Buckle type non-dismantling mold floor slab

A formwork-free and formwork-free technology, applied in floors, structural elements, building components, etc., can solve problems such as instability, impact on construction quality, time-consuming and labor-intensive installation, and achieve fast installation speed, improve work efficiency, and source raw materials. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings.

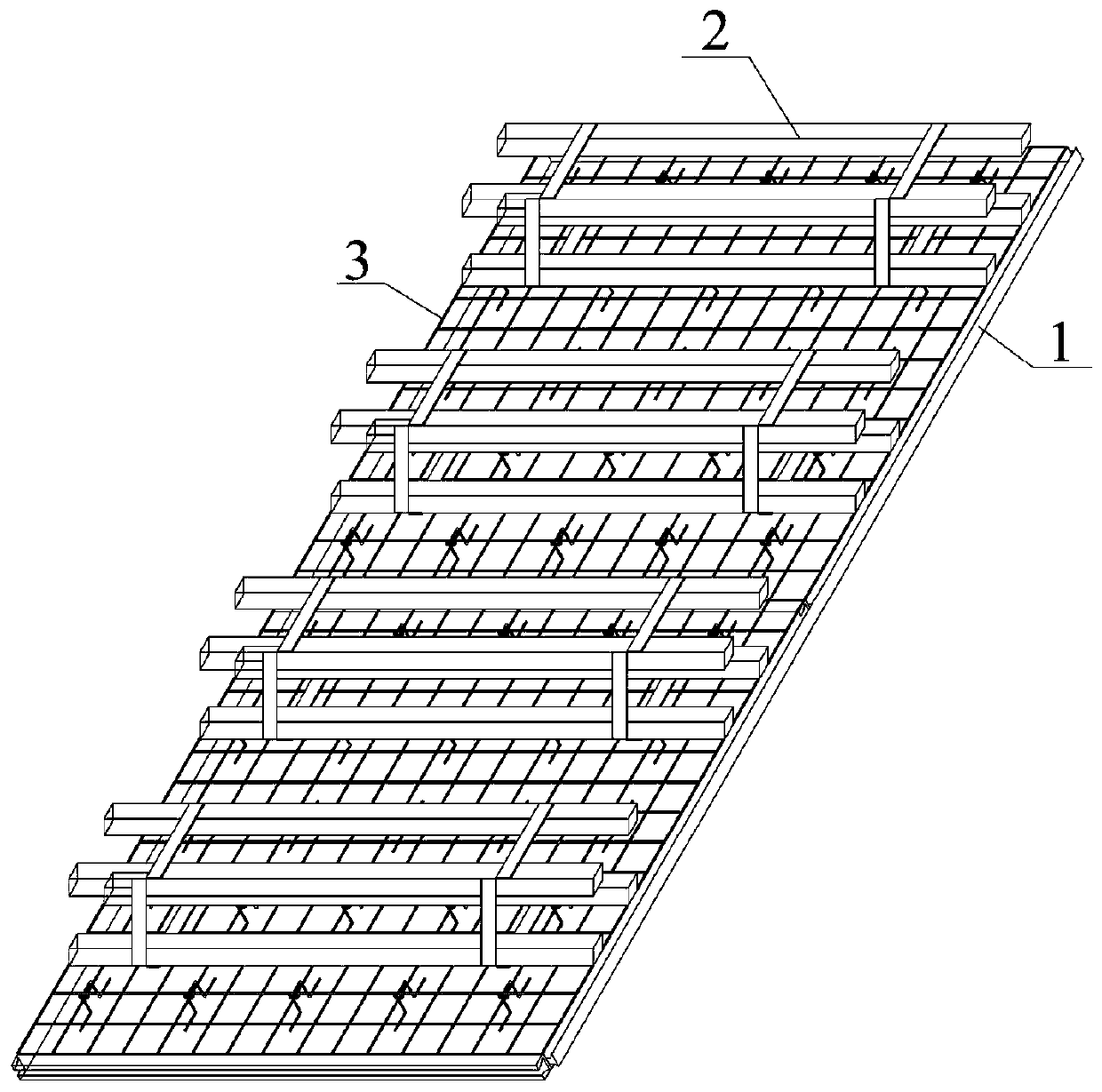

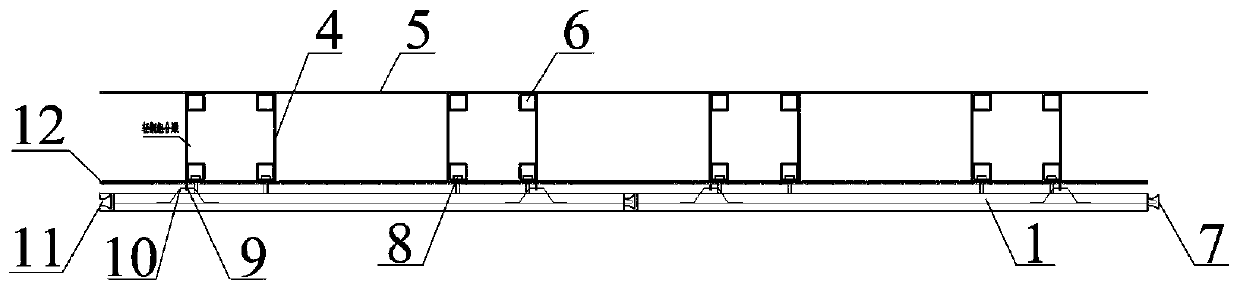

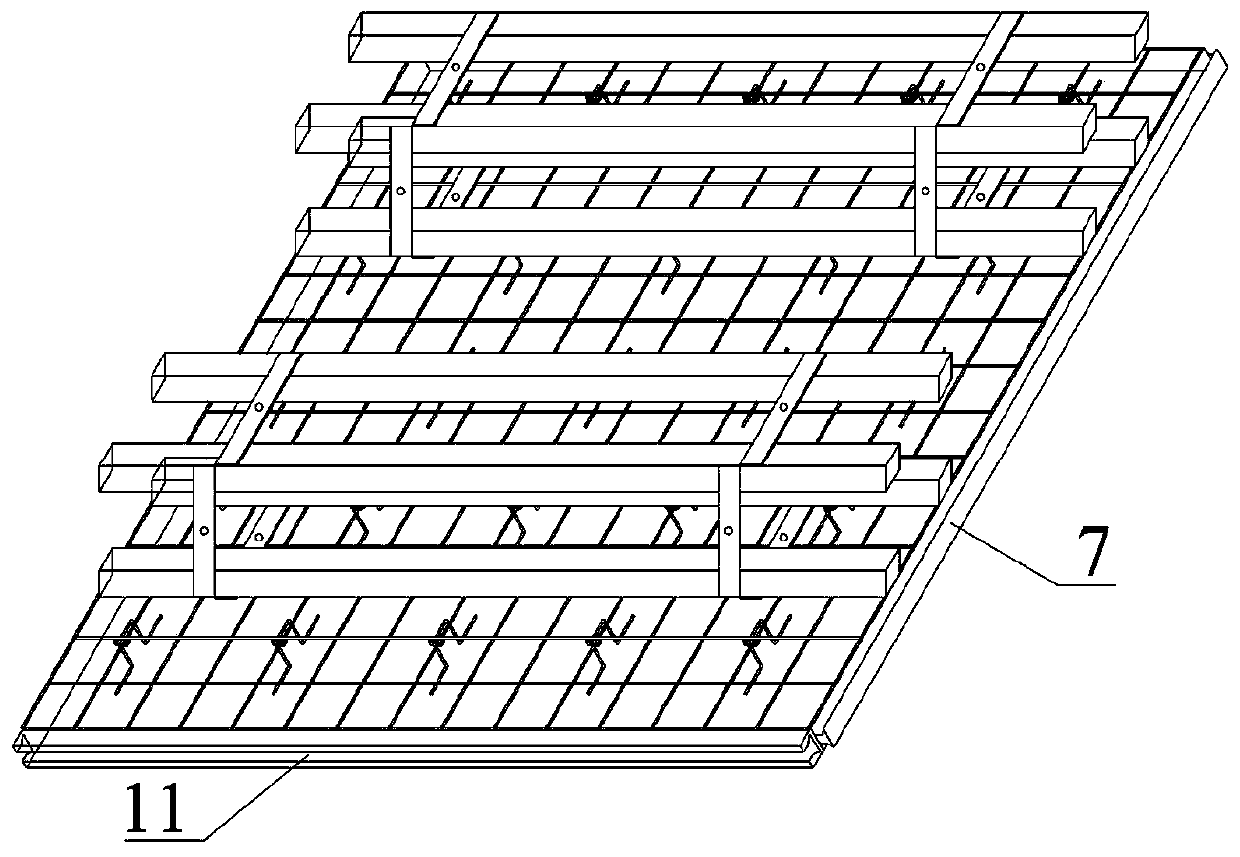

[0047] Such as Figure 1-4As shown, the present invention discloses a buckle-free formwork-free floor slab, which includes a formwork-free formwork 1, a steel wire mesh 3, light steel columns 2 and steel braces 5, and the formwork-free formwork 1 One side is a smooth plane, and the other side is provided with several pre-embedded shapes 10 and several T-shaped buckles 8, and the four sides of the non-dismantling formwork 1 are provided with several male grooves 7 and female grooves 11. The steel wire mesh is provided with several hanging buckles 9, and the light steel column 2 is provided with several T-shaped slots 13, and the embedded several shapes 10 and the steel wire mesh 3 are fixedly connected by the first buckle mode; The bottom surface of the steel column 2 and the non-dismantling formwork 1 are fixedly connected by the second buckle mode; The connection be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com