Press-forming mould of loudspeaker elastic wave

A technology for pressing molds and loudspeakers, which is applied to sensors, electrical components, etc., can solve the problems of operator and enterprise injury, prone to wrinkles, work-related accidents, etc., to reduce waste and defective products, eliminate pressing wrinkles, and improve safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

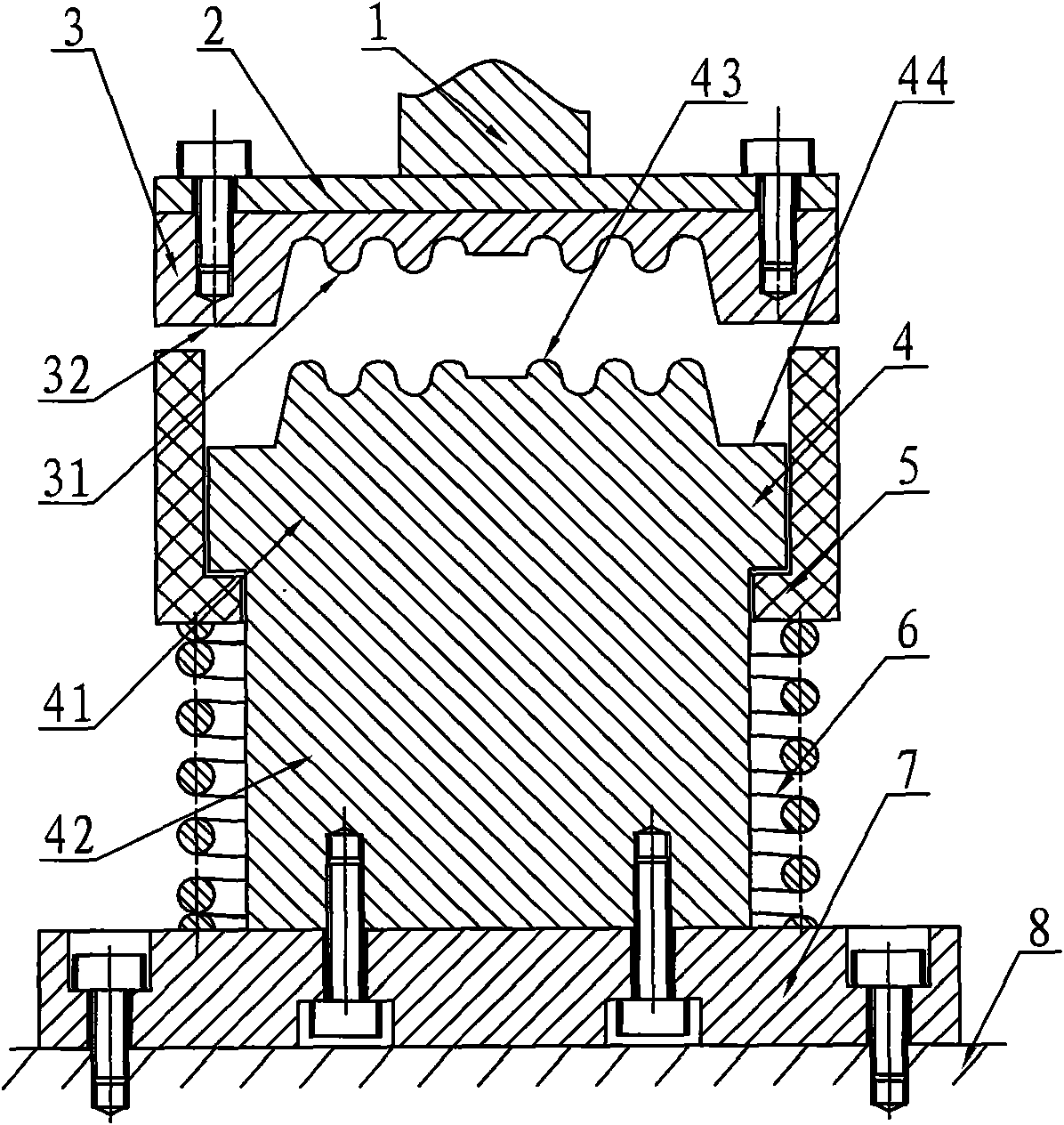

[0012] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

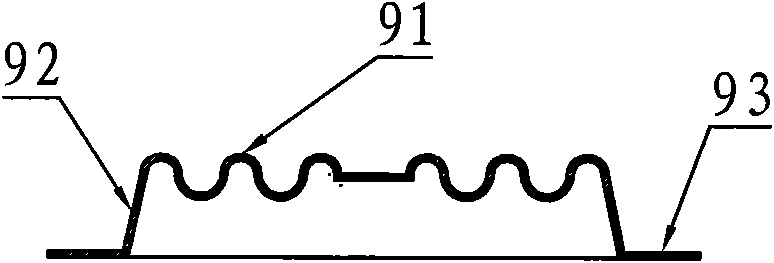

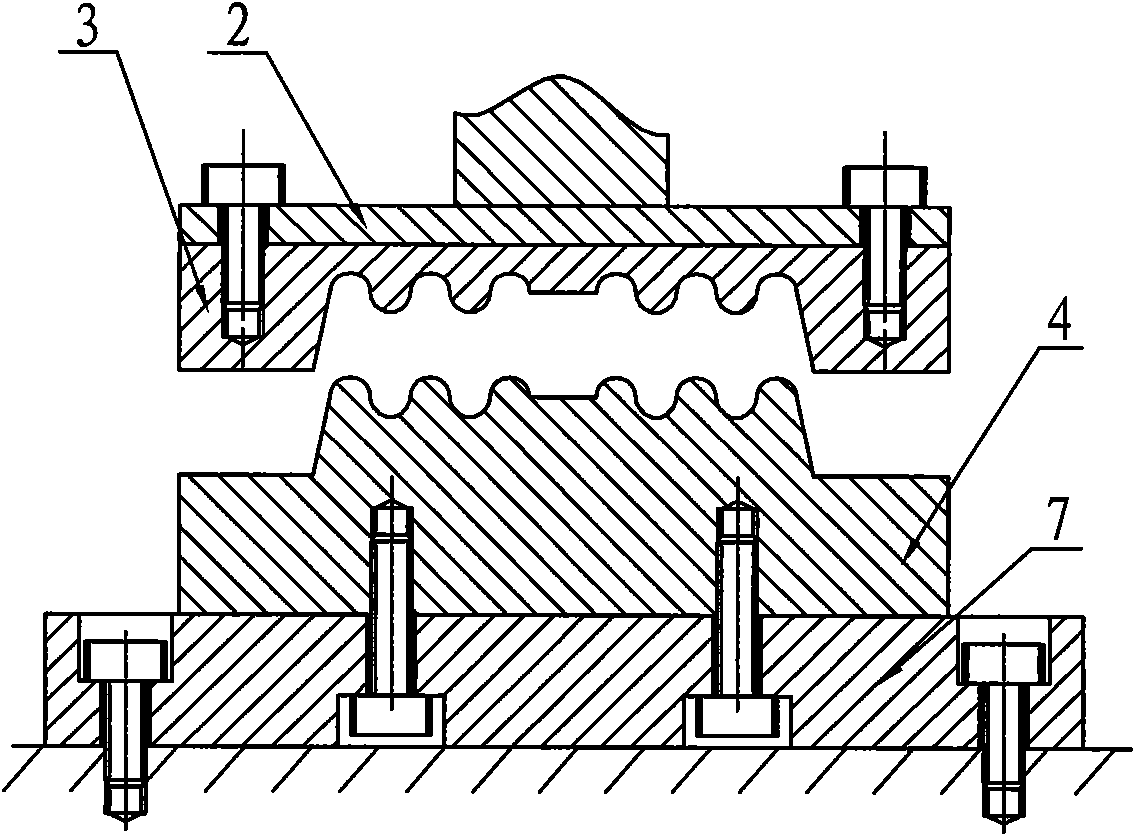

[0013] Such as image 3 , Figure 4 As shown, the loudspeaker elastic wave forming pressing mold includes an upper mold part and a lower mold part, and the upper mold part includes an upper template 2 and an upper die head 3, and the upper template 2 is fixedly installed on the telescopic rod 1 of the forming machine, and the upper mold The head 3 is fixedly installed on the lower end surface of the upper template 2. The upper die head 3 is composed of an upper forming surface 31 and an upper pressure ring 32. The shape of the upper forming surface 31 is consistent with the shape of the upper end surface of the corrugated plate 91 of the elastic wave. The width of the ring 32 is greater than the width of the clamping edge 93 of the elastic wave, and the distance between the upper pressing ring 32 and the upper forming surface 31 is equal to the height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com