Quantum dot LED package structure and packaging method

A technology of LED encapsulation and encapsulation method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low luminous efficiency and short life of quantum dot LEDs, solve the problems of water and oxygen isolation and heat insulation, and improve stability Sexuality and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

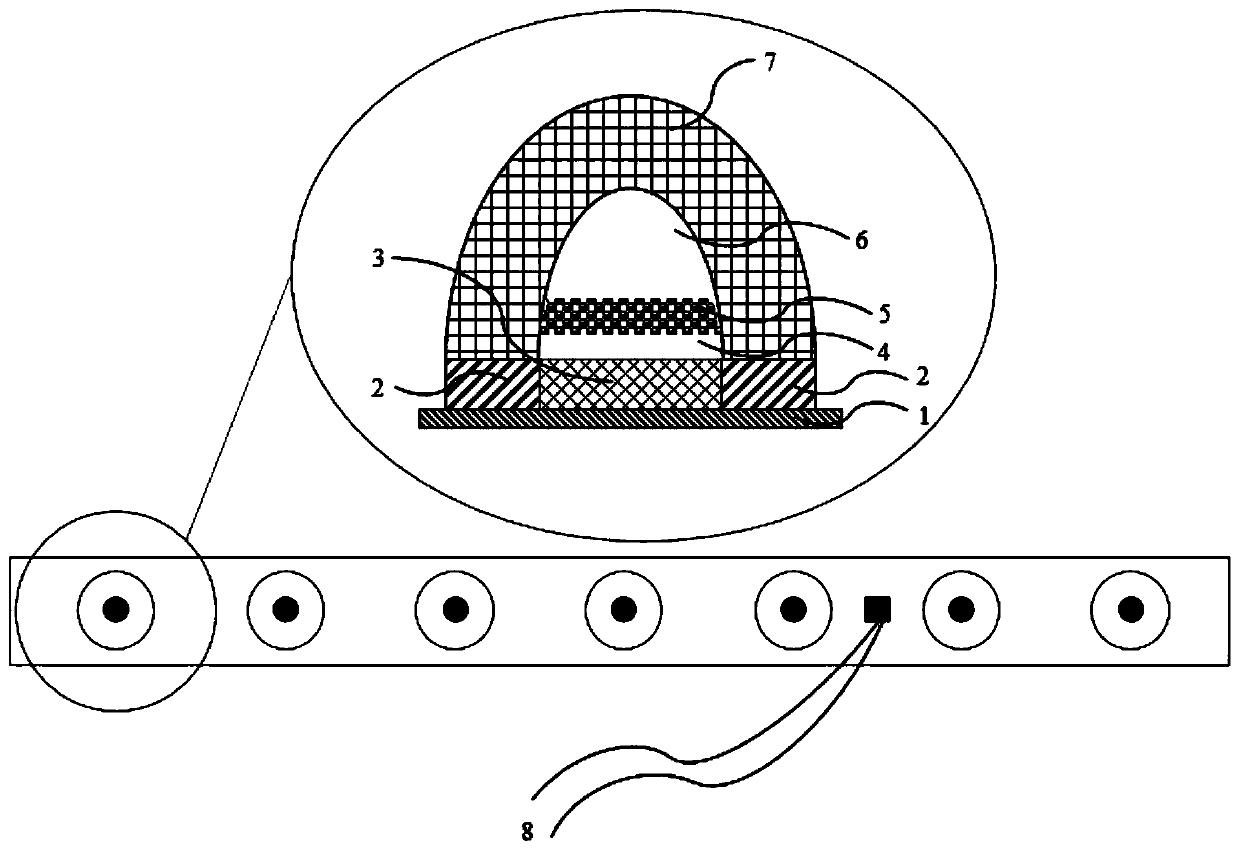

[0051] Such as figure 1 As shown, the present embodiment provides a quantum dot LED package structure, the package structure comprising:

[0052] Blue LED chip (3);

[0053] A strip substrate (1) for fixing the blue LED chip (3);

[0054] connecting the blue LED chip (3) and the electrode (2) of the strip substrate (1);

[0055] Curing the AB glue heat insulation layer (4) on the upper surface of the blue LED chip (3);

[0056] Curing the quantum dot layer (5) on the upper surface of the AB glue heat insulation layer (4);

[0057] Curing the AB glue protective layer (6) on the upper surface of the quantum dot layer (5);

[0058] Cover the blue LED chip (3), electrode (2), AB glue heat insulation layer (4), quantum dot layer (5) and AB glue protective layer (6) and align the above components with the strip substrate (1) A sealed PMMA lens encapsulation layer (7);

[0059]A common electrode (8) arranged on the strip substrate (1) and connecting each blue LED chip (3) in se...

Embodiment 2

[0064] This embodiment provides a packaging method for a quantum dot LED packaging structure, the flow chart of the method is as follows Figure 4 shown, including the following steps:

[0065] S1, fixing the blue LED chip (3) on the strip substrate (1);

[0066] S2. Connect the electrode (2) of each blue LED chip (3) to the strip substrate (1);

[0067] S3, inject AB glue into PMMA lens groove bottom and solidify, form AB glue protective layer (6);

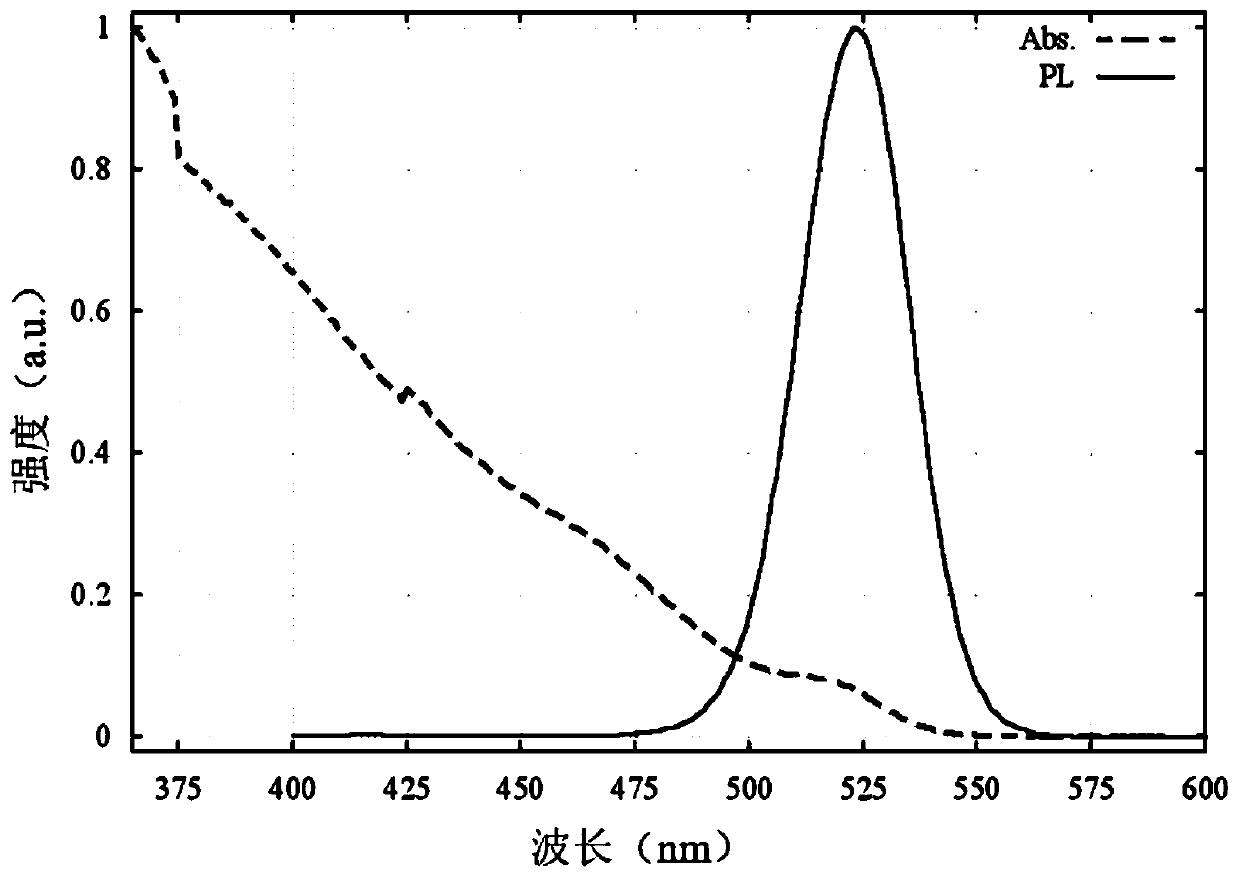

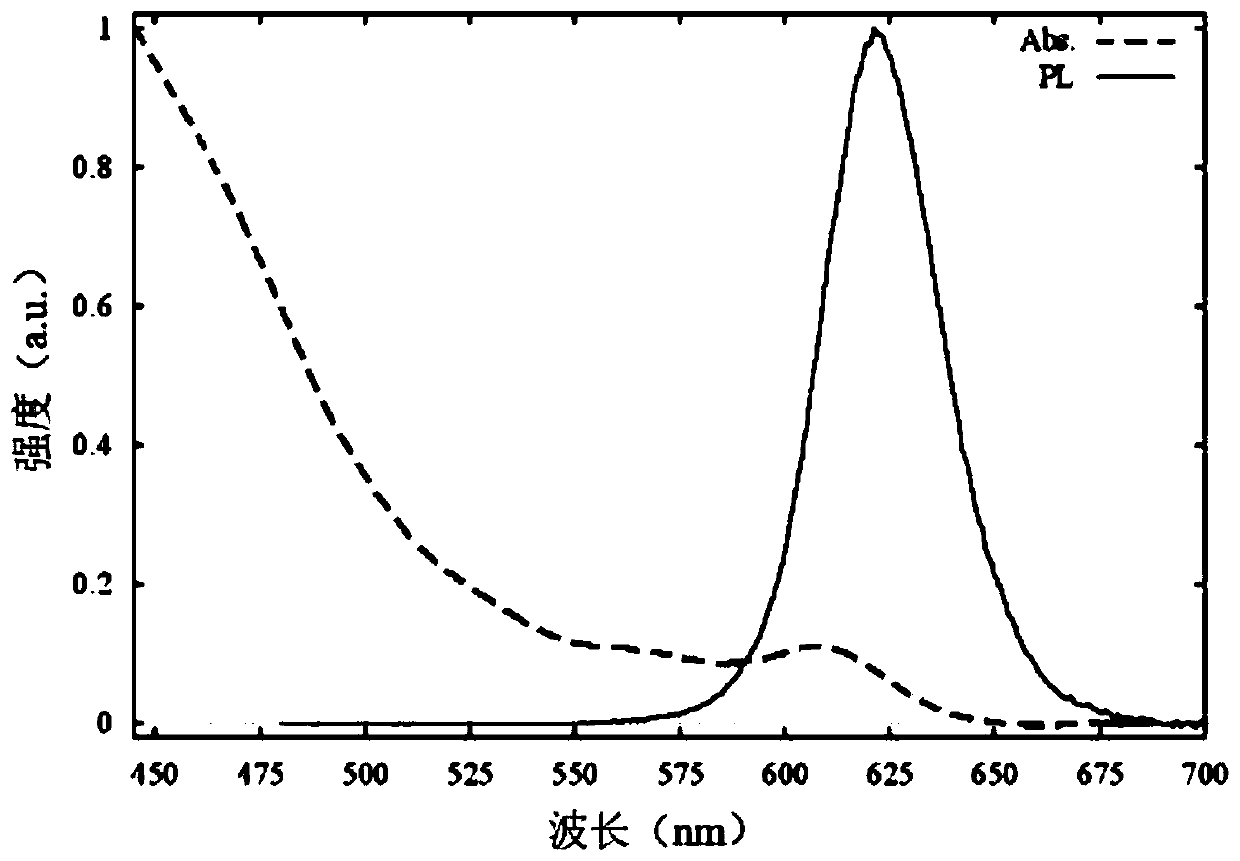

[0068] S4, continue to inject the AB glue that is mixed with CdSe red and green photon quantum dots in PMMA lens groove and solidify, form quantum dot layer (5);

[0069] S5, continue to fill with AB glue in PMMA lens groove and solidify, form AB glue insulation layer (4);

[0070] S6. Apply UV glue to the edge of the filled PMMA lens and fix it directly above the blue LED chip (3) and then cure, and connect each blue LED chip (3) in series through the common electrode (8) to complete the quantum dot LED packaging structure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com