Manufacturing method of light-emitting diode chip provided with omnidirectional reflector (ODR)

A technology of light-emitting diodes and corner mirrors, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of loss of manufacturers' costs, fragile epitaxial wafers, and scrapped epitaxial wafers, etc., to reduce the risk of rupture and save manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

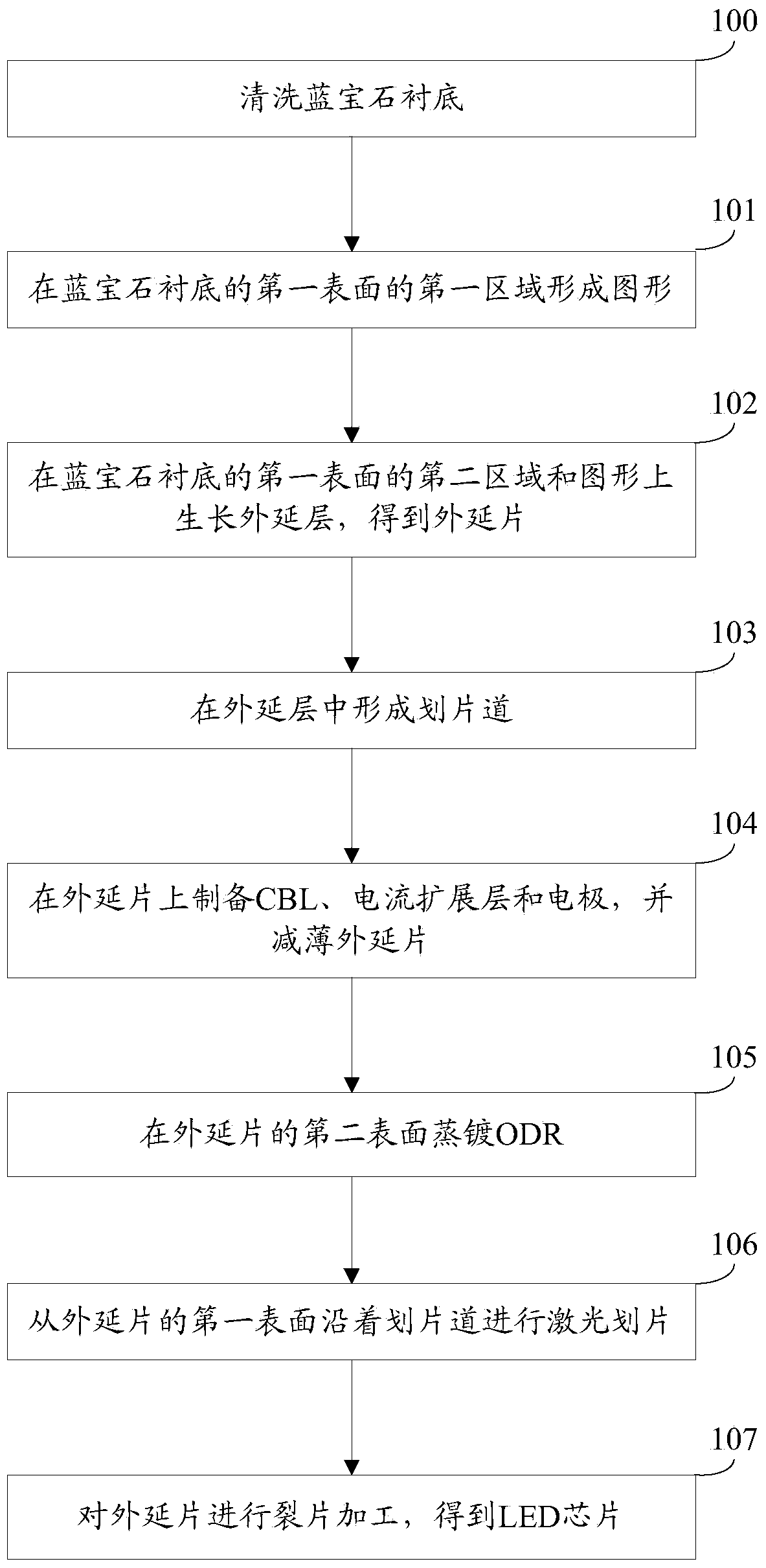

[0052] The embodiment of the present invention provides a method for preparing an LED chip with ODR, see figure 1 , the method includes:

[0053] Step 100: cleaning the sapphire substrate.

[0054] In this embodiment, the composition of the sapphire substrate includes alumina.

[0055] Specifically, this step 100 is a prior art, and will not be described in detail here.

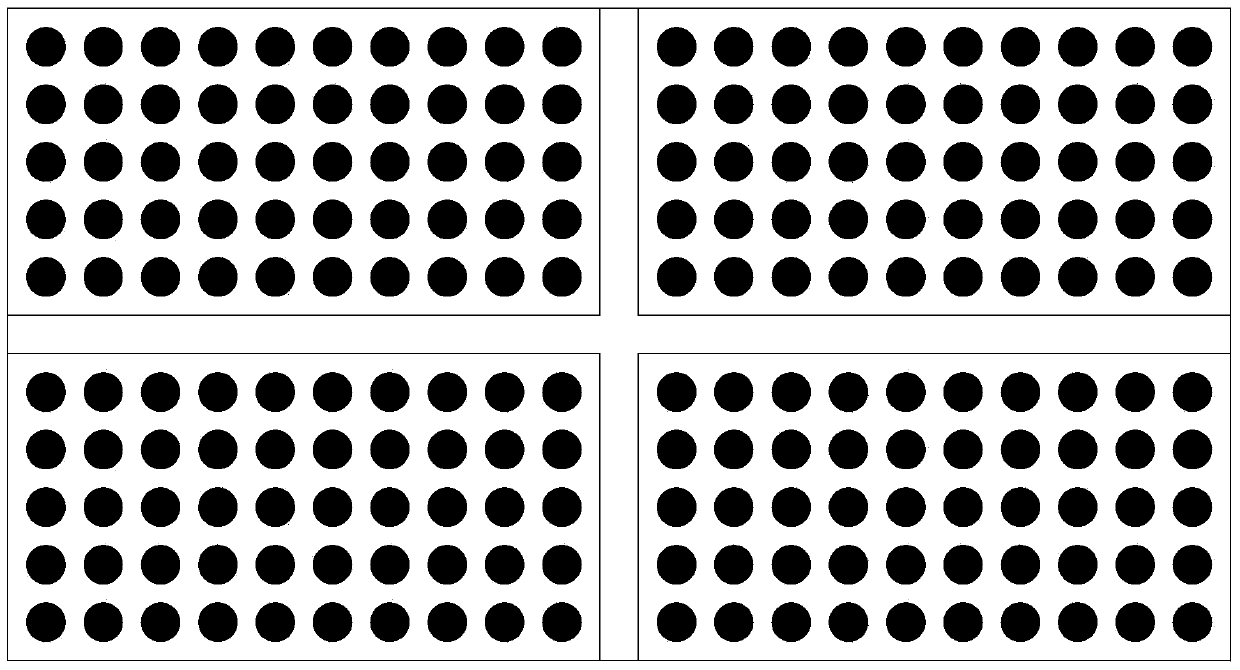

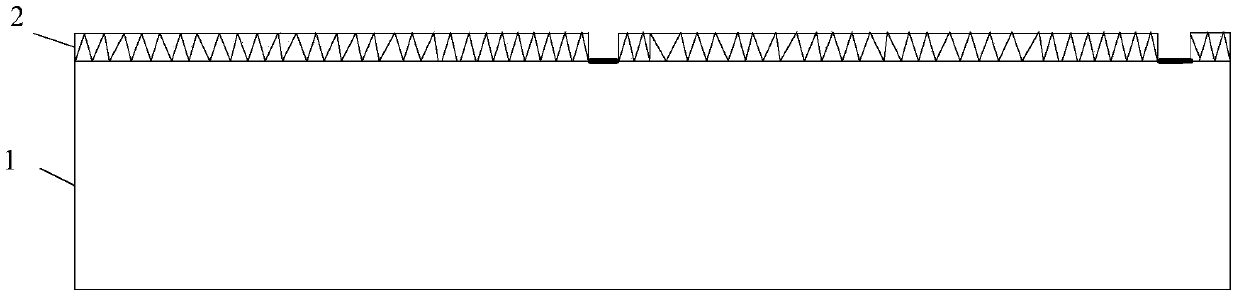

[0056] Step 101: Form a pattern on a first region of a first surface of a sapphire substrate.

[0057]Understandably, the purpose of step 101 is to obtain a PSS (Patterned Sapphire Substrate, patterned sapphire substrate) to improve the light extraction efficiency of the LED chip. Among them, PSS is obtained by growing a mask for dry etching on a sapphire substrate, engraving the mask with a pattern using a standard photolithography process, and etching the sapphire by using ICP (plasma etching) technology.

[0058] In an implementation manner of this embodiment, step 101 may include:

[0059] Coating ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com