Outdoor silver powder coating and preparation method thereof

A powder coating and silver-colored technology, applied in powder coatings, polyester coatings, coatings, etc., can solve problems such as the influence of non-floating aluminum powder dispersion, blackening and darkening of the paint film, and loss of luster in the floating silver layer , to achieve good outdoor weather resistance, high gloss, good appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

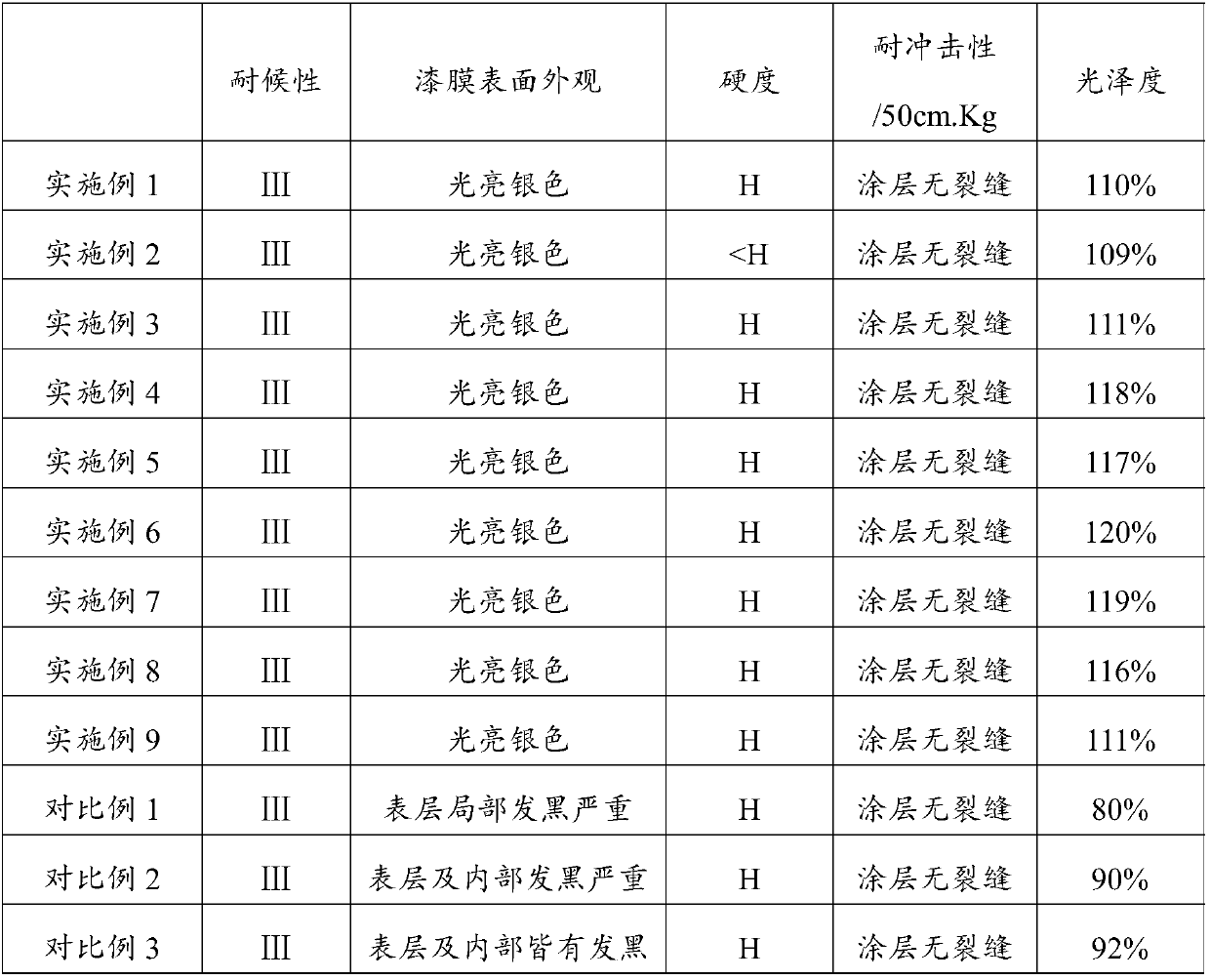

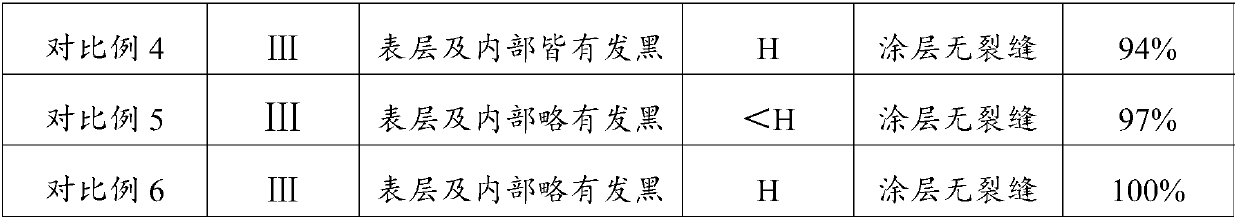

Examples

Embodiment 1

[0043] A kind of outdoor silver powder paint, its preparation raw material is made up of following components:

[0044] Base powder:

[0045] Carboxylated polyester resin 60%, curing agent 5%, leveling agent 1.2%, wax powder 0.8%, high-gloss barium sulfate 13%, titanium white 19%, the glass transition temperature of carboxylated polyester resin is 55 ℃, and the acid value is 35mgKOH / g, the cone-plate viscosity at 200°C is 3000mPa.s, the curing agent is triglycidyl isocyanurate, and the leveling agent is ethylene bisstearamide;

[0046] Non-leafing aluminum powder:

[0047] 1%, flaky, and the particle size is 8um.

[0048] The preparation method of above-mentioned outdoor silver powder coating is:

[0049] (1) Preparation of base powder

[0050] Mix carboxyl polyester resin, curing agent, leveling agent, wax powder, high-gloss barium sulfate and white pigment in a high-speed mixer to obtain a mixture, and the rotation speed of the mixer is 1200r / min;

[0051] The mixture i...

Embodiment 2

[0056] A kind of outdoor silver powder paint, its preparation raw material is made up of following components:

[0057] Base powder:

[0058] Carboxyl polyester resin 65%, curing agent 4.5%, leveling agent 1.0%, wax powder 0.5%, high-gloss barium sulfate 10%, titanium dioxide 17.5%, carboxy polyester resin glass transition temperature is 57 ℃, acid value It is 37mgKOH / g, the cone-plate viscosity at 200°C is 3800mPa.s, the curing agent is triglycidyl isocyanurate, and the leveling agent is ethylene bisstearamide;

[0059] Non-leafing aluminum powder:

[0060] 1.5%, flaky, and the particle size is 8um.

[0061] The preparation method of the above-mentioned outdoor silver powder coating is the same as the preparation method of the outdoor silver powder coating in Example 1.

Embodiment 3

[0063] A kind of outdoor silver powder paint, its preparation raw material is made up of following components:

[0064] Base powder:

[0065] Carboxylated polyester resin 60%, curing agent 5%, leveling agent 1.2%, wax powder 0.8%, high-gloss barium sulfate 13%, lithopone 19%, glass transition temperature of carboxylated polyester resin is 55 ℃, acid value The viscosity is 35mgKOH / g, the cone-plate viscosity at 200°C is 3000mPa.s, the curing agent is triglycidyl isocyanurate, and the leveling agent is ethylene bisstearamide;

[0066] Non-leafing aluminum powder:

[0067] 1%, flaky, and the particle size is 8um.

[0068] The preparation method of the above-mentioned outdoor silver powder coating is the same as the preparation method of the outdoor silver powder coating in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com