Nanometer onion carbon enhanced titanium-based composite material and preparation method thereof

A titanium-based composite material and composite material technology, which is applied in the field of nano-onion carbon-reinforced titanium-based composite materials and its preparation, can solve the problems of easy entanglement of carbon nanotubes and easy agglomeration of graphene sheets, etc., to overcome poor mechanical properties, The effect of high conversion rate and good comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

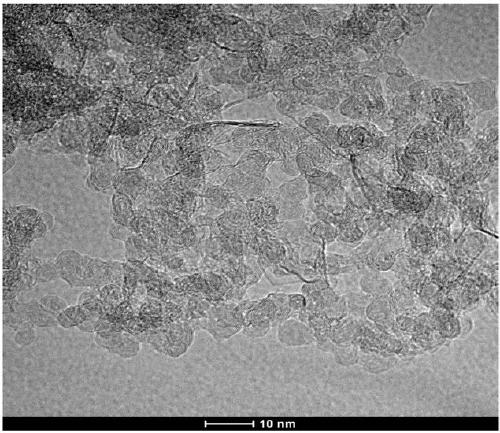

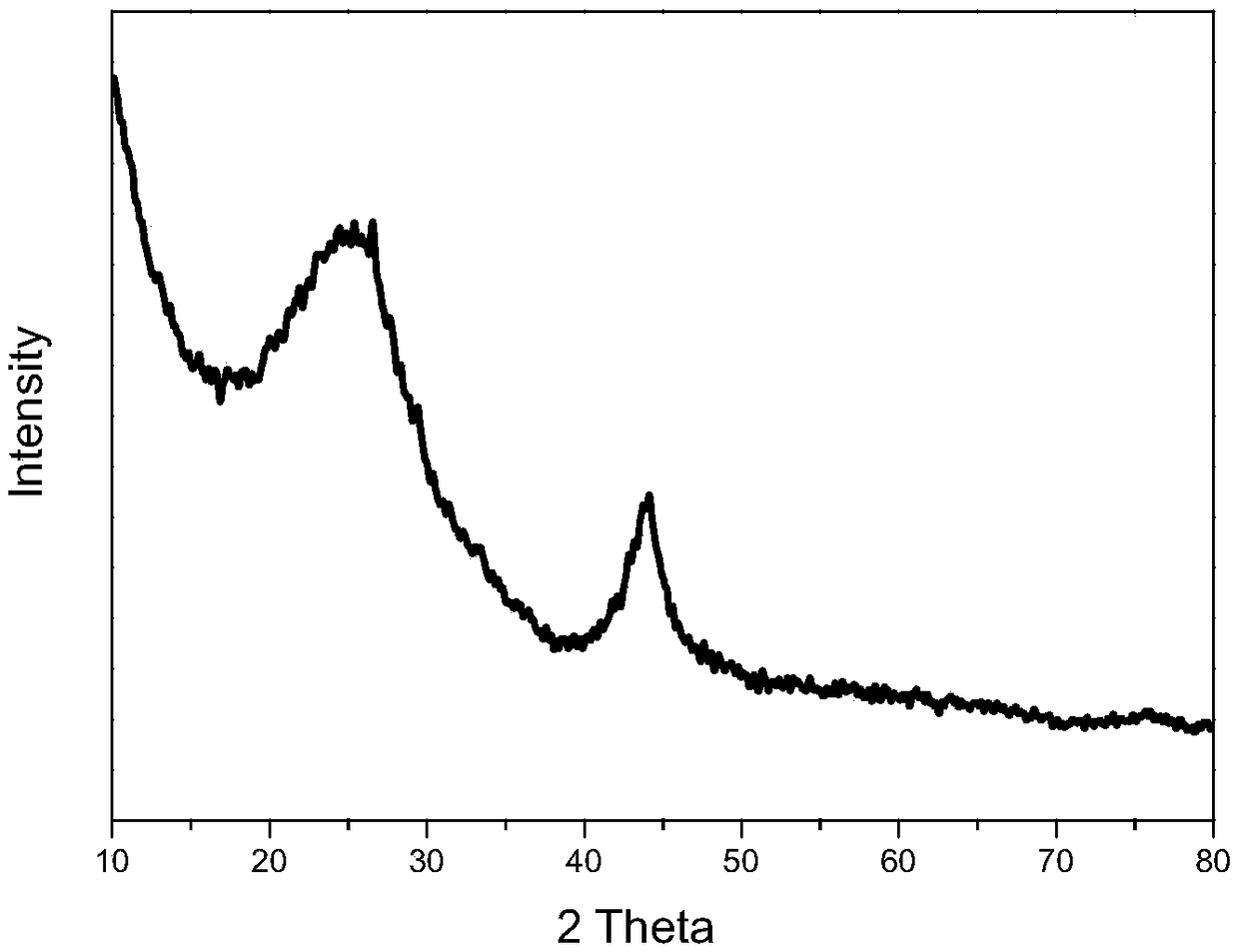

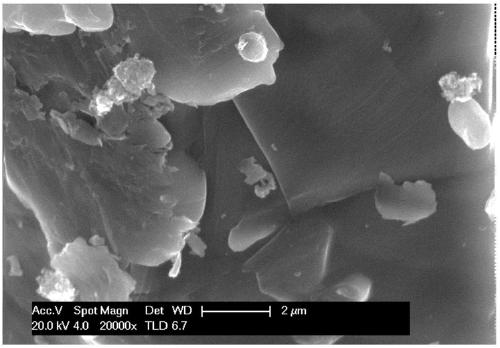

[0043] A preparation method of nano-onion carbon-reinforced titanium-based composite material. First, nano-onion carbon powder (with a size of about 5 nm) is used as a raw material to synthesize nano-onion carbon powder that can be used as a reinforcing phase by discharge plasma sintering; nano-onion carbon powder and pure Titanium powder (purity is 99%) is used as raw material, wherein the grain size of nano-onion carbon is 5-10nm, and the grain size of pure titanium powder is 45μm (325 mesh), which are respectively nano powder and micro powder; the diameter is 20mm A graphite mold made of a cylindrical composite material sintered body with a diameter of 20 mm and a height of 12 mm.

[0044] Specific steps are as follows:

[0045] (1) Weigh 2g (according to the requirements) of nano-diamond powder produced by the blasting method, with an average size of 5nm, and put it into a graphite mold with graphite paper on all sides and on the upper and lower sides to ensure that the up...

Embodiment 2

[0053] A method for preparing a nano-onion carbon reinforced titanium-based composite material. First, nano-onion carbon powder (nano-onion carbon powder) is used as a reinforcing phase by using discharge plasma sintering as a raw material; using nano-onion carbon powder and Ti6Al4V titanium alloy powder (purity is 99%) is raw material, wherein the particle size of nano-onion carbon is 10nm, and the crystallite size of pure titanium powder is 38 μm (400 orders), is nanopowder and micron powder respectively; The graphite mold was used to produce a cylindrical composite material sintered body with a diameter of 20 mm and a height of 12 mm. Specific steps are as follows:

[0054] (1) Weigh 2g (according to requirements) of nano-diamond powder produced by the blasting method, with an average size of 10nm, and put it into a graphite mold with graphite paper on all sides and on the upper and lower sides to ensure that the upper and lower graphite indenters can touch the nano-diamond...

Embodiment 3

[0062] A method for preparing a nano-onion carbon reinforced titanium-based composite material. First, nano-onion carbon powder (nano-onion carbon powder) is used as a reinforcing phase by using discharge plasma sintering as a raw material; nano-onion carbon powder and Titanium-nickel powder is used as raw material, in which the grain size of nano-onion carbon is 20nm, and the grain size of pure titanium powder is 106μm (150 mesh), which are respectively nano-powder and micron-powder; use a graphite mold with a diameter of 30mm to make a diameter of 30mm And a cylindrical composite material sintered body with a height of 10 mm.

[0063] Specific steps are as follows:

[0064] (1) Weigh 2g (according to requirements) of nano-diamond powder produced by the blasting method, with an average size of 20nm, and put it into a graphite mold with graphite paper on all sides and on the upper and lower sides to ensure that the upper and lower graphite indenters can touch the nano-diamond ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com