Hybrid asphalt shield pavement protection seal material and preparation method thereof

It is a hybrid and drain-shielding technology, which is applied in the field of waterproof and anti-skid protective seals. It can solve the problems of durability, economy, and construction convenience, which are difficult to obtain a better balance point, and achieve performance improvement and durable adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The preparation method of the above-mentioned hybrid asphalt shield pavement protective seal material adopts firstly injecting epoxy resin, reactive diluent, non-reactive diluent, coupling agent, and color paste into the Lekshield A mixing tank, and stirring for 5 minutes to form asphalt Shield A liquid material; then inject the curing agent and accelerator into the Lidun B mixing tank, and stir for 5 minutes to form the Lidun B liquid material. Half an hour before construction, mix and stir the quartz sand with Lidun A liquid material and Lidun B liquid material respectively to form Lidun A and Lidun B.

[0069] Specifically include the following steps:

[0070]Step 1: Weigh 50-60 parts of epoxy resin, 2-4 parts of reactive diluent, 1-3 parts of non-reactive diluent, 1-3 parts of coupling agent, 1-2 parts of color paste, and pour them into the mixing tank , after stirring for 5 minutes, prepare Lidun A liquid material;

[0071] Step 2: Weigh 5-60 parts of curing agen...

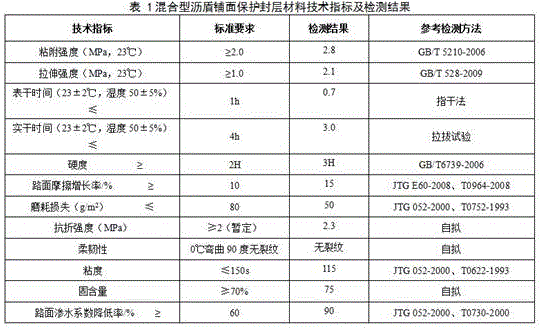

Embodiment 1

[0075] Prepare Lidun A and Lidun B with 40% sand content:

[0076] The preparation of protective seal material Lek Shield A and Lek Shield B according to the present invention is calculated as 100 parts according to the total weight of Lek Shield A and Lek Shield B:

[0077] The ratio of Lidun A is:

[0078] Lidun A liquid material 60 parts

[0079] Quartz sand 40 parts

[0080] The ratio of Lidun B is:

[0081] Lidun B liquid material 60 parts

[0082] Quartz sand 40 parts

[0083] The preparation method is:

[0084] The preparation method of the present invention is to firstly weigh epoxy resin, reactive diluent, non-reactive diluent, coupling agent, and color paste according to the proportioning ratio; secondly, dilute the weighed epoxy resin and reactive diluent Adding agent, non-reactive diluent, coupling agent, and color paste are injected into the special mixing tank, and after stirring for 5 minutes, the Lidun A liquid material is prepared; thirdly, the weighed c...

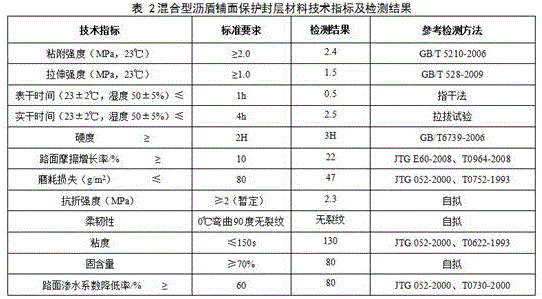

Embodiment 2

[0089] Prepare Lidun A and Lidun B with 50% sand content:

[0090] The preparation of protective seal material Lek Shield A and Lek Shield B according to the present invention is calculated as 100 parts according to the total weight of Lek Shield A and Lek Shield B:

[0091] The ratio of Lidun A is:

[0092] Lidun A liquid material 50 parts

[0093] Quartz sand 50 parts

[0094] The ratio of Lidun B is:

[0095] Lidun B liquid material 50 parts

[0096] Quartz sand 50 parts

[0097] The preparation method is:

[0098] The preparation method of the present invention is to firstly weigh epoxy resin, reactive diluent, non-reactive diluent, coupling agent and color paste respectively according to the proportion; secondly, dilute the weighed epoxy resin and reactive diluent Adding agent, non-reactive diluent, coupling agent, and color paste are poured into the special mixing tank, and after stirring for 5 minutes, the Lidun A liquid material is prepared; thirdly, the weighed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com