Compressor

A compressor and thrust technology, applied in the field of compressors, can solve problems such as friction and wear, and achieve the effects of simplifying assembly, solving the problem of stator and rotor clearance, and improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

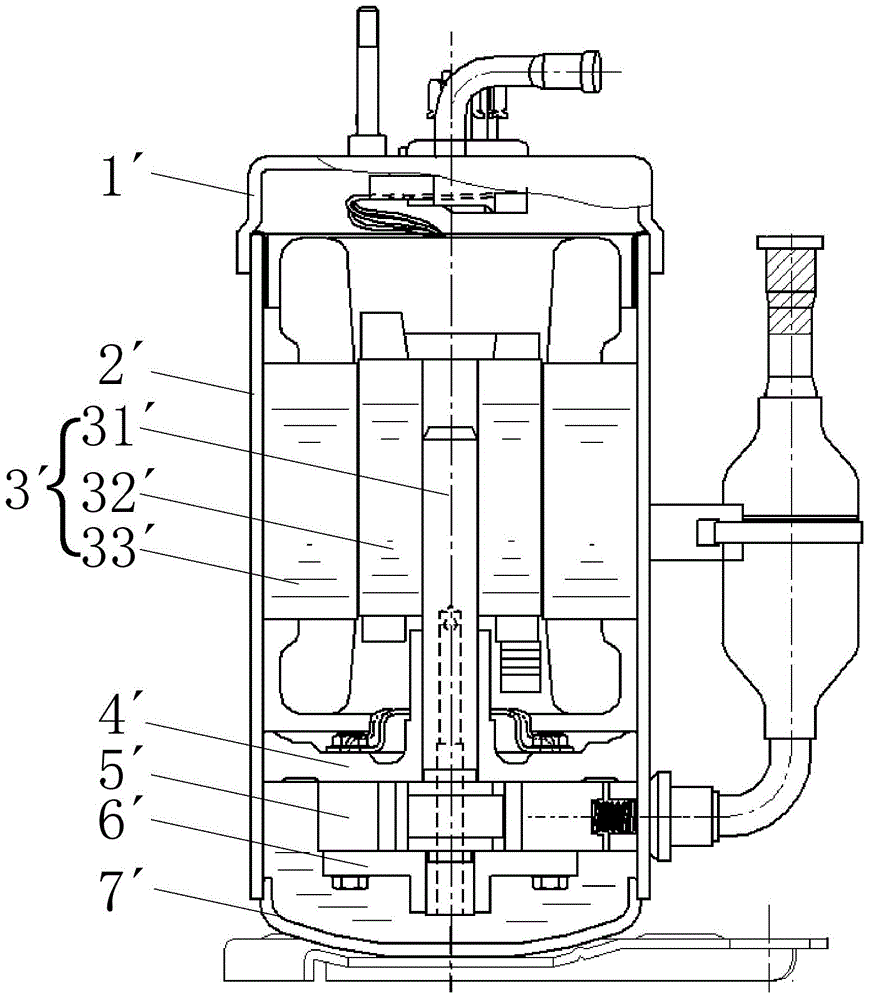

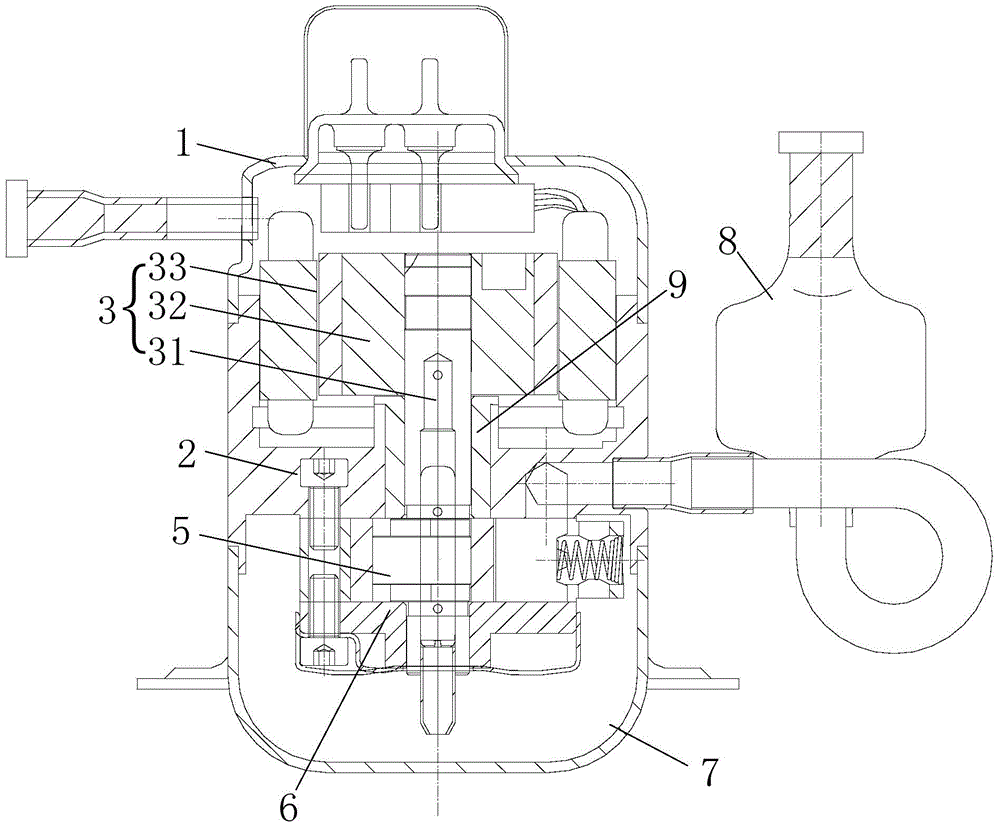

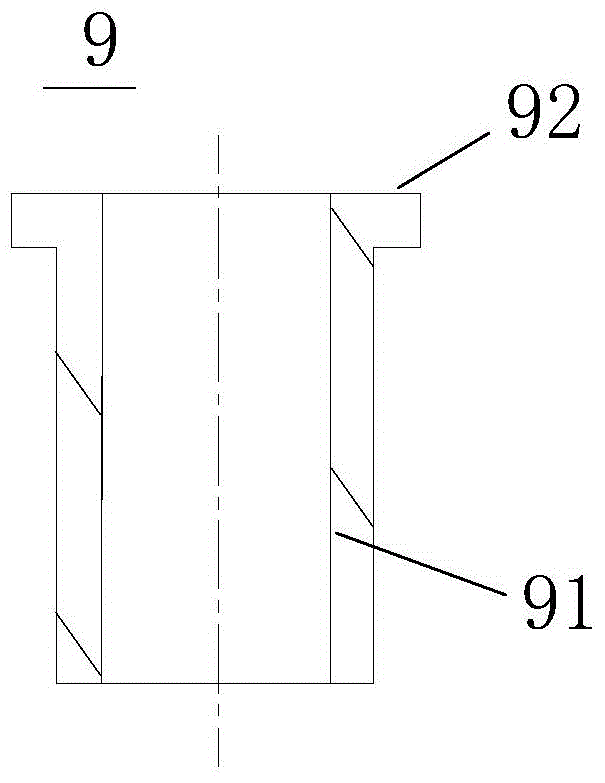

[0085] like figure 2 As shown, the compressor of the present invention includes: a housing; the motor 3 is accommodated in the upper space in the housing; the cylinder 5 is accommodated in the lower space in the housing; the crankshaft 31 has a long axis portion 311 and an eccentric portion 312 and short axis portion 313 (such as Figure 4 shown), the crankshaft 31 transmits the rotational force of the motor 3 to the cylinder 5 to compress the refrigerant; the first bearing assembly and the second bearing assembly together define the compression space with the cylinder 5 and support the crankshaft 31, wherein the first bearing assembly Including at least upper bearing 2 (ie main bearing) and thrust bushing 9, upper bearing 2 is located between motor 3 and cylinder 5, thrust bushing 9 has a crankshaft supporting part 91 and a thrust part 92 carrying crankshaft 31 (like image 3 shown); the second bearing assembly includes at least the lower bearing 6 (ie the auxiliary bearin...

no. 2 example

[0096] like Image 6 As shown, in a modification example, the outer edge of the thrust portion 92a of the thrust bushing 9a is bent downward to extend a flange portion 93a, and a thrust support piece 10 is added to be arranged on the flange portion 93a and the upper bearing 2 between the upper surfaces of the disc portion 21. The thrust bush 9a is still made of self-lubricating material, and other technical features are the same as those of the first embodiment, and will not be repeated here.

[0097] like Figure 7 As shown, compared with the first embodiment, the second embodiment improves the structure of the thrust bush 9a in order to better distribute the weight of the crankshaft 31 carried by the thrust bush 9a. Specifically, the inner hole of the crankshaft supporting portion 91a of the thrust bush 9a and the flange portion 93a can clamp the inner edge portion 25 of the upper bearing 2, so that the thrust bush 9a and the upper bearing 2 are more stable. And the thrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com