Pulper low in power consumption and noise

A low-noise, pulper technology, used in textile and papermaking, raw material separation, fiber raw material processing, etc., can solve problems such as high power consumption and high noise, reduce vibration, reduce energy consumption, and improve pulping. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

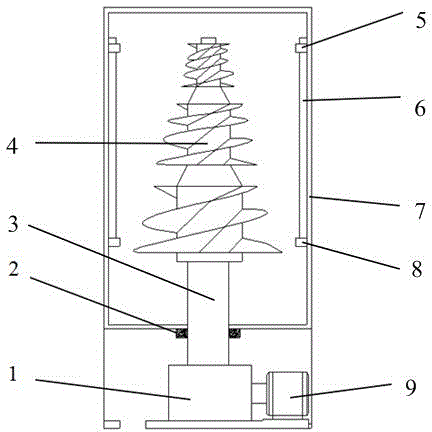

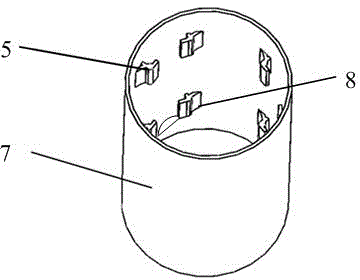

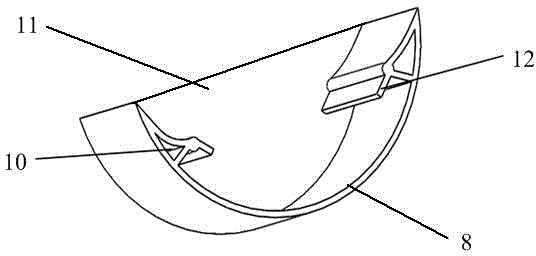

[0025] Such as figure 1 As shown, a pulper with low power consumption and low noise of the present invention is mainly composed of a cylinder wall 7, a motor 9, a reducer 1, a sealing device 2, a main shaft 3, a helical blade rotor 4, an upper vortex plate groove 5, The lower vortex plate groove 8 and the vortex plate 6 are composed. The rotational power of the helical blade rotor 4 is driven by the motor 9, and is transmitted to the helical blade rotor 4 in turn through the reducer 1 and the main shaft 3; the cylinder wall 7 is installed on the motor 9 and On the upper end of the reducer 1, the upper vortex plate groove 5 and the lower vortex plate groove 8 are installed on the cylinder wall 7, and are fixed on the cylinder wall 7 by bolts, and the upper and upper vortex plate grooves 5 and the lower vortex plate groove 8 are installed There is a vortex plate 6, and the vortex plate 6 is fixed by the lower vortex plate groove bottom plate 11 and the upper and lower vortex pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com