Nano micromolecule hyaluronic acid and preparation method thereof

A technology of hyaluronic acid and small molecules, which can be used in food preparation, medical preparations containing active ingredients, and pharmaceutical formulas, etc. Control and other problems to achieve the effect of promoting wound healing, high skin affinity and permeability, and treating rough skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

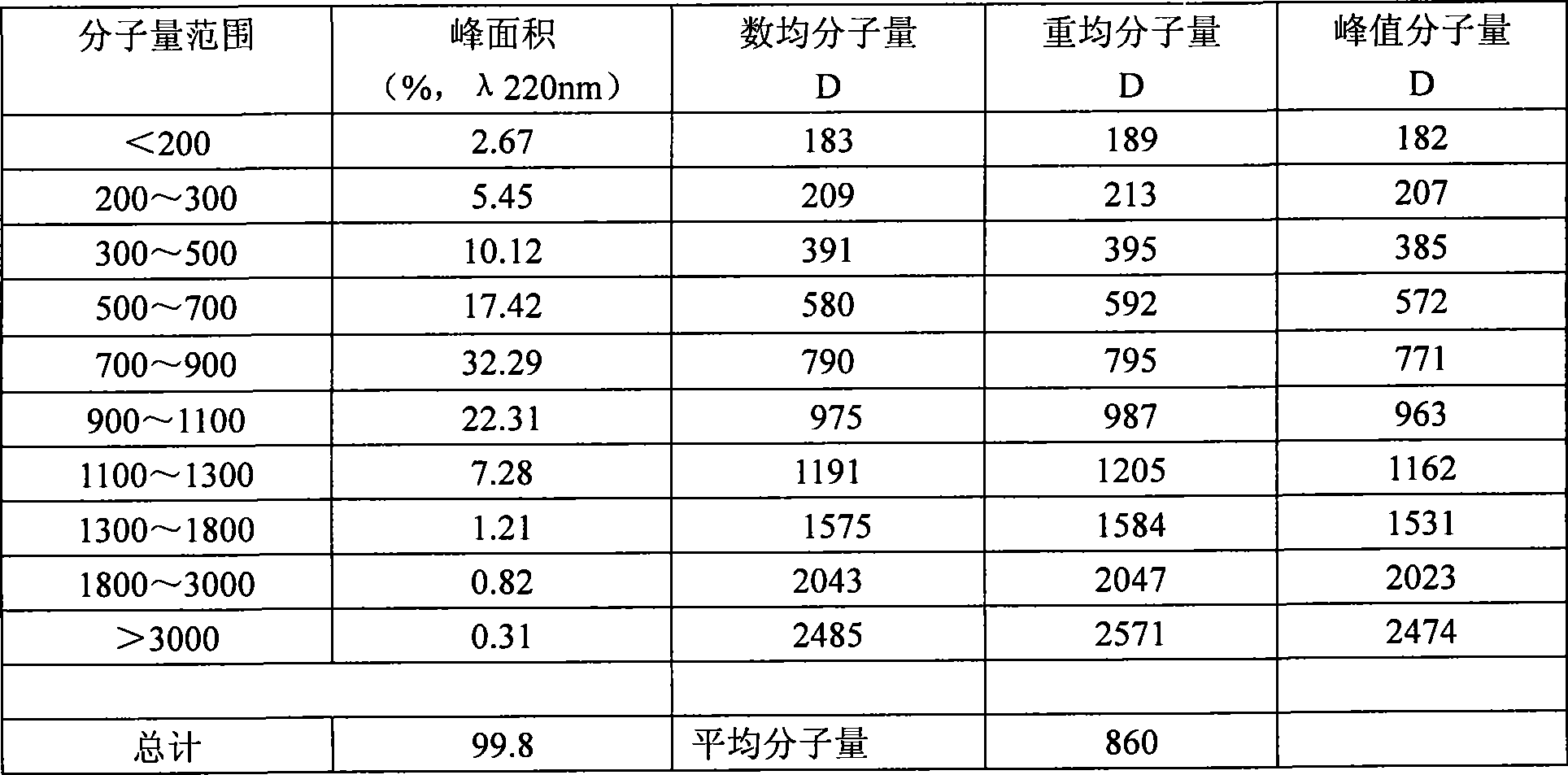

[0016] Example 1: Add 1000 g of water to 10 g of sodium hyaluronate (47.3 percent glucuronic acid content) with a molecular weight of 1.5 million, and stir to dissolve. Hydrolysis under acidic conditions: pH value is 2.5, hydrolysis at 85°C for 3 hours; enzymatic degradation: cool down to 50°C, add hyaluronidase (enzyme dosage 150,000 U / L), pH value is 5, hydrolysis at 50°C for 3 hours hours, and then heated to 90°C for 10 minutes to inactivate the enzyme. Filter with filter paper to obtain a transparent, colorless, odorless, transparent small molecule hyaluronic acid degradation solution. The above products are concentrated in vacuum at 60°C and spray-dried to obtain white powder small molecule hyaluronic acid.

[0017] After chemical analysis of the above liquid product, the content of glucuronic acid, the disaccharide labeling unit of hyaluronic acid in the product molecule, reached 46.1%, and its effective retention rate after degradation reached 97.4%; the above liquid p...

Embodiment 2

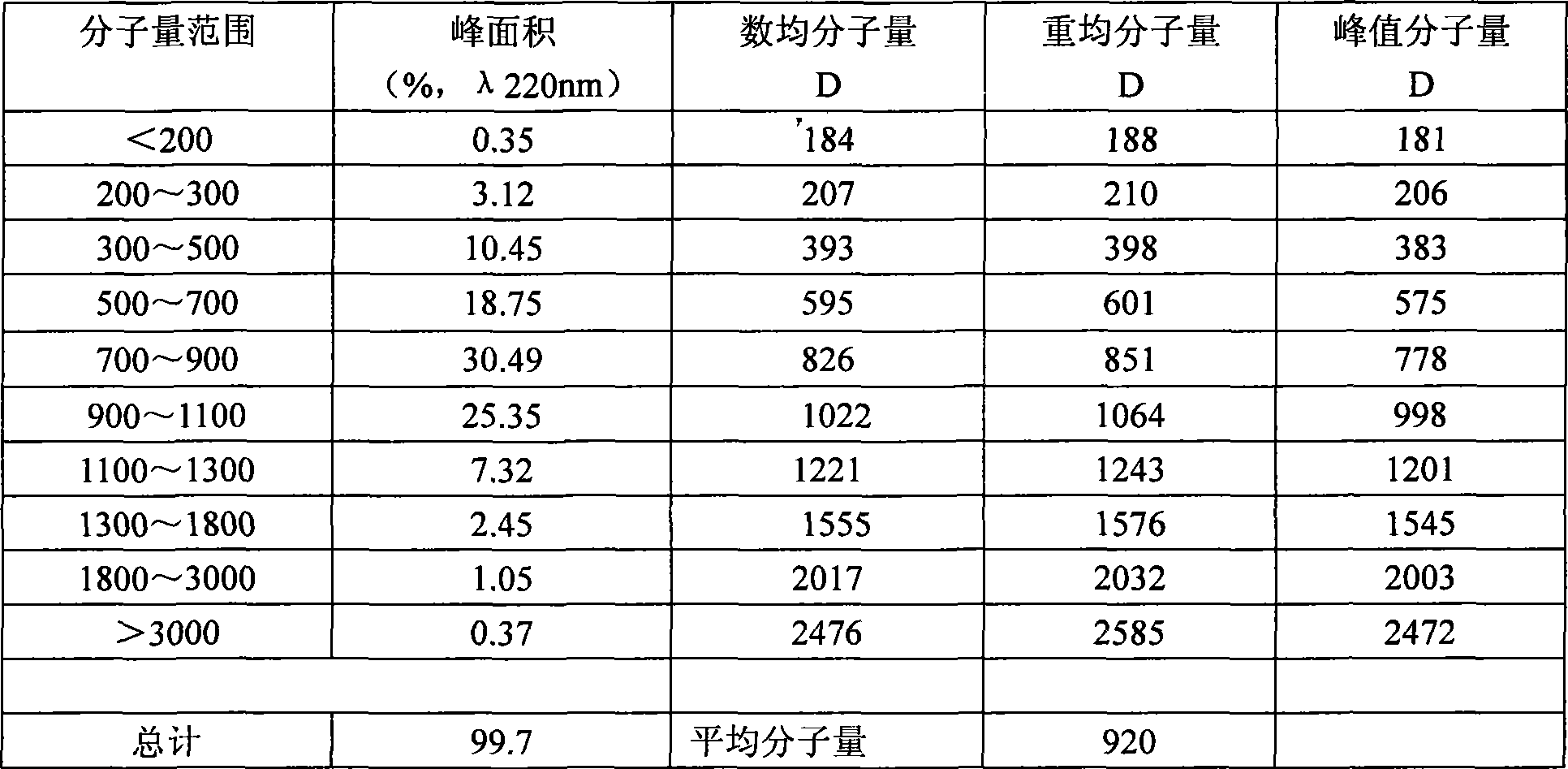

[0020] Example 2: 50 g of sodium hyaluronate (47.3% glucuronic acid content) with a molecular weight of 1.5 million was added to 950 g of water and stirred to dissolve. Hydrolysis under acidic conditions: pH value is 2, hydrolysis at 70°C for 4 hours; enzymatic degradation: cool down to 40°C, add hyaluronidase (enzyme dosage: 800,000 U / L), pH value is 6, hydrolysis at 40°C for 3 hours hours, and then heated to 90°C for 10 minutes to inactivate the enzyme. Filter with filter paper to obtain a transparent, colorless, odorless, transparent small molecule hyaluronic acid degradation solution. The above products are concentrated in vacuum at 60°C and spray-dried to obtain white powder small molecule hyaluronic acid.

[0021] After chemical analysis of the above liquid product, the content of glucuronic acid, the disaccharide labeling unit of hyaluronic acid in the product molecule, reached 46.5%, and its effective retention rate after degradation reached 98.3%; the above liquid pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com