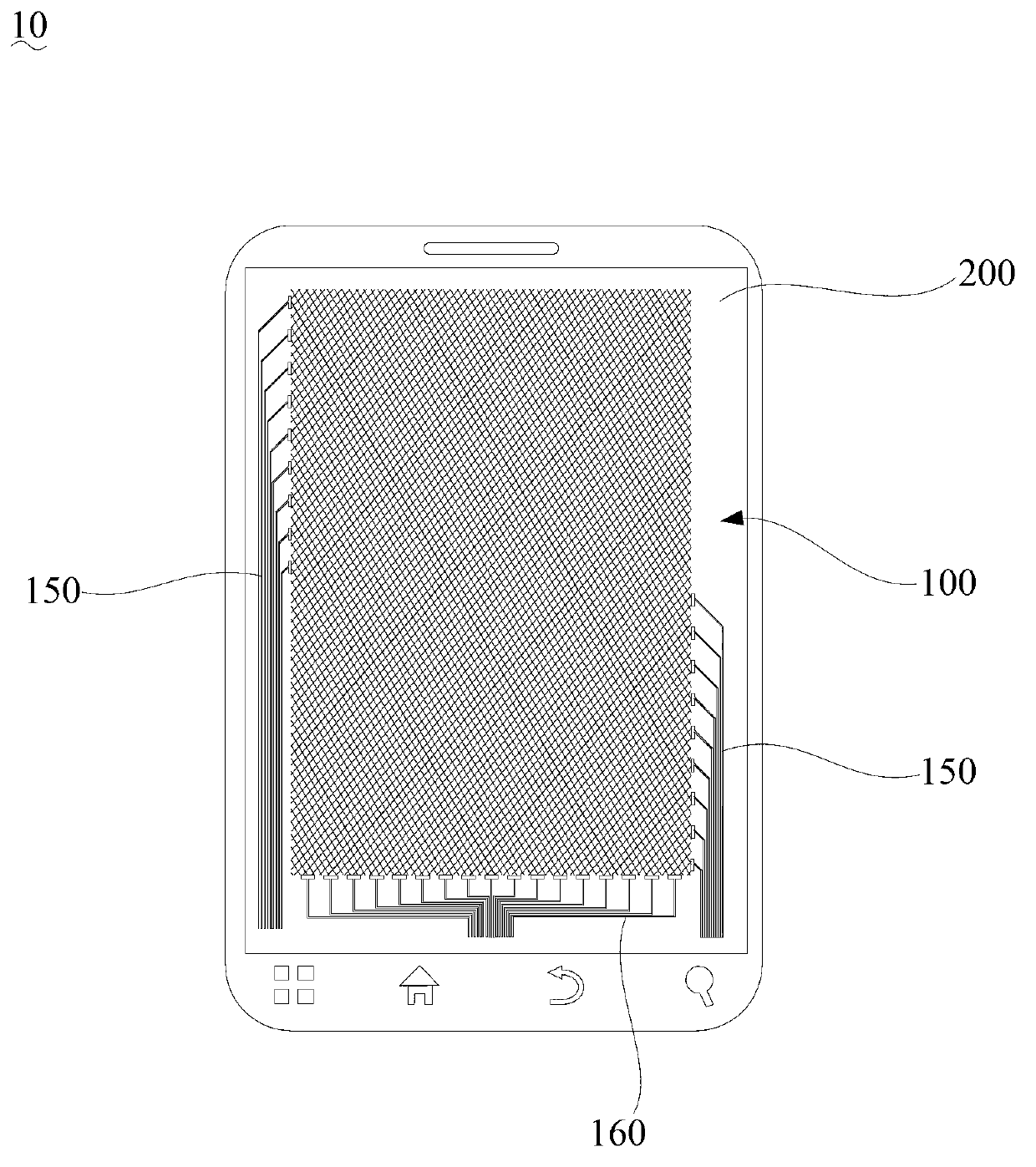

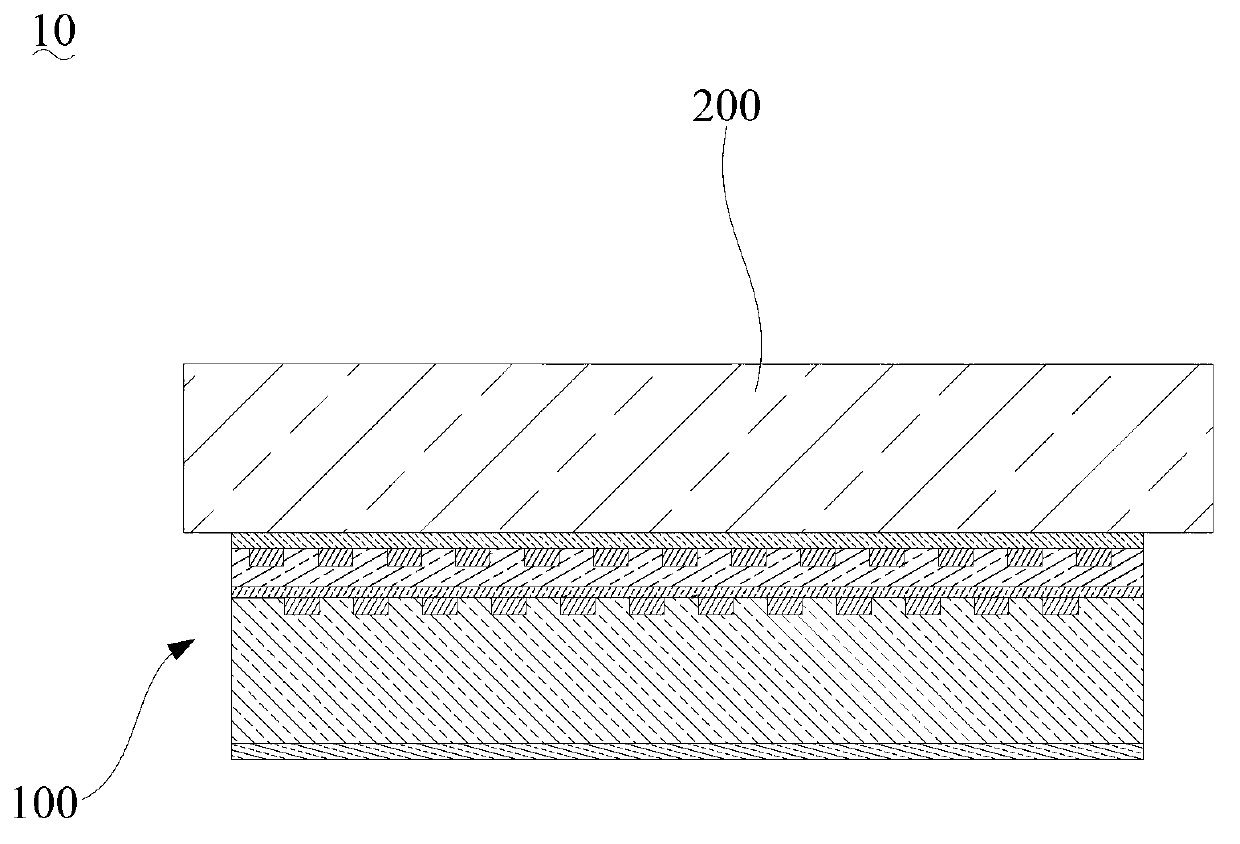

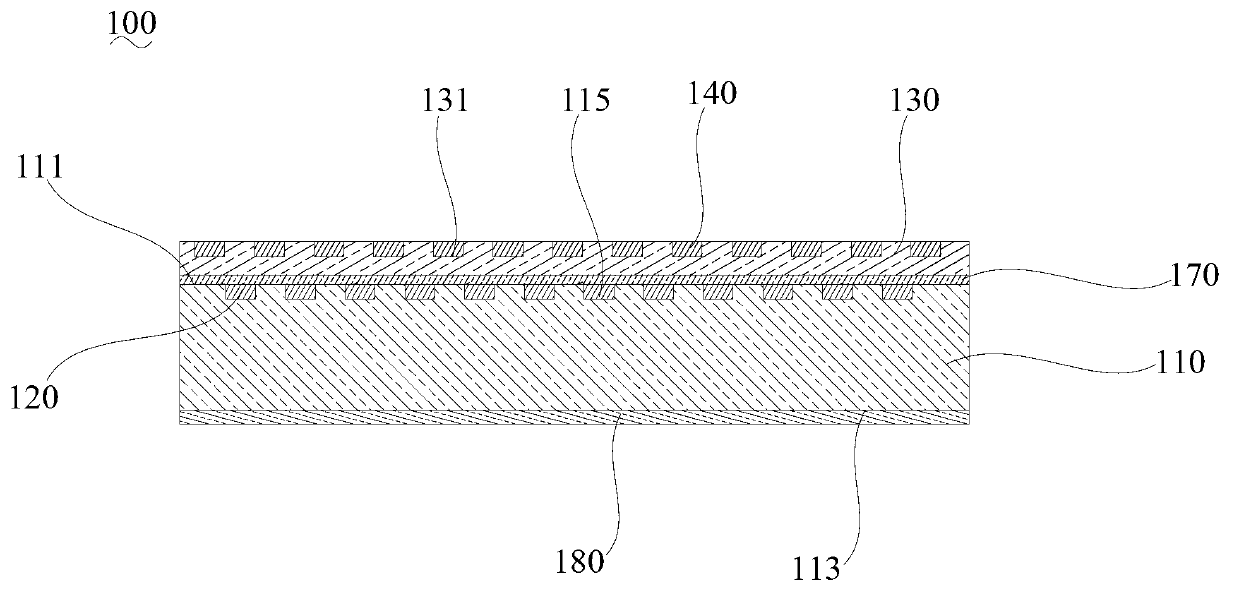

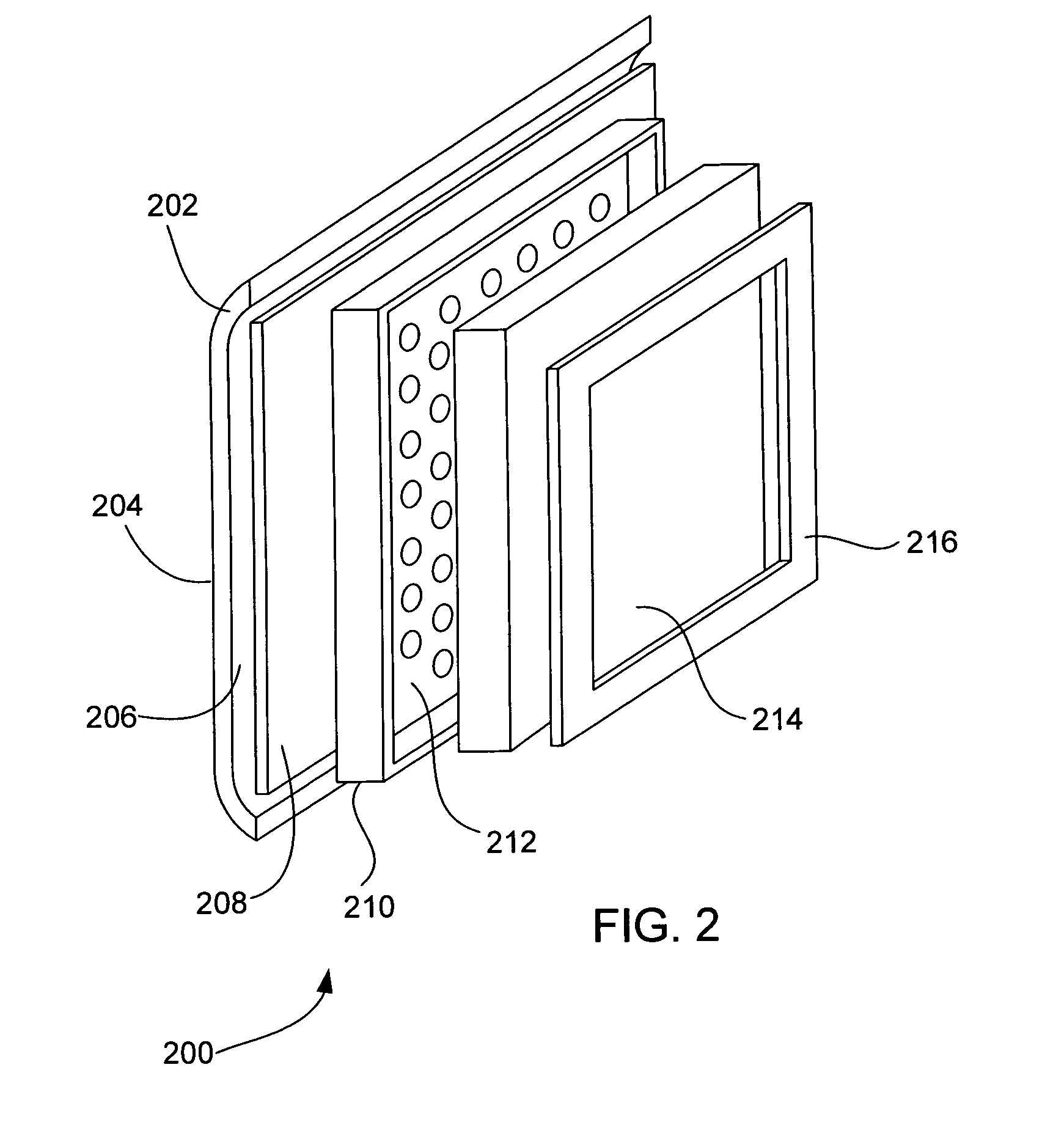

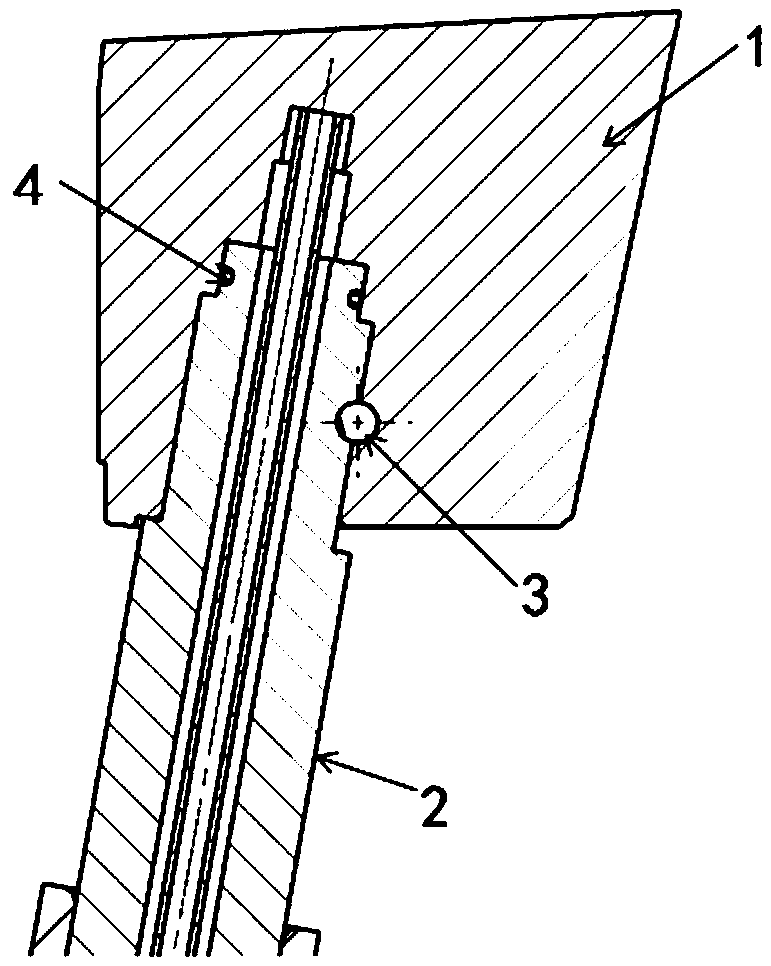

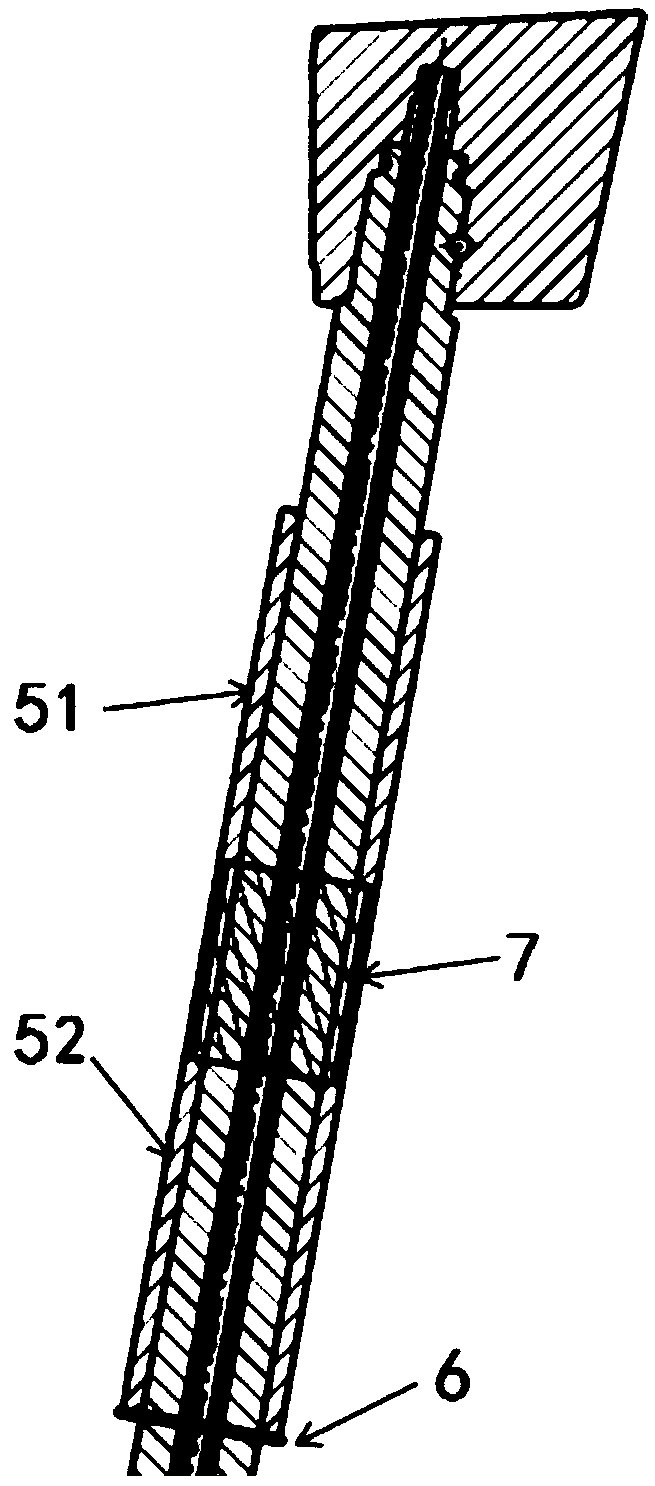

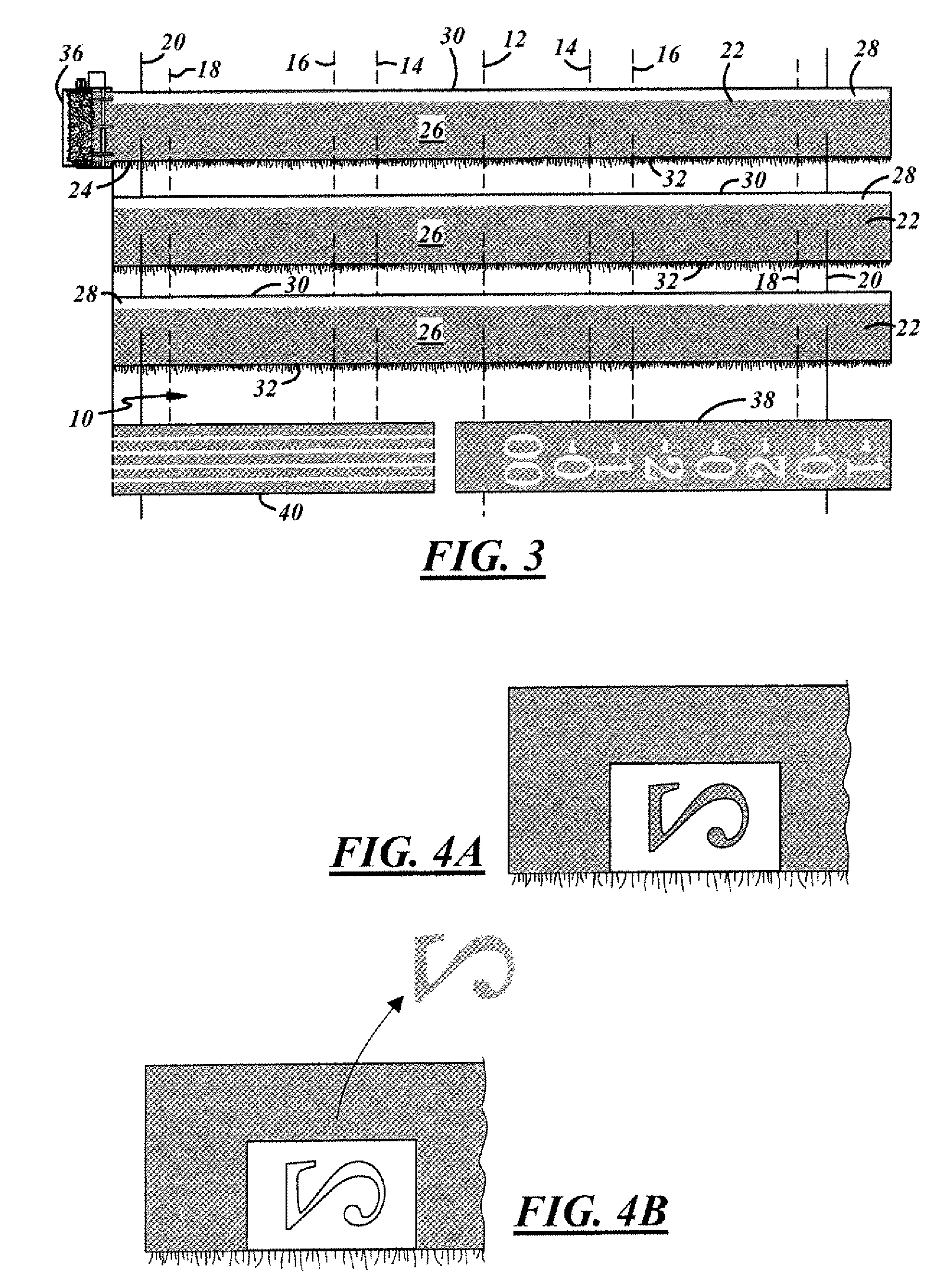

Conducting film and preparation method thereof and touch screen comprising the same

ActiveCN103106953AReduce thicknessAffect appearanceConductive layers on insulating-supportsCable/conductor manufactureCapacitanceElectrically conductive

The invention discloses a conducting film which comprises a base sheet, a first conducting layer, a substrate layer and a second conducting layer, wherein the base sheet comprises a first surface and a second surface which is arranged opposite to the first surface, and the first conducting layer is embedded in the base sheet. The substrate layer is attached to the first surface of the base sheet and is formed by curing a jelly like substance coated on the first surface. The second conducting layer is embedded in the substrate layer and is insulated from the first conducting layer by the substrate layer. Due to the fact that capacitance can form between the first conducting layer and the second conducting layer, when the conducting film is used for manufacturing a touch screen, two conducting films do not need to be combined together in a bonding mode, and all that is needed is to attach the conducting film to a glass panel. In addition, the substrate layer is formed by curing the jelly like substance coated on the base sheet, the thickness is far smaller than that of the base sheet, and therefore the touch screen made of the conducting film has a quite small thickness. Moreover, the invention further provides a preparation method of the conducting film and the touch screen comprising the conducting film.

Owner:江西卓讯微电子有限公司

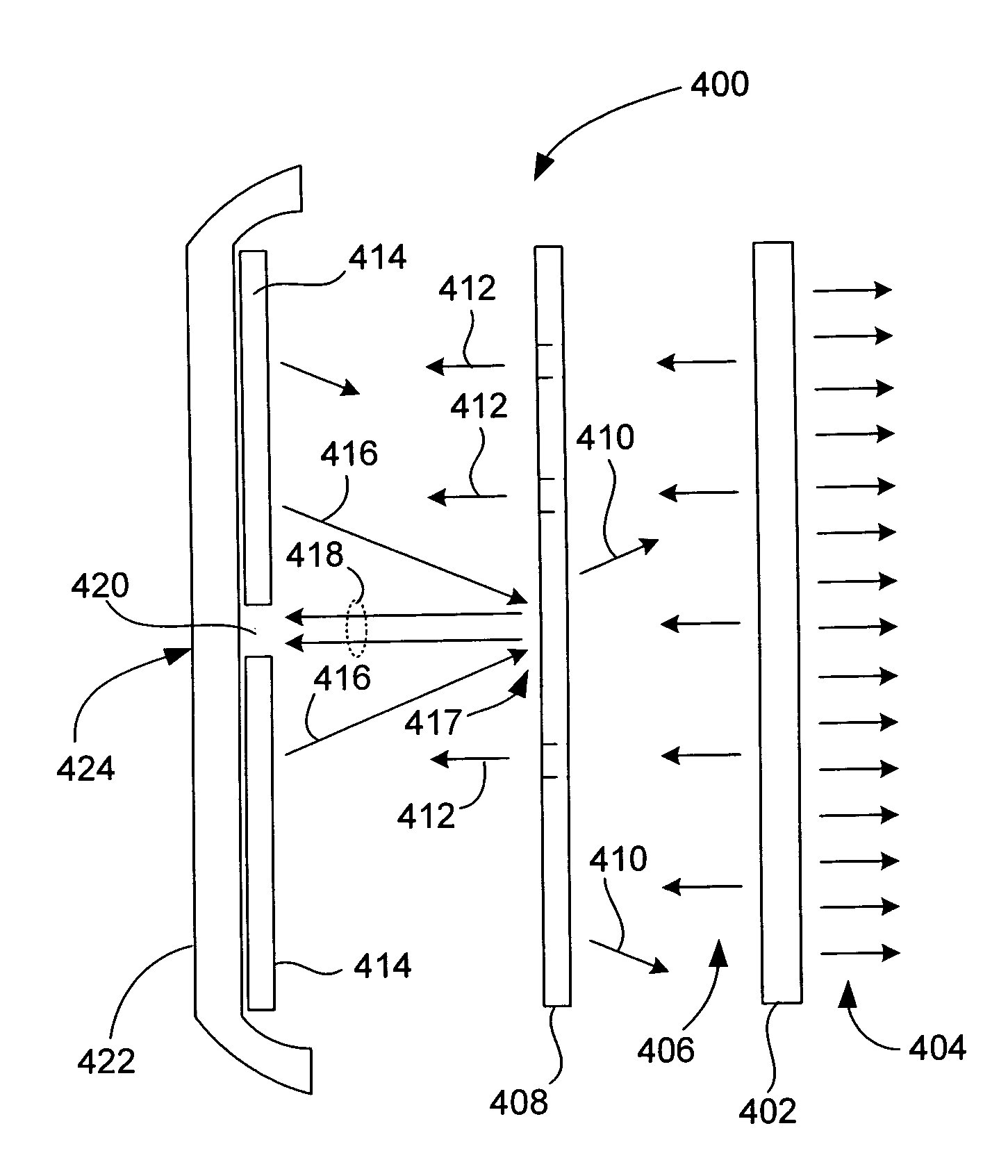

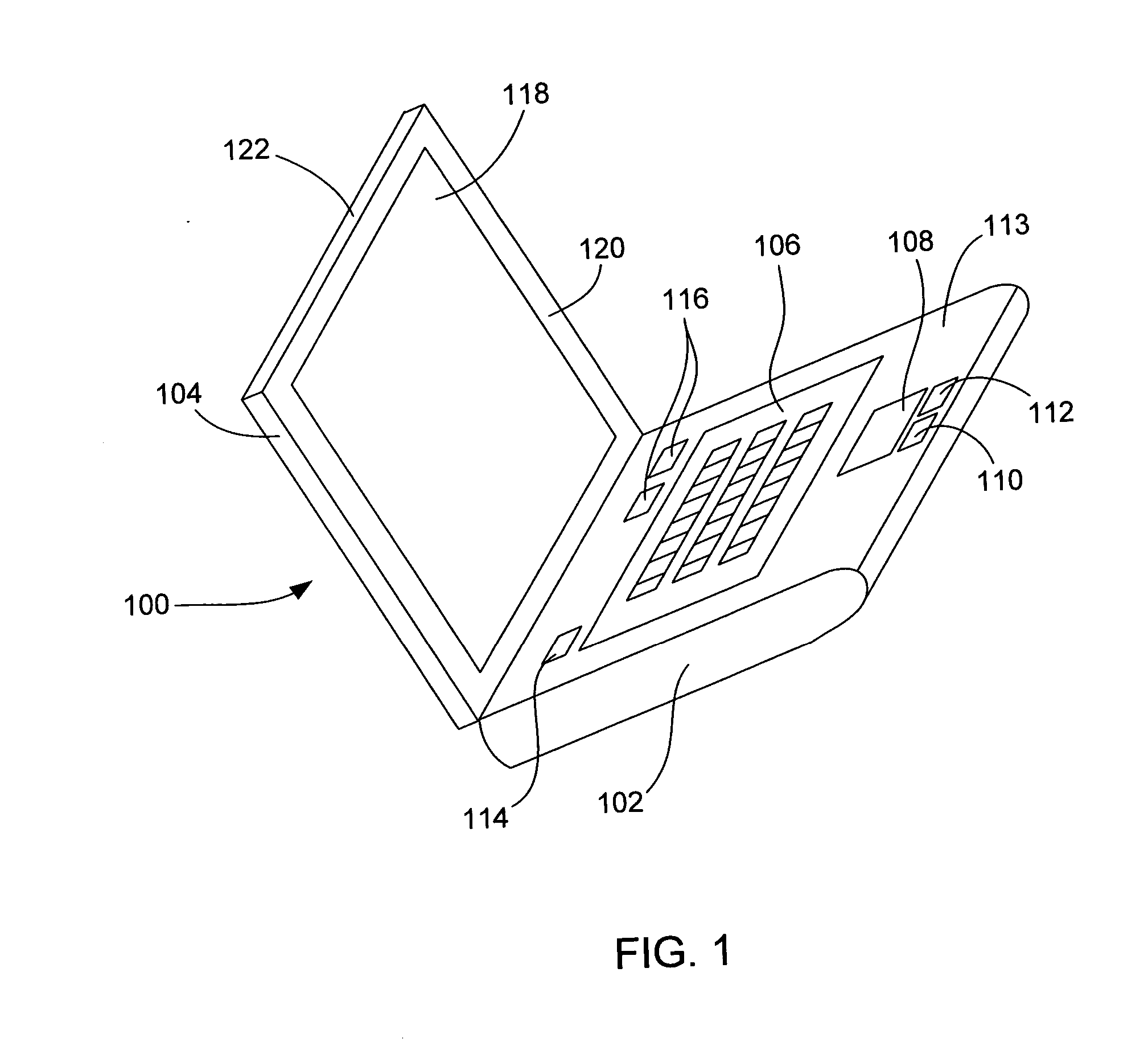

Display housing for computing device

InactiveUS20050270734A1Affect appearanceMeasurement apparatus componentsDetails for portable computersLight sourceSemi transparent

A personal computing device is disclosed. The personal computing device includes a housing having a translucent portion. The housing encloses internally various components that provide computing operations for the personal computing device. The personal computing device also includes a light source disposed inside the housing. The light source is configured to produce light inside the housing so as to illuminate at least a portion of the translucent portion. The illumination of the translucent portion affecting the appearance of the housing in a non trivial manner.

Owner:APPLE INC

Satiety emulsions and food compositions

InactiveUS20060105093A1Increase satietyGood satiety effectMetabolism disorderFinished edible oils/fats preservationFood composition dataPalm oil

The present invention provides edible aqueous oil-in-water emulsions comprising 15-70% wt oil having a saturated fatty acid content of at least 20% wt and at least 10% wt of said oil being solid at 37° C., 0.1-5% wt emulsifier which is a protein and 25-84.9% wt water. The oil preferably comprises palm oil and the emulsifier preferably comprises partially denatured egg white. The emulsions provide good satiety benefits and do not adversely affect the taste of products into which they are incorporated. Furthermore the emulsions are very stable which has benefits also for the food products and beverages into which they are incorporated. Also provided are food and beverage products comprising the emulsion of the invention.

Owner:CONOPCO INC D B A UNILEVER

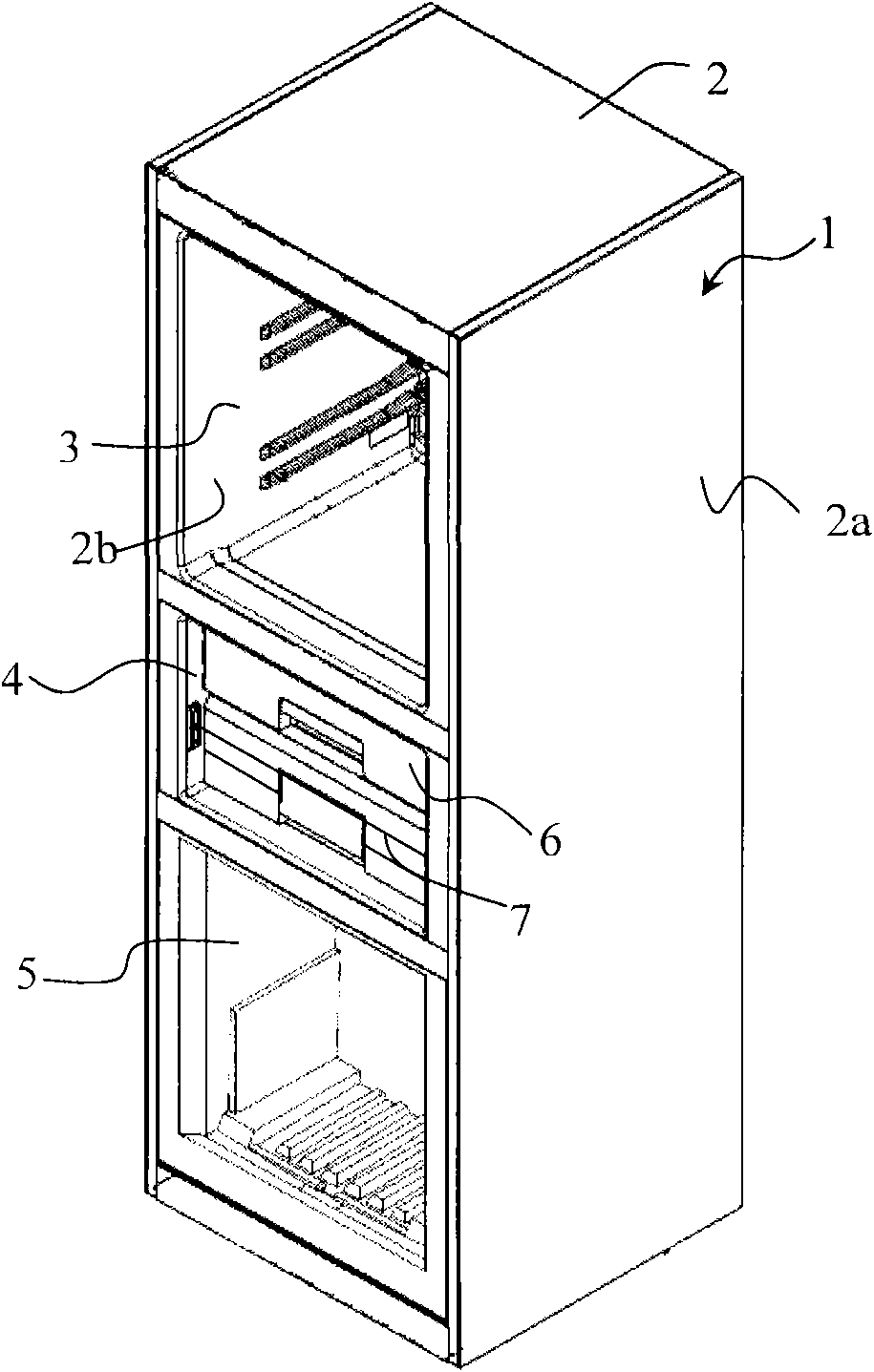

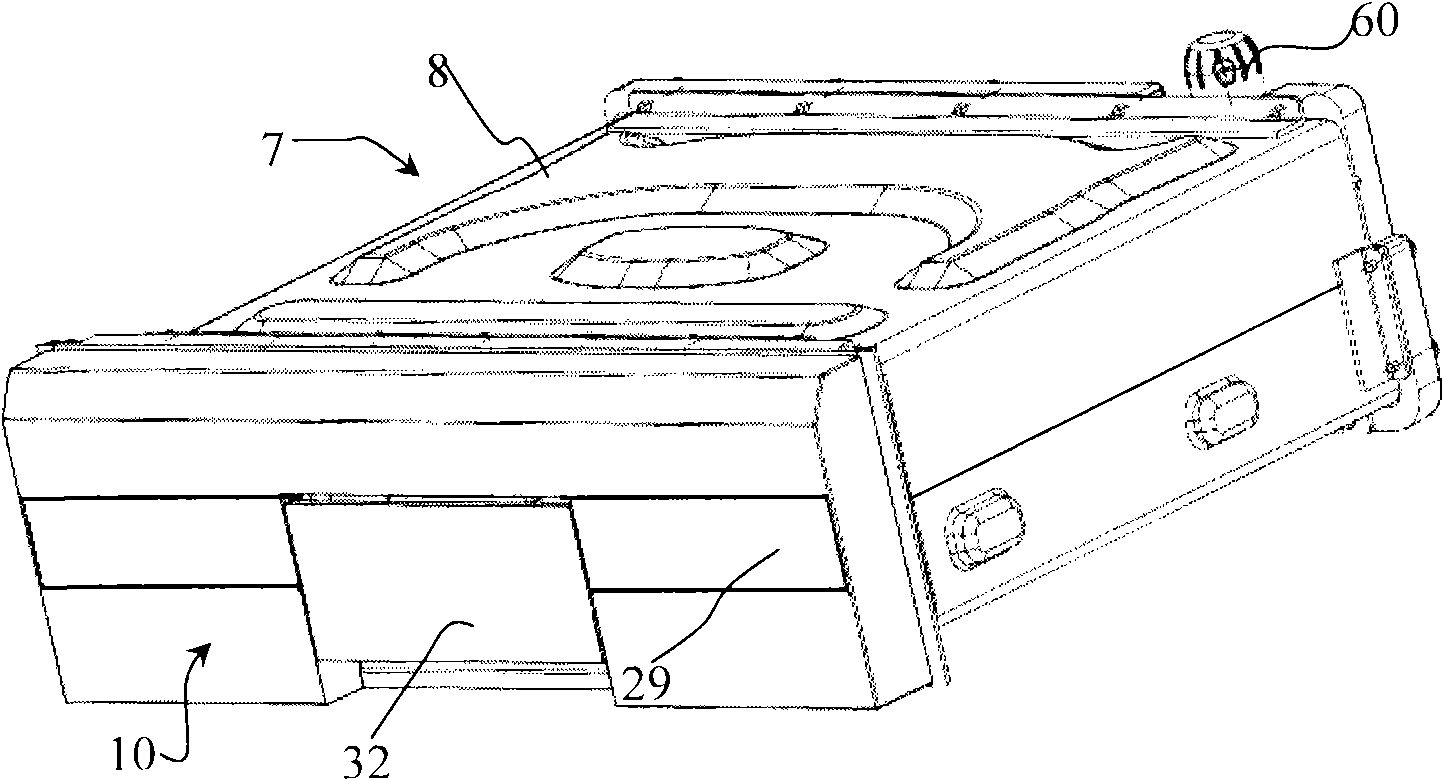

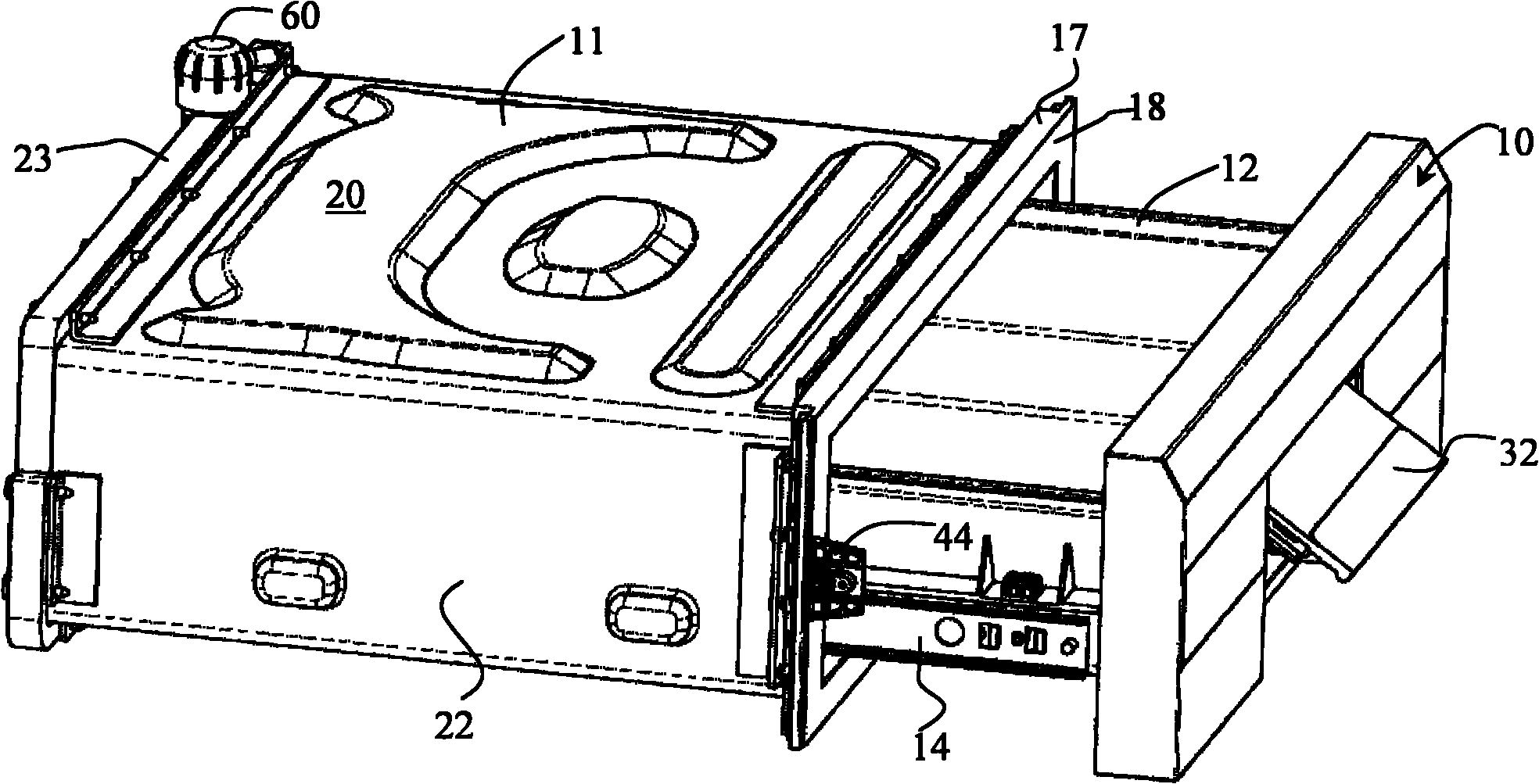

Storage unit and refrigeration appliance with same

ActiveCN102338538AReduce usageGood lookingLighting and heating apparatusBuilding locksLocking mechanismRefrigeration

The invention relates to a storage unit and a refrigeration appliance with the same. The storage unit comprises a main body (8), a door (10), locking mechanisms (34, 44) and a handle (32), wherein the body defines a storage room (15) with an opening part (15a) used for taking and putting materials; the door (10) is used for selectively opening and closing the opening part (15a); the locking mechanisms (34, 44) are used for locking the door (10) and the body (8) when the door (10) is in the closed position and comprise first matching parts (34) on the door (10) and second matching parts (44) on the body (8); and the handle (32) is arranged in connection with the first matching parts (34). The storage unit is characterized by also comprising rod bodies (33) connected between the handle (32) and the first matching parts (34), wherein the rod bodies (33) are driven by the handle (32) to rotate in such a manner that the central axes (X) of the rod bodies (33) do not carry out displacement relative to the door (10) and the first matching parts (34) are driven by the rod bodies (33) to move.

Owner:博西华家用电器有限公司

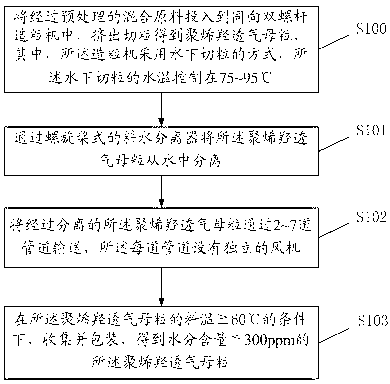

Polyolefin breathable masterbatch, and preparation method thereof

The invention discloses a polyolefin breathable masterbatch which comprises the following raw materials by weight ratio: 40-70 % of polyolefin resin, and 40-70 % of inorganic filling materials; and a moisture content of the polyolefin breathable masterbatch prepared from the polyolefin resin and the inorganic filling materials is less than or equal to 300 ppm. Correspondingly, the invention discloses a preparation method of the polyolefin breathable masterbatch. The polyolefin breathable masterbatch need not to be dried, and moisture of the breathable masterbatch can be removed through adjusting a temperature of cooling water, controlling a surface temperature of particles after being passed through a vibrating screen and using a delivery way with multichannel airducts. According to the invention, the polyolefin breathable masterbatch is good in physical and chemical properties, and greatly reduced in moisture content; production operation is simplified, energy consumption is minimized, subsequent requirements on film making is satisfied, quality and output of products are guaranteed, and influence of excess moisture on appearances, physical properties and pH value of the subsequently prepared films, as well as generation of broken holes and other adverse circumstances can be prevented.

Owner:SHENZHEN JIANCAI TECH DEVING

Stuffing for roasted food and its prepn process

InactiveCN101088345APrevent agingGuaranteed liquidityBakery productsFood preparationMonoglycerideColloid

The present invention relates to one kind of stuffing for roasted food and its preparation process. The stuffing consists of sugar 10-30 wt%, modified starch 0-11 wt%, hydrophilic colloid 0.1-0.6 wt%, steamed monoglyceride 1-5 wt%, potassium sorbate 0.01-0.1 wt%, food water preserver 5-30 wt%, edible essence and / or edible color 0.2-0.5 wt%, and water for the rest, with water content being less than wt%. The stuffing has the synergistic effect of colloid and modified starch, high flowability, high water preserving capacity, high freezing resistance and stable quality, and the roasted food with the stuffing has good taste.

Owner:MASSON GROUP

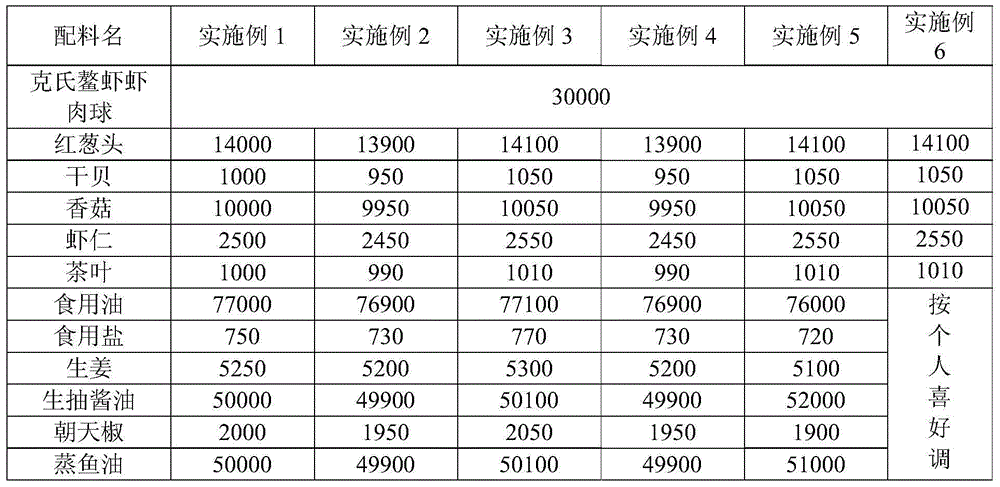

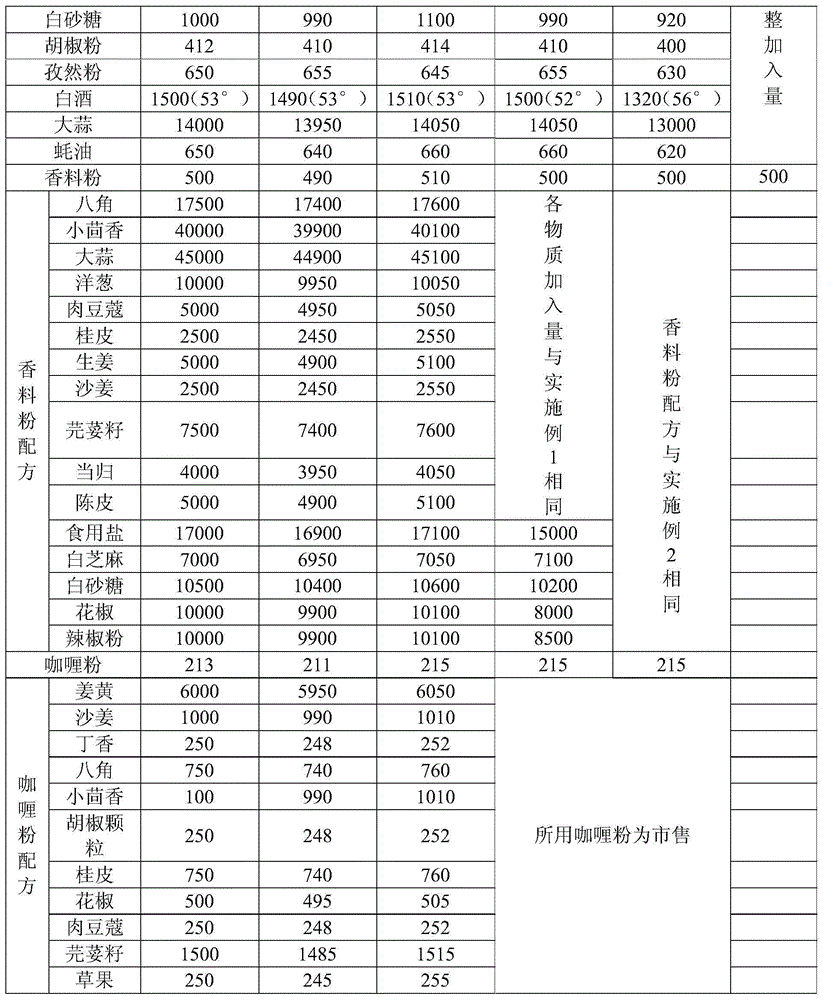

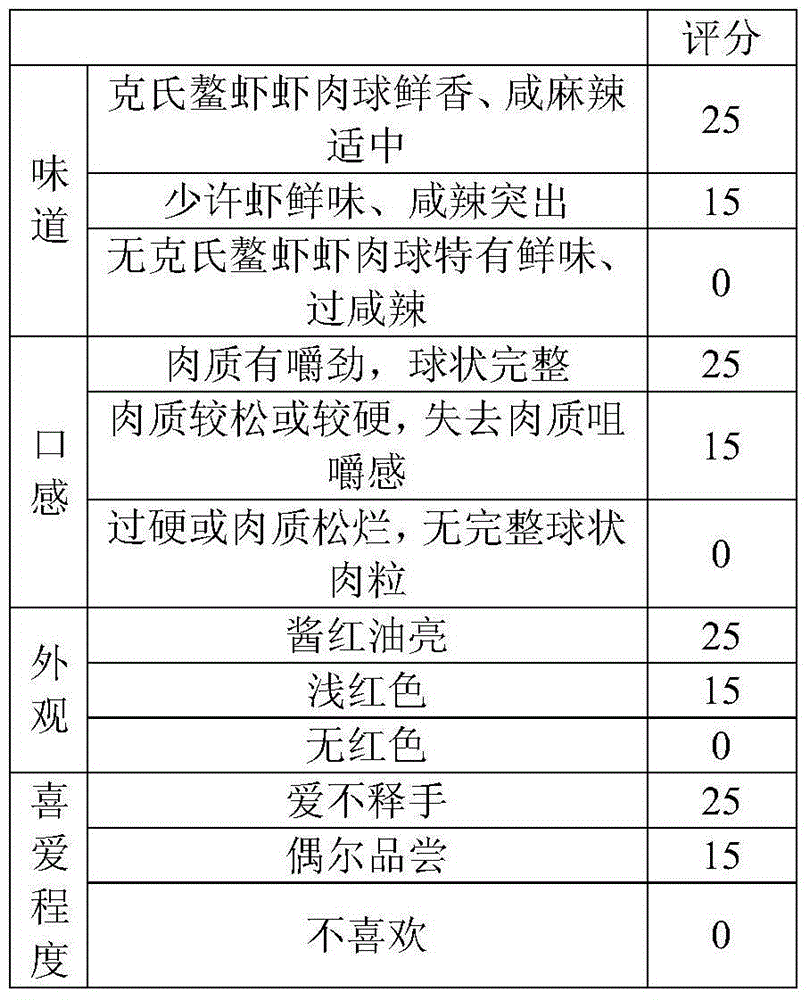

Crayfish paste and method for stewing crayfish paste

InactiveCN104543963AEnhance fresh and sweet tasteImprove spicy tasteFood preparationPreservativePrawn

The invention provides a crayfish paste and a method for stewing the crayfish paste. The crayfish paste is obtained by stewing a crayfish meat ball by using spice powder, shallot, scallop, curry powder, lentinus edodes, shrimp meat and tea. According to the crayfish paste, on one hand, the self earthy taste of the crayfish meat ball is eliminated; on the other hand, the fresh and sweet taste and spicy and hot taste of the crayfish meat ball are increased. The crayfish paste provided by the invention can be kept uncorroded for a long time under the condition that a preservative agent is not used, thereby preventing the adverse effect of the preservative agent on the taste of the crayfish paste.

Owner:顺祥食品有限公司

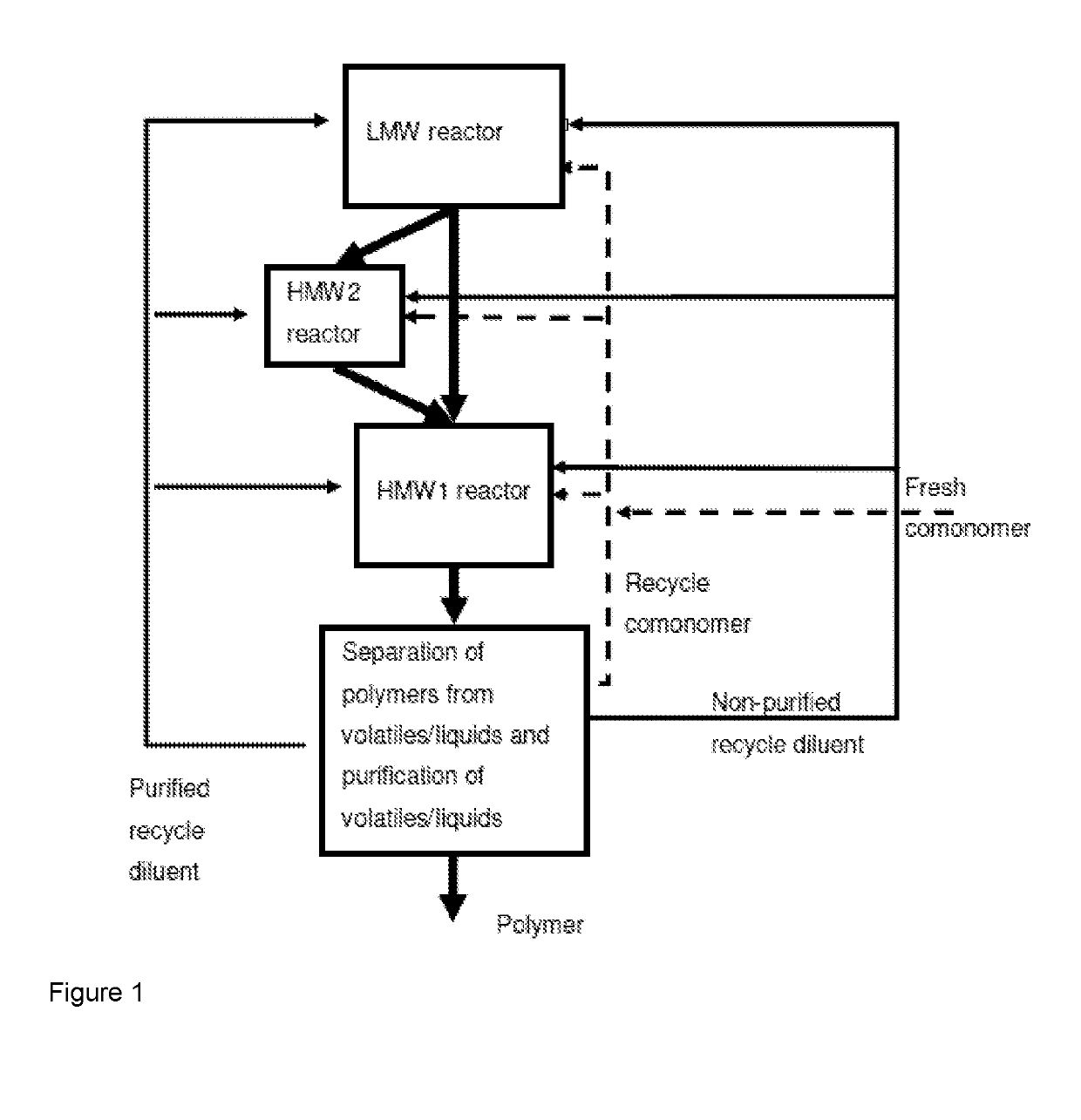

Polyethylene for pipes

InactiveUS20190185594A1High activityParticles in good shapeFlexible pipesRigid pipesPolymer scienceAlpha-olefin

The present invention provides a process for the preparation of a multimodal polyethylene, said multimodal polyethylene preferably having a bimodal or trimodal M.W. distribution, comprising: (i) polymerizing ethylene and optionally an α-olefin comonomer in a first polymerization stage to produce a first ethylene polymer; and (ii) polymerizing ethylene and optionally an α-olefin comonomer, in the presence of said first ethylene polymer, in a second polymerization stage, wherein said first and second polymerization stages are carried out in the presence of an unsupported metallocene catalyst, which is a complex of a group 4-10 metal having at least two ligands, wherein at least one of the ligands is persubstituted and comprises a delocalized pi system of electrons, each polymerization stage produces at least 5% wt of said multimodal polyethylene, and said multimodal polyethylene has a multimodal M.W. distribution, a M.W. of at least 50,000 g / mol and a bulk density of at least 250 g / dm3.

Owner:NORNER VERDANDI AS

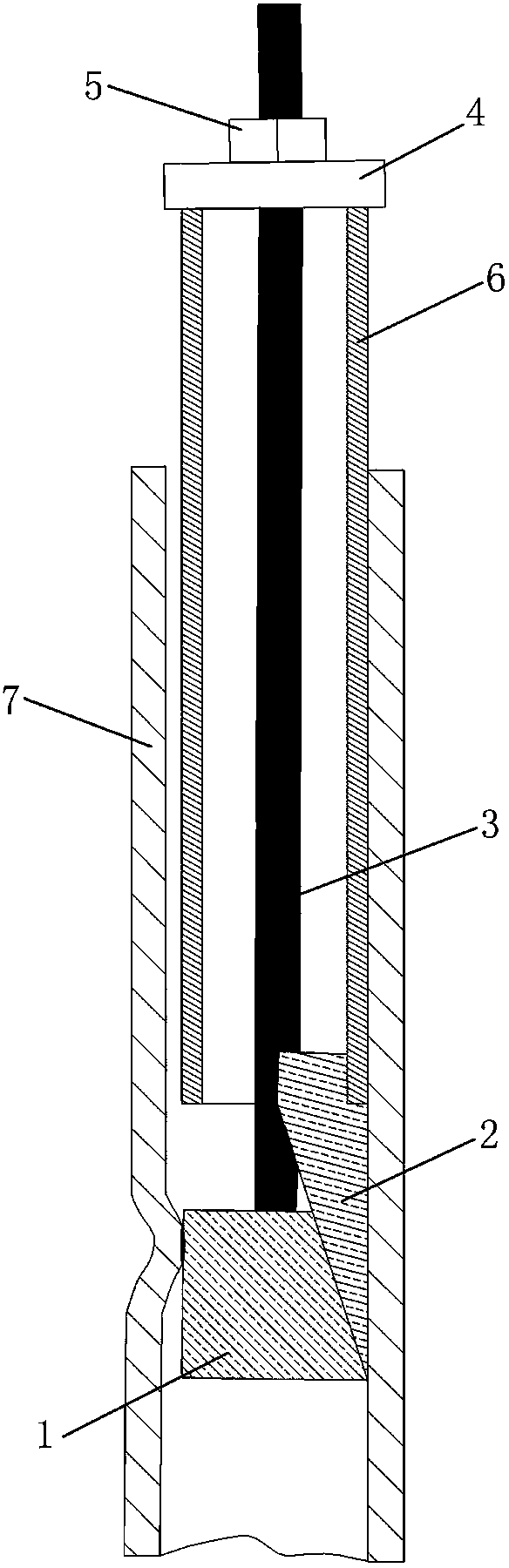

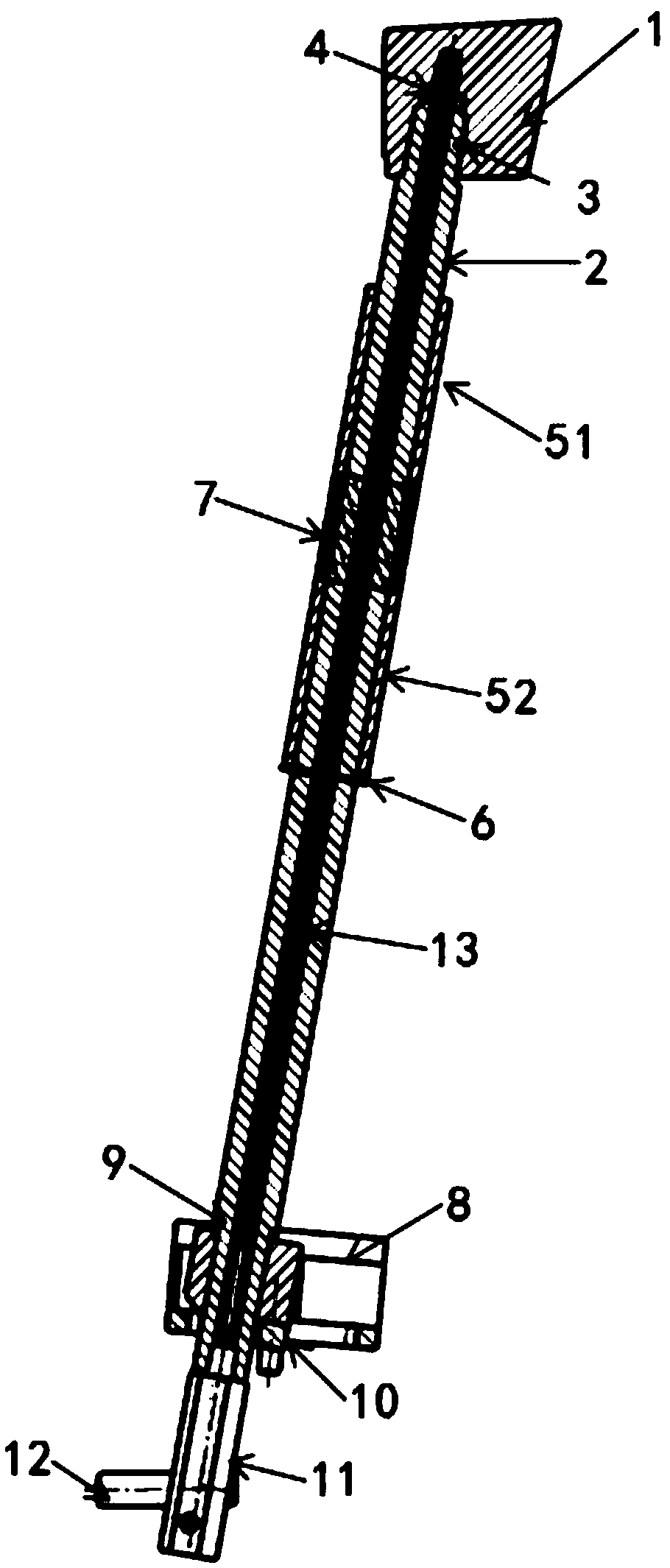

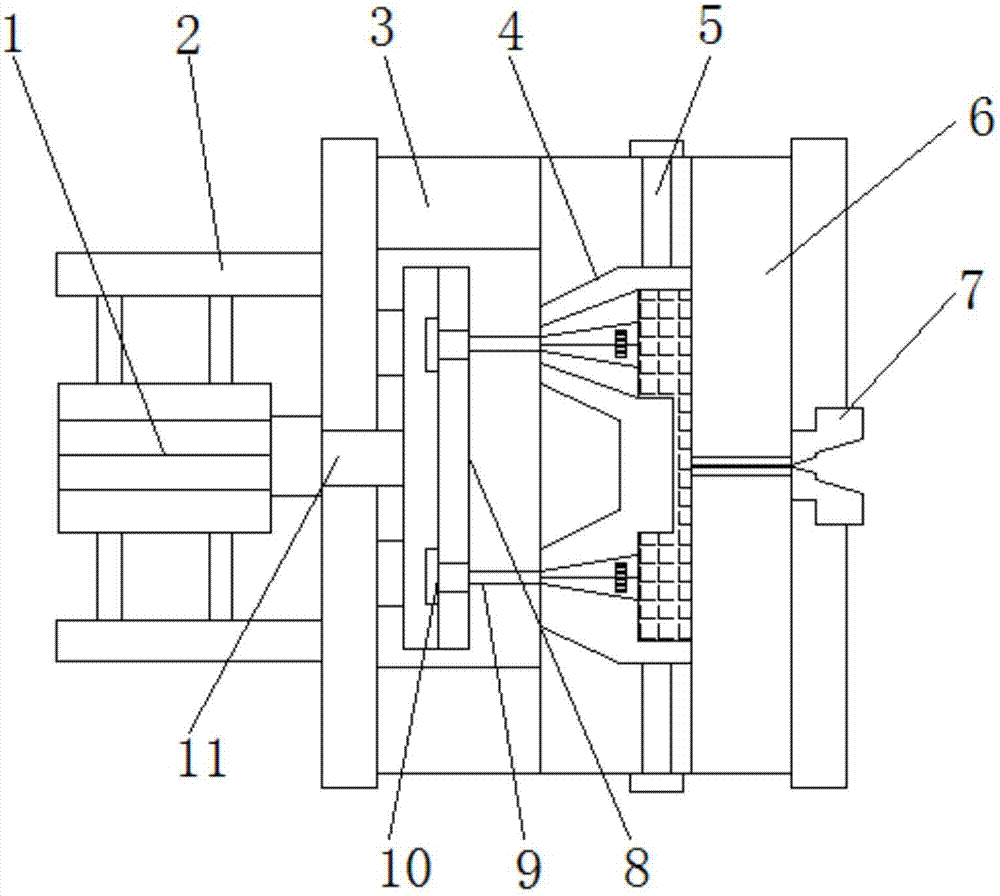

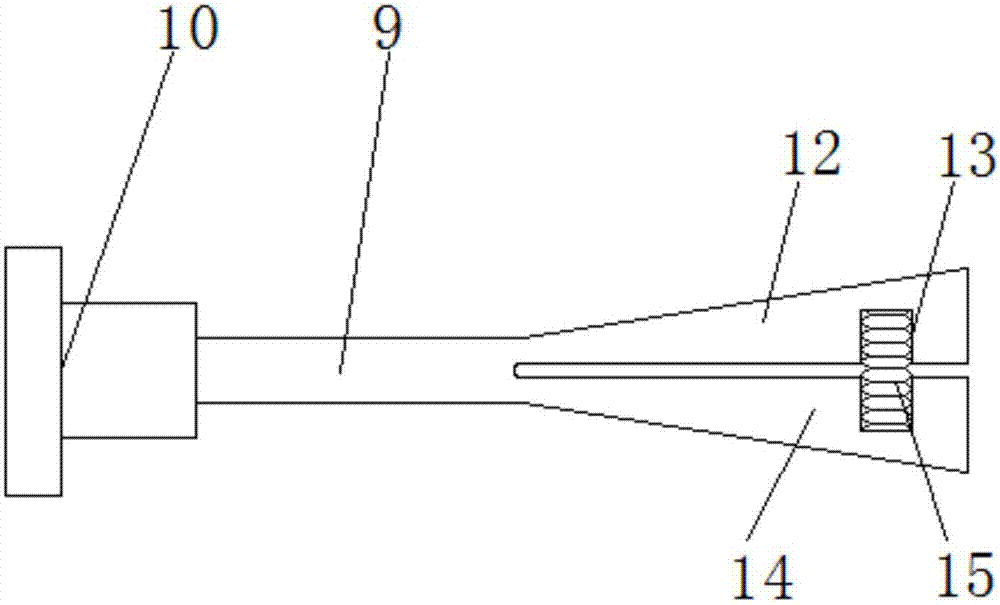

Method and device for measuring cable force

ActiveCN103278279AAffects architectural stylingAffect appearanceTension measurementLinear relationshipEngineering

The invention discloses a method and a device for measuring a cable force. The device comprises a pin shaft and an ear plate, wherein an axial through hole is arranged in the axial axle wire of the pin shaft, two ends of the axial through hole are respectively and symmetrically provided with a transmitting end and a receiving end of an optical measurement system, a measurement plane of the optical measurement system is coplanar with the axial axes of the pin shaft and the action direction of load, and the ear plate is provided with a limit device to be connected with the pin shaft. On the basis that the pin shaft has the characteristics of being even in material and completely and linearly elastic under the stress state, the cable force of an inhaul cable is confirmed by the measurement of the tinny deformation of the pin shaft of a connecting node under the action of the cable force and the linear relationship between the cable force and the deformation. The method and the device provided by the invention are nondestructive testing technologies, thereby being wide in application range.

Owner:SOUTH CHINA UNIV OF TECH

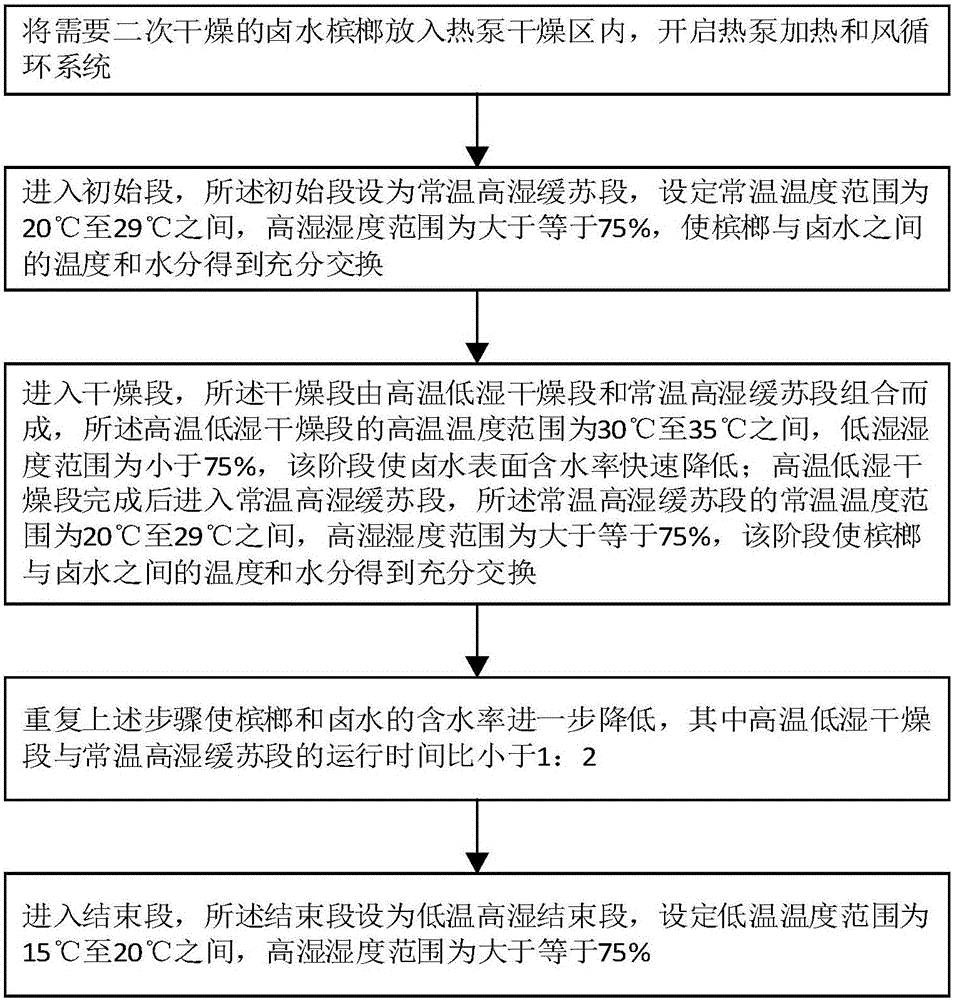

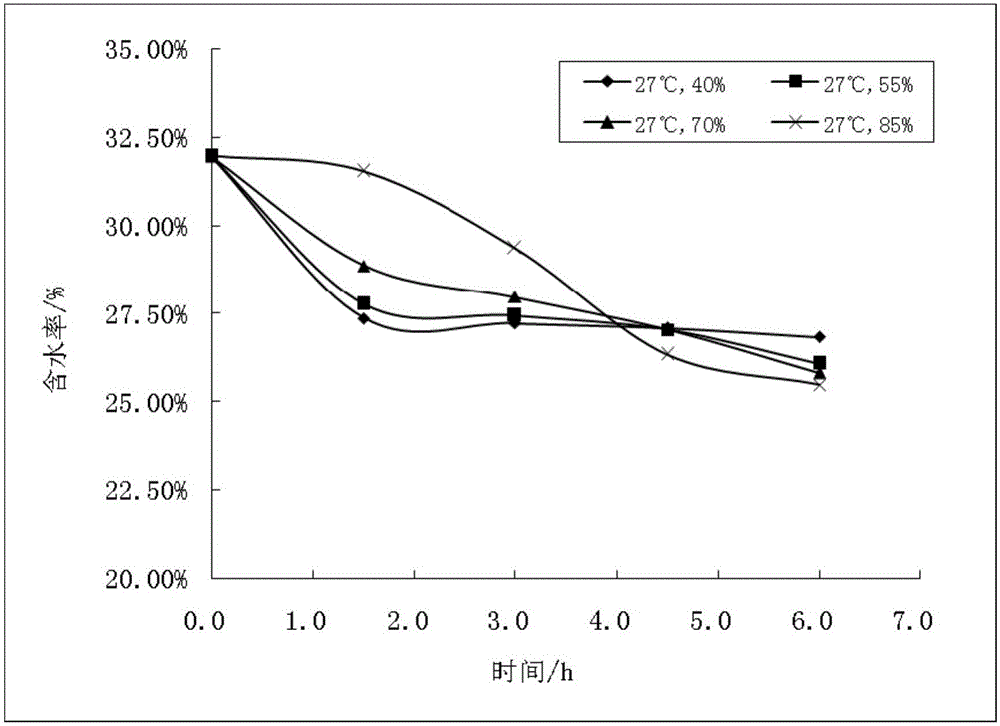

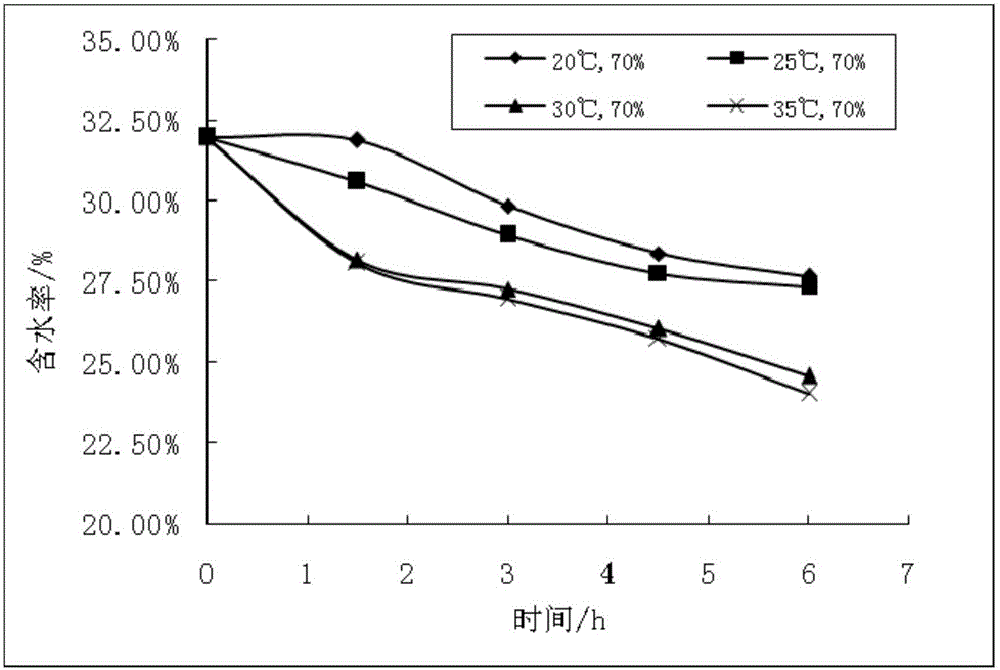

Heat pump drying method for marinated betel nuts

ActiveCN106017049AAffect appearanceAffect the tasteHeat pumpsDrying gas arrangementsBetel nutsEnd stages

The invention discloses a heat pump drying method for marinated betel nuts. The method comprises an initial stage, a drying stage and an ending stage, and high-temperature and low-humidity drying and normal-temperature and high-humidity tempering are combined for drying the betel nuts circularly; and finally, the betel nuts are post-treated in a low-temperature and high-humidity environment, and thus the taste of the betel nuts is remarkably improved. It is shown by a multi-stage circulating drying experiment result that the betel nuts can be well promoted to be tasty through normal-temperature and high-humidity tempering, the dehumidification purpose can be achieved rapidly through short-time high-temperature and low-humidity drying, and serious incrustation of the surface of marinade is prevented; compared with traditional marinated betel nuts obtained after being dried in shade, the marinated betel nuts are more aromatic; the purposes of shortening the drying time and improving the production efficiency are achieved; and the obtained marinated betel nut drying technique has important significance for the production practice and the realization of automatic production.

Owner:GUANGDONG PROVINCE MODERN AGRI EQUIP RES INST +1

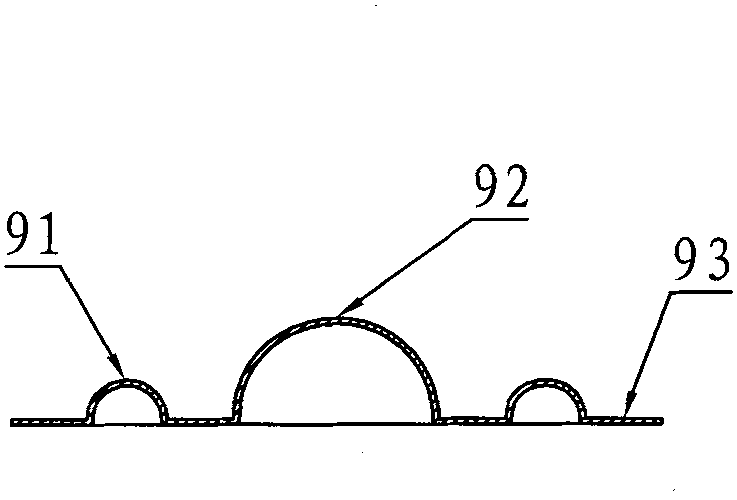

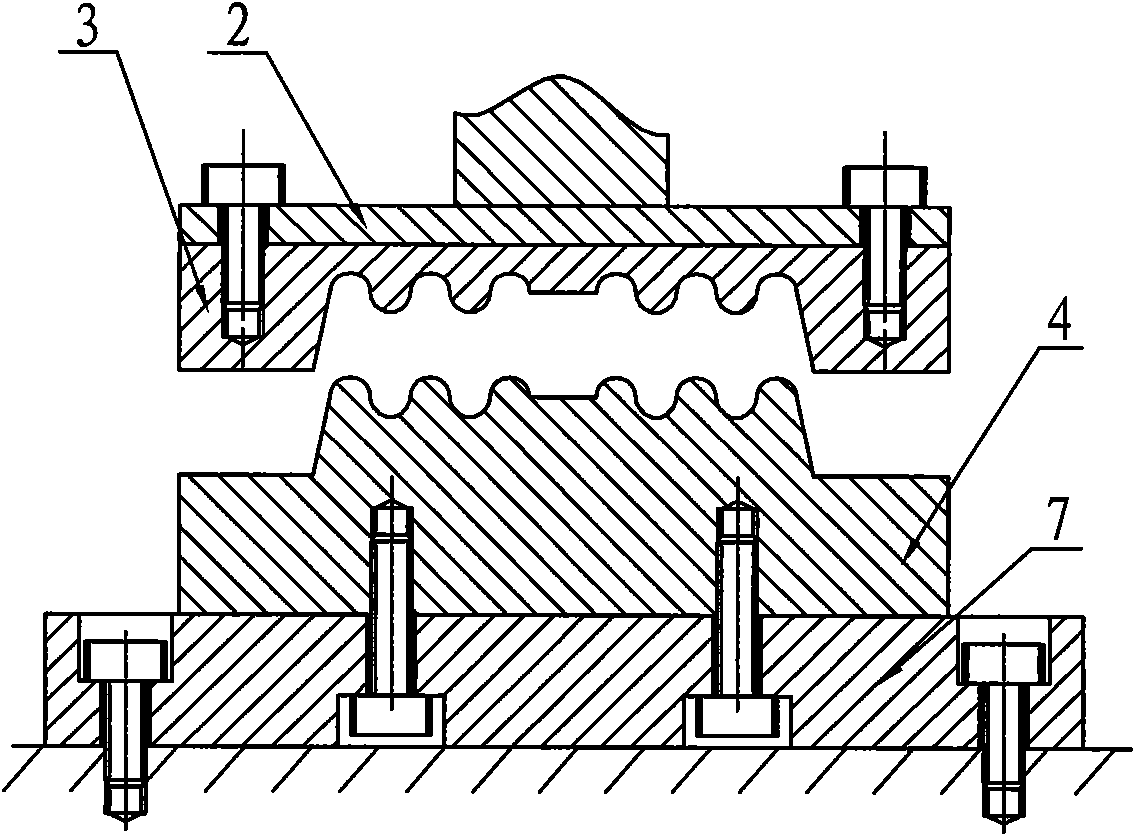

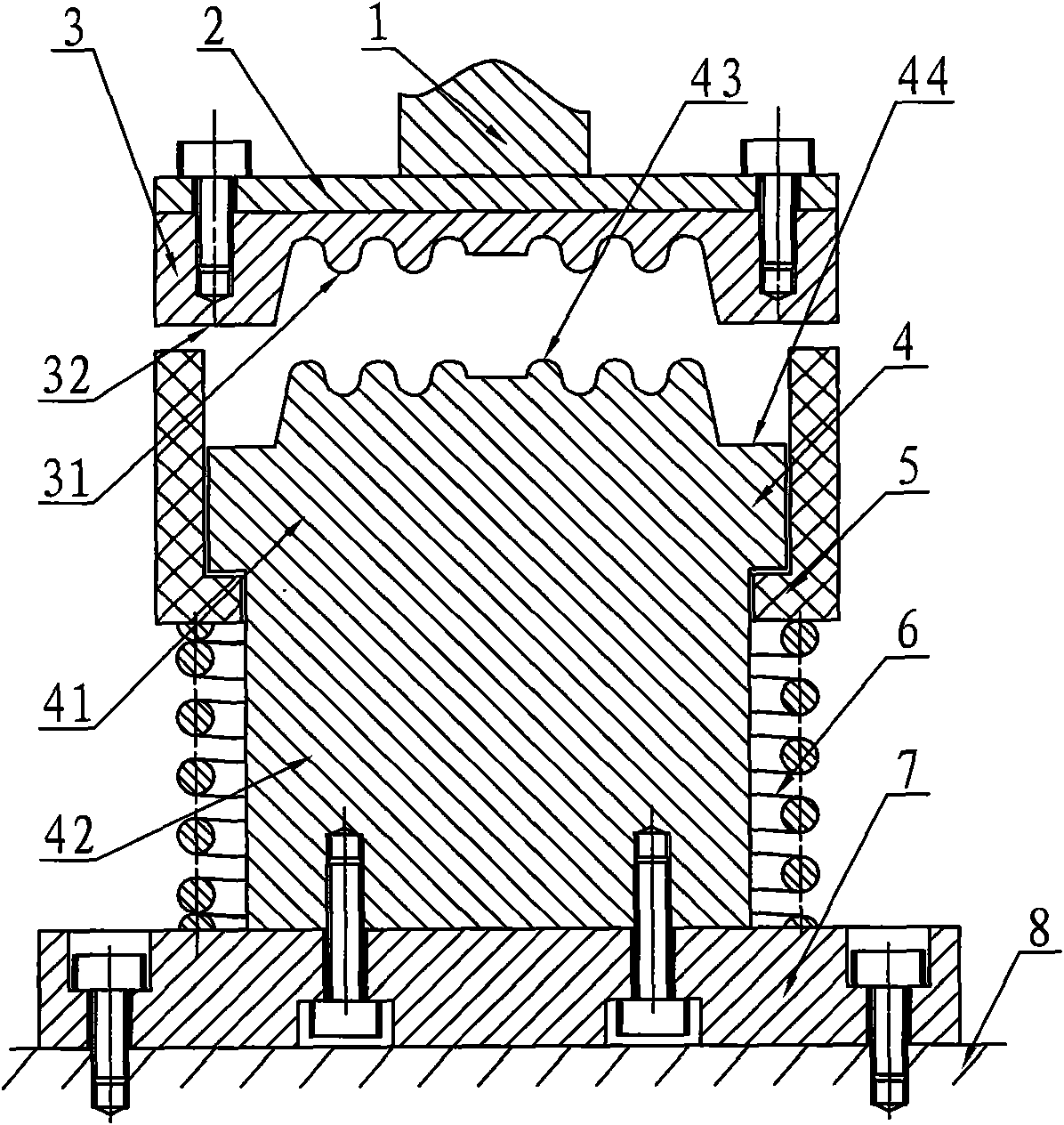

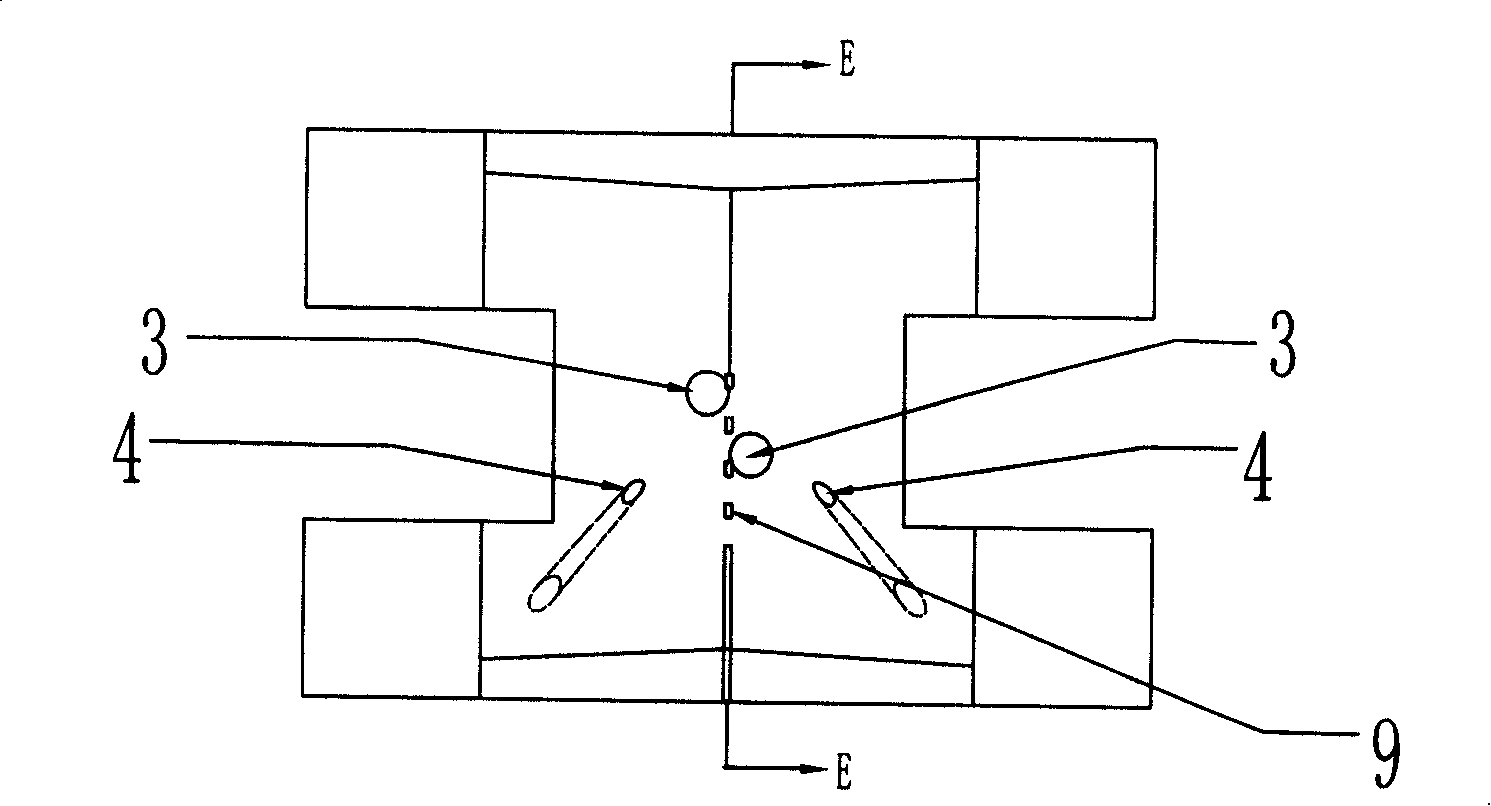

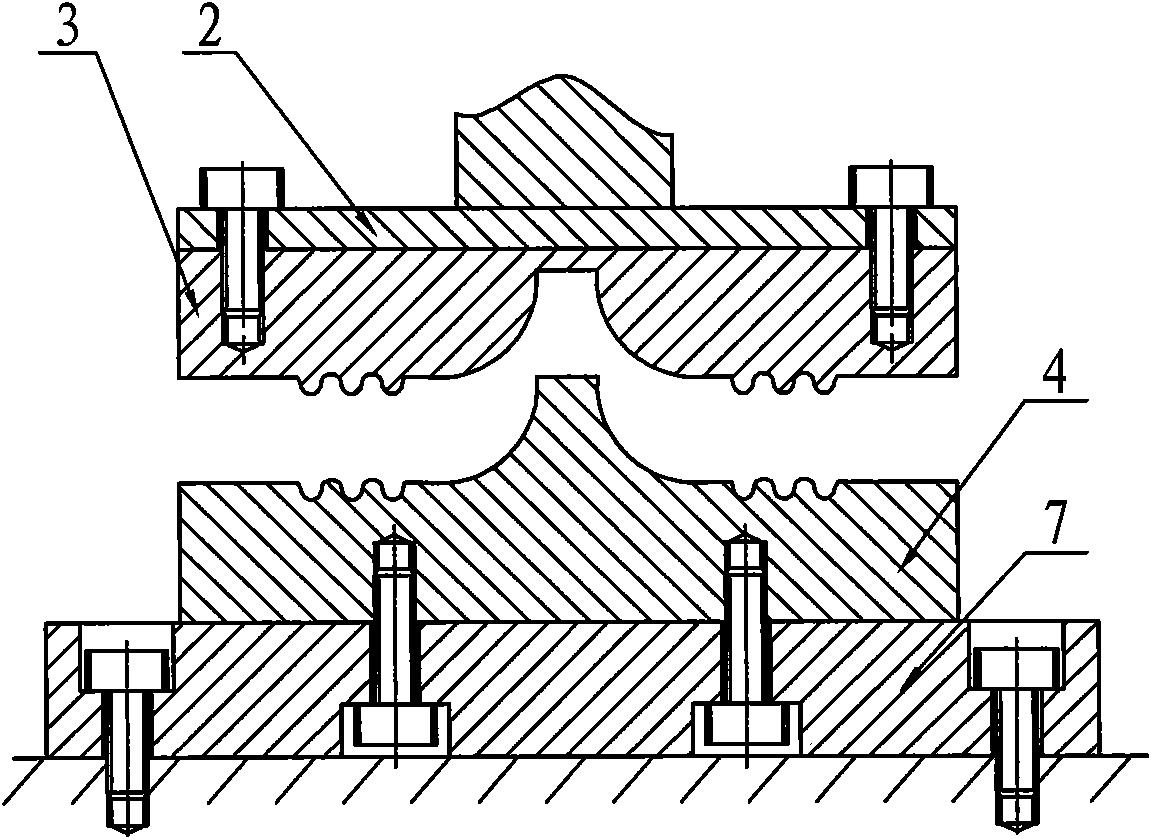

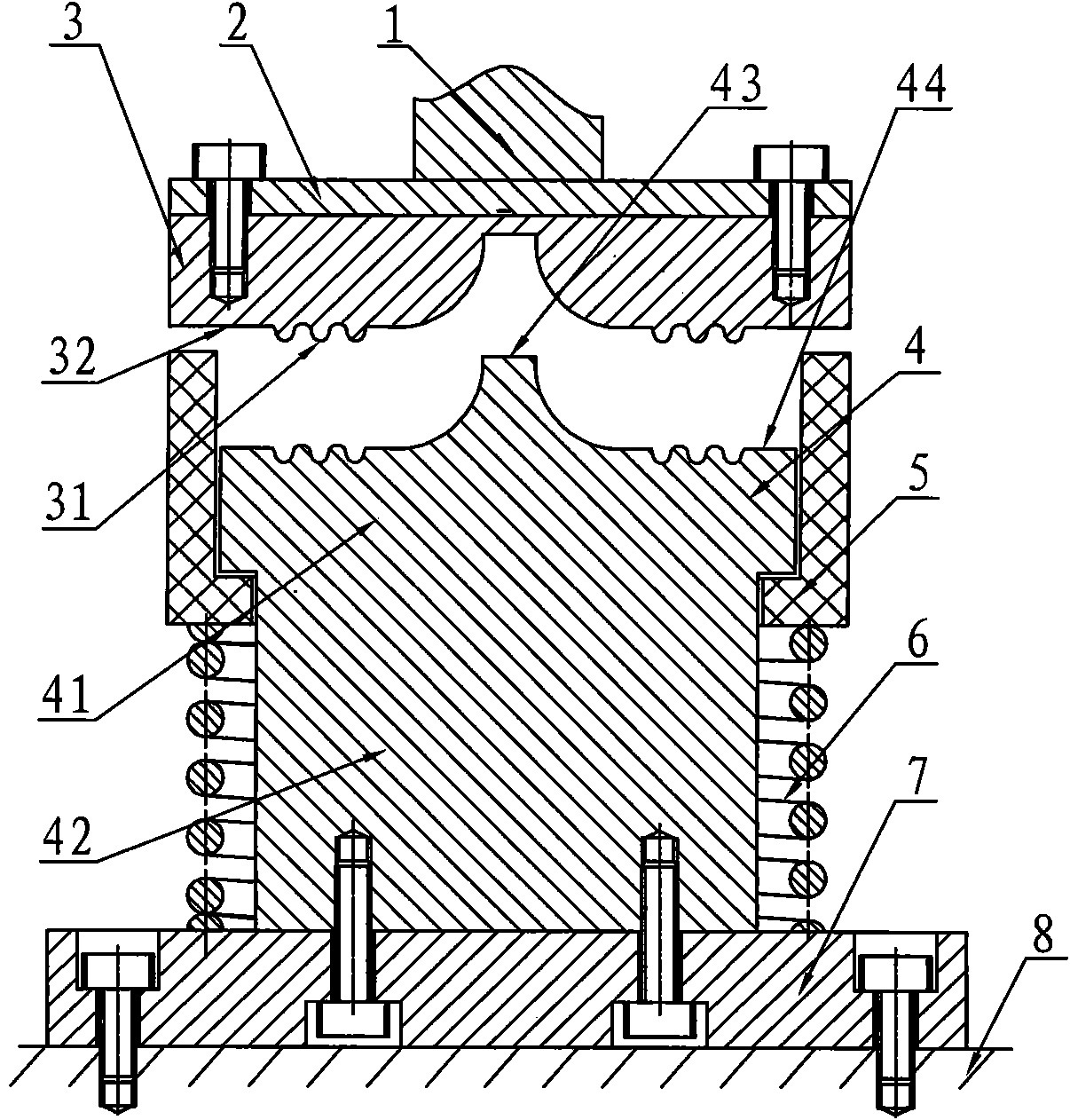

Sound film molding pressing die for loudspeaker

InactiveCN102014334AEliminate Causes of Press WrinklingReduce generationShaping toolsElectrical transducersEngineeringLoudspeaker

The invention provides a sound film molding pressing die for a loudspeaker, consisting of an upper die part and a lower die part. The lower die part consists of a lower die head, a movable pressing sleeve, a reset spring and a lower template, wherein the lower die head comprises a molding die body and a bearing column; the molding die body consists of a lower molding surface and a lower plunger ring; the movable pressing sleeve is sleeved on the molding die body and the bearing column; the reset spring is sleeved on the bearing column, and is positioned between the movable pressing sleeve and the lower template; and an upper die head is coaxial with the lower die head. Because the movable pressing sleeve and the reset spring are additionally arranged in the lower die head part, when the sound film is pressed, grey cloth to be molded is firstly compacted by an upper plunger ring and the movable pressing sleeve so as to ensure that the peripheral cloth is stressed uniformly and then is subject to drawing and compression moulding. Therefore, the folding phenomenon on the periphery of a sound film finished product can be eliminated, the sound film molding pressing die can be operated only by one person, the finished product can be automatically demoulded, and the operation is safe, convenient, and labor-saving.

Owner:江苏东禾电声配件有限公司 +1

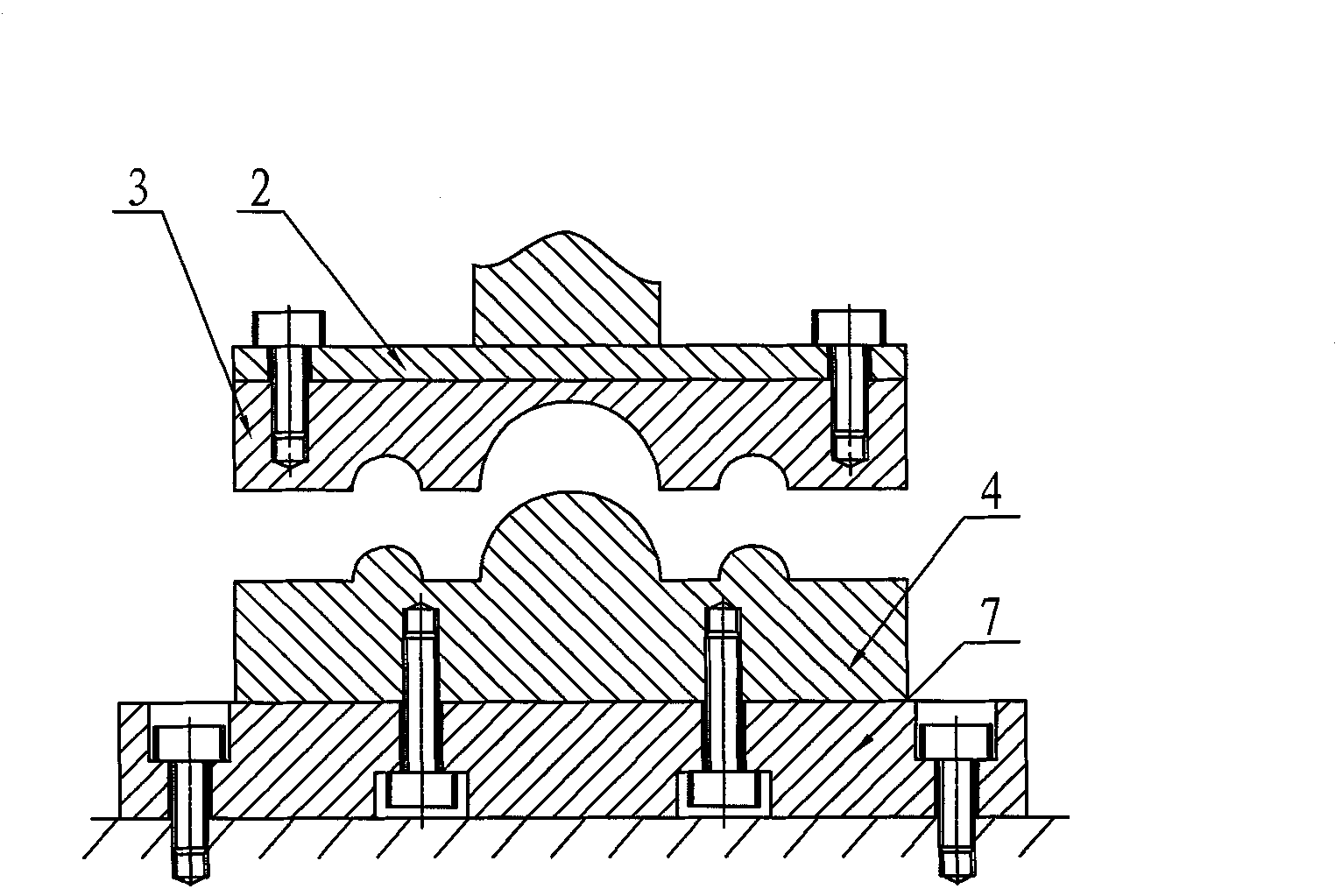

Press-forming mould of loudspeaker elastic wave

InactiveCN102088656AEliminate forceEliminate Causes of Press WrinklingElectrical transducersLoudspeakerMaterials science

The invention provides a press-forming mould of a loudspeaker elastic wave, comprising an upper mould component and a lower mould component. The lower mould component comprises a lower mould head, a movable press sleeve, return springs and a lower template, wherein the lower mould head comprises a moulding body and a bearing column; the moulding body comprises a lower moulding surface and a lower press ring; the movable press sleeve is sleeved on the moulding body and the bearing column; the return springs are sleeved on the bearing column and positioned between the movable press sleeve and the lower template; and the upper mould head and the lower mould head are coaxial. The movable press sleeve and the return springs are added to the lower mould head so that, in the operation of pressing an elastic wave, the upper press ring and the movable press sleeve first press cloth blanks to be moulded tight and ensure that peripheral cloth receives even force; and then the cloth blanks are deeply drawn and pressed to form a finished product so that the folds of the peripheral parts of the finished product of elastic wave can be eliminated. The press-forming mould of the invention can be operated by only one person; and moreover, the finished product can be automatically demoulded, which provides safe, convenient and labor-saving operation.

Owner:江苏东禾电声配件有限公司 +1

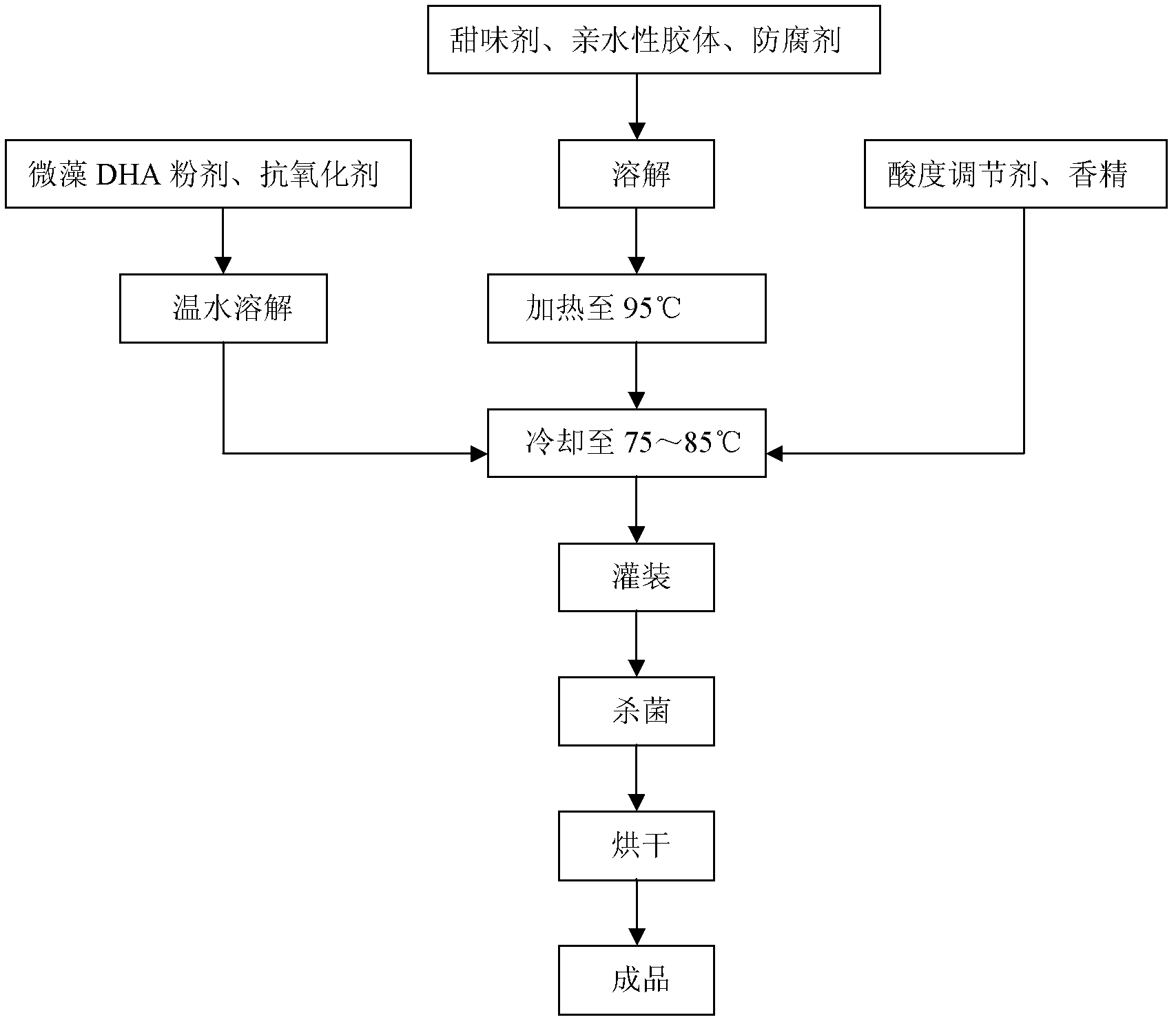

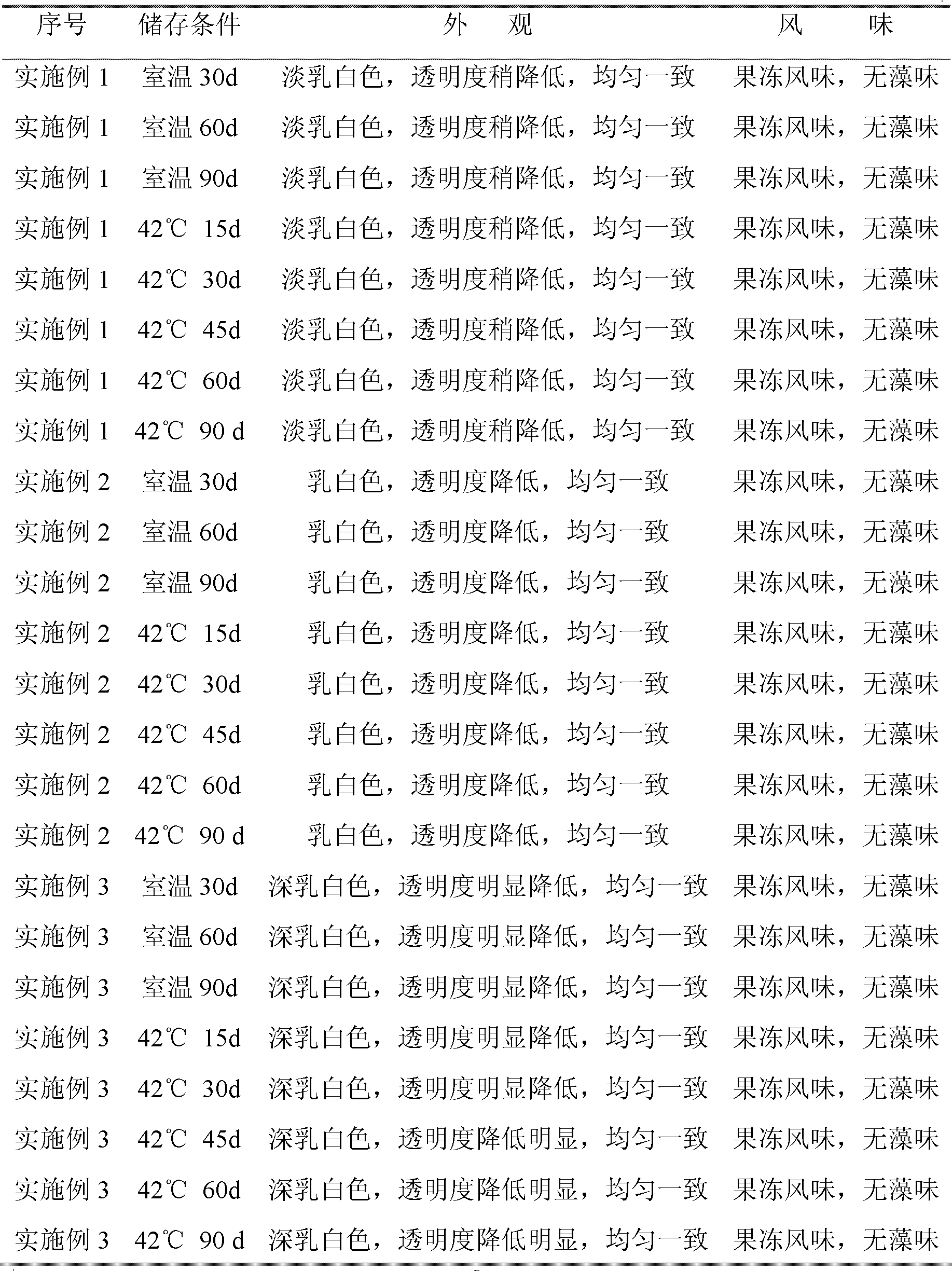

Nutrient jelly containing microalgae DHA (Docosahexaenoic Acid) and preparation method thereof

ActiveCN102423021AImprove qualityStrong sustainable developmentFood preparationFlavorDocosahexaenoic acid

The invention discloses a nutrient jelly containing microalgae DHA (Docosahexaenoic Acid) and a preparation method thereof. The nutrient jelly comprises the following components of 0.002-0.0105 percent of the microalgae DHA, 0.20-0.50 percent of hydrophilic colloid, 10.0-15.0 percent of sweetening agent, 0.25-0.50 percent of acidity regulator, 0.02-0.05 percent of preservative, 0.005-0.012 percent of antioxidant and 0.1-0.3 percent of flavor composition. The preparation method disclosed by the invention comprises the following steps of: uniformly mixing the sweetening agent, the hydrophilic colloid and the preservative, then adding the mixer in water and uniformly stirring; heating the mixer until the hydrophilic colloid is completely dissolved; reducing the temperature to be 75-85DEG C; adding microalgae DHA powder, the antioxidant and the acidity regulator; adding to a certain weight with water; filling, sealing, sterilizing, fishing, leaching and cooling the mixer; and after the mixer is qualified by the inspection, obtaining the nutrient jelly containing the microalgae DHA. The nutrient jelly obtained by improving the formula and the preparation process retains original mouthfeeling within the guarantee period without adverse off flavor; and the microalgae DHA has favorable stability within the guarantee period of the jelly without influencing the mouthfeeling and the flavor of the jelly.

Owner:GUANGDONG RUNKE BIOLOGICAL ENG

Flattened metallic pipe repairing tool

The invention discloses a flattened metallic pipe repairing tool which comprises a repairing assembly and a transmission assembly. The repairing assembly comprises a repairing sliding block (1) and a fixing block (2) with a notch and a slant face; the transmission assembly comprises a lead screw (3), a cushion block (4) with a circular hole, an adjusting screw nut (5) and a supporting pipe (6), one end of the lead screw (3) is fixedly connected with the repairing sliding block (1), and the other end of the lead screw (3) is sequentially connected with the cushion block (4) and the adjusting screw nut (5). The lead screw (3) is located inside the supporting pipe (6) and is concentric with the supporting pipe (6), and the supporting pipe (6) is located inside a damaged pipe (7) and is concentric with the damaged pipe (7). The flattened metallic pipe repairing tool has the advantages that the repaired metallic pipe is recovered to be in the original size, and quality, performance and appearance of the metallic pipe are not influenced so that the metallic pipe can be continuously used, and unnecessary scrapping is reduced.

Owner:NANTONG YONGDA PIPE IND

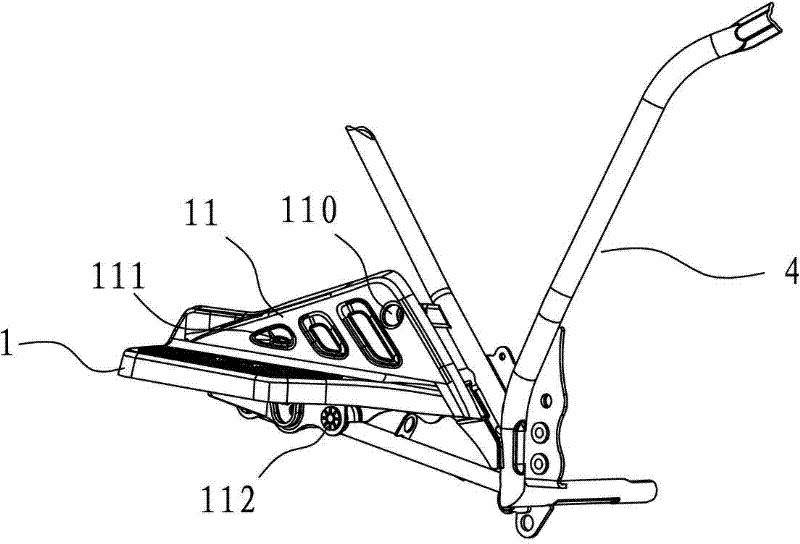

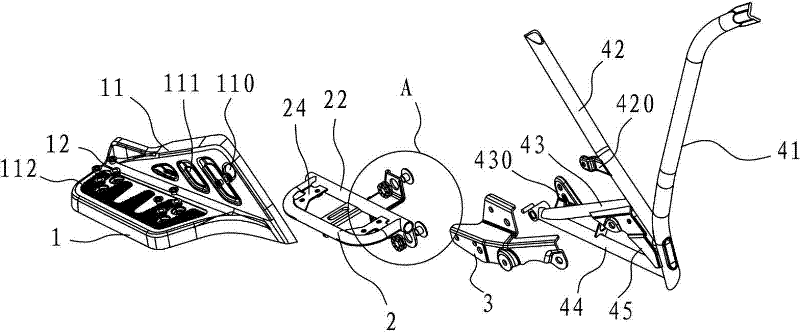

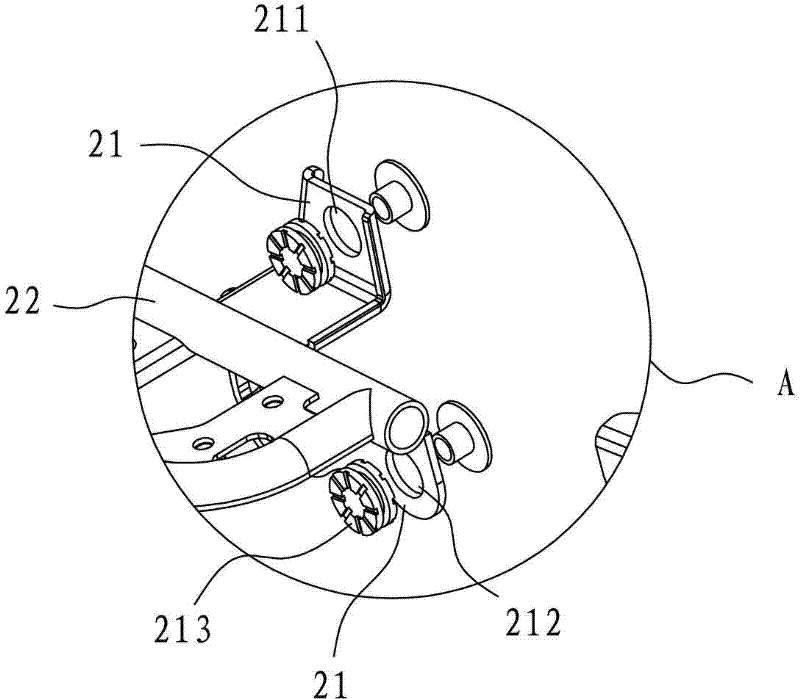

Rear pedal for motorcycle

The invention discloses a rear pedal for a motorcycle, which comprises a supporting pedal framework and a pedal mounted on the pedal framework, wherein the periphery of the pedal framework is covered by the pedal, and a frame connecting lug is arranged on the pedal framework and is located aside the pedal framework. The rear pedal for the motorcycle provided by the invention is high in comfortableness; the rear pedal need not be connected to a rear storage rack; a chroming technology is unnecessary; the environmental pollution and influence on appearance of the motorcycle are avoided; the safety is higher; and the feet are prevented from being hurt by a rear wheel and dirtied by muddy water.

Owner:JIANGMEN DACHANGJIANG GROUP CO LTD

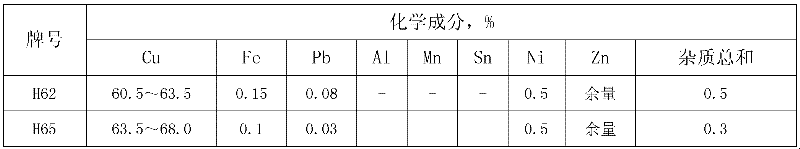

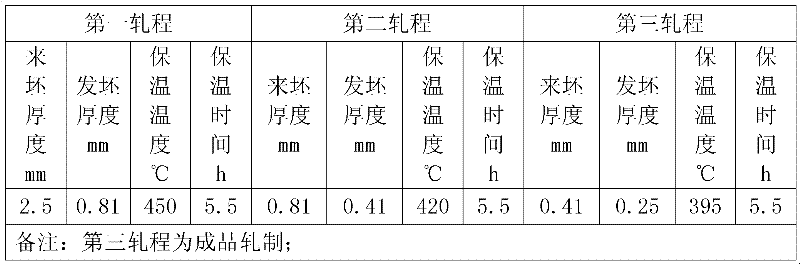

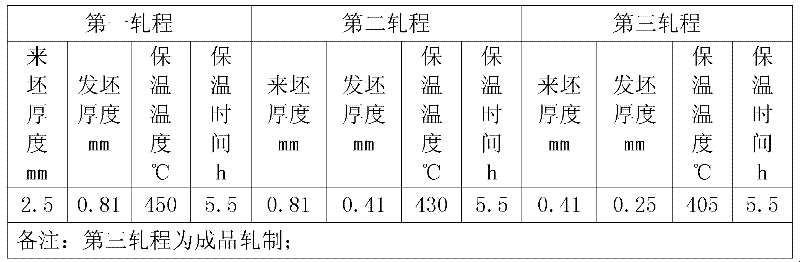

High-tensile property brass band for lamp holder and production process thereof

The invention discloses a high-tensile property brass band for a lamp holder and a production process thereof. The brass band comprises the following components in percentage by weight: less than or equal to 0.01 percent of lead, less than or equal to 0.02 percent of iron, less than or equal to 0.02 percent of tin, less than or equal to 0.02 percent of nickel, 0.001 to 0.003 percent of phosphor, 63.0 to 64.5 percent of copper, and the balance of zinc. Compared with the prior art, the high-tensile property brass band has the advantages that: the produced high-tensile property brass band for a lamp holder can fulfill the requirement for excellent plasticity in a lamp holder forming process, and prevent pitted surface of a product which is subjected to deep tension from influencing the appearance and yield by reasonably controlling the content of impure elements, grain sizes of finished products and deep drawability.

Owner:清远楚江高精铜带有限公司

Blast-furnace slag powder and blast-furnace slag and coal cinder compound powder excitant

A trigger for stimulating the early-phase activity of the blast furnace slag powder or the mixture of blast furnace slag powder and cinder powder is proportionally prepared from triethanolamine and early strengthening agent (calcined gypsum or bihydrated gypsum or potassium chromium sulfate).

Owner:SOUTH CHINA UNIV OF TECH

Mold angle ejector rod structure capable of adding cooling water

The invention discloses a mold angle ejector rod structure capable of adding cooling water, and belongs to the field of automobile injection molds. The mold angle ejector rod structure comprises an angle ejector block, an inclined ejector rod, an angle ejector sliding seat and an angle ejector change-over block, wherein the angle ejector block is connected with the head part of the hollow; the tail part of the inclined ejector rod is connected with the angle ejector sliding seat; the angle ejector sliding seat is capable of adjusting the relative height between the angle ejector sliding seat and the angle ejector rod through an O-shaped cushion block and is in clamping connection with the angle ejector rod through a U-shaped clamping block; the angle ejector rod is sequentially provided with a first self-lubricating copper guide sleeve, a hollow aluminum pipe and a second self-lubricating copper guide sleeve; an annular pipe is arranged in a cavity in the angle ejector rod along a longitudinal direction; the tail part of the angle ejector rod is connected with the angle ejector change-over block; the angle ejector change-over block is provided with a water pipe joint; the tail partof the annular pipe is communicated with the water pipe joint through the angle ejector change-over block; the head part of the annular pipe stretches out of the angle ejector rod. According to the mold angle ejector rod structure disclosed by the invention, addition of the cooling water to a single-rod angle ejector rod structure of a precision mold is realized, and meanwhile, an occlusion action process of an angle ejector rod can be avoided.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

Powdery styrene-butadiene rubber preparation method

The invention belongs to the field of rubber synthesis, and particularly relates to a powdery styrene-butadiene rubber preparation method, which comprises: (1) sequentially adding water, styrene-butadiene latex and a reducing agent aqueous solution into a polymerization kettle, carrying out stirring heating, adding an oxidizing agent, and carrying out a cross-linking reaction to obtain surface-cross-linked styrene-butadiene latex; and (2) adding water and an anti-aging agent to the surface-cross-linked styrene-butadiene latex, then adding a primary agglomeration agent and a secondary agglomeration agent, carrying out agglomeration to obtain a powder polymer aqueous suspension, dewatering, washing, screening, and drying. According to the present invention, the chemical cross-linking is performed on the surface of the styrene-butadiene latex particles, such that the number of the rubber molecules active points on the surface of the particles is reduced, the plasticity of the surface of the particles is improved, the viscoelasticity of the surface is reduced, the deformation of the product is reduced, the long-lasting and stable chemical separation effect is generated between the rubber particles, the consumption of the inorganic separation agent is low, the influence on the performance of the rubber product is low, and the prepared powdery styrene-butadiene rubber has characteristics of uniform particles, good fluidity and good storage stability.

Owner:CHINA PETROLEUM & CHEM CORP

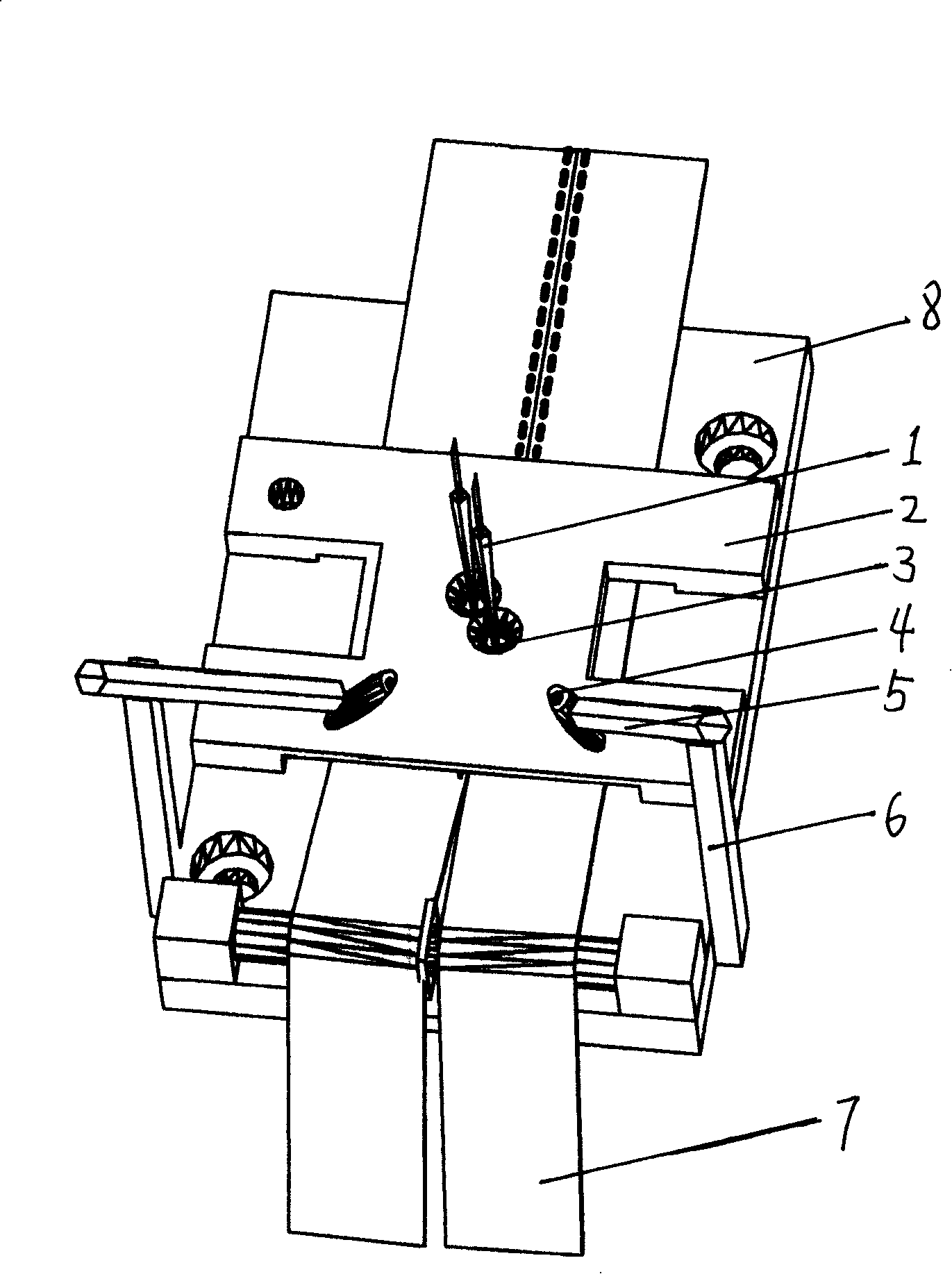

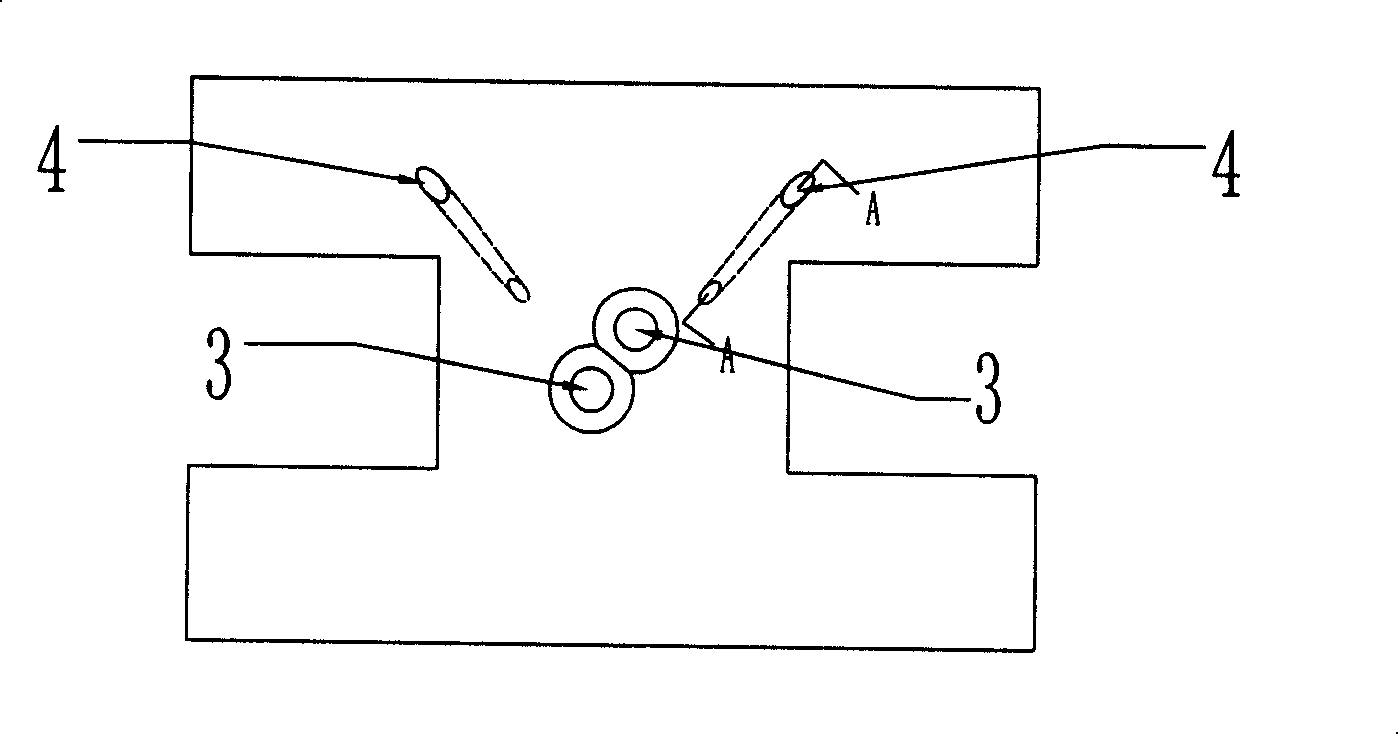

Processing device of waterproof slide fastener

InactiveCN101228982ASolve the gap problemSuture smoothlySlide fastenersWork-feeding meansLeft halfAgricultural engineering

The invention relates to a production and processing device of a waterproof zipper. The invention solves the problem that a gap is generated between a right waterproof glue layer and a left waterproof glue layer of the zipper when processing waterproof zippers in the prior art. The invention adds an opposite slant hole and a blowing pipe to a pressing board structure of a sewing machine in the prior art; according to aerodynamic principle, the cloth ribbons pasted with waterproof glue layer are pushed to middle by the constant air blowed out from the additionally equipped blowing pipe, thus ensuring that the gap between the waterproof glue layer cloth ribbons at the right half side and the left half side of the zipper is close after sewing; at the same time, a spotted fence on the back of an upper pressing board can avoid overlapping sewing caused by excessive squeeze when the cloth ribbons are pushed to the middle by wind blowing. The invention can guarantee the smooth sewing of the waterproof zipper cloth ribbons pasted with waterproof glue layers and compact sewing gap after sewing, thereby resulting in excellent waterproof performance of the product.

Owner:SHANGHAI EASTDRAGON FABRIC & GARMENT

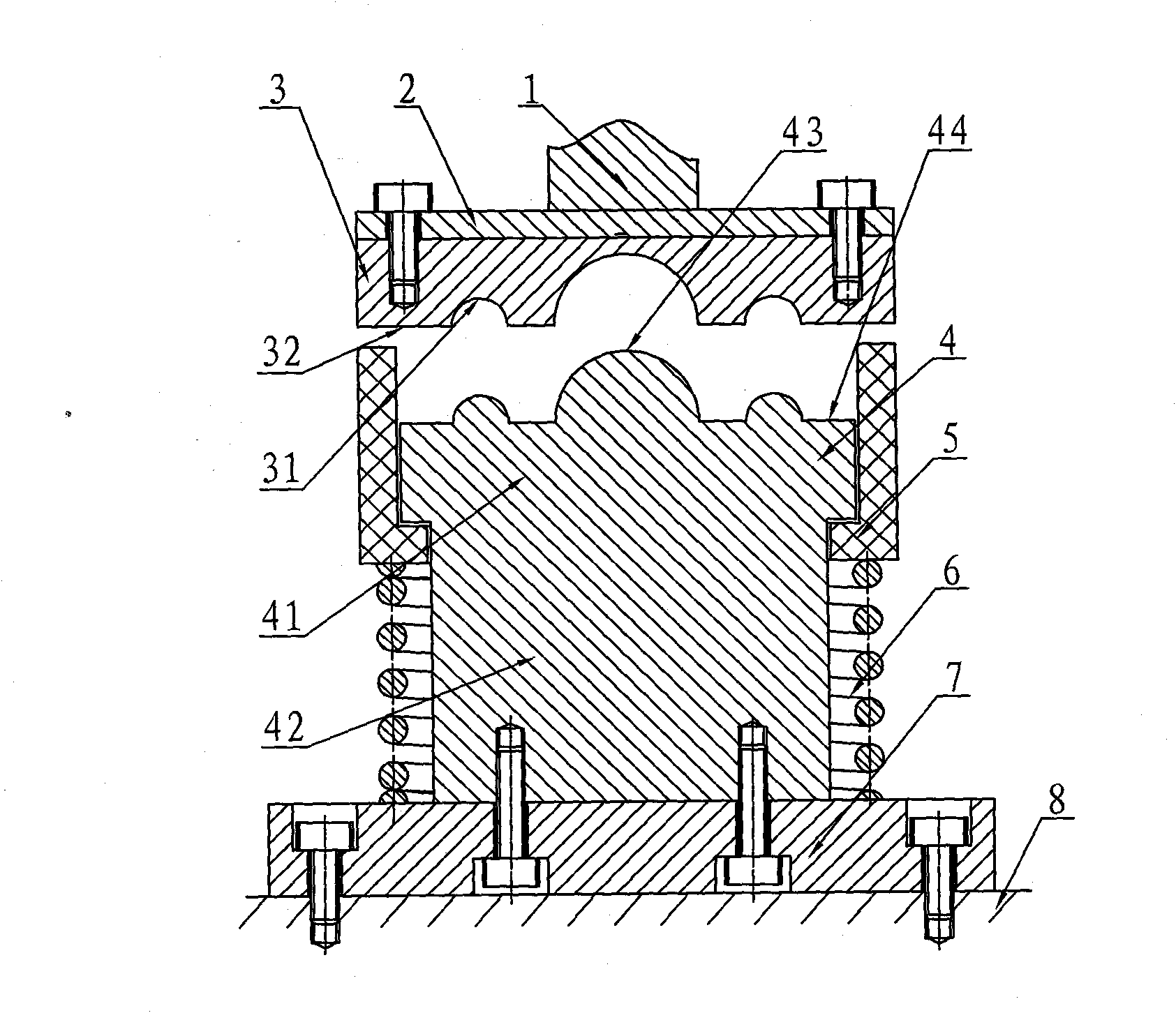

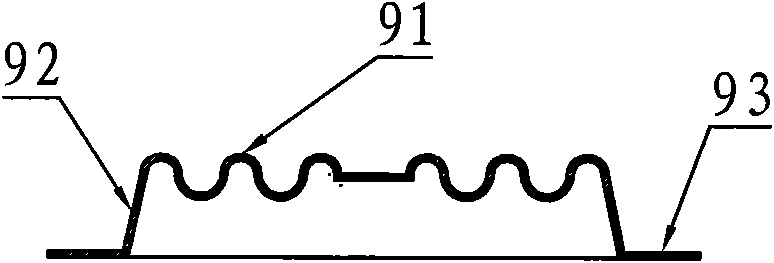

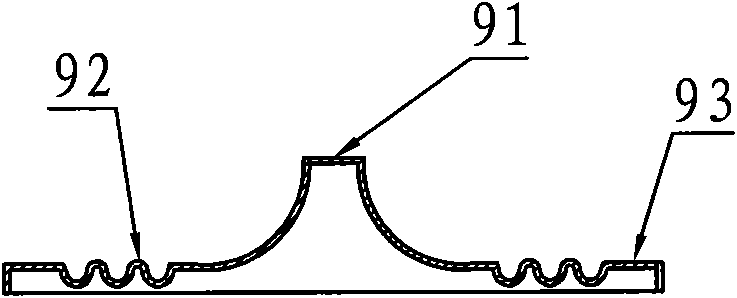

Forming and pressing die for loudspeaker drum paper

InactiveCN102088655AEliminate Causes of Press WrinklingReduce generationShaping toolsElectrical transducersEngineeringLoudspeaker

The invention relates to a forming and pressing die for loudspeaker drum paper. The forming and pressing die for the loudspeaker drum paper consists of an upper die part and a lower die part, wherein the lower die part consists of a lower die head, a moveable pressing sleeve, a return spring and a lower template; the lower die head comprises a forming die body and a pressure-bearing column; the forming die body consists of a lower forming surface and a lower pressing ring; the moveable pressing sleeve is sleeved on the forming die body and the pressure-bearing column; the return spring is sleeved on the pressure-bearing column and is positioned between the moveable pressing sleeve and the lower template; and the upper die head is coaxial with the lower die head. The moveable pressing sleeve and the return spring are arranged on the lower die head; when the drum paper is pressed, cloth blank to be formed is pressed tightly by the upper pressing ring and the moveable pressing sleeve, and peripheral cloth is stressed uniformly and then is pulled deeply, pressed and formed, so that the folding phenomenon of the periphery of the drum paper finished product is eliminated, the finished product can be automatically demoulded by one person, and the forming and pressing die for the loudspeaker drum paper is safe and convenient to operate and labor-saving.

Owner:江苏东禾电声配件有限公司 +1

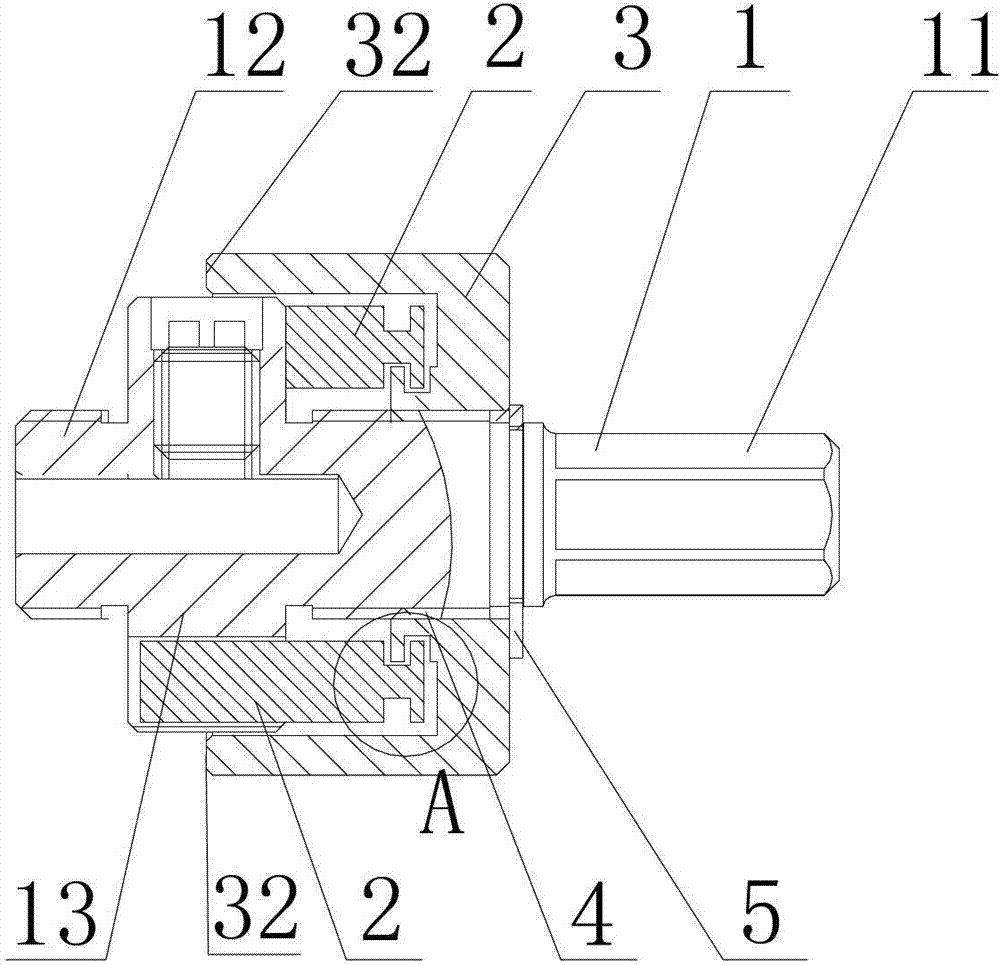

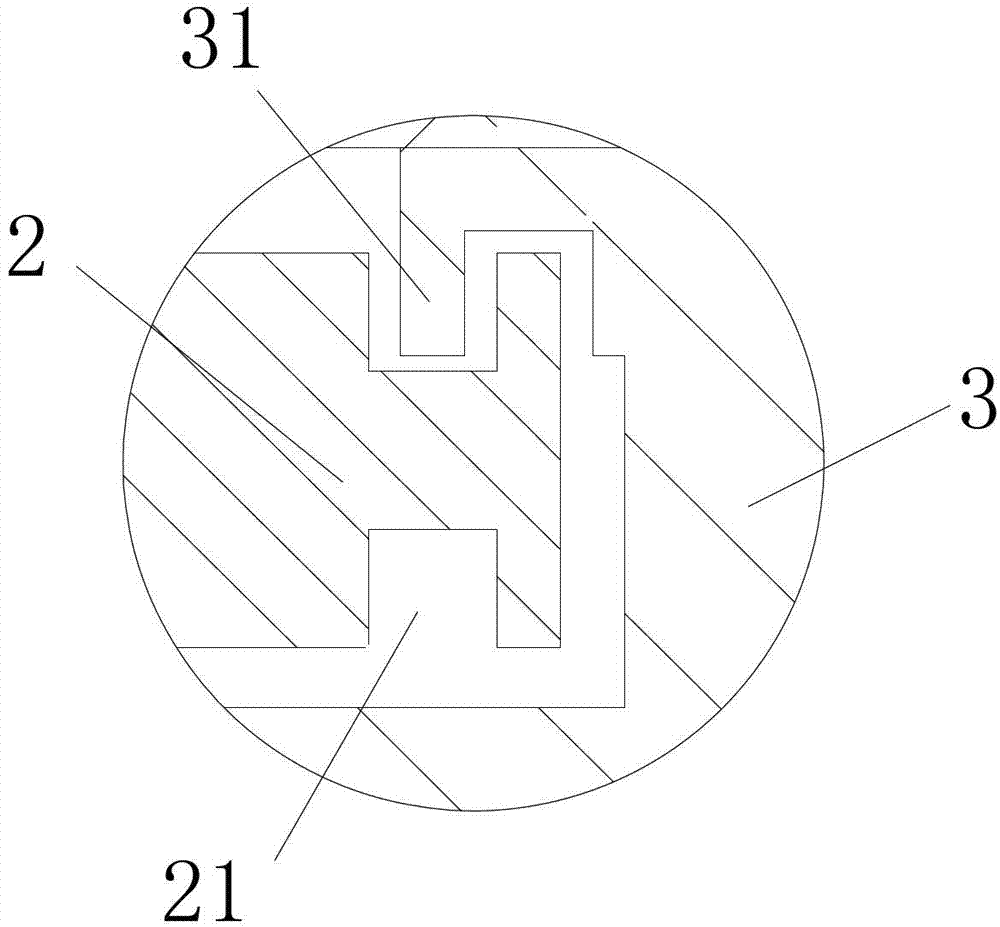

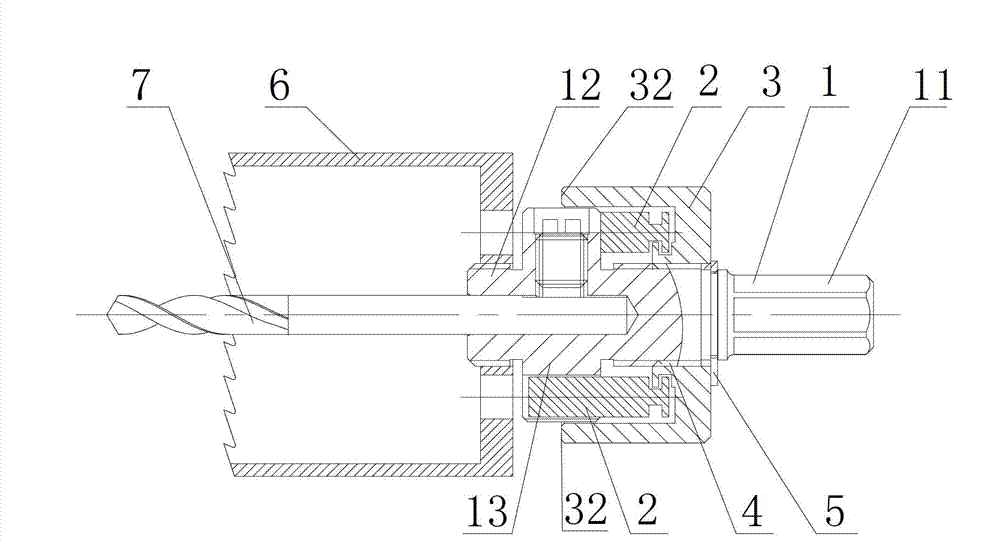

Bimetal hole saw connecting shank

ActiveCN103111664AImprove the finishThere will be no breakageTransportation and packagingTrepanning drillsHole sawEngineering

The invention discloses a connecting shank, and particularly discloses a bimetal hole saw connecting shank. The invention provides the bimetal hole saw connecting shank for preventing a hole saw from swaying after the hole saw is installed. The bimetal hole saw connecting shank comprises a connecting shank body and a transmission pin, wherein the connecting shank body comprises a motive power connecting end, a drilling saw connecting end provided with hole saw connecting threads and a spotter installing hole, and an installing part which is provided with an installing through hole. The installing part is arranged between the motive power connecting end and the drilling saw connecting end, and the transmission pin is arranged in the installing through hole and can move along the axial direction of the installing through hole. The bimetal hole saw connecting shank further comprises a hole saw firming device, wherein the hole saw stable device is arranged on the connecting shank body through a thread structure and can moves along the axis of the connecting shank body through the thread structure, and the hole saw stable device firms the hole saw through the movement along the axis of the connecting shank body. After the hole saw is connected with the drilling saw connecting end and the transmission pin is pushed into a pin hole, the hole saw firming device is continued to be twisted to be attached tightly to the top surface of the hole saw, so that the hole saw cannot sway in use.

Owner:CHENGDU VALUEMAX TOOLS MFG

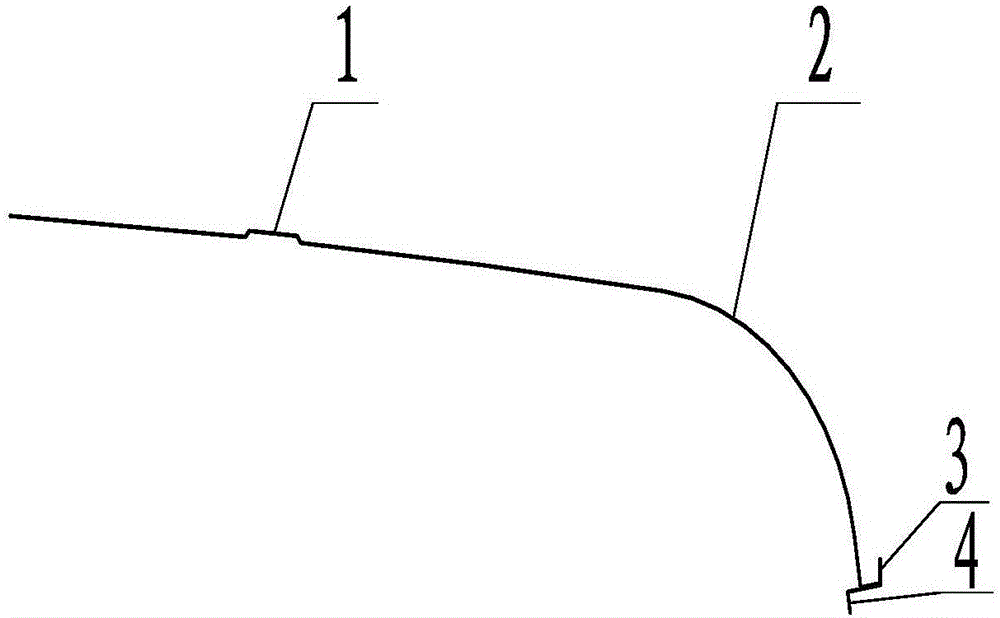

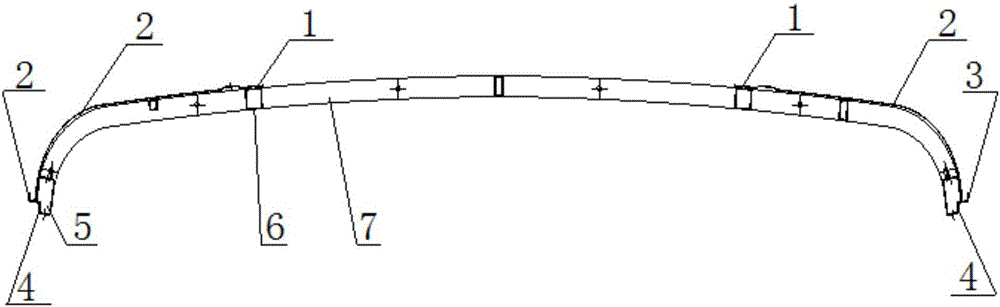

Coach top side skin with novel structure and preparation method thereof

The invention discloses a coach top side skin with a novel structure and a preparation method thereof. The coach top side skin comprises a reinforcing rib, an arc-shaped skin, a water flow channel and an upper window edge seam allowance; the arc-shaped skin is of an arc-shaped sheet structure and is positioned on the side edge of the top of a coach; the reinforcing rib is positioned in the position, approaching to a straight line, of the upper surface of top side skin and is connected with the upper edge of the arc-shaped skin; the water flow channel is made of a double-layer plate material, is positioned at the junction of the top of the coach and a coach window, and is connected with the lower edge of the arc-shaped skin; the upper window edge seam allowance is positioned below the water flow channel; the reinforcing rib, the arc-shaped skin, the water flow channel and the upper window edge seam allowance form a steel plate through rolling. The coach top side skin disclosed by the invention has the advantages of ingenious structure, low manufacturing cost, simple preparation process, low construction intensity, low maintenance cost and the like.

Owner:ZHONGTONG BUS HLDG

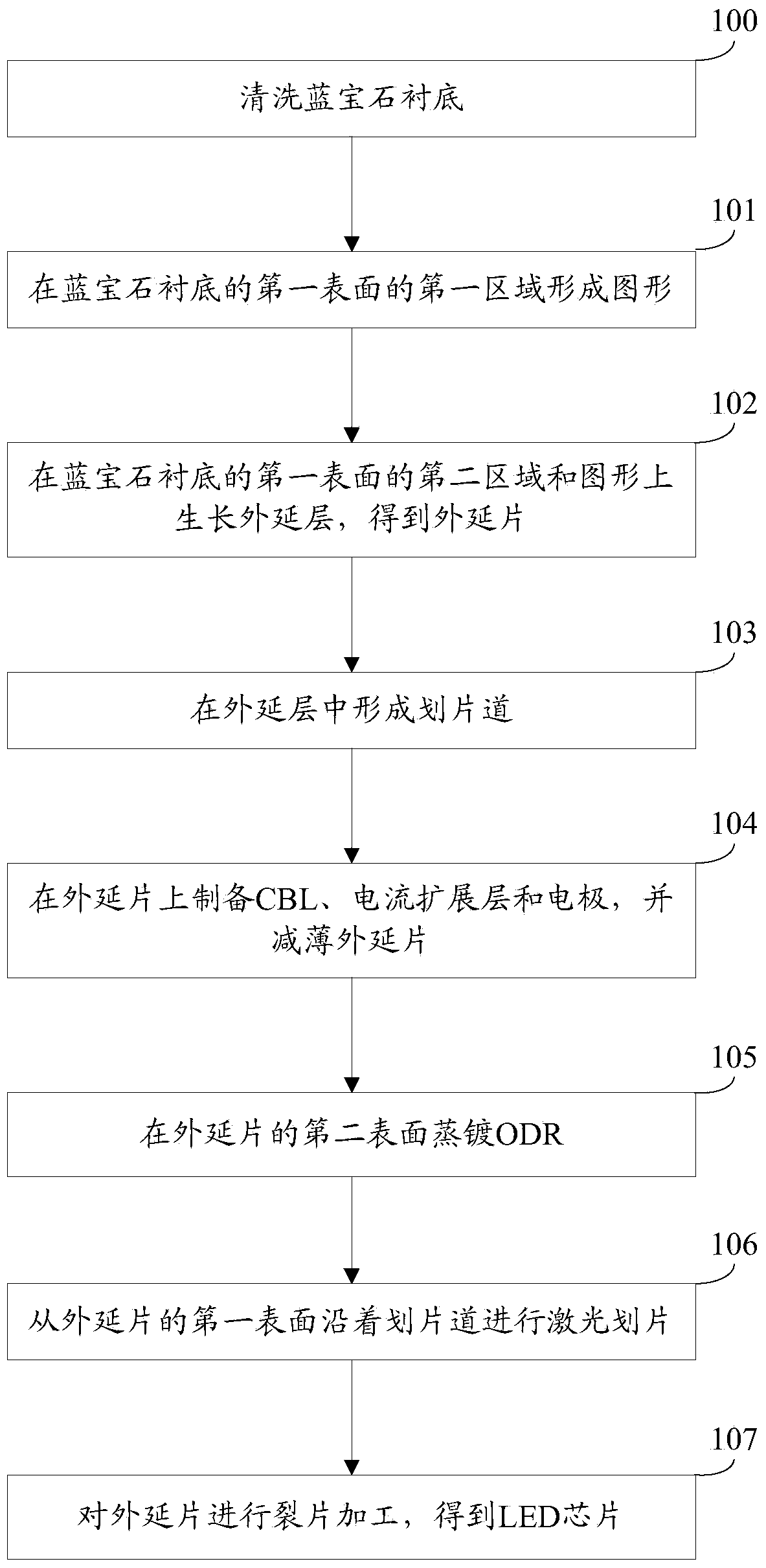

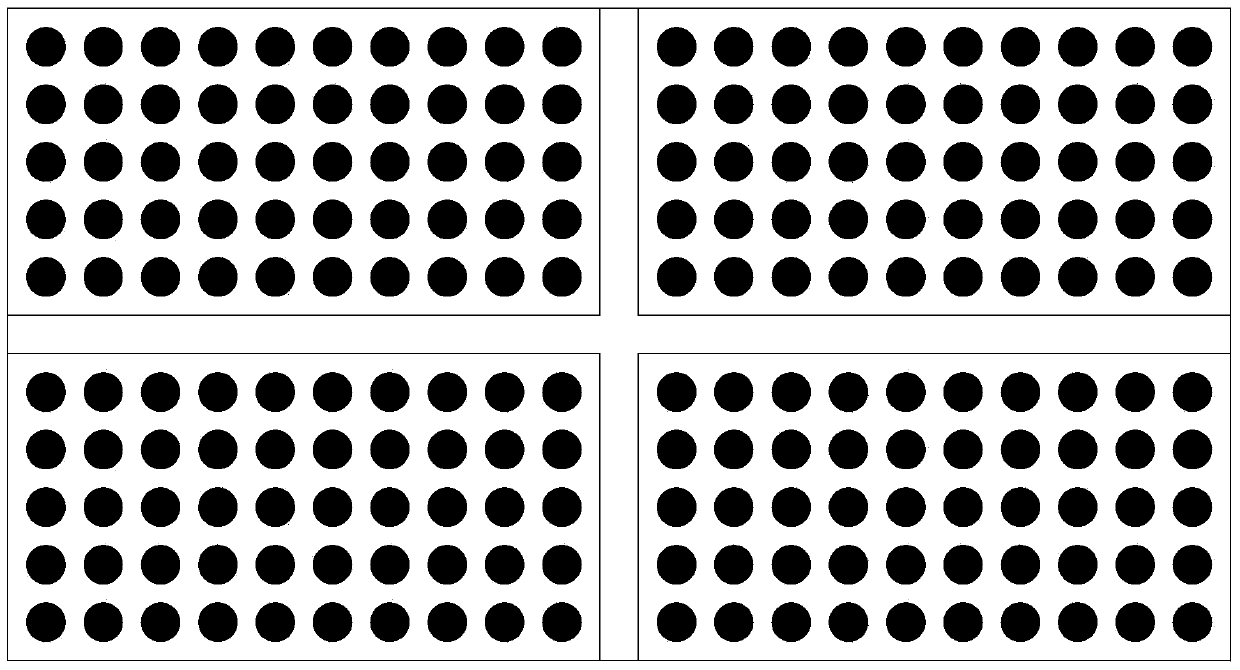

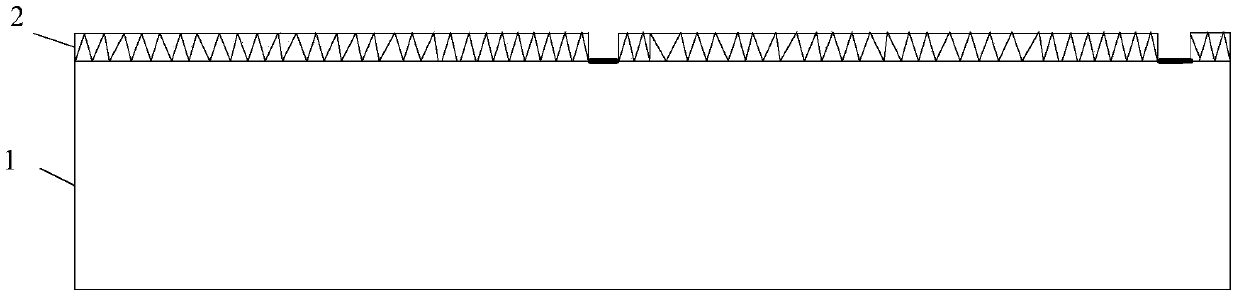

Manufacturing method of light-emitting diode chip provided with omnidirectional reflector (ODR)

ActiveCN104201254AReduce cost lossReduced risk of ruptureSemiconductor devicesLaser scribingLight-emitting diode

The invention discloses a manufacturing method of a light-emitting diode (LED) chip provided with an omnidirectional reflector (ODR), and belongs to the technical field of semiconductors. The method comprises the following steps: forming a pattern on the first region of the first surface of a sapphire substrate; growing an epitaxial layer on the second region of the first surface of the sapphire substrate and the pattern to obtain an epitaxial wafer; forming a scribing channel in the epitaxial layer, wherein the scribing channel extends from the first surface of the epitaxial wafer to the first surface of the sapphire substrate, and the scribing channel is positioned in the second region when the epitaxial wafer is overlooked from the first surface of the epitaxial wafer; manufacturing a current barrier layer, a current expansion layer and an electrode on the epitaxial wafer, and thinning the epitaxial wafer; evaporating the ODR on the second surface of the epitaxial wafer; performing laser scribing along the scribing channel from the first surface of the epitaxial wafer; performing splitting machining on the epitaxial wafer to obtain the LED chip. Through adoption of the method, the problems of easiness in breaking of the epitaxial wafer, direct scalding of the epitaxial wafer and bringing of cost loss to a manufacturer are solved.

Owner:HC SEMITEK SUZHOU

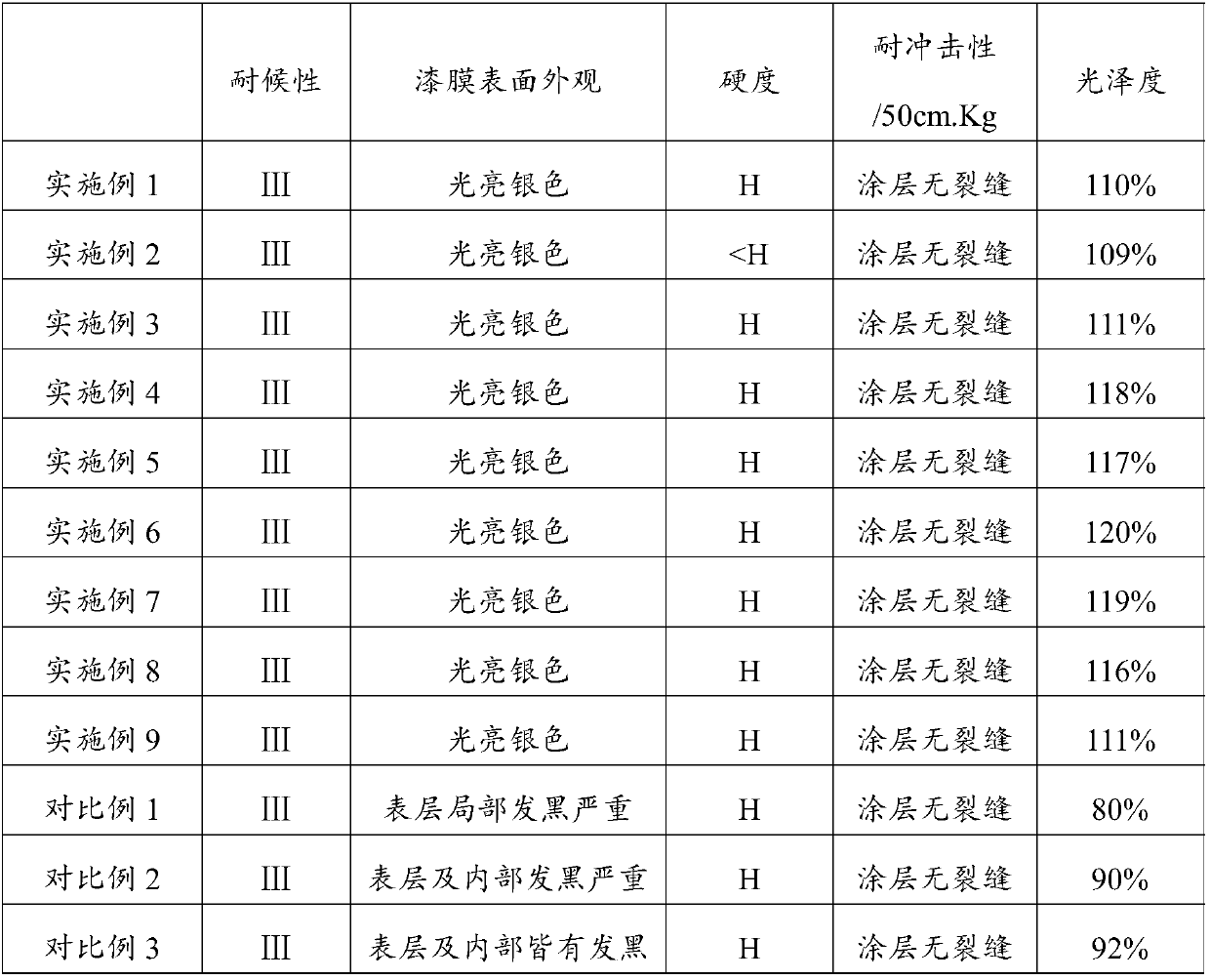

Outdoor silver powder coating and preparation method thereof

ActiveCN109627931AImprove the level ofGood flexibilityPowdery paintsPolyester coatingsVitrificationWax

The invention provides an outdoor silver powder coating which is prepared by non-floating aluminum powder and bottom powder by a bonding process. The bottom powder in preparation raw materials contains, by weight, the following components: 55-65% of carboxyl polyester resin, 4.5-5.5% of a curing agent, 0.8-1.5% of a flatting agent, 0.5-1% of wax powder, 10-20% of high-gloss barium sulfate and 15-25% of a white pigment, wherein the glass transition temperature of the carboxyl polyester resin is 55 DEG C or above, an acid value is 32-37 mg of KOH per g, the viscosity of a conical plate is 2800-3800 mPa.s at 200 DEG C, the curing agent is triglycidyl isocyanurate, the flatting agent is NN'-ethylene bis-stearamide, and the non-floating aluminum powder accounts for 0.05-2% of the preparation raw materials. The adopted wax powder, high-gloss barium sulfate and the NN'-ethylene bis-stearamide can make the white pigment uniformly dispersed in the resin, so that it can be avoided that the whitepigment in the bottom powder is dispersed ununiformly to interfere the bonding of the non-floating aluminum powder, and the non-floating aluminum powder is uniformly adhered to the surface of the bottom powder particles in the bonding process. Therefore, the non-floating aluminum powder is uniformly dispersed in paint film, and a better appearance effect and high gloss are obtained.

Owner:东莞市爱粤金属粉末有限公司

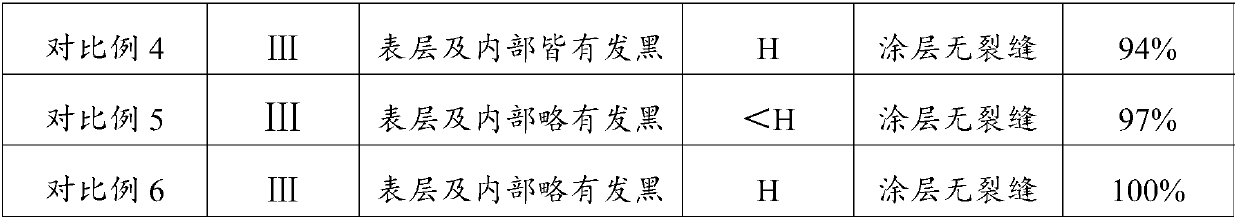

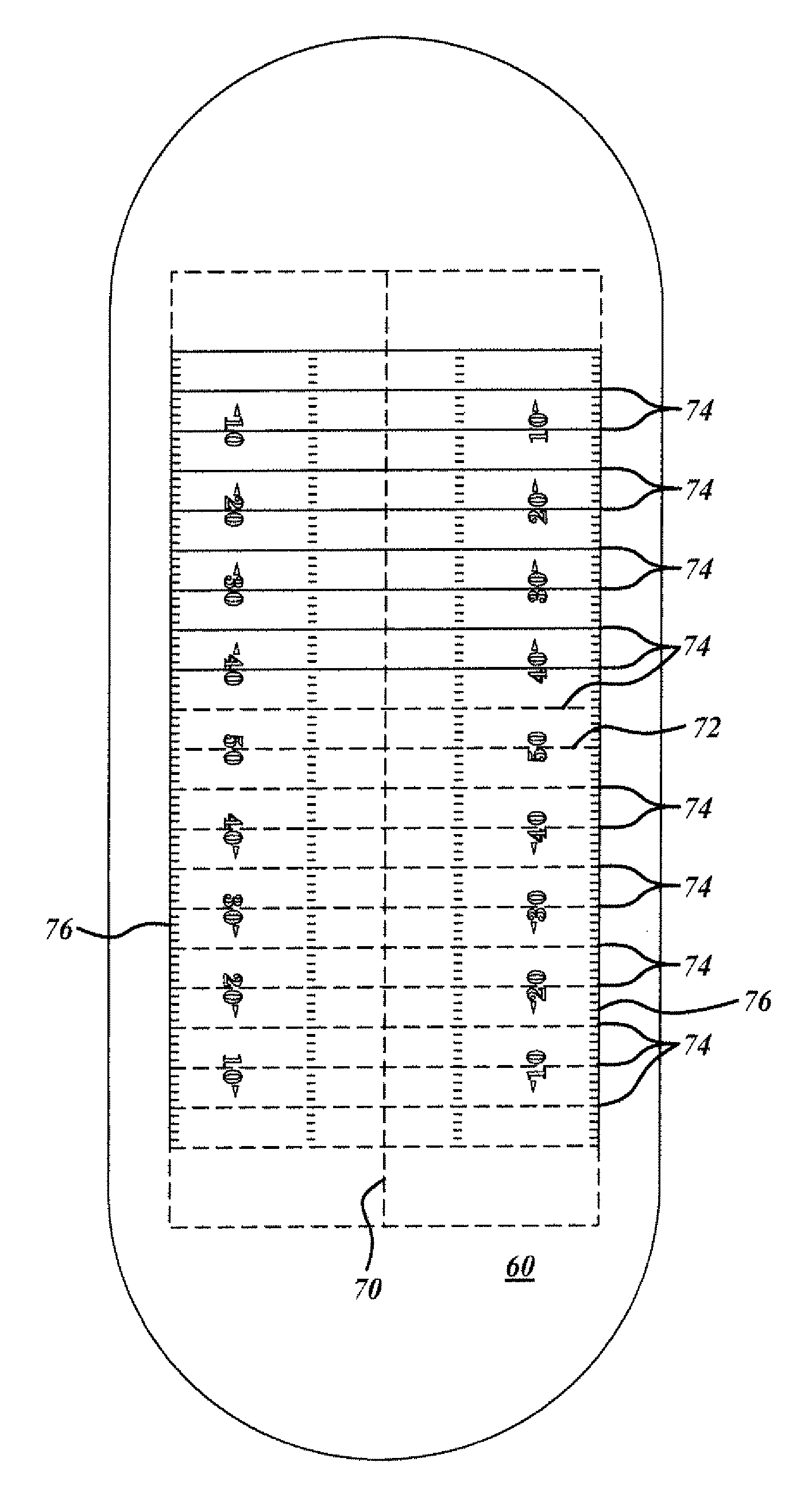

Method and apparatus for pre-fabricating a synthetic sports field

ActiveUS8123880B2Reduces inherent variableReduce and minimize inherent variableDead plant preservationLamination ancillary operationsVisual markingMarking out

Owner:APT ADVANCED POLYMER TECH CORP +1

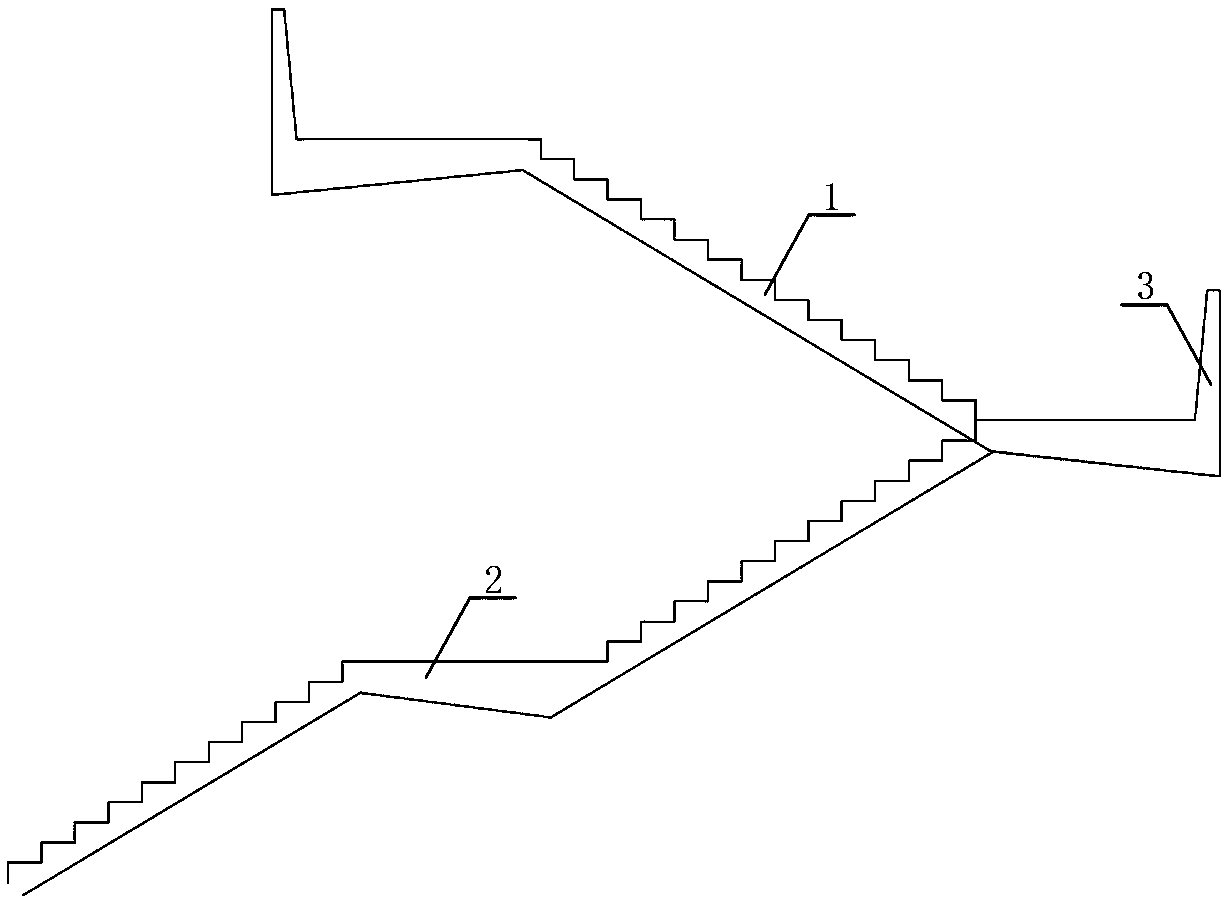

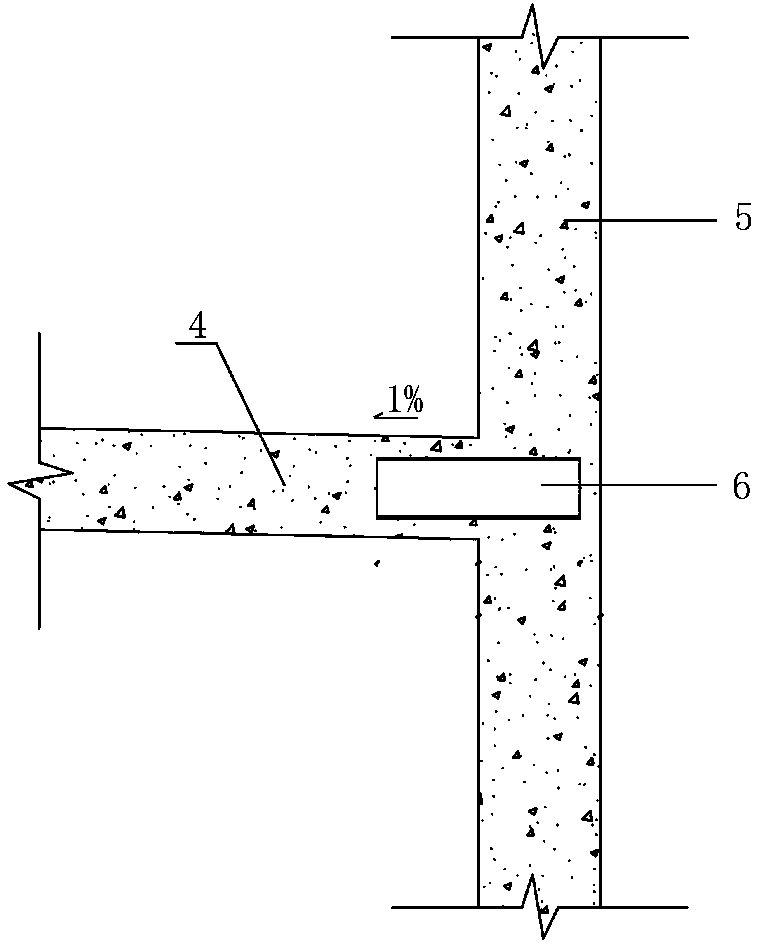

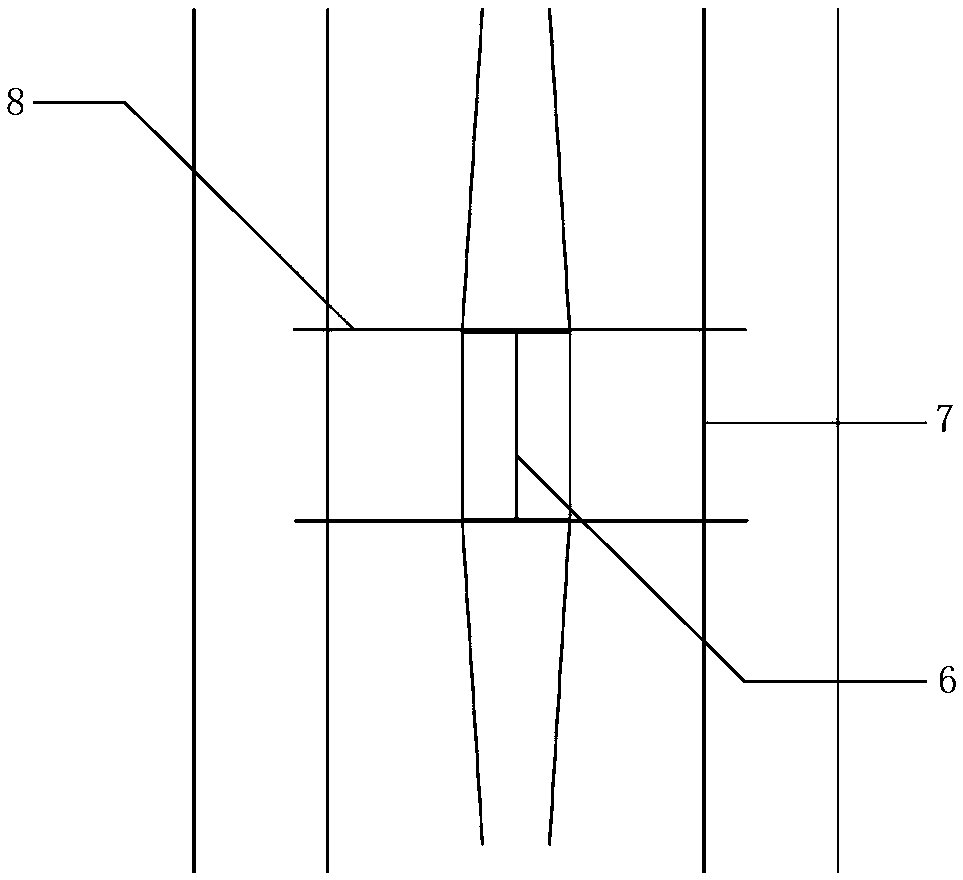

Large cantilever bare concrete stair and construction method thereof

ActiveCN107630531AEnsure structural safetyGuaranteed clear water effectForms/shuttering/falseworksStairwaysPre embeddingCantilever

The invention relates to a large cantilever bare concrete stair and a construction method thereof. The large cantilever bare concrete stair comprises stairsteps and stair platforms. One sides of the stairstep and the stair platforms are connected with a wall body; the other sides of the stairstep and the stair platforms are of cantilever structures; shear keys are arranged at connecting positionsof the stair platforms and the wall body and are multiple joist steel pre-embedded into the wall body. The construction method comprises the steps of setting the shear keys, bracing bare cantilever stair formworks, embedding pre-embedded parts, casting bare concrete, maintaining finished products and the like. According to the large cantilever bare concrete stair and the construction method thereof provided by the invention, special treatment measures are adopted for solving the problems of cantilever structure anchoring, bare structure formwork bracing and bear concrete casting, so that the safety of cantilever structures and an impressions effect of the bear concrete are ensured.

Owner:朱锫建筑设计咨询(北京)有限公司

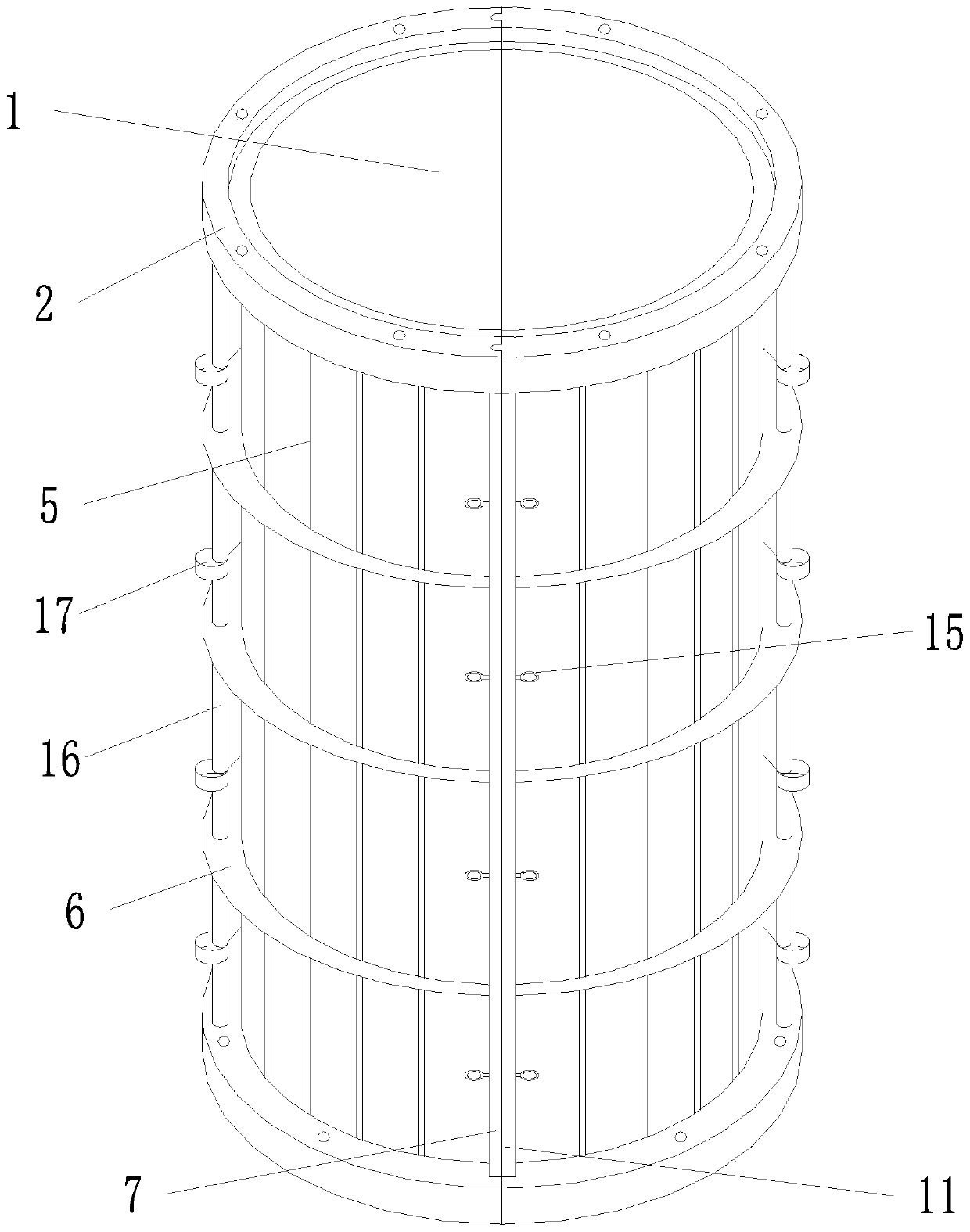

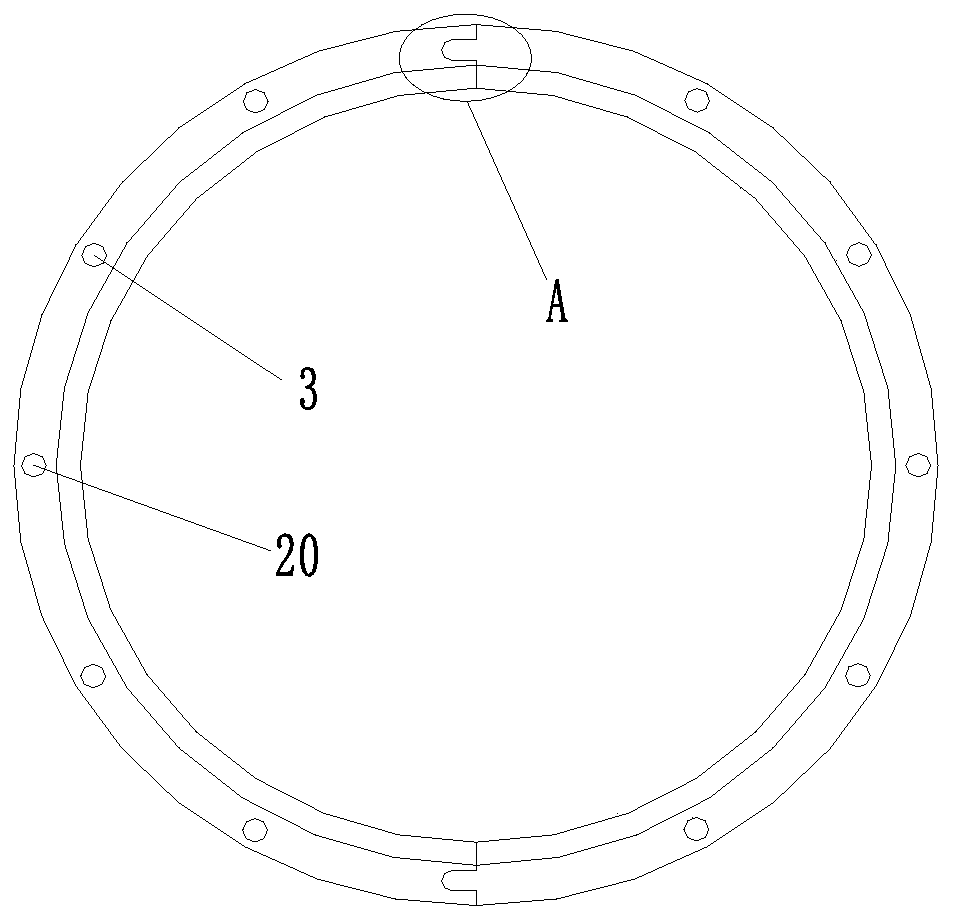

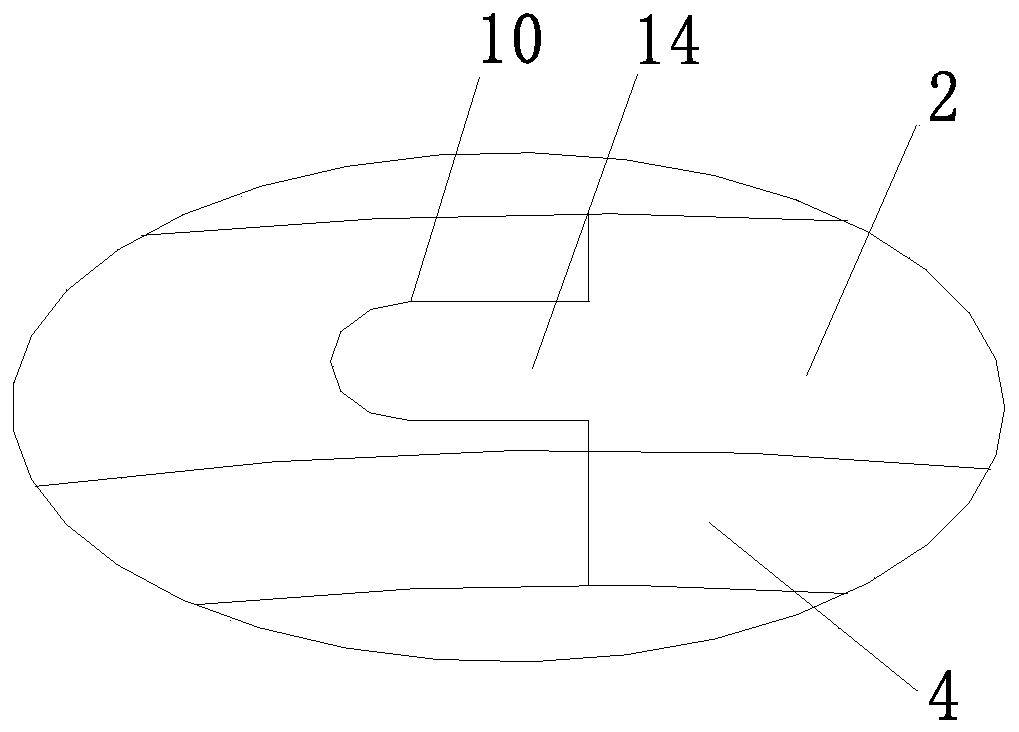

Slurry overflow prevention clamping slot type cylindrical formwork plate and construction method

ActiveCN110424730AQuick connectionQuick assemblyForms/shuttering/falseworksArchitectural engineeringSlurry

The invention discloses a slurry overflow prevention clamping slot type cylindrical formwork plate and a construction method and belongs to the technical field of building cylindrical formwork plates.The slurry overflow prevention clamping slot type cylindrical formwork plate at least comprises two circular arc formwork plate bodies, first connecting parts are fixedly connected to the two ends ofthe two circular arc formwork plate bodies, first connecting holes are formed in the first connecting parts, reinforcing rib plates and connecting steel plates are fixedly connected to the outer walls of the two circular arc formwork plate bodies, second connecting parts are fixedly connected to the two ends of one circular arc formwork plate body, second connecting holes, positioning grooves andflow blocking grooves are formed in the two second connecting parts, third connecting parts are fixedly connected to the two ends of one circular arc formwork plate body, third connecting holes, positioning parts and flow blocking parts are arranged on the two third connecting parts, fourth connecting parts are connected in the third connecting holes and the corresponding second connecting holesin a matched mode, the positioning parts are matched with the positioning grooves, the flow blocking parts are matched with the flow blocking grooves, slurry overflowing and leaking at joints of cylindrical formwork plates can be effectively prevented in concrete construction, and meanwhile the perpendicularity of concrete and the construction quality can be ensured.

Owner:CHINA MCC17 GRP

Demoulding structure of injection molding mould

The invention discloses a demoulding structure of an injection molding mold, which includes a mold fixing frame. A telescopic cylinder is fixed on one side of the mold fixing frame through the cylinder fixing frame, and the telescopic cylinder is released from the inside of the mold fixing frame through a telescopic rod. The mold base is welded, and the center of the housing on the other side of the mold fixing frame is screwed with a mold bin through a fixed stud. An injection port is provided, and a demoulding rod is embedded and fixed on the demoulding frame through a fixing nut. In the present invention, firstly, by providing a telescopic cylinder and two demoulding rods, the telescopic cylinder can be used to control the demolding rods to expand and contract, thereby realizing automatic demoulding, which improves the working efficiency, and the two demoulding rods are up and down symmetrically. Demoulding, so that the mold is evenly stressed, and prevents the mold from being deformed by force due to the incomplete cooling of the mold, thereby affecting the appearance and precision of the product.

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

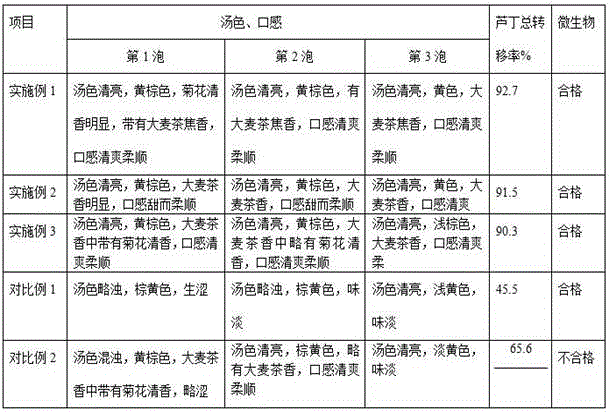

Preparation method of compound sophora flower bud tea bags

The invention discloses a preparation method of compound sophora flower bud tea bags. The preparation method comprises the steps of a, selecting, steaming, drying and frying sophora flower buds and mulberry leaves; b, smashing 40 to 60 percent of the weight of fried sophora flower buds into 16-mesh to 40-mesh coarse powder, and smashing the rest into fine powder with the mesh below 80; c, smashing 40 to 60 percent of the weight of fried mulberry leaves into 16-mesh to 40-mesh coarse powder, and smashing the rest into fine powder with the mesh below 80; d, drying Chinese wolfberry and chrysanthemum, and smashing to enable all of the Chinese wolfberry and chrysanthemum to pass through a 30-mesh sieve; e, uniformly mixing the sophora flower bud fine powder with the mesh below 80 and the mulberry leaf fine powder with the mesh below 80 with Chinese wolfberry coarse powder with the mesh below 30 and chrysanthemum coarse powder with the mesh below 30, adding 75 percent of ethyl alcohol for pelletizing, and drying; f, uniformly mixing dried particles with the 16-mesh to 40-mesh sophora flower bud and mulberry leaf coarse powder, and placing into tea bags, so as to obtain the compound sophora flower bud tea bags. According to the method provided by the invention, dissolving-out speed and dissolving-out efficiency of rutin of the tea bags can be effectively controlled, the phenomenon that precipitation appears after tea soup is cooled to affect the appearance and taste due to the fact that the rutin is dissolved out too quickly can be avoided, the soup colors and taste of three times of brewing are ensured to be basically consistent, and the rutin transfer rate reaches not less than 90 percent.

Owner:GUANGDONG YIFANG PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com