Nutrient jelly containing microalgae DHA (Docosahexaenoic Acid) and preparation method thereof

A technology of microalgae and jelly, applied in the fields of food preparation, application, food science, etc., can solve the problems of being difficult for children and teenagers to accept, poor taste and unattainable taste, etc., and achieve the effect of strong development sustainability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

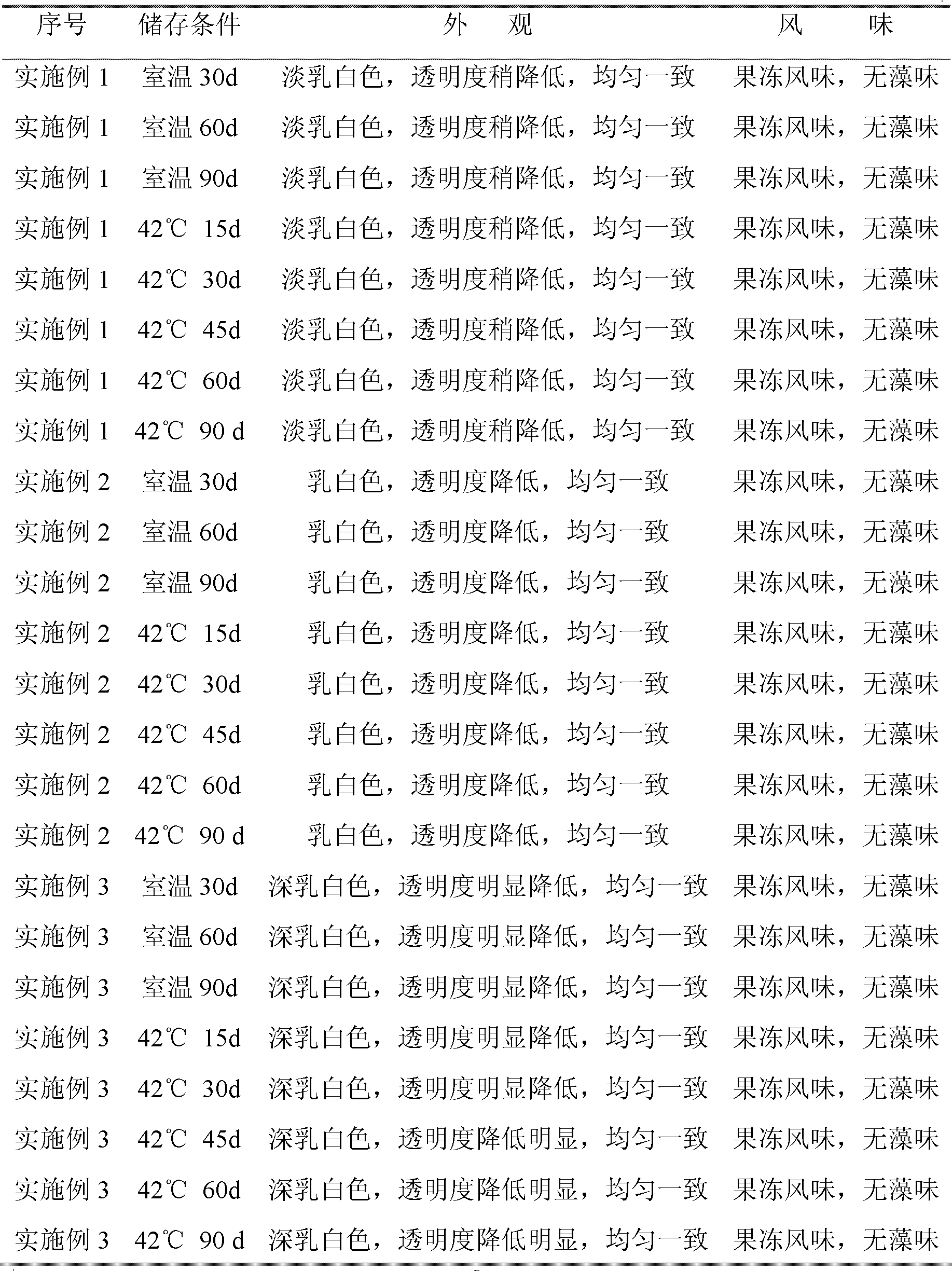

Embodiment 1

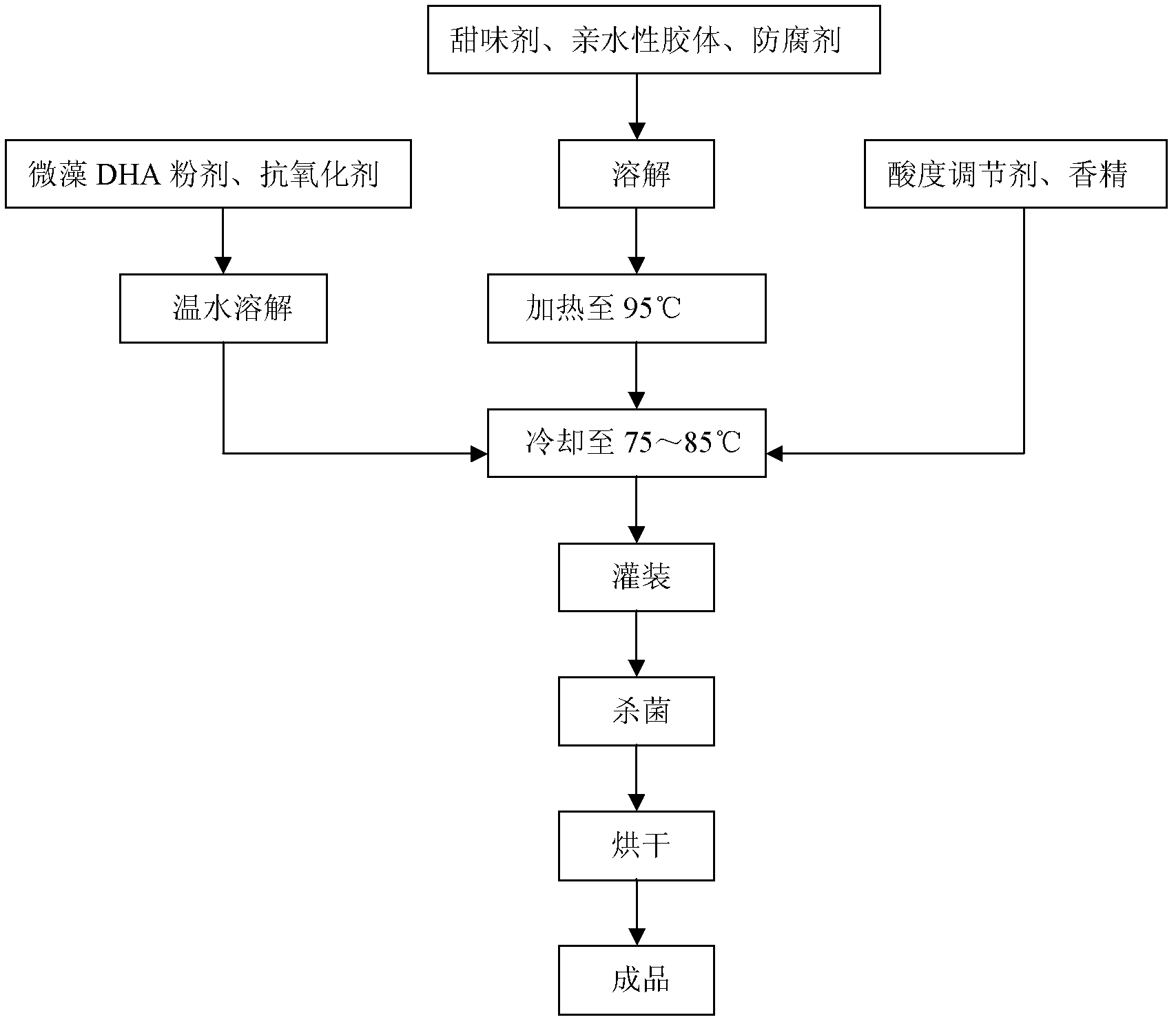

[0049] Preparation of nutritional jellies containing microalgal DHA, such as figure 1 shown:

[0050] (1) 100g white granulated sugar, 2g hydrophilic colloid (1.1g of refined carrageenan, 0.8g of konjac mannan, 0.1g of xanthan gum) and 0.2g of potassium sorbate were uniformly added, and then 750g was added and the temperature was Water at a temperature of 20-25° C., stir evenly, stand for 30 minutes, heat to 95° C. while stirring, and keep the temperature for 5 minutes to obtain a jelly glue solution.

[0051] (2) Weigh 2.5g of acidity regulator (wherein chelate salt KCl is 0.5g, citric acid is 2g) and dissolve with a small amount of warm water (45-55°C) to obtain an acid solution.

[0052] (3) Weigh 0.3g of microalgae DHA powder (the DHA content is 7% by mass, the same as in the following examples) and 0.05g of compound antioxidants (L-ascorbyl palmitate, vitamin E and rosemary extract by mass) The ratio of 20:5:2, the same in the following examples) is uniform, and dissolv...

Embodiment 2

[0058] (1) Mix 120g white granulated sugar, 3.5g hydrophilic colloid (wherein refined carrageenan is 2g, konjac mannan is 1.35g, and xanthan gum is 0.15g) and 0.35g potassium sorbate, and then add 750g temperature Water at 20-25° C., stir evenly, let stand for 30 minutes, heat to 95° C. while stirring, and keep the temperature for 5 minutes to obtain a jelly glue solution.

[0059] (2) Weigh 3g of acidity regulator (wherein chelate salt KCl is 0.8g, citric acid is 2.2g), dissolve with a small amount of warm water (45-55°C) to obtain an acid solution.

[0060] (3) Weigh 1 g of microalgae DHA powder and mix with 0.08 g of compound antioxidant, and dissolve with a small amount of warm water (45-55 °C).

[0061] (4) When the jelly glue solution is naturally lowered to 75°C, add the acid solution obtained in step (2), the solution obtained in step (3) and 2 g of orange essence, and stir evenly, the pH value is 3.7-4, and the solution is heated with heat. The weight of boiling wate...

Embodiment 3

[0066] (1) Mix 150g white granulated sugar, 5g hydrophilic colloid (wherein refined carrageenan is 2.8g, konjac mannan is 2g, and xanthan gum is 0.2g) and 0.5g potassium sorbate, and then add 750g and the temperature is Water at a temperature of 20-25° C., stir evenly, stand for 30 minutes, heat to 95° C. while stirring, and keep the temperature for 5 minutes to obtain a jelly glue solution.

[0067] (2) Weigh 5g of acidity regulator (wherein chelate salt KCl is 1g, citric acid is 4g), dissolve with a small amount of warm water (45~55℃) to obtain acid solution.

[0068] (3) Weigh 1.5g of microalgae DHA powder and mix with 0.12g of compound antioxidant, and dissolve with a small amount of warm water (45~55℃).

[0069] (4) When the jelly glue solution is naturally lowered to 75°C, add the acid solution obtained in step (2), the solution obtained in step (3) and 3 g of orange essence, and stir evenly, the pH value is 3.7-4, and the The weight of boiling water is fixed to 1000g t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com