Lithium battery lamination method and adopted separator membrane turn-over system

A technology of lithium battery and diaphragm, which is applied in the field of lithium battery production, can solve the problems of loose batteries and achieve the effect of increasing production capacity and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

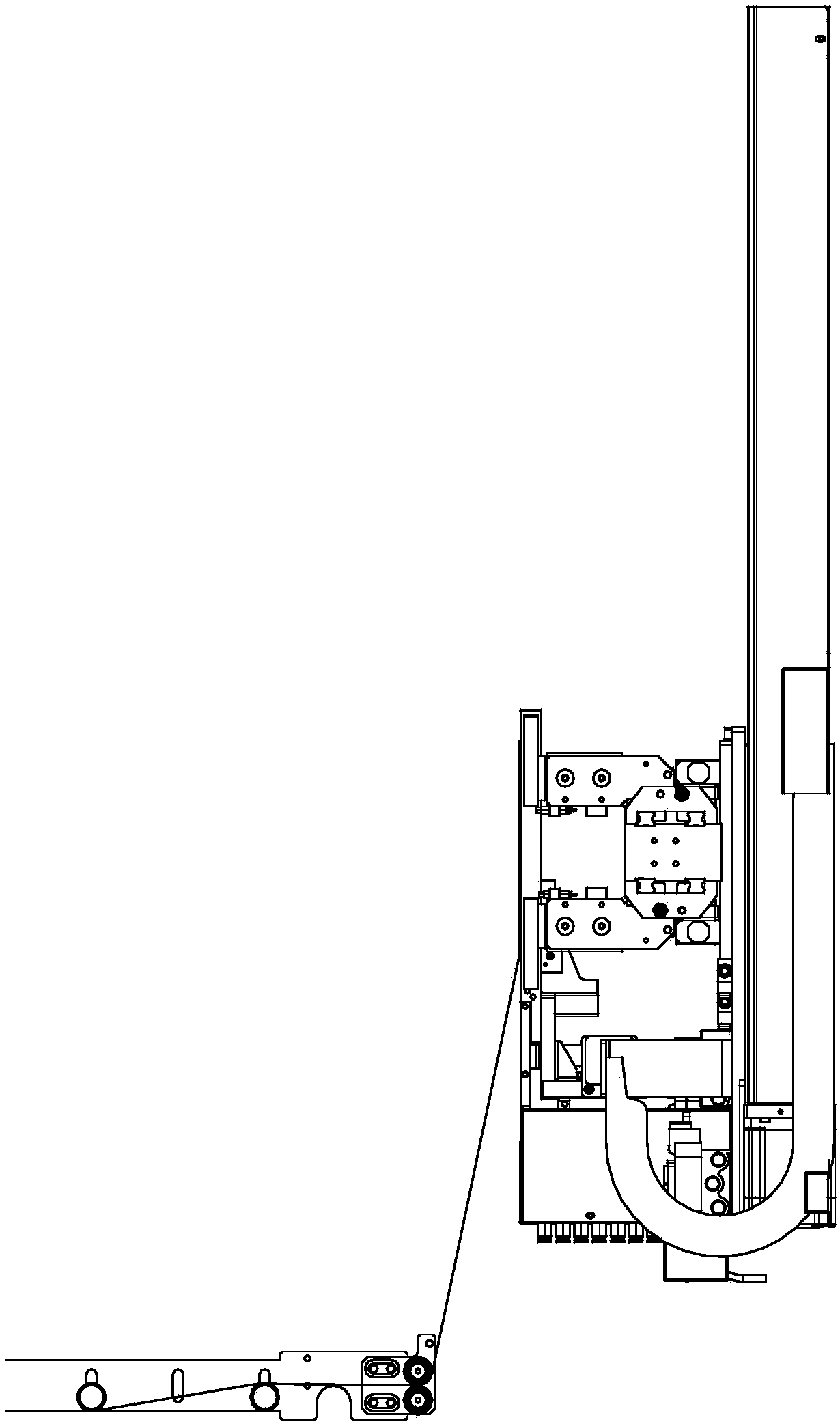

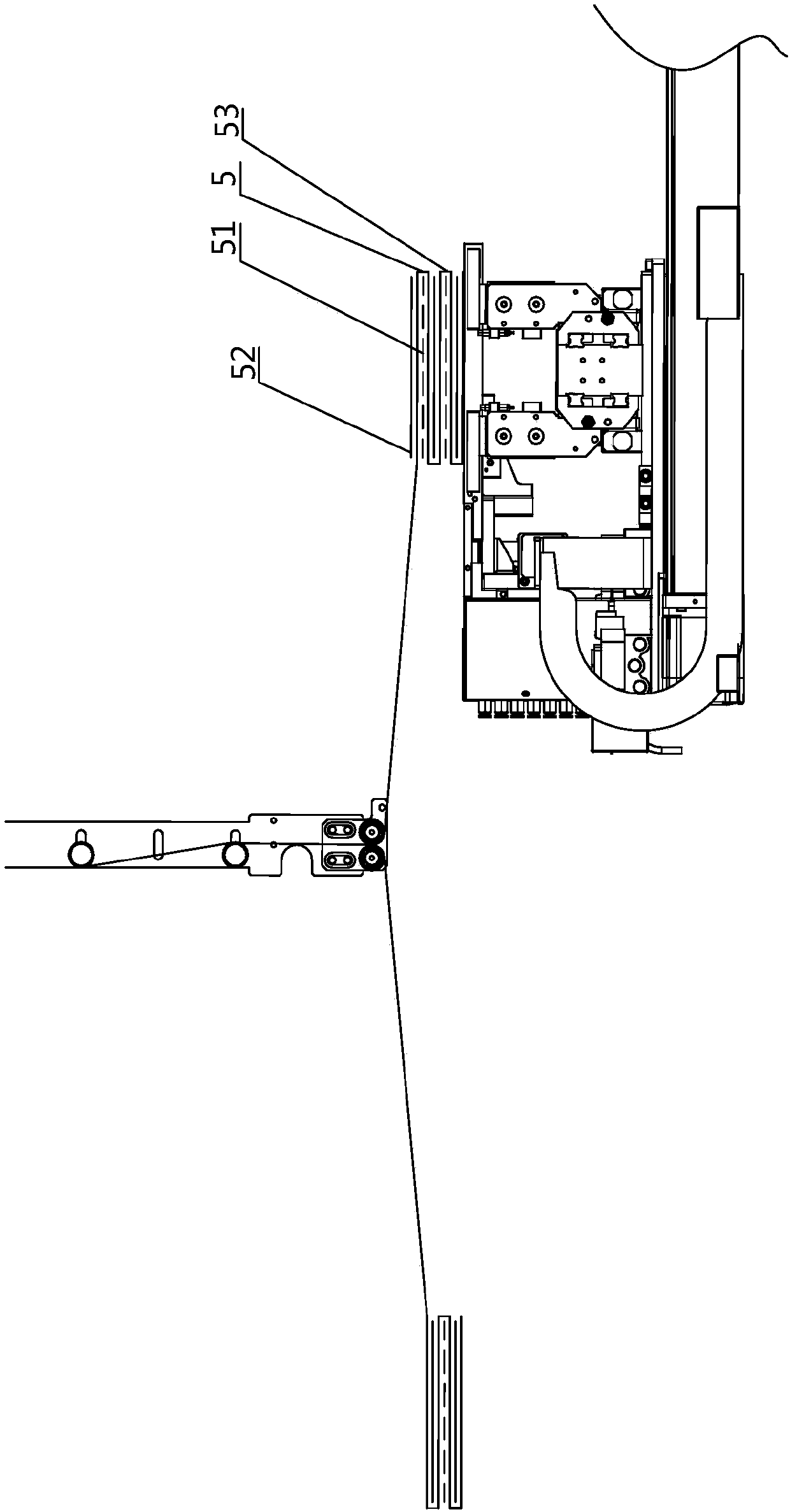

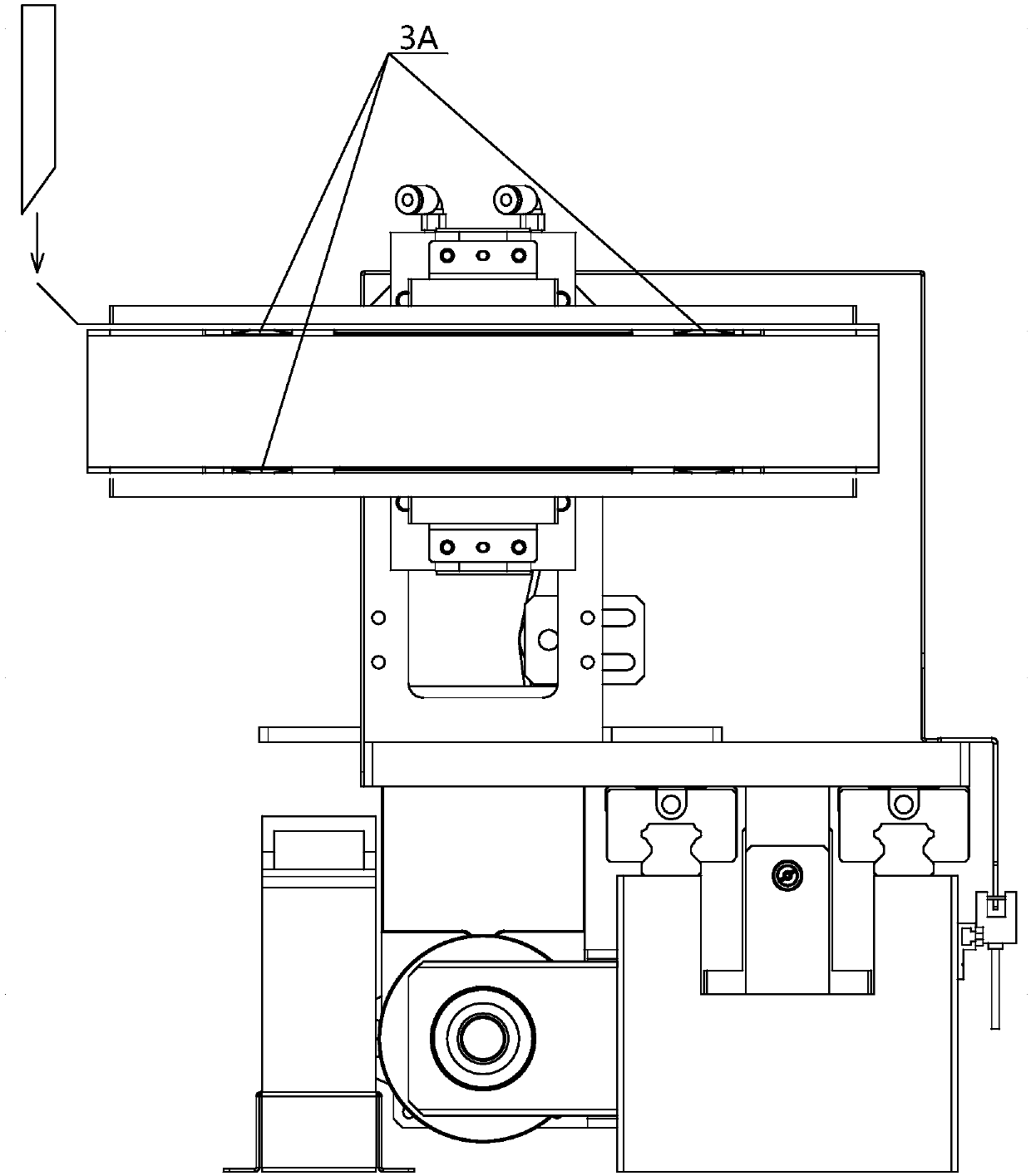

[0045] Such as Figure 4-9 As shown, the lithium battery stacking method described in Embodiment 1 of the present invention mainly consists of the following steps:

[0046] (1) First, install the film releasing device equipped with the diaphragm turning mechanism 4 vertically above the stacking platform and make the diaphragm 53 be conveyed from the film releasing device and adsorbed on the upper surface of the stacking platform. The film unloading device is on the upper right of the lamination table, that is, relative to the film unloading device, the lamination table is on the left side of the film unloading device (the state is as follows Figure 6 shown);

[0047] (2) The first negative electrode sheet 52 is stacked on the diaphragm 53 on the surface of the stack, and then the stacking table is moved to the right side of the film release device, because the diaphragm 53 at the bottom of the first negative electrode sheet 52 is adsorbed on the stack The stage is fixed, an...

Embodiment 2

[0056] Such as Figure 4-9 As shown, a diaphragm turning system includes a lamination platform, above which there is a film releasing device equipped with a diaphragm turning mechanism 4 and the stacking platform is arranged on the left side of the film releasing device, the specific position It is set that if the film releasing device is used as a reference object, when a battery stack 5 is not processed or has been processed and the next one is ready to be processed, the real-time position of the stacking table is on the left side of the film releasing device, so as to realize Lamination processing on the left provides necessary processing conditions.

[0057] The specific settings between the above-mentioned film releasing device and the stacking table are as follows:

[0058] The upper surface of the stacking platform absorbs a layer of diaphragm 53 from the film release device, and the upper surface of the diaphragm 53 is stacked with the first negative electrode sheet 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com