Crayfish paste and method for stewing crayfish paste

A technology of crayfish and shrimp meat balls, which is applied in the field of crayfish sauce and the sauce, can solve the problems of neglecting removal, easy bursting, and inability to meet the needs of canned crayfish shrimp meat balls. Achieve the effect of increasing fresh and sweet taste, avoiding adverse effects, and increasing spicy taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

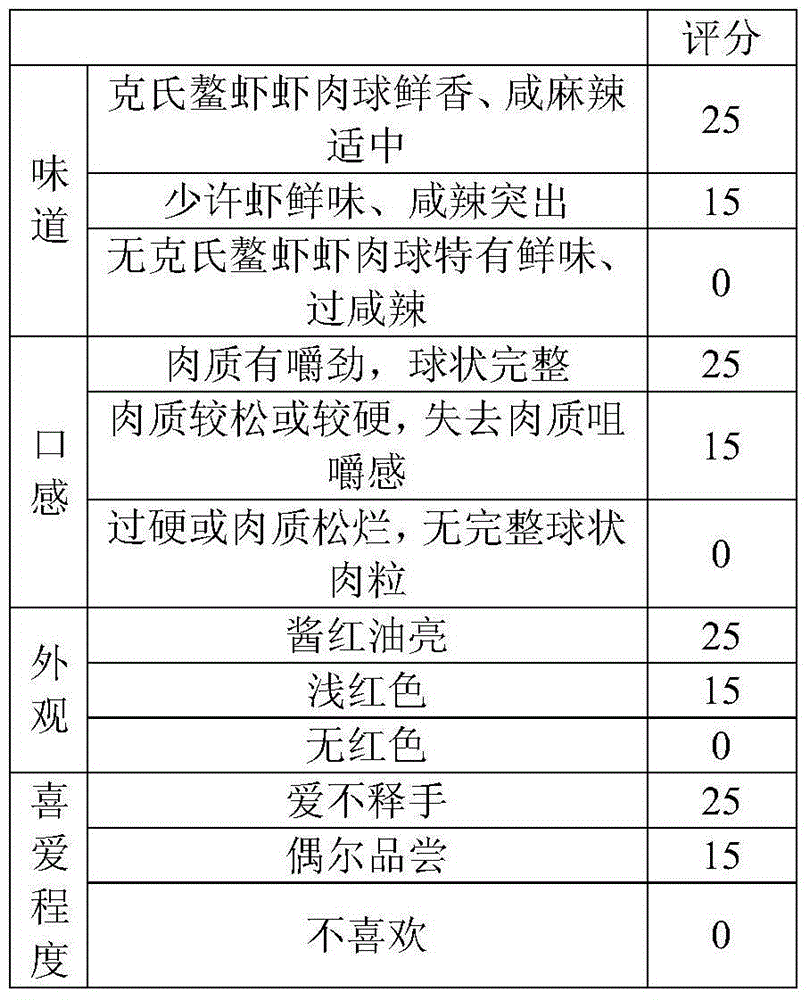

Examples

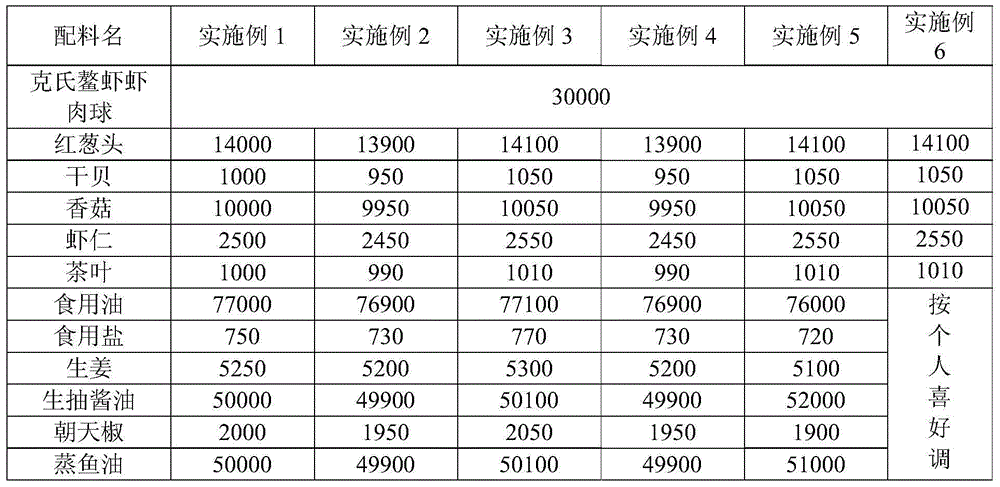

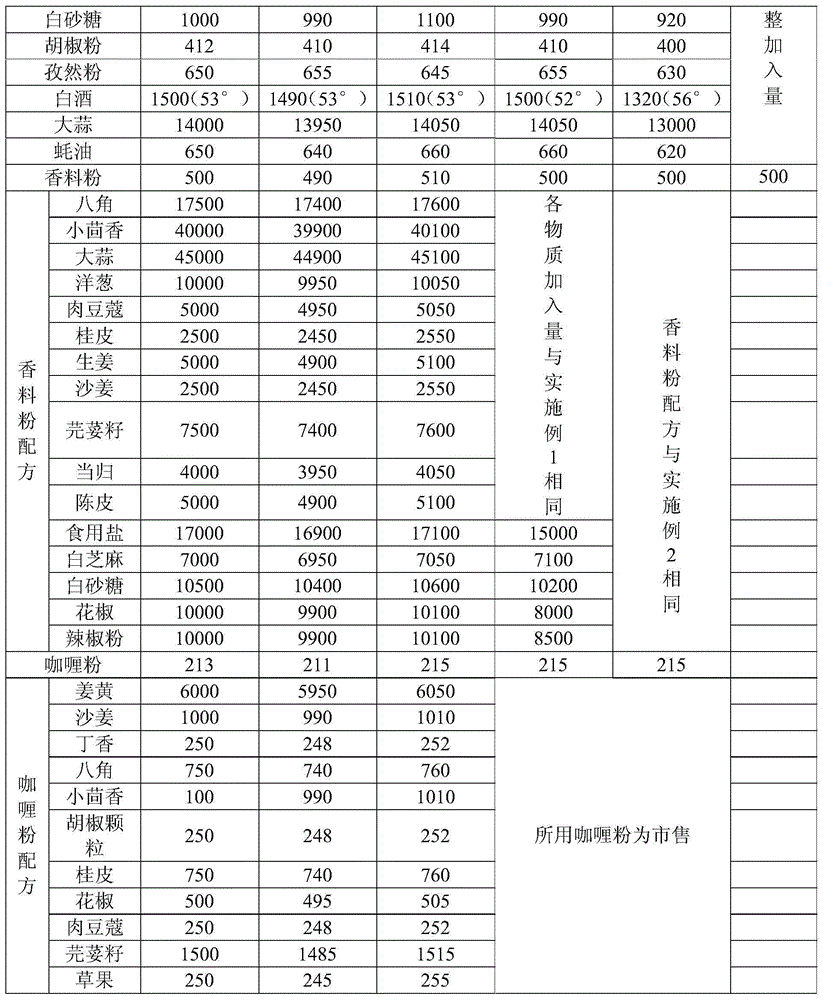

Embodiment 1

[0068] Make by the batching in the shrimp paste embodiment 1, the preparation method of shrimp paste may further comprise the steps:

[0069] 1) Put shallots, ginger, garlic, chili powder, shiitake mushrooms, tea leaves and shrimps into cooking oil at 138°C in order, and boil them separately. Boil shallots for 28 minutes, then add ginger and boil for 13 minutes. Then add garlic and chili powder in order and cook for 8 minutes respectively. Add shiitake mushrooms and simmer for 10 minutes, add tea leaves and simmer for 13 minutes. Then add shrimps and cook for 8 minutes to obtain the first sauce.

[0070] 2) Add the deep-fried crayfish balls fried for 5 minutes at an oil temperature of 140°C to the first sauce, boil for 8 minutes, add edible salt, white sugar, pepper, curry powder, and spice powder Boil for 15 minutes with cumin powder to get the second sauce;

[0071] 3) Add light soy sauce, steamed fish oil, oyster sauce and white wine to the second sauce and stir evenly t...

Embodiment 2

[0073] Make by the batching in shrimp paste embodiment 3, the preparation method of shrimp paste may further comprise the steps:

[0074] 1) Put shallots, ginger, garlic, chili powder, shiitake mushrooms, tea leaves and shrimps into cooking oil at 142°C in order, and boil them separately. Boil shallots for 32 minutes, then add ginger and boil for 17 minutes. Then add garlic and chili powder in order and cook for 12 minutes respectively. Add shiitake mushrooms and simmer for 5 minutes, add tea leaves and simmer for 17 minutes. Then add shrimps and cook for 12 minutes to obtain the first sauce.

[0075] 2) Add the deep-fried crayfish balls fried for 5 minutes at an oil temperature of 140°C to the first sauce, boil for 12 minutes, add edible salt, white sugar, pepper, curry powder, and spice powder Boil for 25 minutes with cumin powder to get the second sauce;

[0076] 3) Add light soy sauce, steamed fish oil, oyster sauce and white wine to the second sauce and stir evenly to ...

Embodiment 3

[0078] Make by the batching in the shrimp paste embodiment 5, the preparation method of shrimp paste may further comprise the steps:

[0079] Oil temperature is 140°C, add shallots and cook for 30 minutes, add ginger and cook for 15 minutes, add garlic and cook for 10 minutes, add chili powder and cook for 10 minutes, add shiitake mushrooms and cook for 10 minutes, add tea leaves Boil for 15 minutes. After adding shelled shrimps and boiling for 10 minutes, add the deep-fried lobster shrimp meat balls obtained after frying at 140° C. for 5 minutes, and boil for 10 minutes. Add edible salt, white granulated sugar, pepper powder, curry powder, spice powder and cumin powder and boil for 20 minutes. Add light soy sauce, steamed fish oil, oyster sauce and white wine and stir to get Crawfish Sauce 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com