Polyolefin breathable masterbatch, and preparation method thereof

A technology of air-permeable masterbatch and polyalkylene hydroxyl, which is applied in the field of new materials, can solve the problems of film solution improvement, affecting the scope of use, and increasing the process, so as to simplify the production process, meet the requirements of production and processing and use requirements, and ensure quality and yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

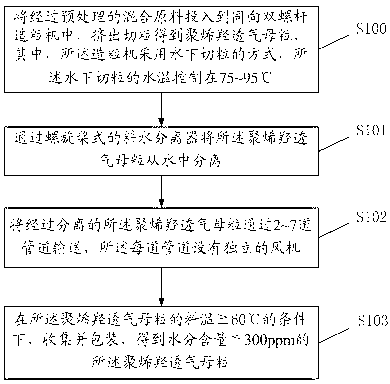

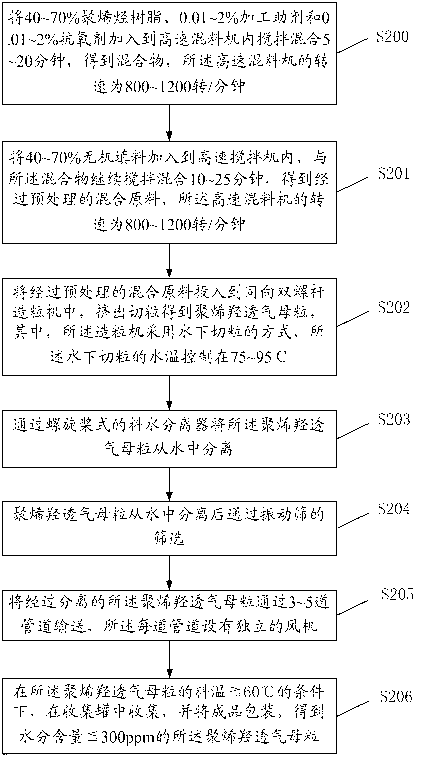

[0109] like figure 1 As shown, the embodiment of the present invention also provides a preparation method of polyolefin breathable masterbatch, including:

[0110] S100, put the pretreated mixed raw material into a co-rotating twin-screw granulator, extrude and granulate to obtain polyolefin breathable masterbatch, wherein the granulator adopts underwater granulation, and the underwater granulator The water temperature of the grains is controlled at 75~95°C.

[0111] The aspect ratio of the granulator is 35 ~ 50;

[0112] Wherein, the temperature distribution of the screw barrel of the granulator is as follows: Zone 1 170~180°C, Zone 2 180~190°C Zone 3 190~195°C, Zone 4 180~190°C, Zone 5 175~185°C, Zone 6 180~190℃, zone 7 190~200℃, die head 200~220℃.

[0113] Wherein, the vacuum degree of the sixth zone of the barrel of the granulator is set to -0.2 MPa ~ -0.01MPa.

[0114]Preferably, the vacuum degree of the sixth zone of the barrel of the granulator is set to -0.1 MPa to...

Embodiment 1

[0168] Add 45% polyolefin resin (low-density polyethylene: linear low-density polyethylene = 1:5), 1% zinc stearate and 1% hindered phenolic antioxidant (grade 1010) into the high-speed mixer and mix for 10 Minutes, the speed is 1000 rpm; then add 45% ultrafine inorganic filler calcium carbonate (particle size is 0.5 microns to 10 microns) into the high-speed mixer and stir and mix for 15 minutes, the speed is 1000 rpm Then put it into the twin-screw granulator, the temperature of the barrel: 180°C in the first zone, 185°C in the second zone, 190°C in the third zone, 180°C in the fourth zone, 175°C in the fifth zone, 185°C in the sixth zone C, Zone 7 190°C, die head 210°C, vacuum at the exhaust port is -0.07 MPa, circulating water temperature is set to 85°C, underwater granulation; air-permeable particles pass through a propeller-type material-water separator to separate water and The air-permeable masterbatch is separated, and after being screened by a vibrating screen, it en...

Embodiment 2

[0170]Add 50% polyolefin resin (low-density polyethylene: linear low-density polyethylene = 1:3), 0.5% zinc stearate and 0.5% hindered phenolic antioxidant (grade 1010) into the high-speed mixer and mix for 10 Minutes, the speed is 1000 rpm; then add 52% ultrafine inorganic filler calcium carbonate (particle size is 0.5 micron to 10 microns) into the high-speed mixer and stir and mix for 15 minutes, the speed is 1000 rpm Then put it into the twin-screw granulator, the temperature of the barrel: 180°C in the first zone, 185°C in the second zone, 190°C in the third zone, 180°C in the fourth zone, 175°C in the fifth zone, 185°C in the sixth zone C, Zone 7 is 190°C, die head is 210°C, the vacuum degree of the exhaust port is -0.0,6 MPa, the circulating water temperature is set to 90°C, and the pellets are cut underwater; the air-permeable particles pass through the propeller-type water separator The water is separated from the air-permeable masterbatch, and after being screened by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com