Coach top side skin with novel structure and preparation method thereof

A new type of structure and skin technology, applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problems affecting the appearance and sealing effect of passenger cars, water-like rust on the body, and inconvenient installation process, etc., to achieve comprehensive The production cost is reduced, the production and assembly process is simplified, and the production efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

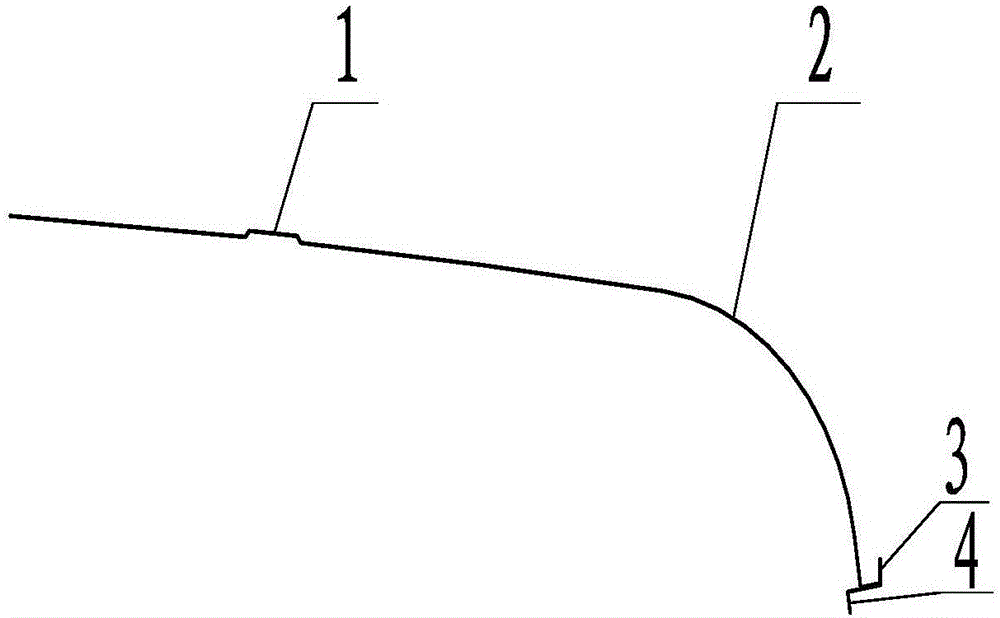

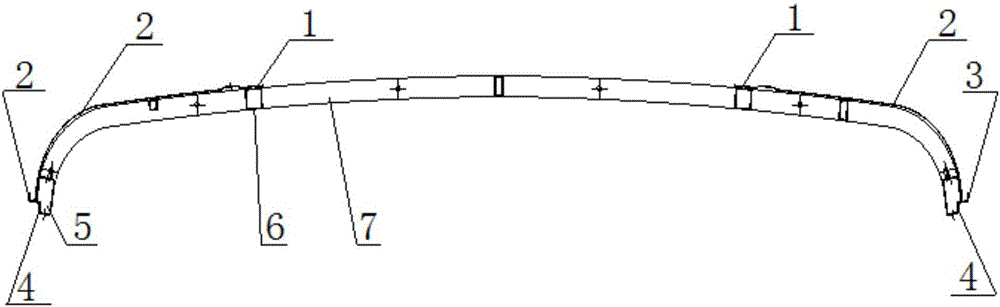

[0024] like figure 1 As shown, a new structure of the top side skin of a passenger car, the steel plate structure is in the shape of an arc bent up and down, and the length is suitable for the length of the passenger car. 3 and the upper edge of the window 4, the arc-shaped skin 4 constitutes an arc-shaped body, and the reinforcing rib 1 is located at the position where the upper arc of the arc-shaped skin 2 tends to be a straight line, and along the longitudinal direction of the arc-shaped skin 2 Extending, the running water groove 3 is located at the edge of the lower arc section of the arc-shaped skin 2, and the cross-section is double-layered, in a state of bonding, extending along the edge of the lower arc section of the arc-shaped skin 2, and the upper edge of the window 4 Located below the water tank 3, it is bent inward along the bottom surface of the water tank 3, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com