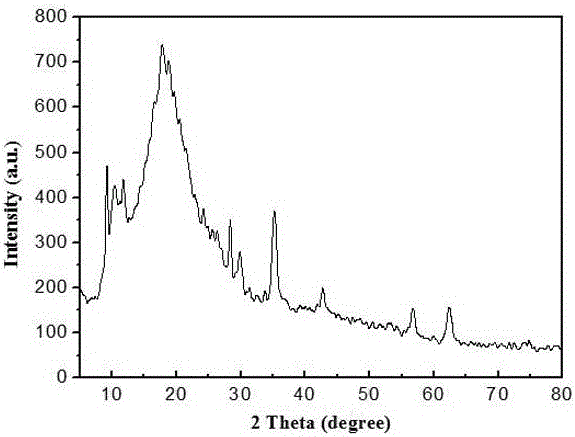

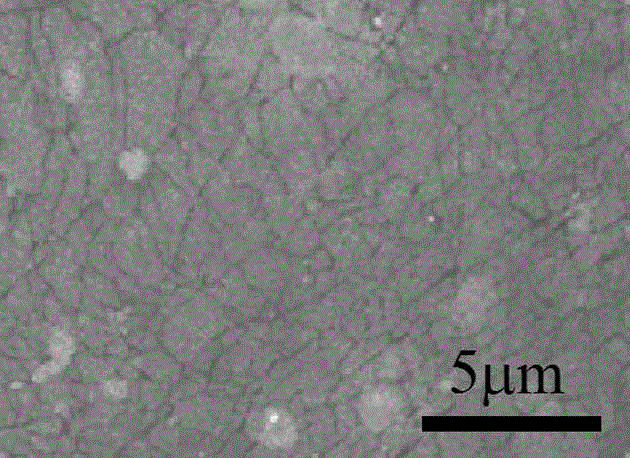

fe 3 o 4 @go/nrMagnetic elastomer composite material and its preparation method

A composite material and elastomer technology, applied in the field of magnetic elastomer composite materials and preparation, can solve the problems of uneven dispersion of magnetic particles, unstable structure and performance, easy aggregation of magnetic particles, etc., to prevent settlement and agglomeration, and improve mechanical mechanics Performance and magnetic properties, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment one: Fe 3 o 4 @GO / NR magnetic elastomer composite preparation method, including the following steps:

[0027] 1) Preparation of stable Fe 3 o 4 water-based magnetic fluid

[0028] 3.6g FeCl 2 4H 2 O and 6.1 g FeCl 3 ·6H 2 O was dissolved in 90mL of deionized water, stirred evenly at 50°C, and then 90mL of NaOH aqueous solution with a concentration of 1.34mol / L was added dropwise under stirring at 500r / min. A black precipitate was obtained by magnetic separation, and the supernatant was removed, then ultrasonically dispersed with deionized water, magnetically separated, and washed repeatedly until the pH of the supernatant was neutral. Then the black magnetic particles were ultrasonically dispersed in a certain volume of deionized water, and mechanically stirred at 200r / min for 10min until a stable Fe concentration of 0.02g / mL was formed. 3 o 4 Water-based magnetic liquid;

[0029] 2) Preparation of completely exfoliated GO suspension

[0030] Unde...

Embodiment 2

[0038] Embodiment two: Fe 3 o 4 @GO / NR magnetic elastomer composite preparation method, including the following steps:

[0039] 1) Preparation of stable Fe 3 o 4 water-based magnetic fluid

[0040] 3.6g FeCl 2 4H 2 O and 6.1 g FeCl 3 ·6H 2 O was dissolved in 90mL of deionized water, stirred evenly at 50°C, and then 90mL of NaOH aqueous solution with a concentration of 1.34mol / L was added dropwise under stirring at 500r / min. A black precipitate was obtained by magnetic separation, and the supernatant was removed, then ultrasonically dispersed with deionized water, magnetically separated, and washed repeatedly until the pH of the supernatant was neutral. Then the black magnetic particles were ultrasonically dispersed in a certain volume of deionized water, and mechanically stirred at 200r / min for 10min until a stable Fe concentration of 0.126g / mL was formed. 3 o 4 Water-based magnetic liquid;

[0041] 2) Preparation of completely exfoliated GO suspension

[0042] Und...

Embodiment 3

[0050] Embodiment three: Fe 3 o 4 @GO / NR magnetic elastomer composite preparation method, including the following steps:

[0051] 1) Preparation of stable Fe 3 o 4 water-based magnetic fluid

[0052] 3.6g FeCl 2 4H 2 O and 6.1 g FeCl 3 ·6H 2 O was dissolved in 90mL of deionized water, stirred evenly at 50°C, and then 90mL of NaOH aqueous solution with a concentration of 1.34mol / L was added dropwise under stirring at 500r / min. A black precipitate was obtained by magnetic separation, and the supernatant was removed, then ultrasonically dispersed with deionized water, magnetically separated, and washed repeatedly until the pH of the supernatant was neutral. Then the black magnetic particles were ultrasonically dispersed in a certain volume of deionized water, and mechanically stirred at 200r / min for 10min until a stable Fe concentration of 0.167g / mL was formed. 3 o 4 Water-based magnetic liquid;

[0053] 2) Preparation of completely exfoliated GO suspension

[0054] U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com