Processing device of waterproof slide fastener

A processing device and waterproof zipper technology, which is applied to sewing machine components, clothing, textiles and papermaking, etc., can solve problems such as gaps in the waterproof adhesive layer, achieve tight gaps and avoid production continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

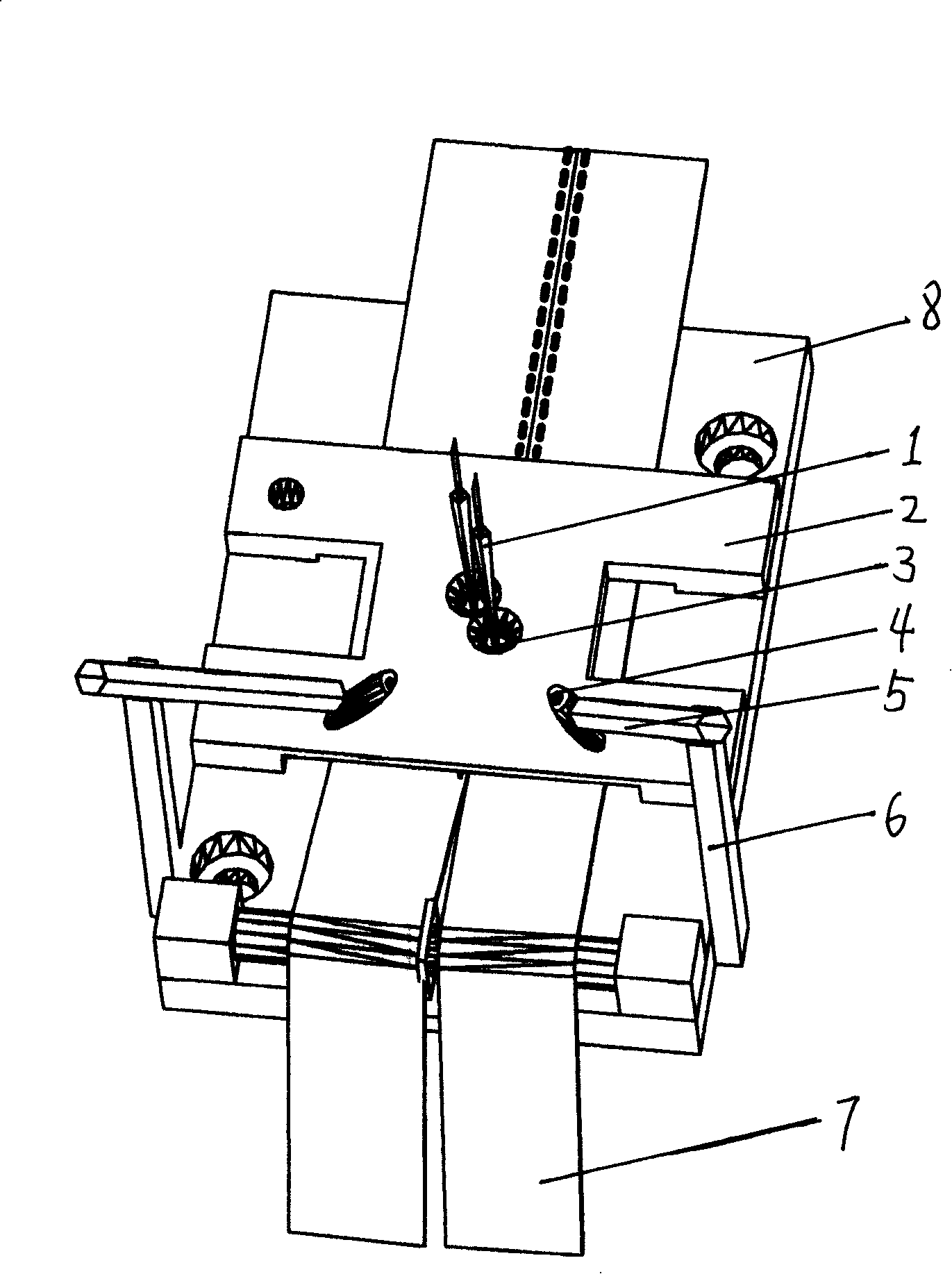

[0017] like figure 1 As shown, the present invention comprises a sewing needle 1, an upper pressing plate 2, a sewing needle pinhole 3, an oblique hole 4, an air blowing pipe 5, an air blowing pipe support 6, a cloth tape 7, and a needle plate 8, and the cloth tape 7 is located on the needle plate 8 Between the upper pressing plate 2, a sewing needle 1 is set on the needle plate 8, and a sewing needle hole 3 is set on the upper pressing plate 2, and the positions of the sewing needle 1 and the sewing needle hole 3 are corresponding so that the sewing needle 1 can pass through the seam. Pinhole 3.

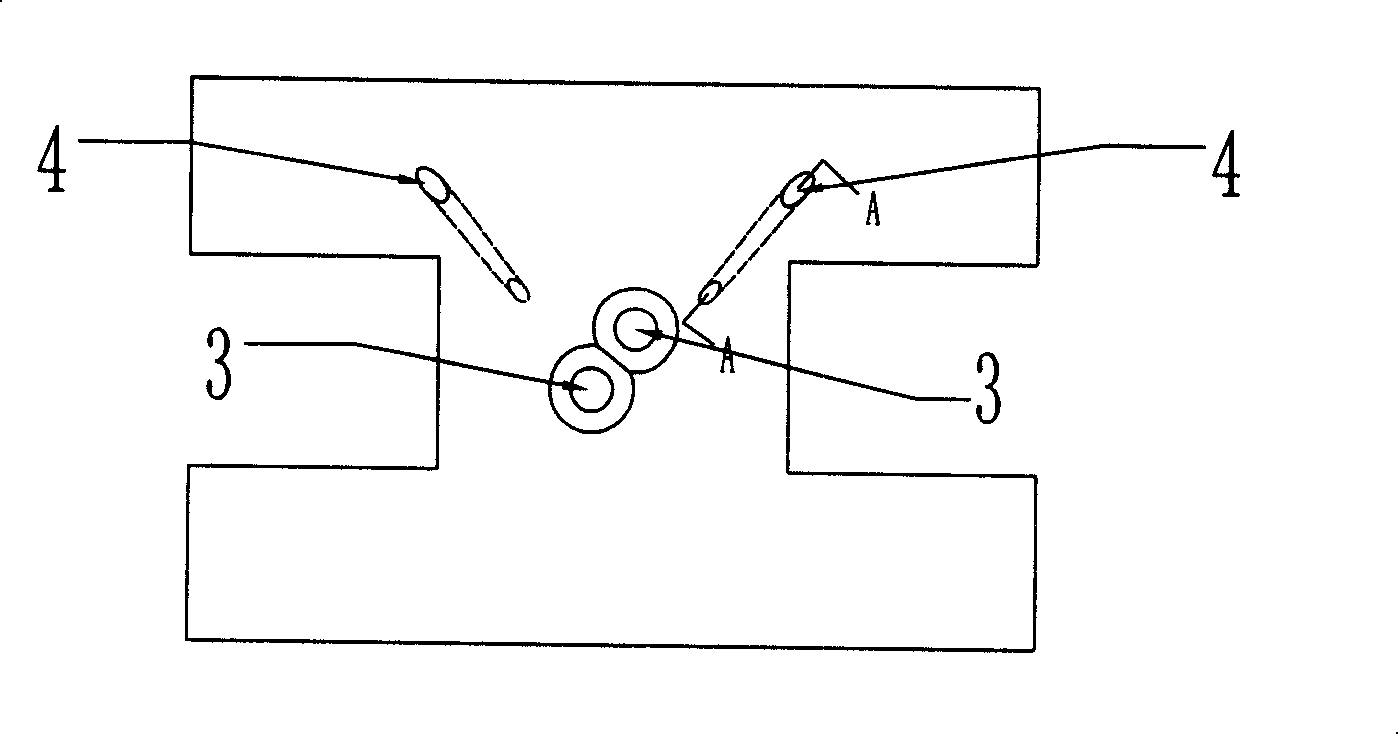

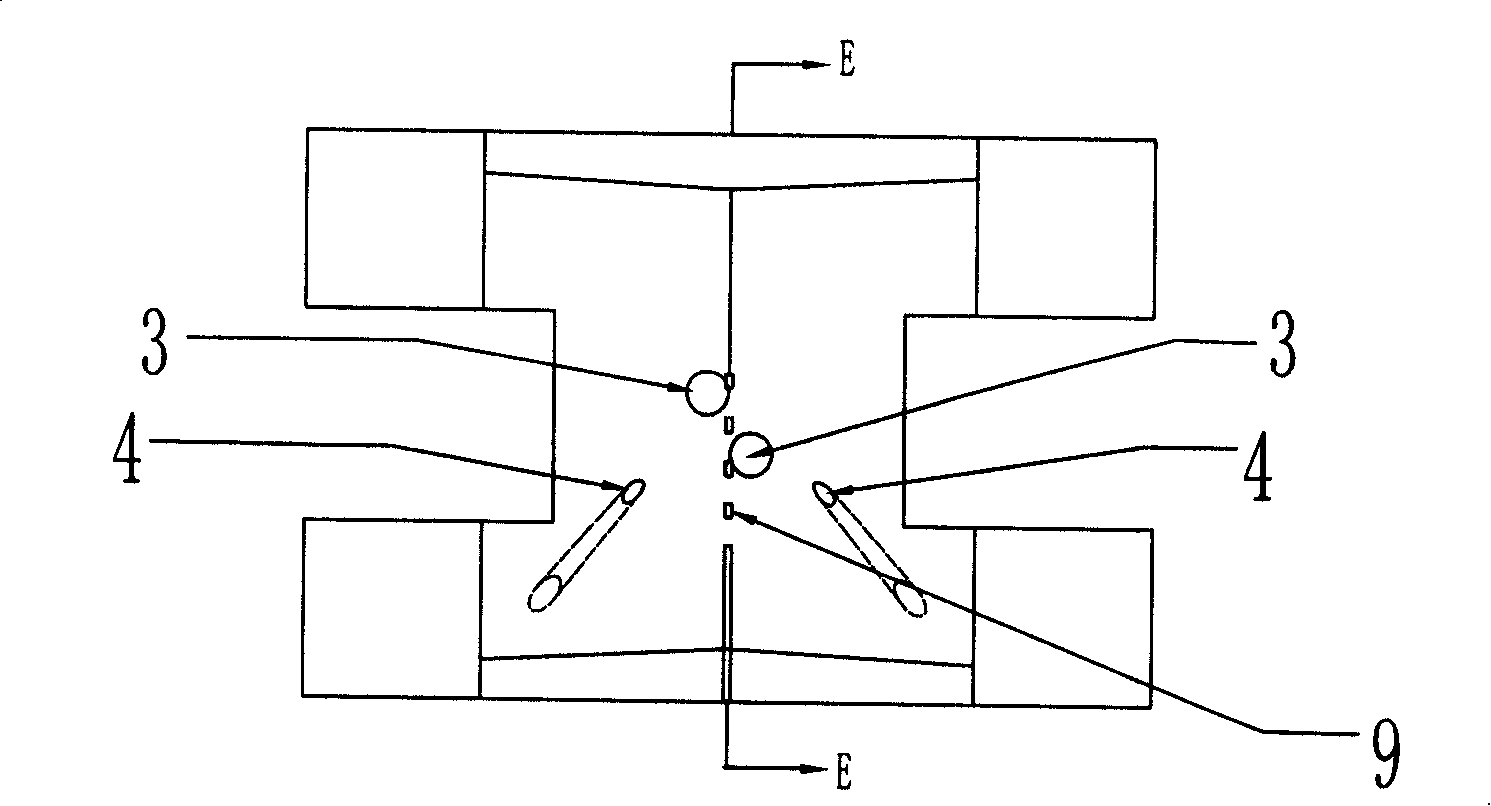

[0018] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the upper platen 2 has two symmetrical oblique holes 4, and the left and right openings of the upper platen 2 near the oblique holes 4 on one side of the cloth belt 7 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com