Energy-saving and environmental composite door and window profile and production method thereof

A door and window profile, energy-saving and environmental protection technology, applied in the field of building materials, can solve the problems of low strength, poor thermal insulation effect, heat-resistant environmental protection effect, etc., and achieve the effects of high strength, elimination of peculiar smell, and non-toxic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

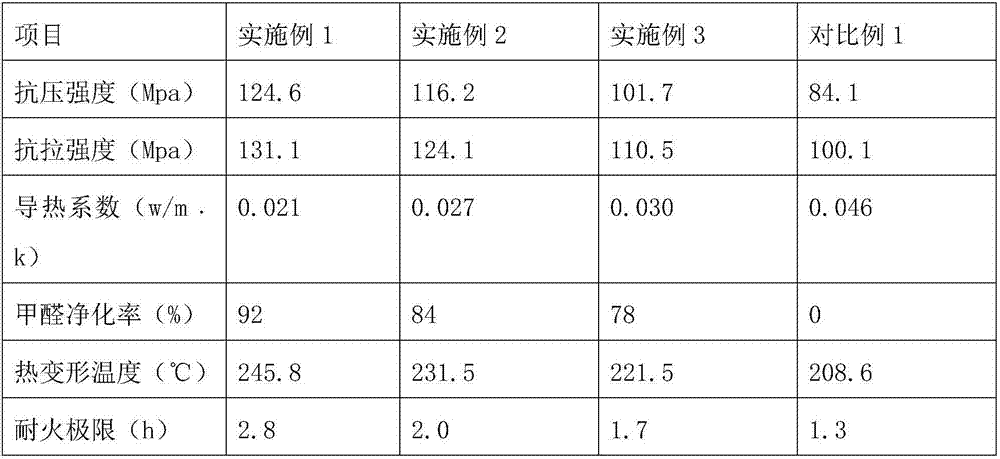

Examples

Embodiment 1

[0037] An energy-saving and environment-friendly composite door and window profile, comprising the following raw materials in parts by weight: 55 parts of vinyl resin, 40 parts of halogenated unsaturated polyester, 29 parts of glass fiber felt, 22 parts of metal fiber, 15 parts of ceramic fiber, and 18 parts of bamboo charcoal powder , 13 parts of nano titanium dioxide, 29 parts of airgel, 18 parts of phenolic foam, 13 parts of polyamide fiber, 0.4 part of flame retardant, 0.4 part of coupling agent, 0.5 part of antioxidant and 0.3 part of flow modifier.

[0038] Metal fiber is added to the raw material, and the metal fiber has the characteristics of good elasticity, wear resistance and high temperature resistance.

[0039] Ceramic fiber is added to the raw material. Ceramic fiber is a fibrous lightweight refractory material with the characteristics of light weight, high temperature resistance and low thermal conductivity.

[0040] Bamboo charcoal is added to the raw materials...

Embodiment 2

[0054] An energy-saving and environment-friendly composite door and window profile, comprising the following raw materials in parts by weight: 50 parts of vinyl resin, 35 parts of halogenated unsaturated polyester, 22 parts of glass fiber felt, 13 parts of metal fiber, 12 parts of ceramic fiber, and 15 parts of bamboo charcoal powder , 9 parts of nano titanium dioxide, 23 parts of airgel, 13 parts of phenolic foam, 11 parts of polyamide fiber, 0.2 part of flame retardant, 0.3 part of coupling agent, 0.3 part of antioxidant and 0.2 part of flow modifier.

[0055] Metal fiber is added to the raw material, and the metal fiber has the characteristics of good elasticity, wear resistance and high temperature resistance.

[0056] Ceramic fiber is added to the raw material. Ceramic fiber is a fibrous lightweight refractory material with the characteristics of light weight, high temperature resistance and low thermal conductivity.

[0057] Bamboo charcoal is added to the raw materials....

Embodiment 3

[0071] An energy-saving and environment-friendly composite door and window profile, comprising the following raw materials in parts by weight: 60 parts of vinyl resin, 45 parts of halogenated unsaturated polyester, 36 parts of glass fiber felt, 31 parts of metal fiber, 18 parts of ceramic fiber, and 21 parts of bamboo charcoal powder , 17 parts of nano titanium dioxide, 35 parts of airgel, 23 parts of phenolic foam, 15 parts of polyamide fiber, 0.6 part of flame retardant, 0.5 part of coupling agent, 0.7 part of antioxidant and 0.4 part of flow modifier.

[0072] Metal fiber is added to the raw material, and the metal fiber has the characteristics of good elasticity, wear resistance and high temperature resistance.

[0073] Ceramic fiber is added to the raw material. Ceramic fiber is a fibrous lightweight refractory material with the characteristics of light weight, high temperature resistance and low thermal conductivity.

[0074] Bamboo charcoal is added to the raw materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com