A kind of preparation method of mofs-derived nio electrode material

A technology of electrode material and deionized water, which is applied in the field of preparation of NiO electrode materials, can solve the problems of small amount of prepared samples and easy agglomeration, and achieve the effect of overcoming small amount of samples, low equipment requirements, and high rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

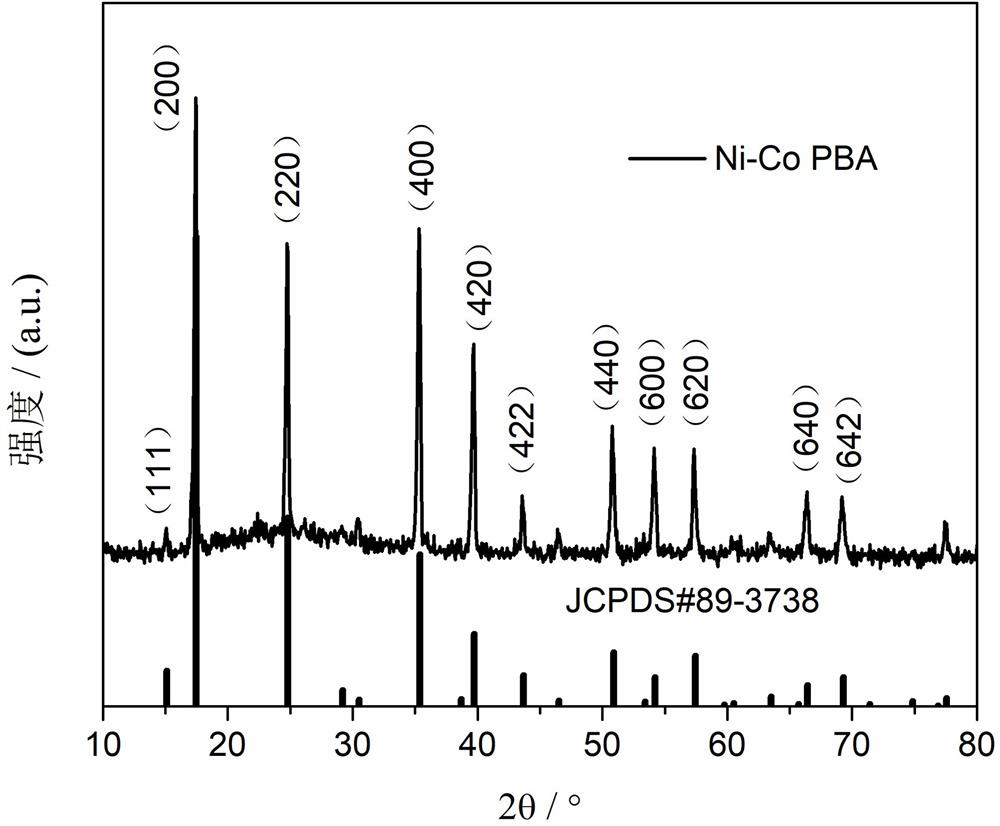

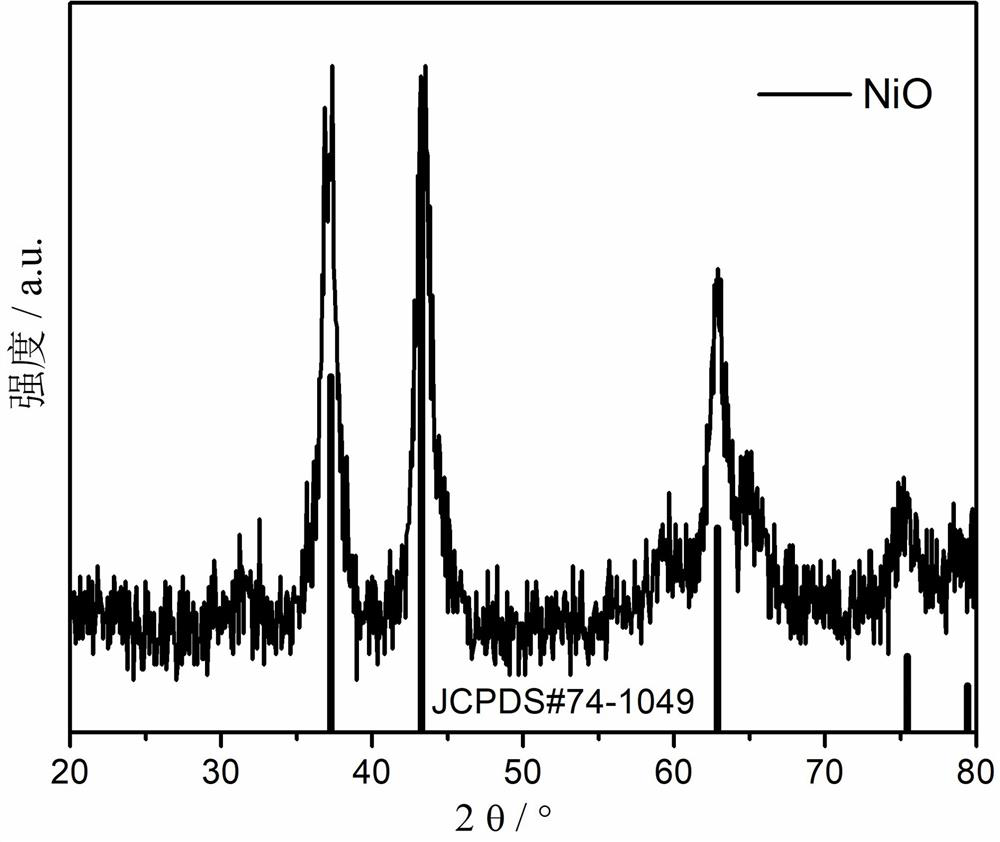

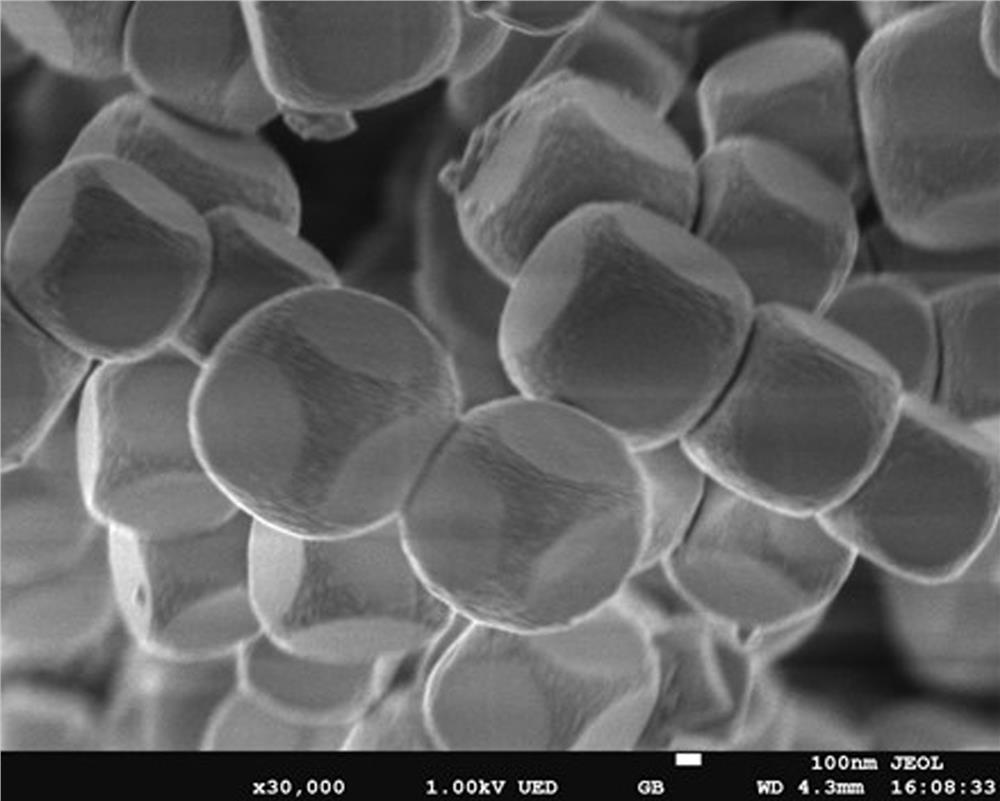

[0032] A preparation method of MOFs-derived NiO electrode material, the method is realized by the following steps:

[0033] S1: Preparation of solution A: First, dissolve 2.4 mmol of nickel nitrate hexahydrate in 80 mL of deionized water, and stir evenly with magnetic force; This obtains solution A;

[0034] S2: Preparation of solution B: Weigh 1.6 mmol of potassium cobalt cyanide and dissolve it in 80 mL of deionized water, and stir uniformly with magnetic force to obtain solution B;

[0035] S3: Preparation of Precipitate C: Pour solution B into solution A and stir magnetically for 25min; after stirring, let stand for 30h to collect blue-white precipitate C;

[0036] S4: Washing of Precipitate C: First, wash Precipitate C with deionized water three times, then wash Precipitate C three times with absolute ethanol, and then centrifuge at a speed of 6000 rpm for 8 min to obtain Washed Precipitate C;

[0037] S5: Drying: The washed precipitate C was placed in a 60°C oven to dr...

Embodiment 2

[0046] A preparation method of MOFs-derived NiO electrode material, the method is realized by the following steps:

[0047] S1: Preparation of solution A: First, take 4.5 mmol of nickel nitrate hexahydrate and dissolve it in 75 mL of deionized water, and stir evenly with magnetic force; This obtains solution A;

[0048] S2: Preparation of solution B: Weigh 3.0 mmol of potassium cobalt cyanide and dissolve it in 75 mL of deionized water, and stir uniformly with magnetic force to obtain solution B;

[0049] S3: Preparation of Precipitate C: Pour solution B into solution A, stir magnetically for 10min; after stirring, let stand for 12h to collect blue-white precipitate C;

[0050] S4: Washing of Precipitate C: First, wash Precipitate C with deionized water for six times, then wash Precipitate C with absolute ethanol for six times, and then centrifuge at 8000 rpm for 5 min to obtain washed Precipitate C ;

[0051] S5: drying: the washed precipitate C is placed in a 40°C oven to...

Embodiment 3

[0054] A preparation method of MOFs-derived NiO electrode material, the method is realized by the following steps:

[0055] S1: Preparation of solution A: First, take 3.0 mmol of nickel nitrate hexahydrate and dissolve it in 120 mL of deionized water, and stir evenly with magnetic force; This obtains solution A;

[0056] S2: Preparation of solution B: Weigh 2.0 mmol of potassium cobalt cyanide and dissolve it in 120 mL of deionized water, and stir uniformly with magnetic force to obtain solution B;

[0057] S3: Preparation of Precipitate C: Pour solution B into solution A and stir magnetically for 30min; after stirring, let stand for 36h to collect blue-white precipitate C;

[0058] S4: Washing of Precipitate C: First, wash Precipitate C with deionized water four times, then wash Precipitate C with absolute ethanol four times, and then centrifuge at 5000 rpm for 10 min to obtain washed Precipitate C ;

[0059] S5: Drying: The washed precipitate C is placed in an oven at 80°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com