Preparation method of compound sophora flower bud tea bags

A compound locust tree and rice bag technology, which is applied in the field of health products and food, can solve the problems of difficulty in ensuring product hygiene, low transfer rate of rutin, bad appearance and taste, etc., achieve good soup color and taste, reduce vascular permeability, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

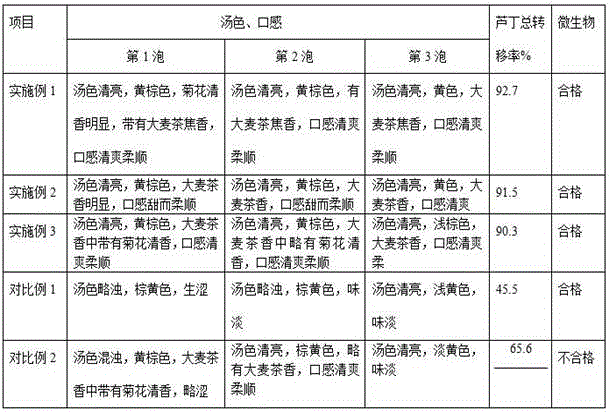

Examples

Embodiment 1

[0035] Raw material ratio:

[0036] 2 parts of Sophora japonica, 1 part of chrysanthemum, 1 part of mulberry leaf, 0.5 part of medlar.

[0037] Its preparation process comprises the following steps:

[0038] a. Select Sophora japonica and mulberry leaves, steam for 45 minutes at a steam temperature of 105°C and a steam pressure of 25-30MPa, then dry at 80°C for 4 hours until the moisture is lower than 6.0%, and dry the dried Sophora japonica Fry the rice and mulberry leaves with slow fire (125~135°C) for 10 minutes each;

[0039] b. 50% of the weight of Sophora japonica after frying is crushed into coarse powder of 16-40 mesh, and the rest is crushed into fine powder below 80 mesh;

[0040] c. Grinding 50% of the fried mulberry leaf weight into coarse powder of 16-40 mesh, and crushing the rest into fine powder below 80 mesh;

[0041] D, dry medlar, chrysanthemum, pulverize and make all pass through 30 mesh sieves;

[0042] e. Mix fine Sophora japonica rice powder below 80...

Embodiment 2

[0045] Raw material ratio:

[0046] 1 part of Sophora japonica, 0.2 part of chrysanthemum, 0.2 part of mulberry leaf, 0.4 part of medlar.

[0047] Its preparation process comprises the following steps:

[0048] a. Select Sophora japonica and mulberry leaves, steam for 60 minutes at a steam temperature of 100°C and a steam pressure of 25-30MPa, then dry at 70°C for 5 hours until the moisture is lower than 6.0%, and dry the dried Sophora japonica Fry the rice and mulberry leaves with slow fire (125~135°C) for 10 minutes each;

[0049] b. Grinding 40% of the weight of Sophora japonica after frying into 16-40 mesh coarse powder, and the rest are crushed into fine powder below 80 mesh;

[0050] c. Grinding 60% of the fried mulberry leaf weight into coarse powder of 16-40 mesh, and crushing the rest into fine powder below 80 mesh;

[0051] D, dry medlar, chrysanthemum, pulverize and make all pass through 30 mesh sieves;

[0052] e. Mix Chinese pagoda japonica fine powder below 80 ...

Embodiment 3

[0055] Raw material ratio:

[0056] 1.5 parts of pagoda seed, 0.5 part of chrysanthemum, 0.5 part of mulberry leaf, 0.2 part of medlar.

[0057] Its preparation process comprises the following steps:

[0058] a. Select Sophora japonica and mulberry leaves, steam for 30 minutes at a steam temperature of 110°C and a steam pressure of 25-30MPa, then dry at 60°C for 6 hours until the moisture is lower than 6.0%, and dry the dried Sophora japonica Rice and mulberry leaves are fried with slow fire;

[0059] b. Grinding 60% of the weight of Sophora japonica after frying into coarse powder of 16-40 mesh, and crushing the rest into fine powder below 80 mesh;

[0060] c. Grinding 40% of the fried mulberry leaf weight into coarse powder of 16-40 mesh, and crushing the rest into fine powder below 80 mesh;

[0061] D, dry medlar, chrysanthemum, pulverize and make all pass through 30 mesh sieves;

[0062] e. Mix pagoda japonica fine powder below 80 mesh, mulberry leaf fine powder below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com