A kind of preparation method of the graphene oxide composite material modified by carboxymethyl chitosan

A technology of carboxymethyl chitosan and composite materials, which is applied in the field of preparation of graphene oxide composite materials, can solve the problems of chitosan application limitations, and achieve the effect of mild experimental conditions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

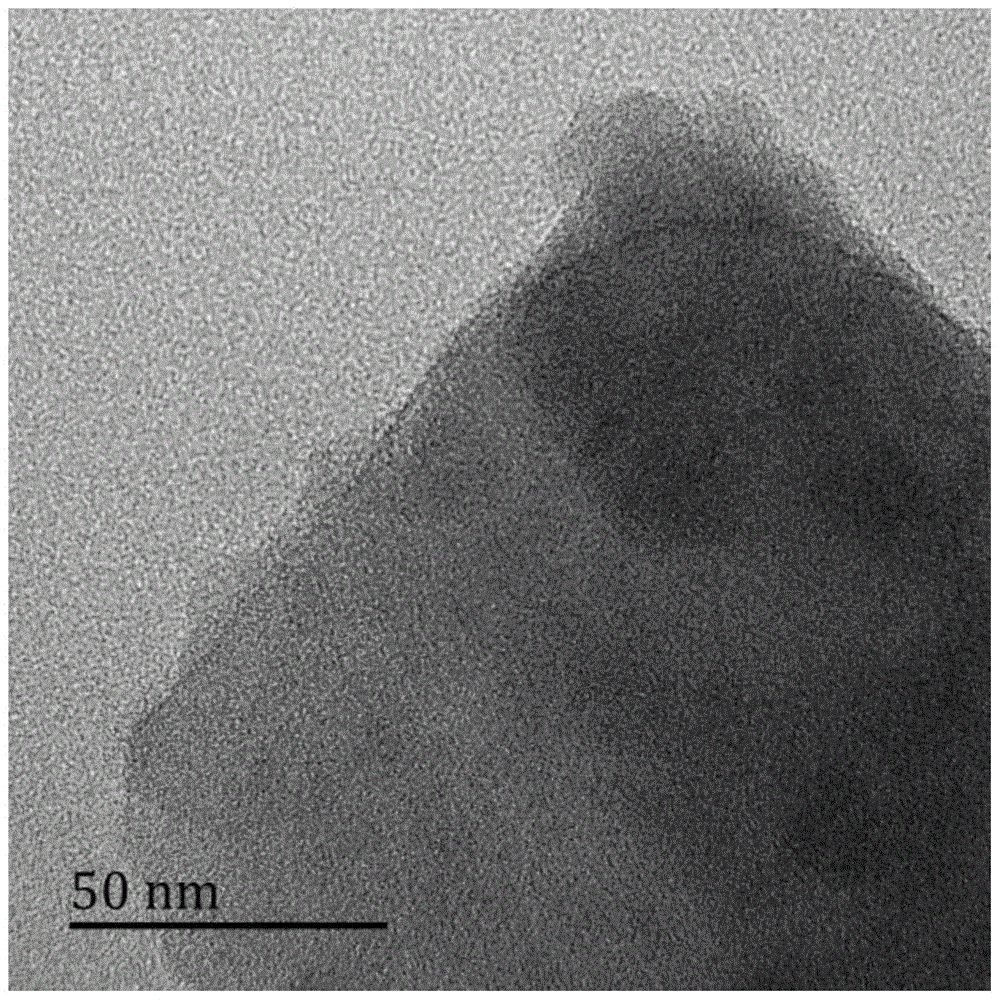

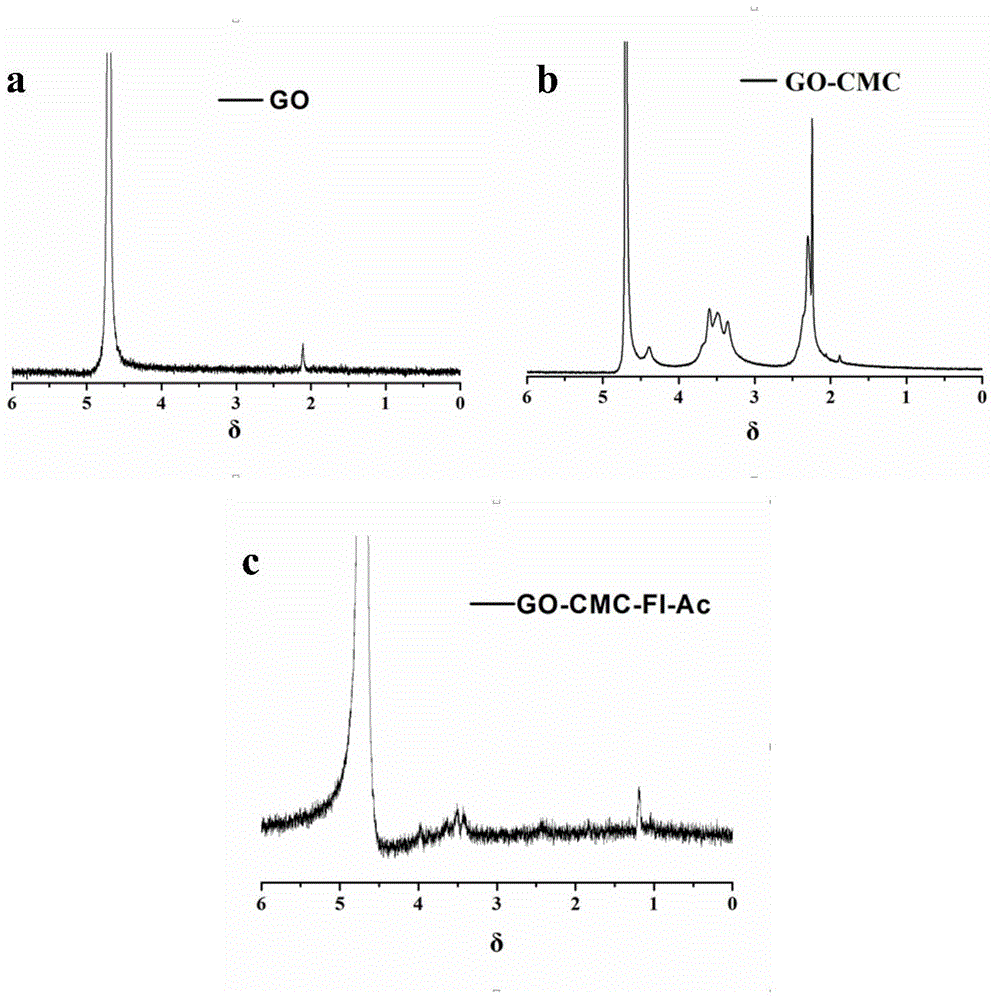

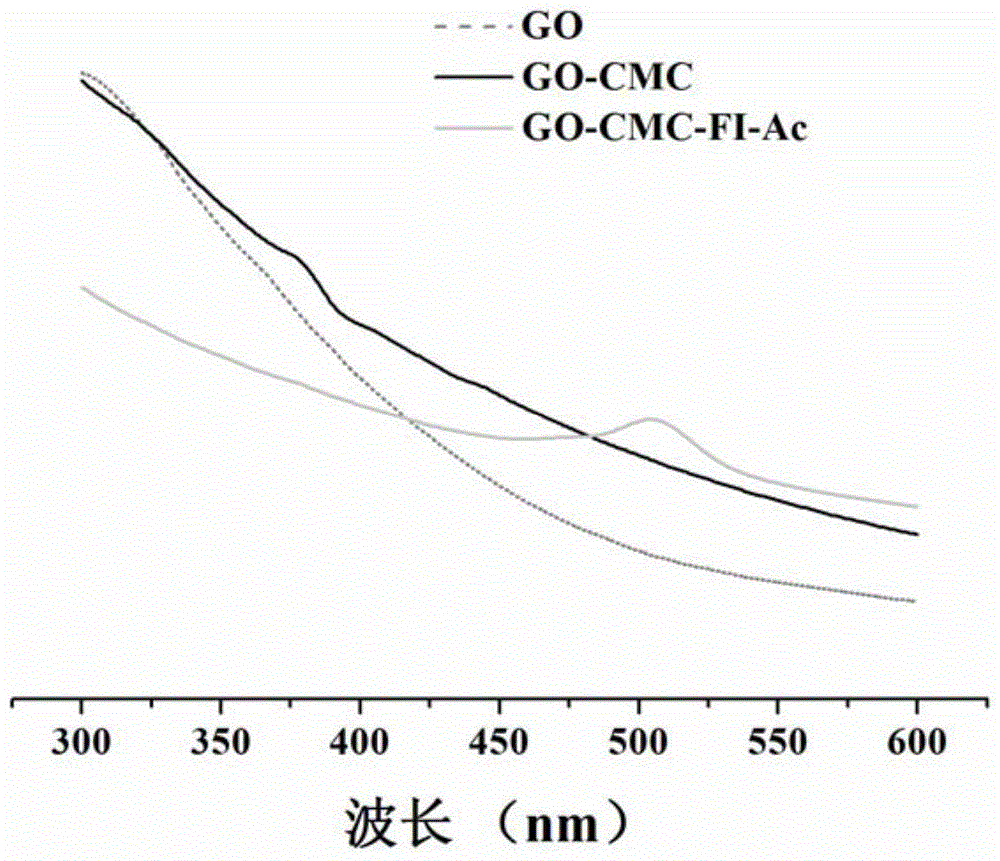

[0026] (1) Graphene oxide GO (50 mg) was dissolved in 10 mL of water, activators EDC (30 mg) and NHS (18 mg) were added, and the reaction was stirred at room temperature for 2 h. During the reaction, 5 mL of an aqueous solution containing CMC (75 mg) was added dropwise, and the reaction was stirred at room temperature for 24 h. After the reaction, the solution was dialyzed with a dialysis bag (MW=100,000). After dialyzing twice with PBS, each volume is 2 L, and then dialyzing with distilled water for 7 times, each volume is 2 L, to remove impurities and by-products in the solution. The obtained product was freeze-dried to synthesize GO-CMC.

[0027] (2) Dissolve 40 mg of GO-CMC from the above product in an appropriate amount of distilled water, add 1.2 mg of fluorescein isothiocyanate FITC in DMSO solution, and stir for 3 h at room temperature.

[0028] (3) Add 360uL of triethylamine to the above product, mix and stir for 30min, add 240uL of acetic anhydride and mix, and rea...

Embodiment 2

[0031] (1) Graphene oxide GO (100 mg) was dissolved in 25 mL of water, and activators EDC (45 mg) and NHS (35 mg) were added, and the reaction was stirred at room temperature for 2 h. During the reaction, 20 mL of an aqueous solution containing CMC (200 mg) was added dropwise, and the reaction was stirred at room temperature for 24 h. After the reaction, the solution was dialyzed with a dialysis bag (MW=100,000). After dialyzing twice with PBS, each volume is 2 L, and then dialyzing with distilled water for 7 times, each volume is 2 L, to remove impurities and by-products in the solution. The obtained product was freeze-dried to synthesize GO-CMC.

[0032] (2) Dissolve 30 mg of GO-CMC from the above product in an appropriate amount of distilled water, add 1 mg of fluorescein isothiocyanate FITC in DMSO solution, and stir for 3 h at room temperature.

[0033] (3) Add 280uL triethylamine to the above product, mix and stir for 20min, add 160uL acetic anhydride and mix, and reac...

Embodiment 3

[0036] (1) Graphene oxide GO (78 mg) was dissolved in 10 mL of water, activators EDC (45 mg) and NHS (40 mg) were added, and the reaction was stirred at room temperature for 2.5 h. During the reaction, 20 mL of an aqueous solution containing CMC (120 mg) was added dropwise, and the reaction was stirred at room temperature for 24 h. After the reaction, the solution was dialyzed with a dialysis bag (MW=100,000). After dialyzing twice with PBS, each volume is 2 L, and then dialyzing with distilled water for 7 times, each volume is 2 L, to remove impurities and by-products in the solution. The obtained product was freeze-dried to synthesize GO-CMC.

[0037] (2) Dissolve 20 mg of GO-CMC from the above product in an appropriate amount of distilled water, add 0.8 mg of fluorescein isothiocyanate FITC in DMSO solution, and stir for 3 h at room temperature.

[0038] (3) Add 200uL triethylamine to the above product, mix and stir for 30min, add 115uL acetic anhydride and mix, and react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com