Patents

Literature

50results about How to "Wrap implementation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-nickel single-crystal ternary cathode material with low surface residual alkali content and preparation method thereof

InactiveCN110436531AIn-situ encapsulationUniform coating in situCell electrodesSecondary cellsLithium hydroxideSingle crystal

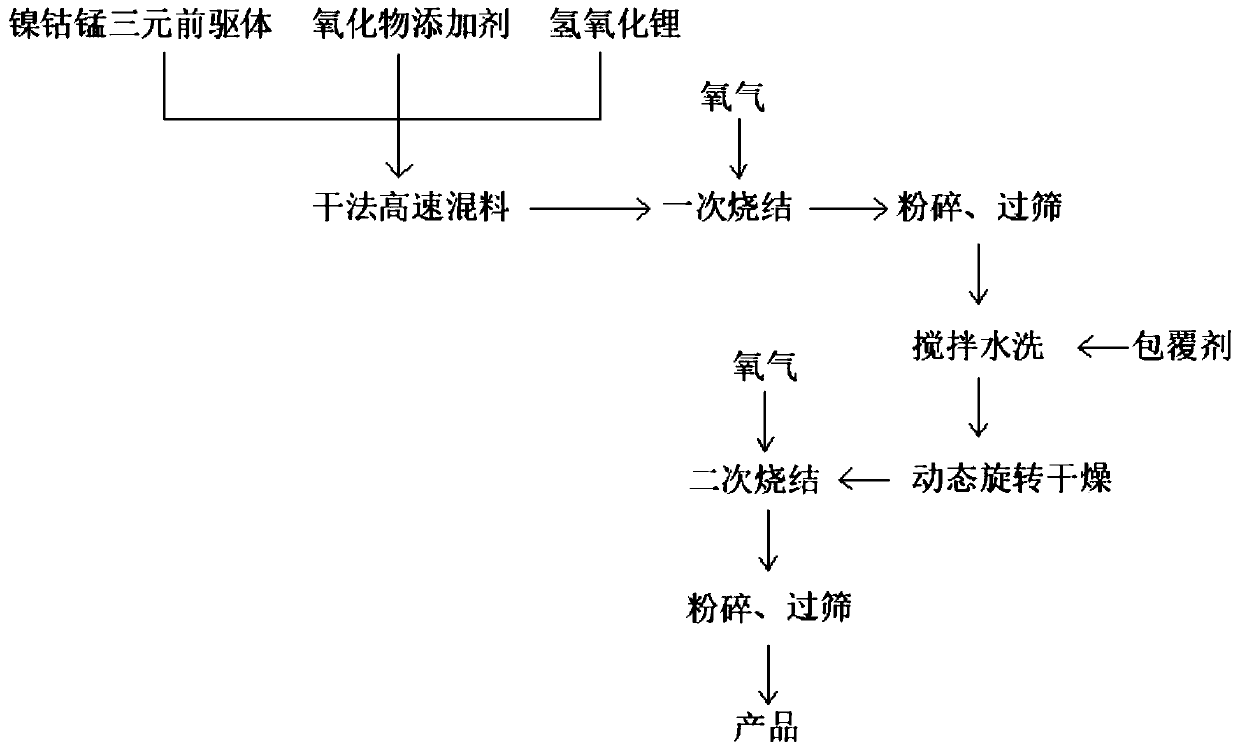

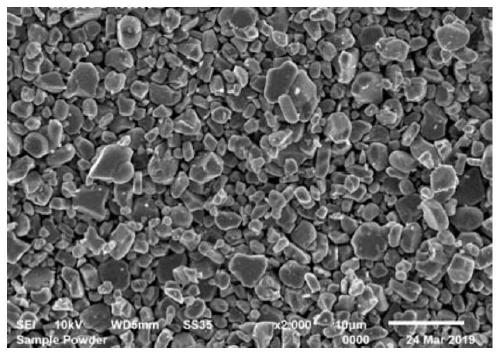

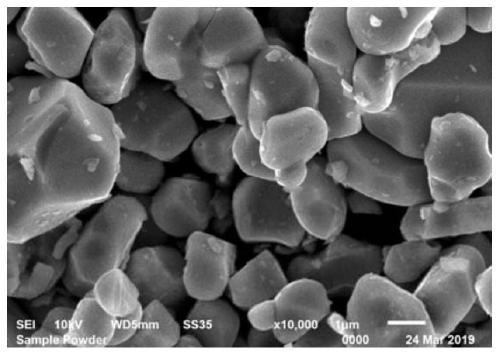

The invention discloses a high-nickel single-crystal ternary cathode material with low surface residual alkali content and a preparation method thereof. The preparation method comprises the followingsteps: weighing lithium hydroxide, an oxide additive and a nickel-cobalt-manganese ternary precursor, and carrying out uniform mixing through a dry high-speed mixing process so as to prepare a mixed material; subjecting the mixed material to first sintering so as to obtain a first sintered material; crushing the first sintered material, and carrying out sieving so as to obtain a first crushed material; weighing the first crushed material, a coating agent and deionized water, and carrying out water washing under stirring so as to prepare a slurry, wherein the coating agent comprises an elementX which is one or more selected from the group consisting of B, Al, Ba, Zr, Mg, Ca, Ti, Si, V, Sc, Nb, Ta and Z; drying the slurry under a vacuum condition through a dynamic rotary drying process so as to obtain a dry material; subjecting the dry material to secondary sintering so as to obtain a secondary sintered material; and crushing the secondary sintered material, and carrying out sieving soas to obtain a product. The high-nickel single-crystal ternary cathode material and the preparation method thereof provided by the invention has the following advantages: alkali reduction by water washing and in-situ coating by a wet process can be synchronously completed; the process is simple; high compaction density is realized; and the content of residual alkali is low.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

Modification method of lithium nickelate, cobaltate and manganate ternary material

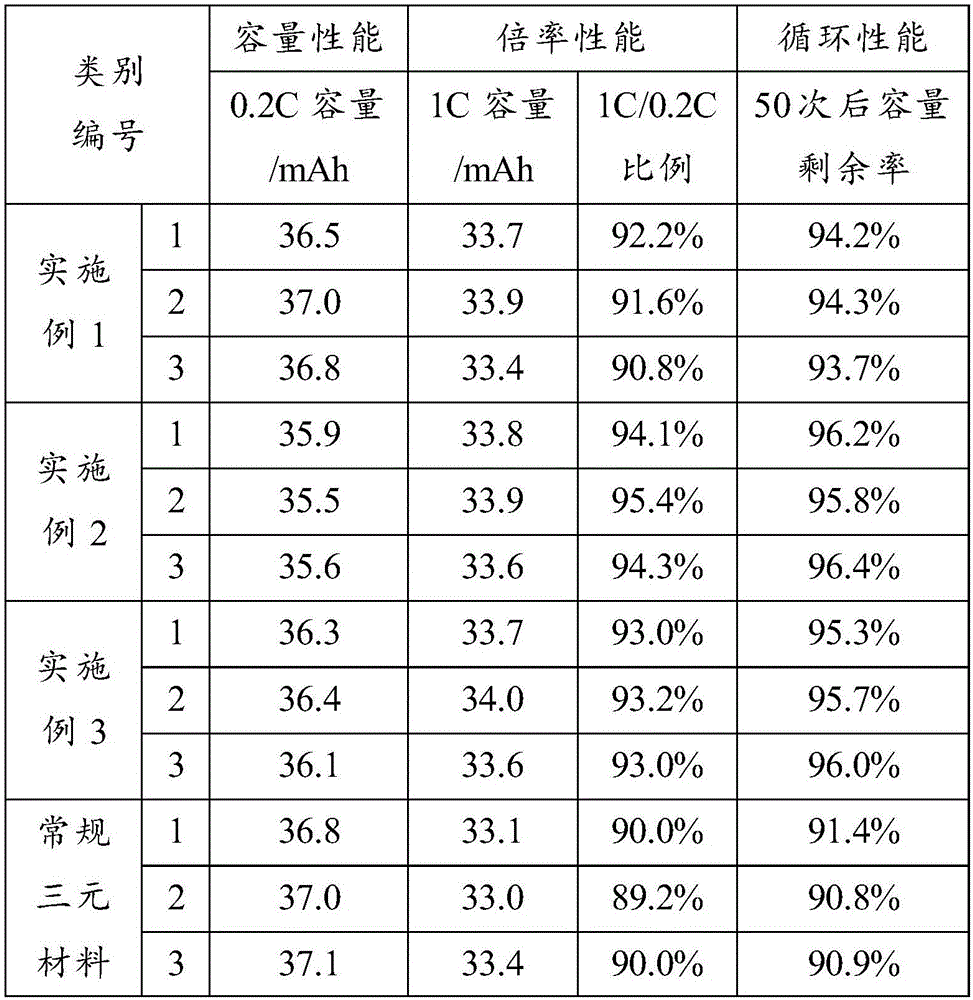

ActiveCN106450217ASimple processReduce shufflingCell electrodesSecondary cellsCarbon coatingCarbon source

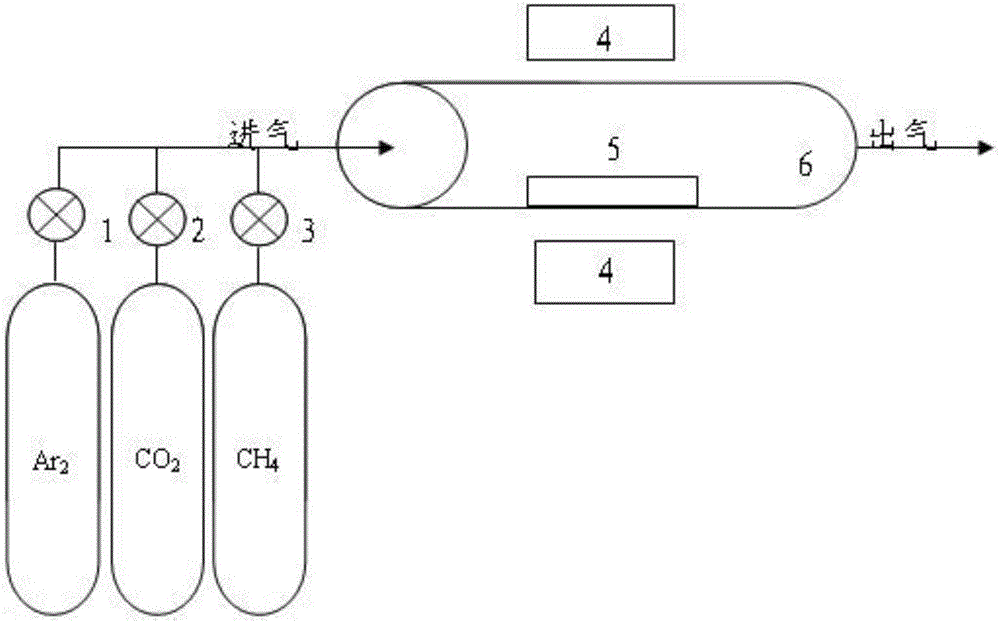

The invention provides a modification method of a lithium nickelate, cobaltate and manganate ternary material. The method comprises the step that after a lithium nickelate, cobaltate and manganate material is subjected to vapor phase deposition under the conditions of carbon source gas and protective gas, a carbon-coated modified lithium nickelate, cobaltate and manganate material is obtained. The modification method provided by the invention has the benefits that carbon deposits on the surface of the lithium nickelate, cobaltate and manganate ternary material through a vapor phase deposition method, so that carbon coating is realized; by adopting simpler processes, with the aid of the protective gas, the ternary material is carbon-coated, so that the problem of lithium nickelate reduction in the coating process of a traditional ternary material is effectively solved, and the coating of a carbon layer on the surface of the ternary material is realized; through the lithium nickelate, cobaltate and manganate ternary material coating carbon, the first-time charging and discharging efficiencies are improved, the lithium ion diffusion coefficients and the electronic conductivity of the material are improved, and the electrochemical performance of the NCM material is improved. According to the modification method provided by the invention, equipment is relatively simple, the process is less, and the structure is controllable; the material has higher battery capacity, cycle performance and rate capability.

Owner:GREE ELECTRIC APPLIANCES INC

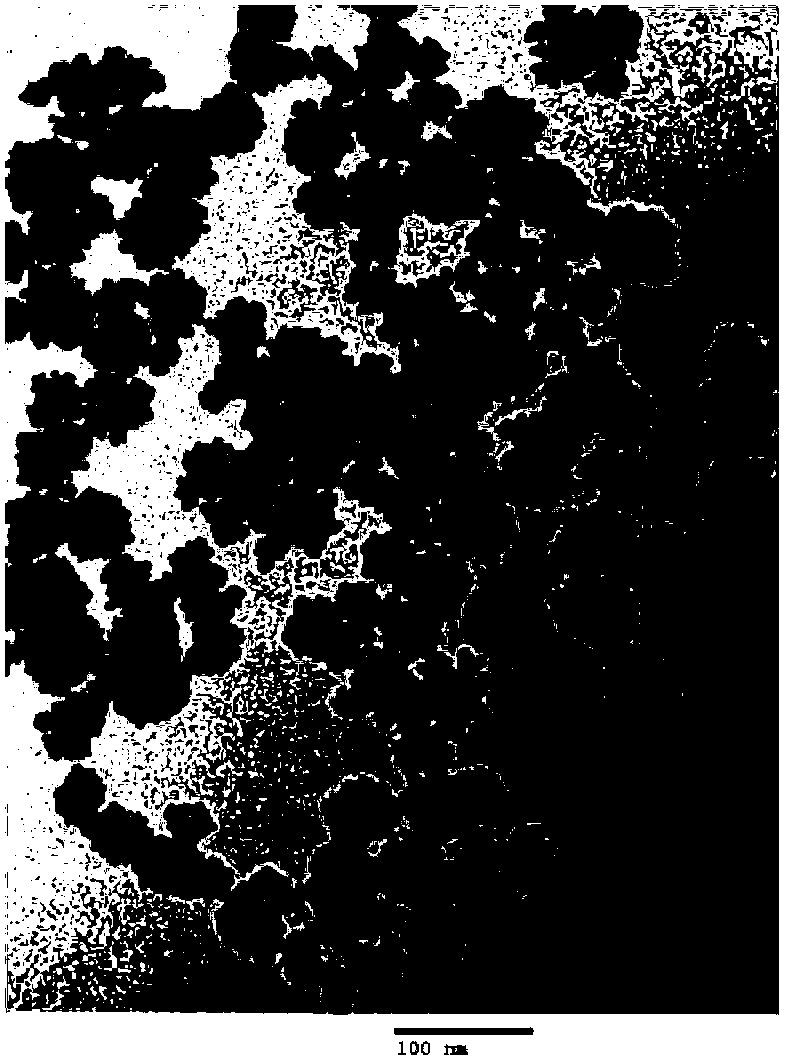

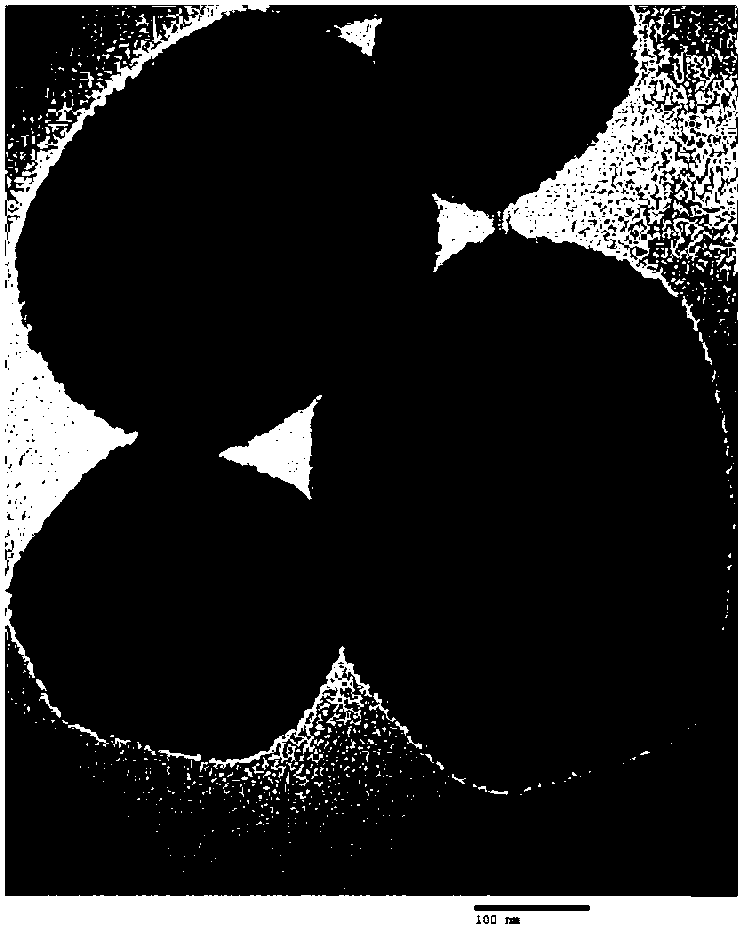

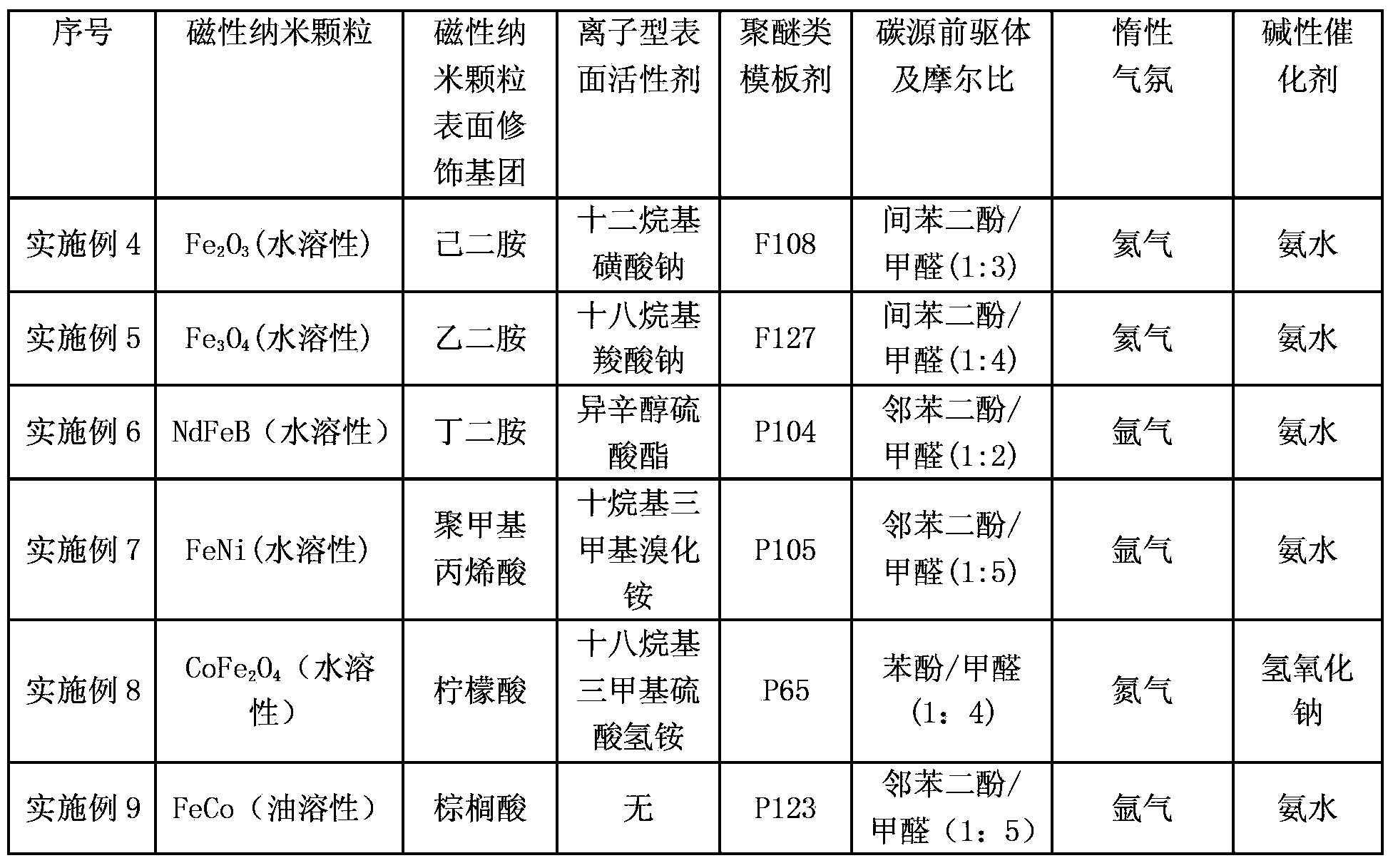

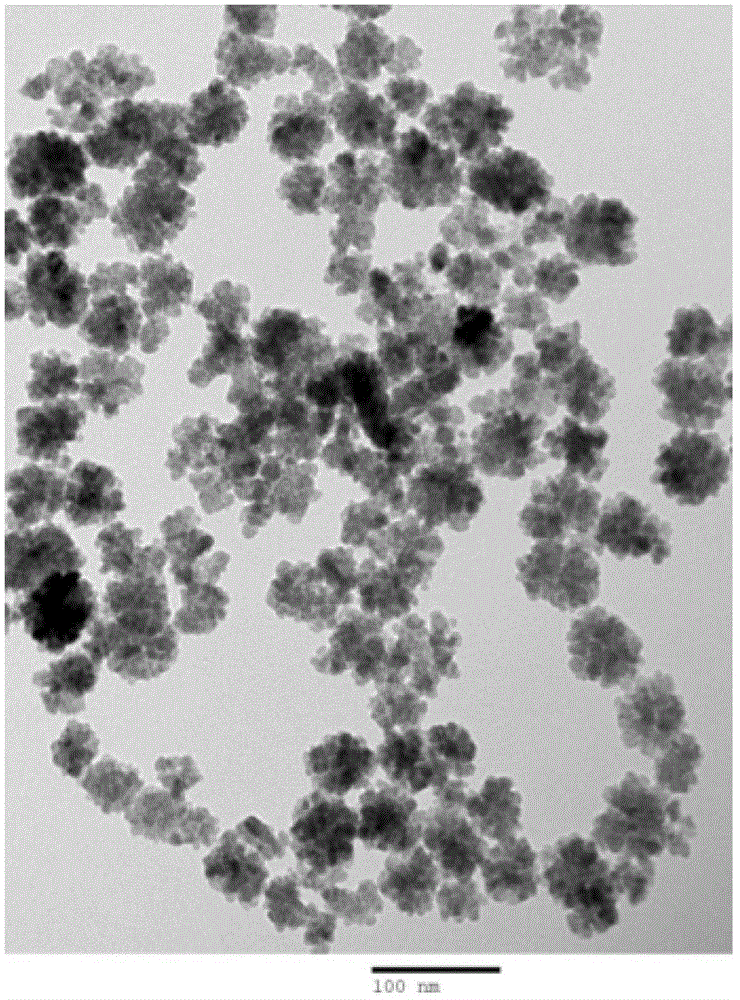

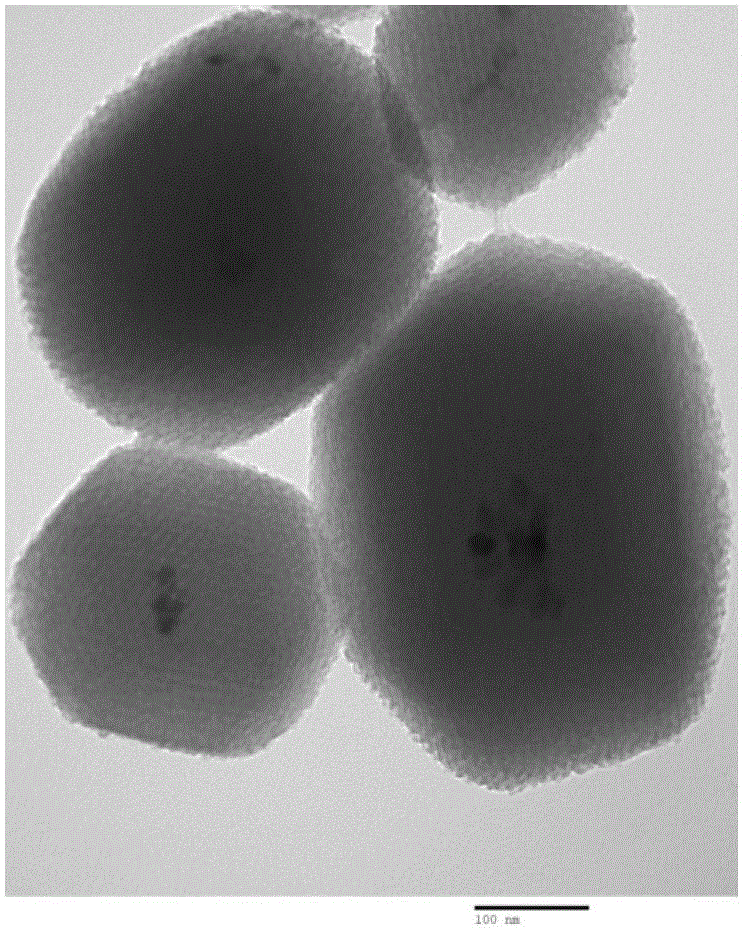

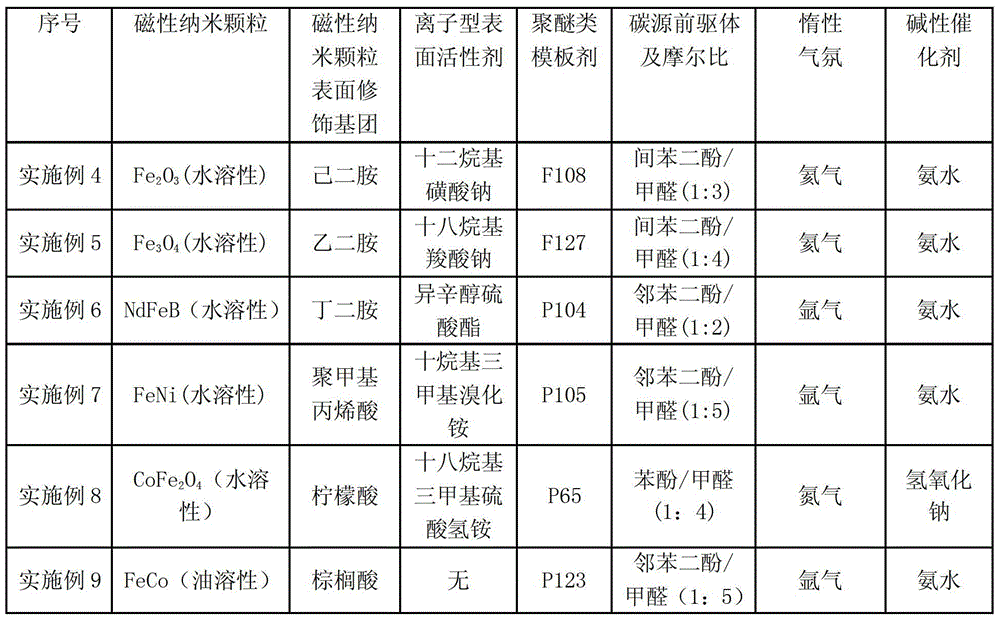

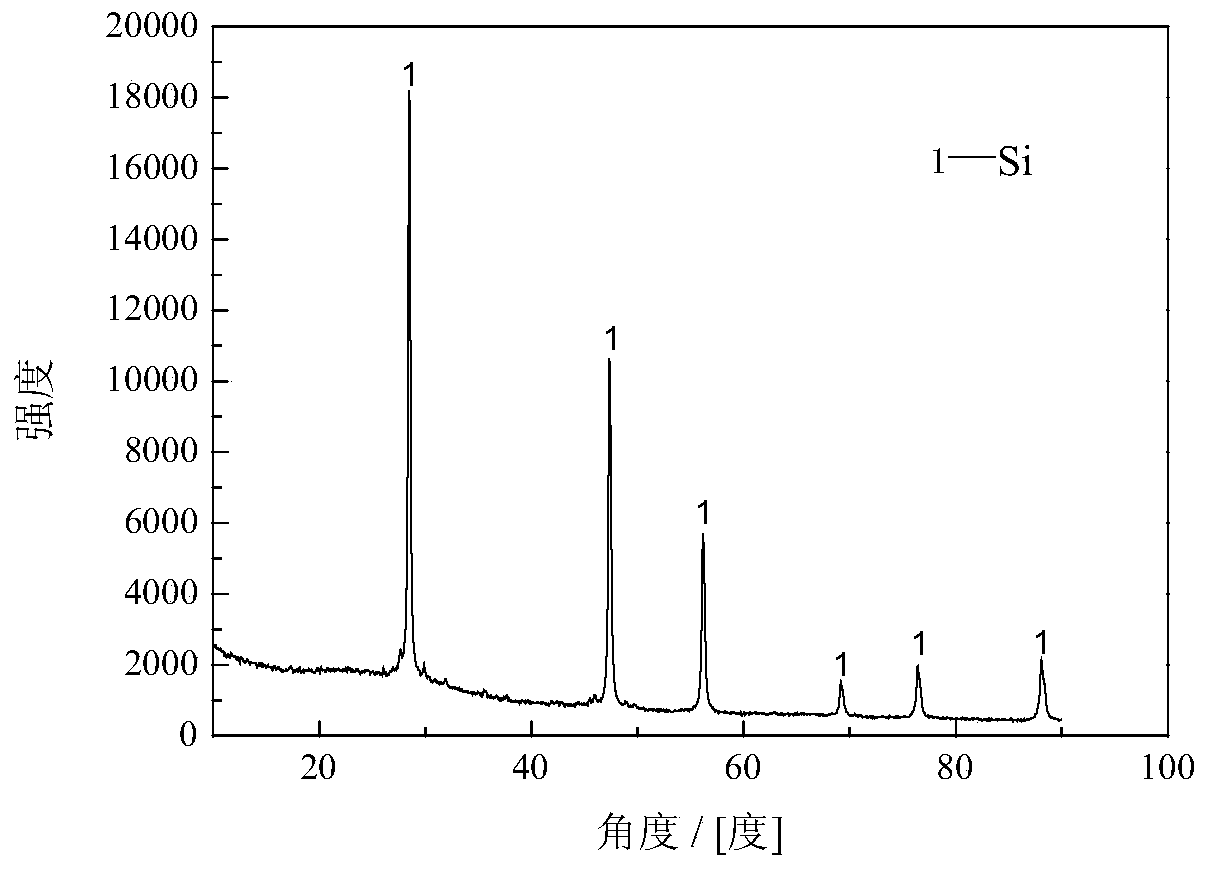

Preparation method for magnetic nanoparticles coated with highly ordered mesoporous carbon

ActiveCN104134504AAvoid exposureSimple preparation stepsMaterial nanotechnologyInorganic material magnetismSelf-assemblyNanometre

The invention relates to a preparation method for magnetic nanoparticles coated with highly ordered mesoporous carbon. The method comprises the following steps of: making the magnetic nanoparticles as an inner core; fully coating the outer layer of the magnetic inner core with an organic template agent by static or hydrophobic interaction; and carbonizing at a high temperature to form the magnetic nanoparticles coated with the channel height ordered mesoporous carbon through self-assembly coating of an organic polymer precursor which can be used for forming mesoporous carbon and the organic template agent on the surface of the magnetic inner core. The magnetic nanoparticles coated with highly ordered mesoporous carbon, which is prepared according to the method, can be applicable for the fields such as bioseparation, medicine transfer, magnetic resonance imaging radiography and catalysis.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

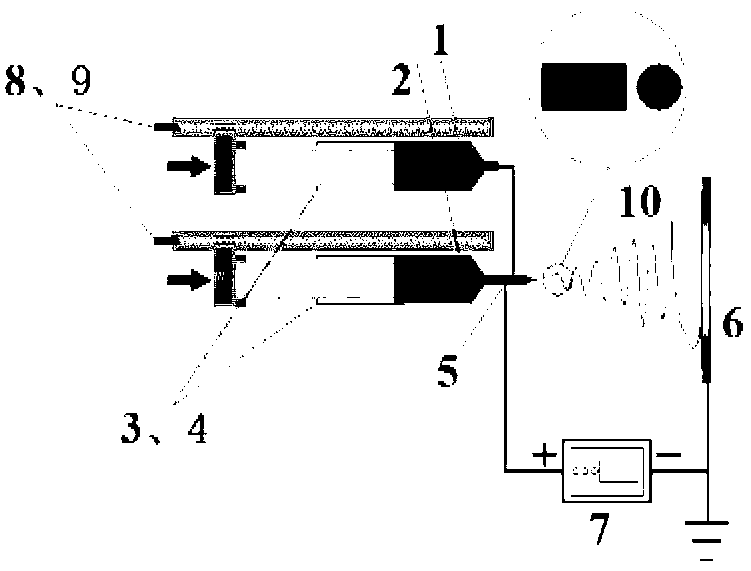

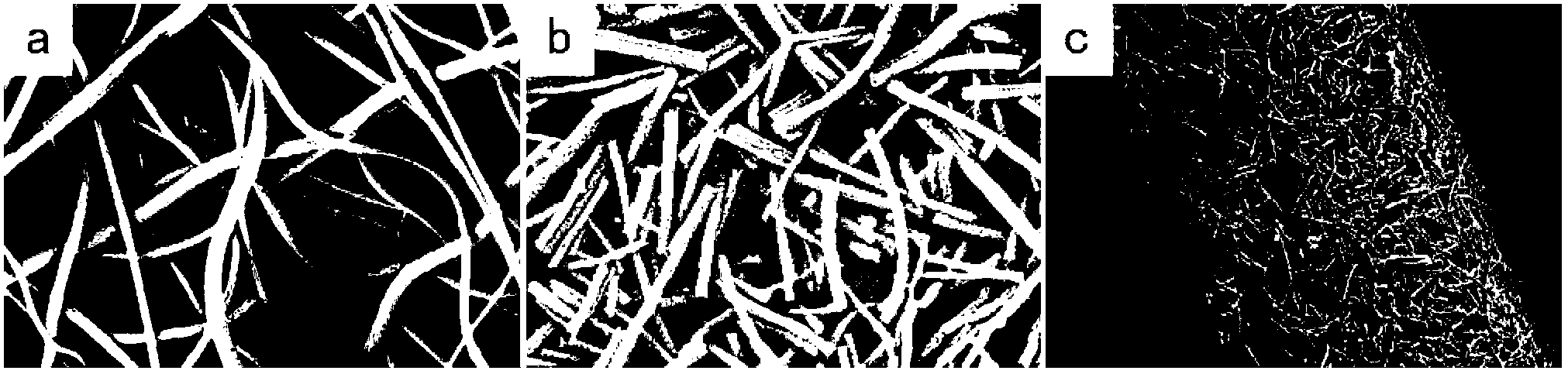

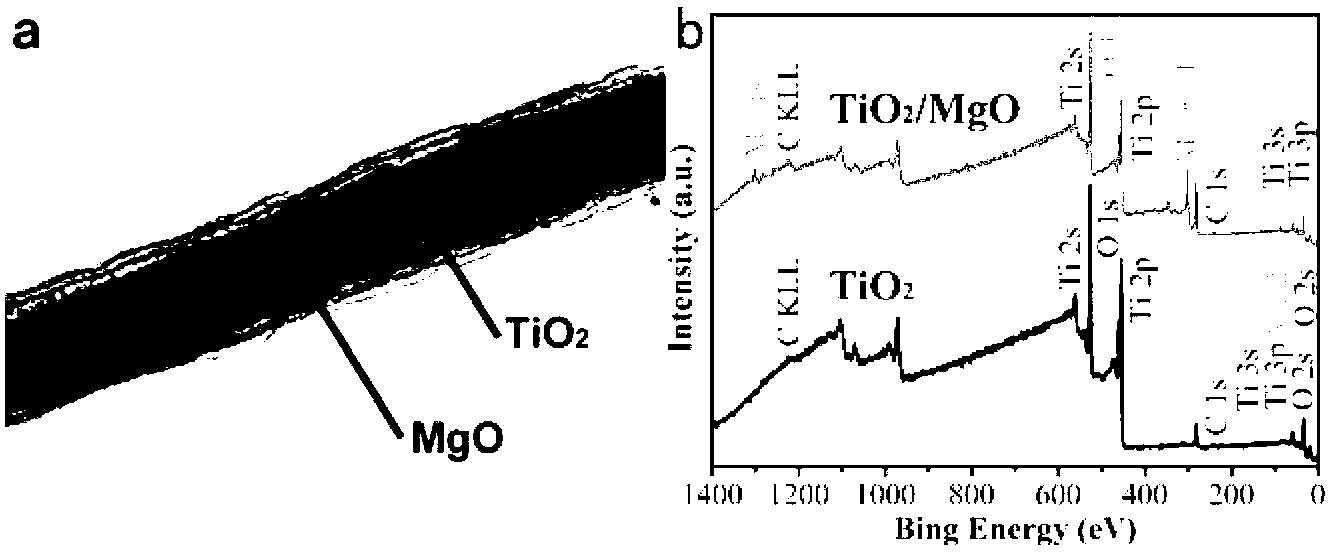

Preparation method of photocatalytic functional fabric based on titanium dioxide/magnesium oxide core-shell nanorod

InactiveCN103184685AWrap implementationEfficient degradationPhysical/chemical process catalystsFibre typesPolyesterSpinning

The invention discloses a preparation method of a photocatalytic functional fabric based on a titanium dioxide / magnesium oxide core-shell nanorod. The preparation method comprises the following steps: preparing MgO and TiO2 precursor spinning solution, respectively putting into injectors, adding 18 kV voltage between a coaxial spinneret and a receiving pole plate, controlling the extrusion rate of the respective injectors and collecting the spinning solution onto an aluminum film in a disordered state to form a composite fiber membrane; putting the membrane into a muffle furnace for sintering, cooling, obtaining a TiO2 / MgO core-shell nanometer fiber membrane, adding into absolute ethyl alcohol and carrying out ultrasonic treatment to obtain a TiO2 / MgO core-shell nanometer rod photocatalyst; and preparing nanorod slurry with a mass percentage of 60 percent by using a polyester non-woven fabric as a load fabric and taking self-crosslinking acrylic emulsion as a bonding agent and fixing the photocatalyst on the load fabric by adopting a rolling-drying-baking process. The functional fabric has the advantages of environmental friendliness, recycling capability and large-scale production and can be widely used for treatment of sewage in the industries of printing and dyeing, papermaking and the like.

Owner:ZHEJIANG SCI-TECH UNIV

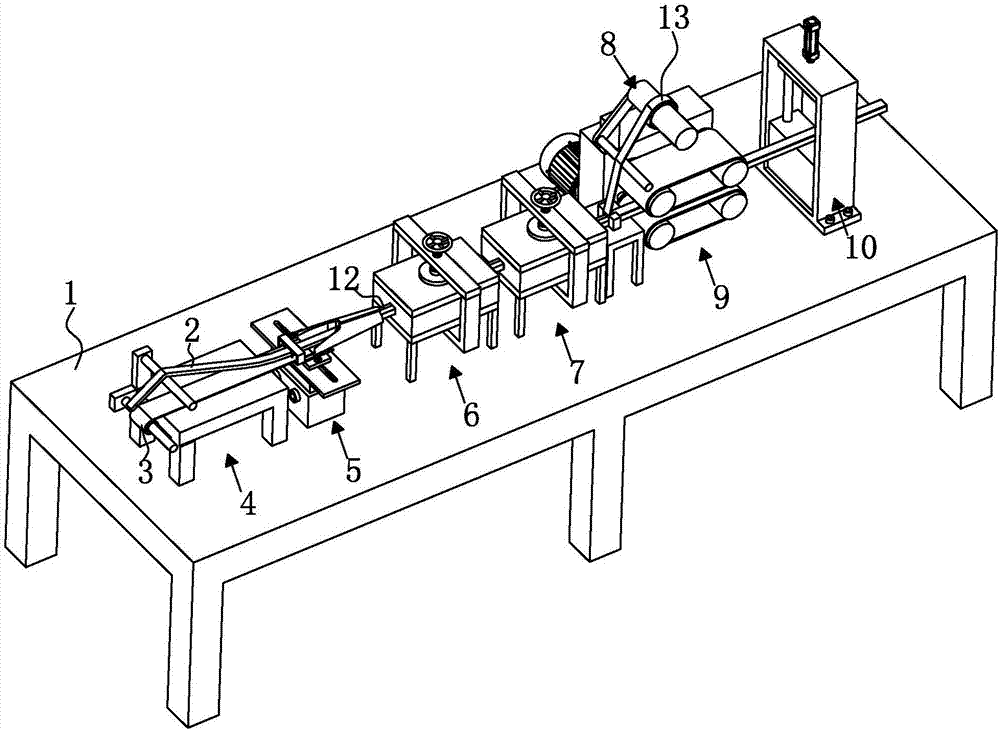

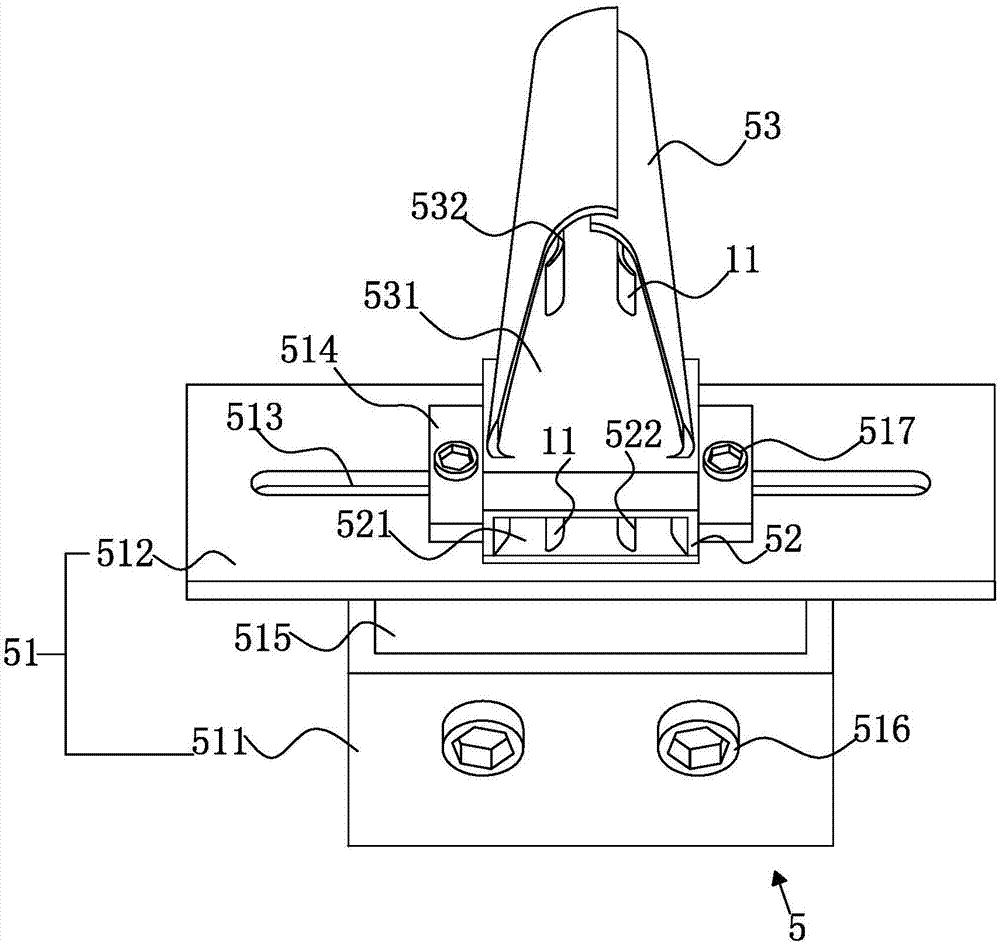

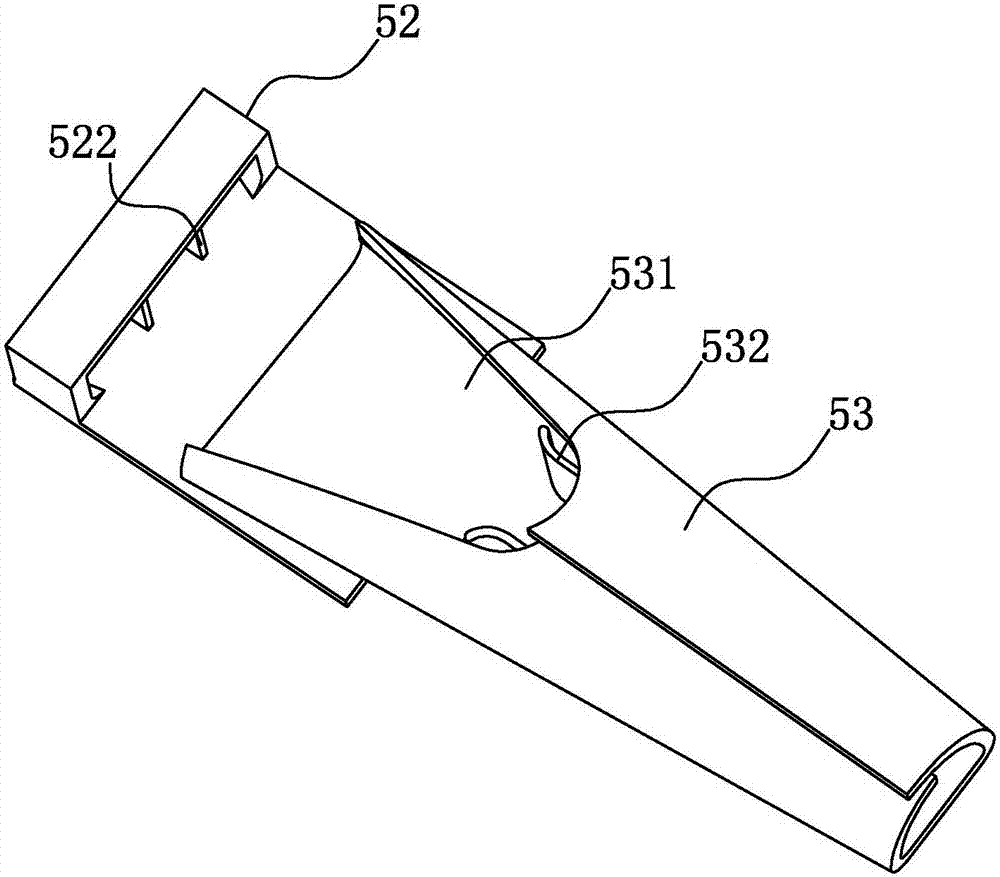

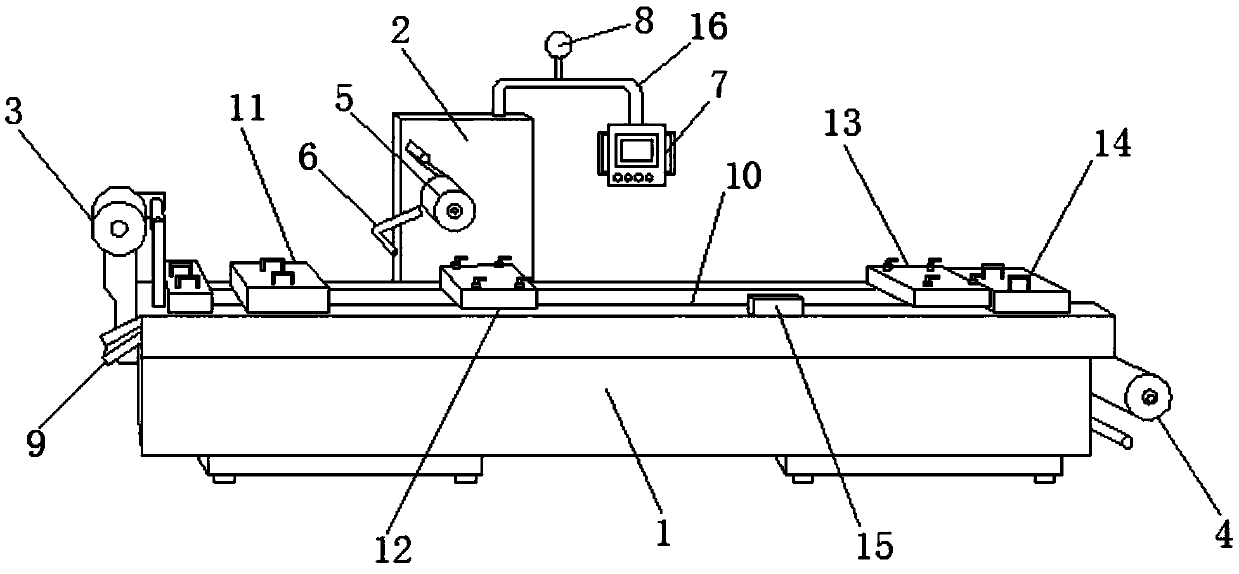

High-speed molding device and preparation method for conductive foam cotton

The invention provides a high-speed molding device and preparation method for conductive foam cotton, and aims at solving the technical problems that the production efficiency is low, and the quality can not be guaranteed when conductive foam cotton is produced through human assistance. According to the technical scheme, the needed conductive foam cotton is obtained by conducting a series of treatment on a conductive cloth and a sponge strip through a cladding molding device, a heating device, a cooling device, a backing adhesive pasting drawing device and a cutting device; in the cladding molding device, by using a side wall curling structure for a guiding frame and a cladding part, the purpose of cladding the conductive cloth and the sponge strip after aligning the conductive cloth with the sponge strip is achieved, not only can subsequent backing adhesive pasting be convenient, but also a backing adhesive can be aligned at the preconceived conductive cloth attaching portion for sealing, and then the quality of the conductive foam cotton is improved; in addition, cladding of the sponge strip by the conductive cloth can be achieved through the guiding frame and the cladding part without artificial participation, therefore, labor is saved, and the production efficiency is improved.

Owner:深圳市金世冠不干胶制品有限公司

Metal fluoride coating ternary material and preparation method thereof

ActiveCN108232131AImprove cycle performanceIncrease storage capacityMaterial nanotechnologyCell electrodesFluorideMaterials science

The invention provides a metal fluoride coating ternary material and a preparation method thereof. The metal fluoride coating ternary material is formed by combining a ternary material and a metal fluoride in a mode of ball milling for many times. According to the preparation method, metal fluoride coating is avoided from being performed by adopting a wet method process, a fluoride precipitant does not need to be used, corrosion cannot be caused to an anode material, and the anti-corrosion requirement for equipment is relatively low. By adopting the preparation method of the metal fluoride coating ternary material, coating of a ternary anode material with nanoscale metal fluoride particles can be realized. The preparation method is simple and efficient, has operability and is suitable forlarge-scale industrial production. The acquired metal fluoride coating ternary material improves the cycle performance and the storage performance of the anode material.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

Preparation method of dopamine stabilized Pickering emulsion and application thereof on immobilized enzymes

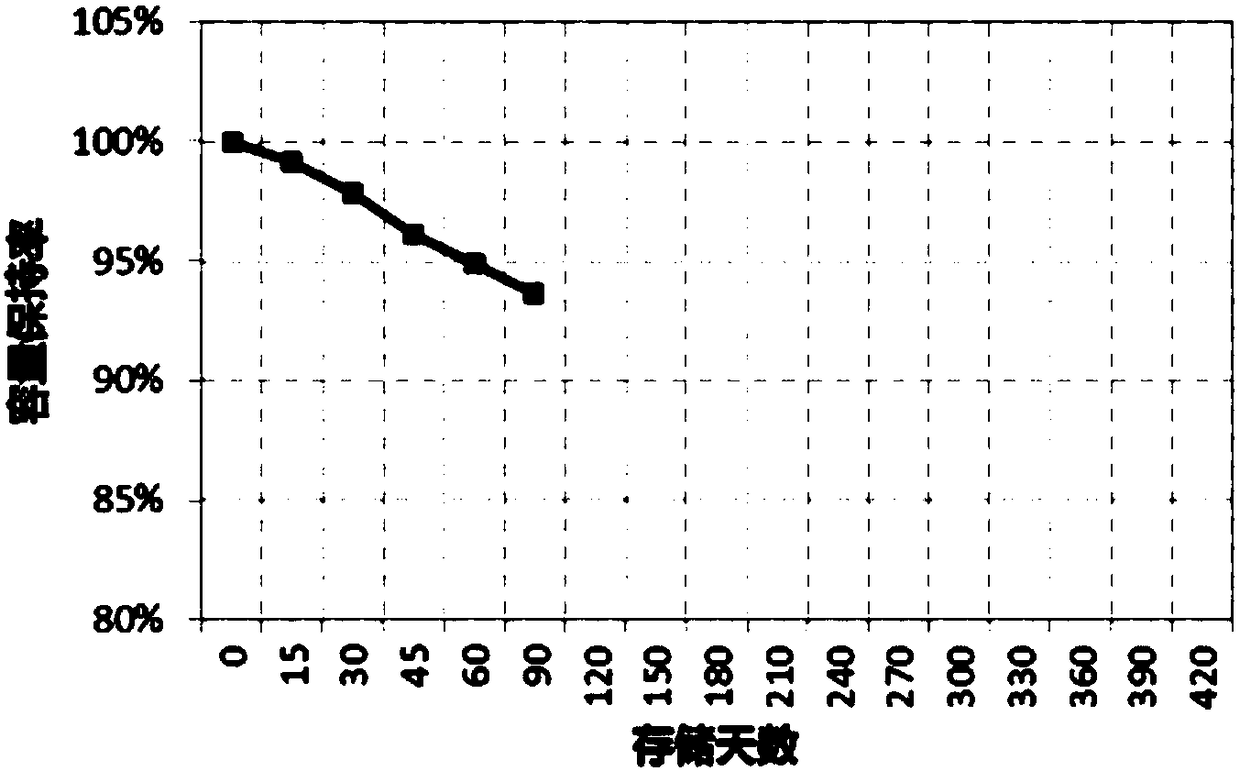

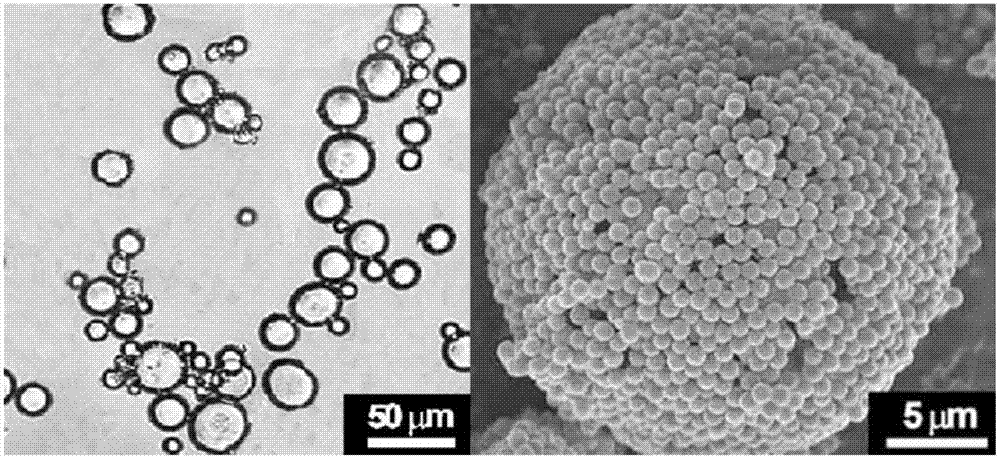

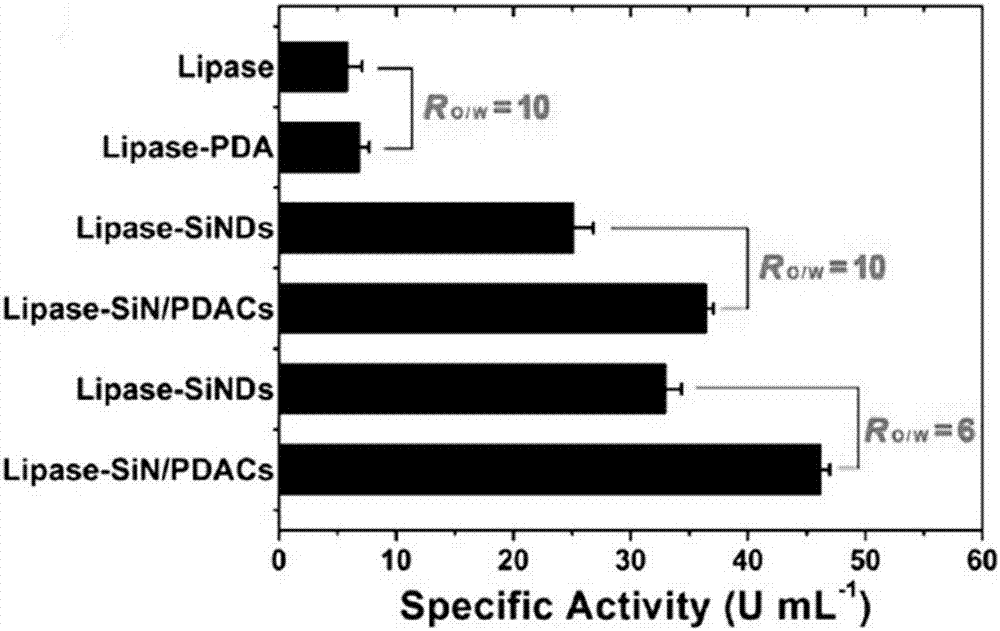

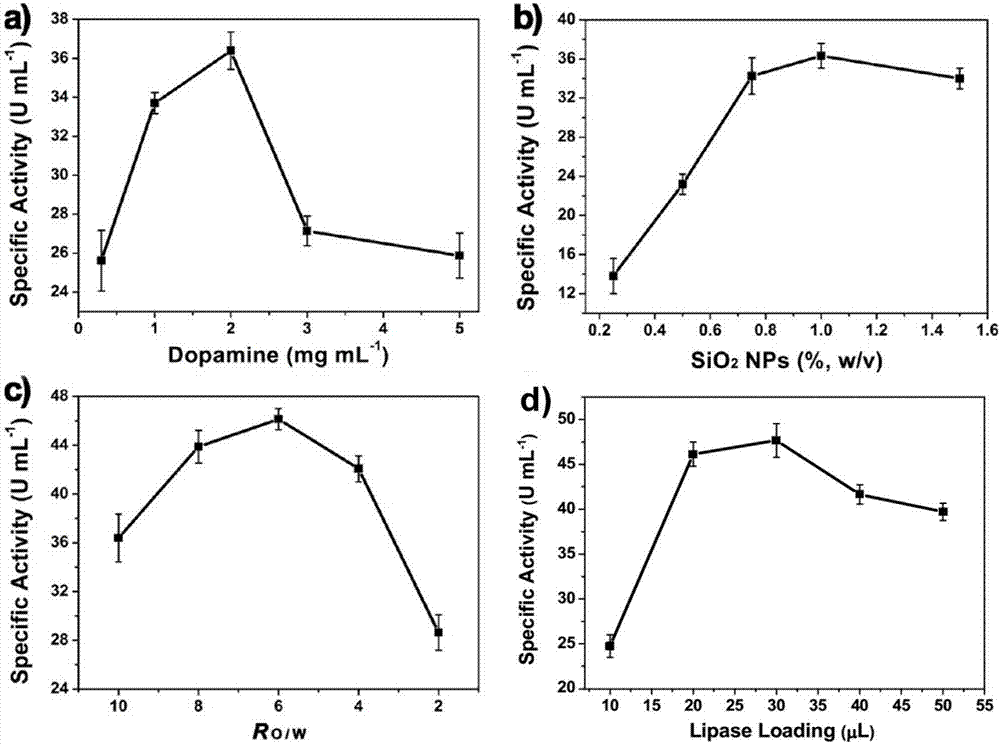

InactiveCN107973919AImprove thermal stabilityGood storage stabilityHydrolasesOn/in organic carrierWater bathsOil phase

The invention relates to a preparation method of a dopamine stabilized Pickering emulsion and application thereof on immobilized enzymes. The preparation method is characterized by that hydrophobic modified SiO2 particles are used as a stabilizer, n-heptane is used as an oil phase, a Tris buffer is used as an aqueous phase, and a high speed homogenizer is used for stirring to obtain a SiO2 particle stabilized Pickering emulsion; dopamine is added into the SiO2 particle stabilized Pickering emulsion, and the obtained emulsion is incubated in a water bath shaker at room temperature to produce ablack Pickering emulsion stabilized by both SiO2 and polydopamine. Enzymes are immobilized in an emulsion aqueous phase to determine the stability and application performance of the Pickering emulsion. The prepared dopamine stabilized Pickering emulsion consists of SiO2 nanometer particles and a polymer coating layer, so that the stability is good, and coating of various enzymes can be realized, thereby making the immobilized enzymes have very good thermal stability, storage stability and reusability; and the Pickering emulsion is low in cost, and the preparation method is easy for operation,so that the Pickering emulsion has very good economic feasibility and practicality.

Owner:TIANJIN UNIV

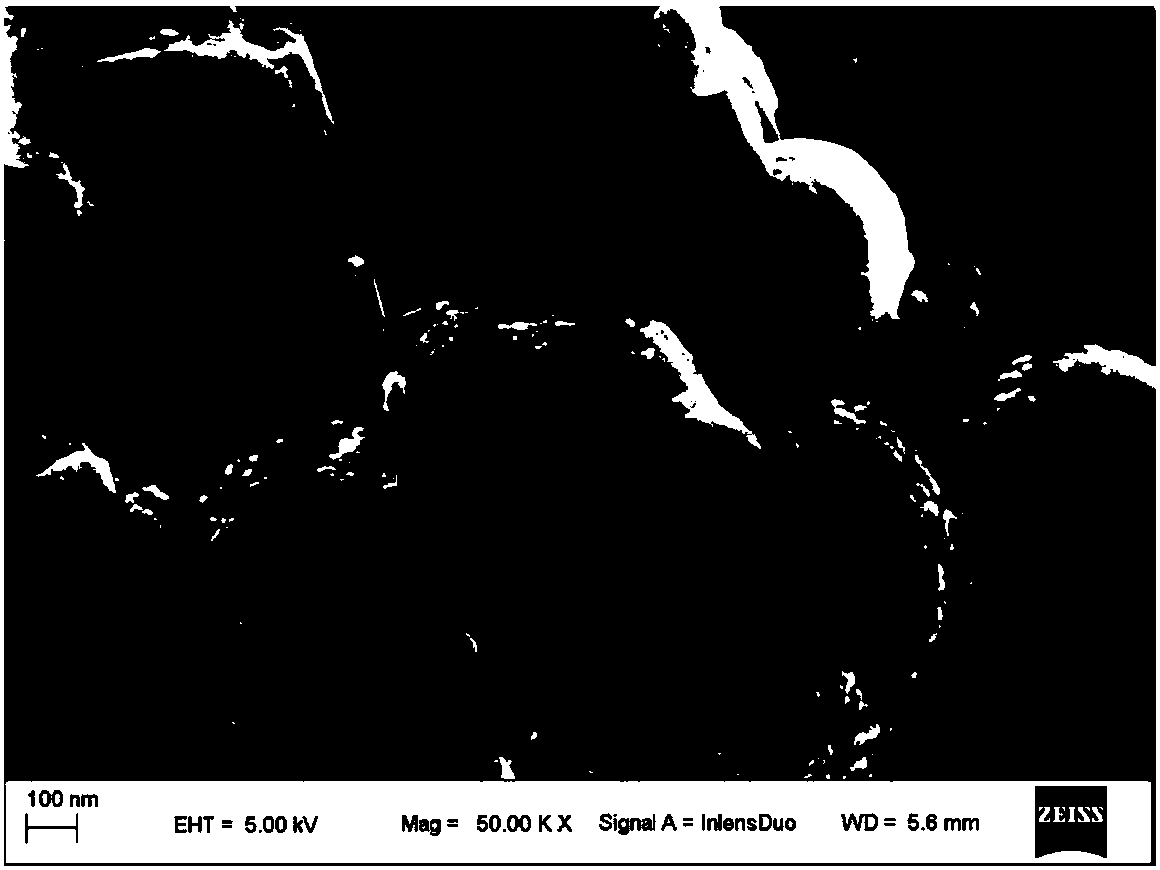

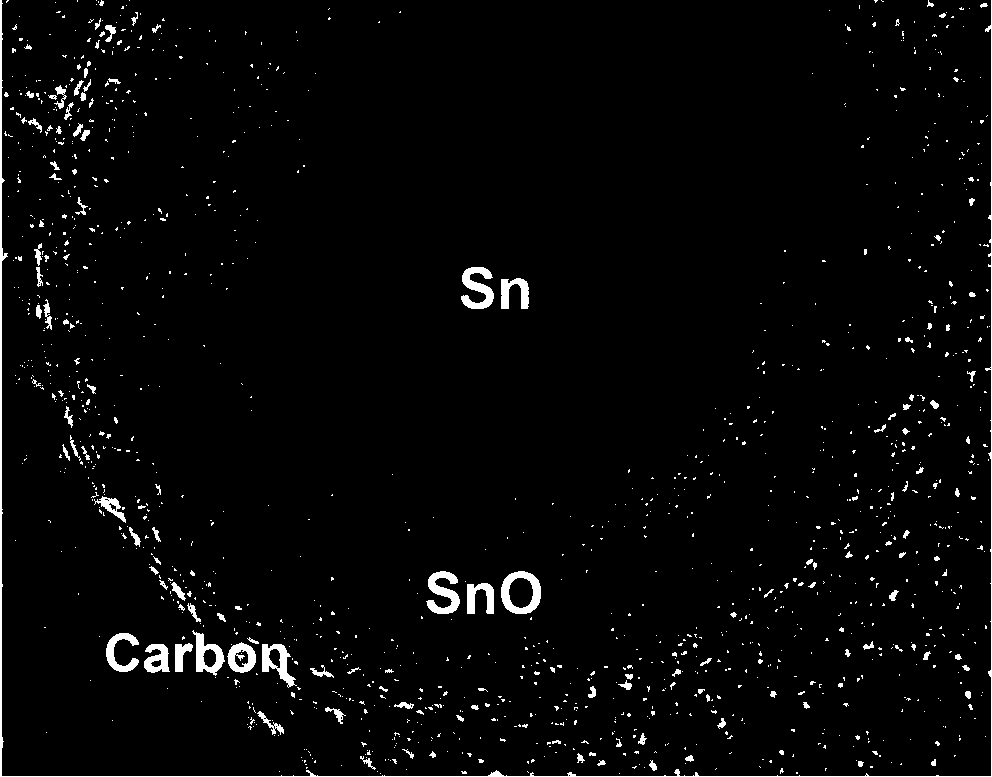

Preparation method of carbon-coated nano tin balls and products and application thereof

InactiveCN107658462AFully coveredWrap implementationMaterial nanotechnologyCell electrodesShielding gasLithium-ion battery

The invention discloses a preparation method of carbon-coated nano tin balls and products and application thereof. The preparation method includes: preparing tin oleate mixed liquid, adding the tin oleate mixed liquid into a crystal template, sufficiently stirring and dispersing to enable tin oleate to effectively cover the surface of the crystal template; transferring a mixture of tin oleate andthe crystal template into a tubular furnace, calcining in an atmosphere of protective gas to obtain solid powder, washing the solid powder, and drying to finally obtain a carbon / tin nano composite material. By the preparation method, preparation of a nanocrystal / carbon material is realized through only one step of direct heating, and obtained tin balls are small in nanocrystal size and complete incarbon coating; the preparation method is simple in step and process and easy to control. The products are conducive to shortening lithium ion transmission path and can inhibit volume expansion of tin in the process of charging and discharging and can avoid the problem of agglomeration of tin in the process of intercalation and deintercalation, lithium storage performance of tin is improved effectively, and the tin balls have great application potential in lithium ion battery electrode materials.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

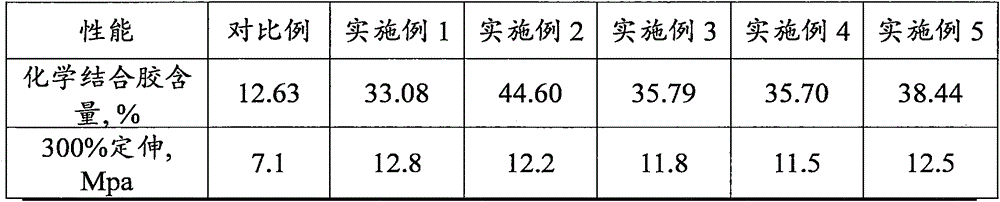

Epoxidized natural rubber coated modified white carbon black and preparation method thereof and rubber material

ActiveCN105330899AImprove dispersion and interfacial bond strengthHigh tensile strengthCarbon blackTemperature treatment

The invention provides epoxidized natural rubber coated modified white carbon black and a preparation method. Compared with a rubber material filled with white carbon black, the rubber material filled with the epoxidized natural rubber coated modified white carbon black can be improved in 300% stretching strength by 80%, the abrasion loss can be reduced by 36%, and the permanent deformation rate can be reduced by 58%. Dispersing liquid of the white carbon black and epoxidized natural rubber are mixed and undergo shearing treatment, solid-liquid separation and high-temperature treatment, so that epoxy groups and silicone hydroxyl undergo chemical bonding, and the epoxidized natural rubber coated modified white carbon black is obtained. The preparation method is simple, convenient and practical and has easiness in industrialization and can be combined with an existing white carbon black production process.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

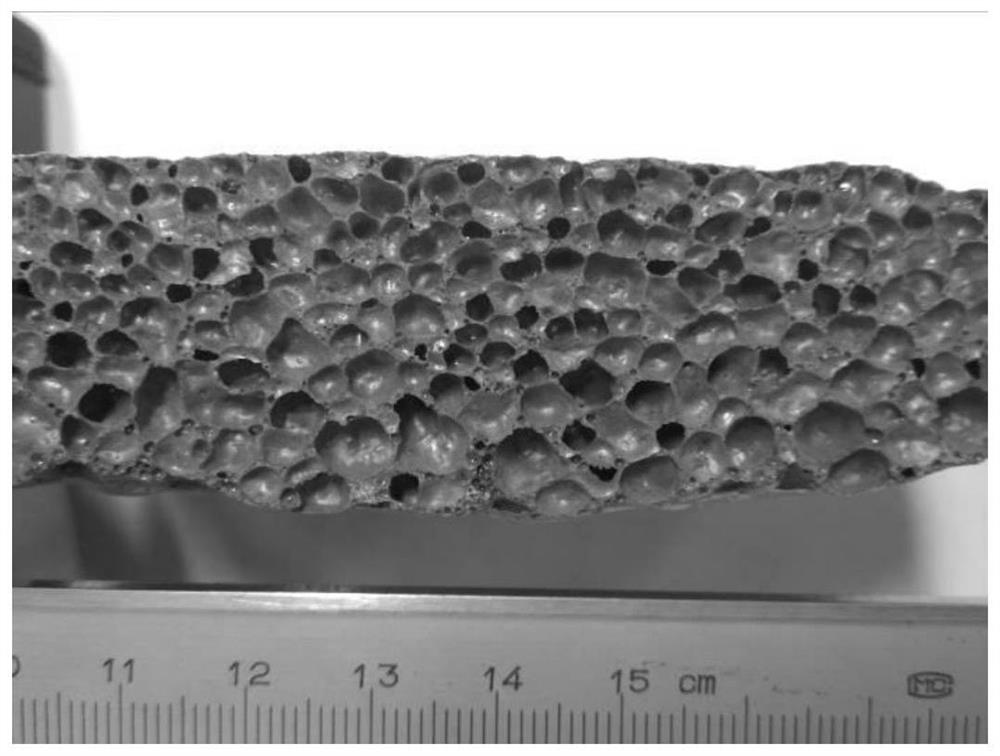

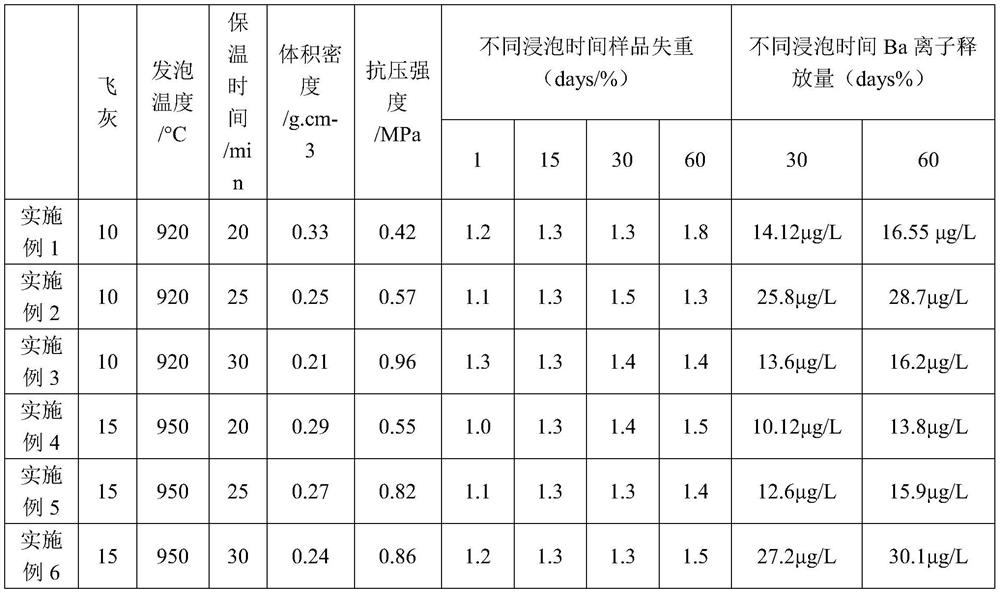

Foam glass prepared from fly ash as well as preparation method and application thereof

PendingCN112279498AEfficient decompositionAvoid harmGlass shaping apparatusFoaming agentPolluted environment

The invention discloses foam glass prepared from fly ash as well as a preparation method and application of the foam glass, and belongs to the technical field of foam glass preparation. Fly ash and glass powder are adopted as raw materials and mixed with a foaming agent, then a PVB alcoholic solution is added for granulation, and after molding, high-temperature foaming is conducted through two times of heating, so that the foam glass is obtained. Through two times of heating and heat preservation, part of dioxin can be effectively decomposed, and meanwhile, the formation amount of a high-temperature melt phase is promoted so as to effectively coat residual dioxin, high chlorine, high calcium and heavy metal components. According to the method, the high-temperature melt effectively coats the high chlorine, high calcium, heavy metal components and residual dioxin, the heavy metal elements are left to stand in water for a long time, leakage of the high calcium and high chlorine componentsis little, and harm of the components to the environment is avoided. The method is simple in process and suitable for large-scale production, the fly ash is adopted as the raw material, and the problem of environmental pollution is solved while the low-cost raw material is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

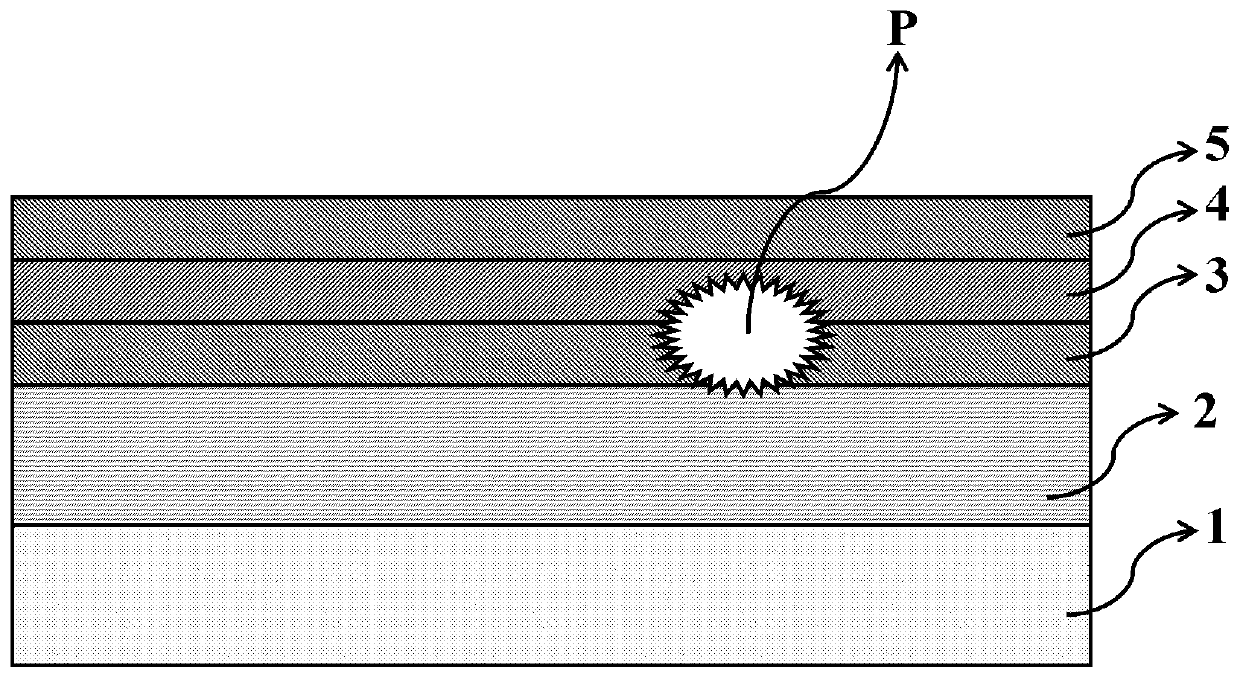

Display panel and display device

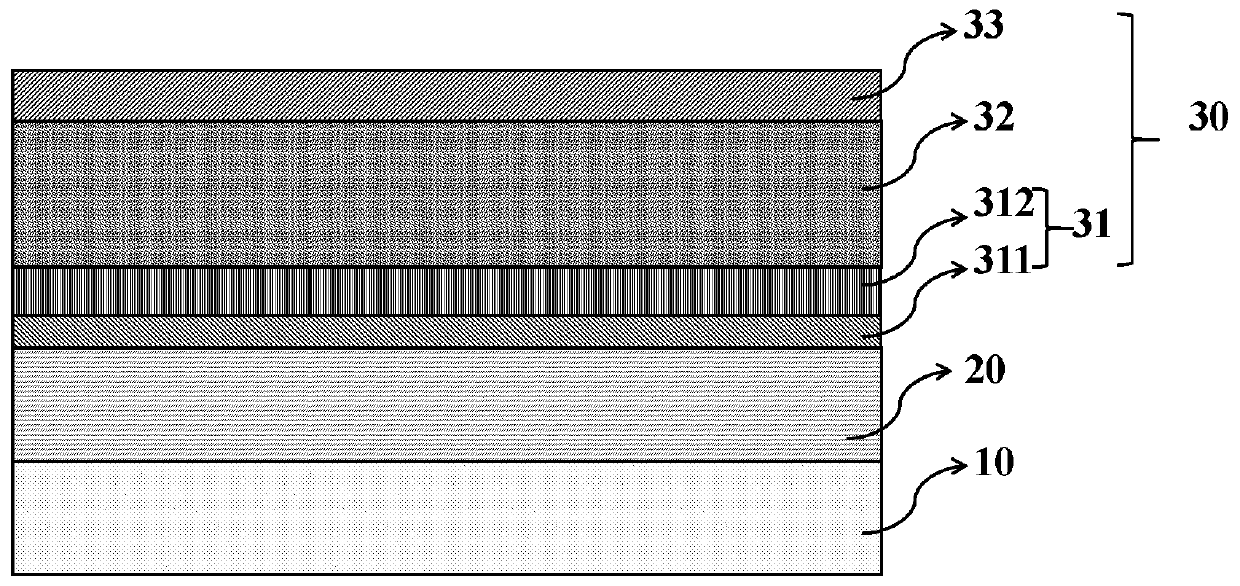

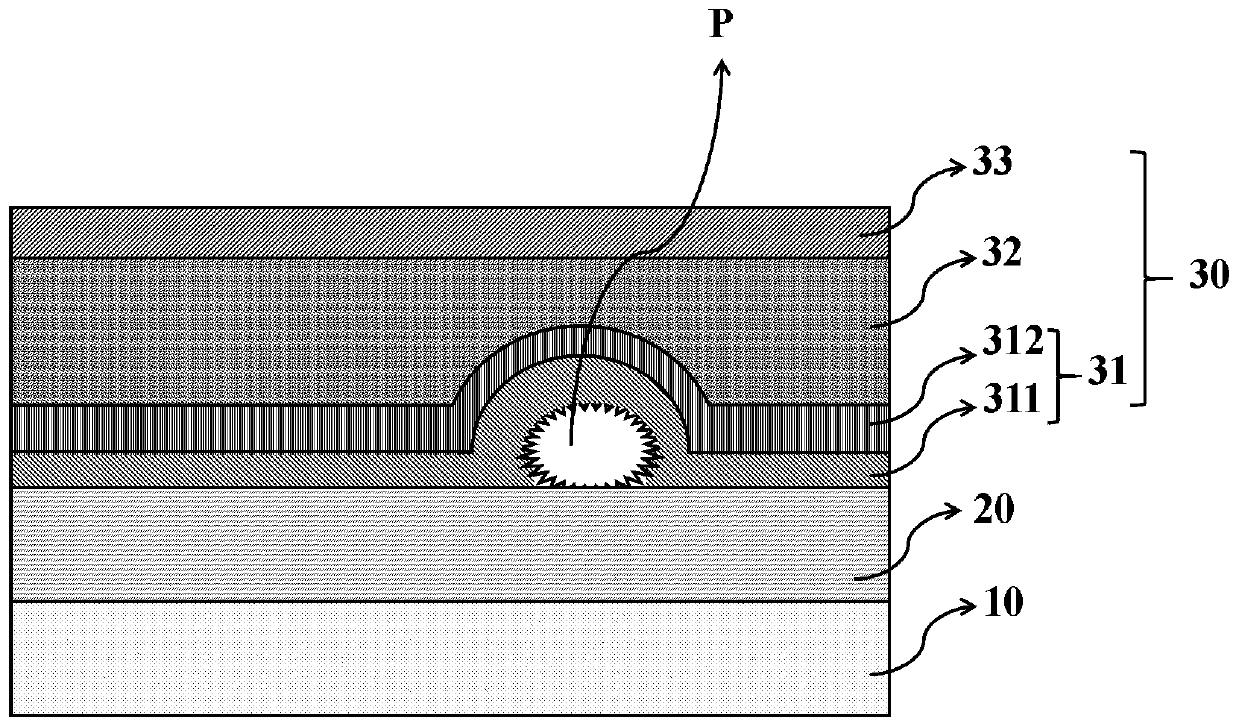

PendingCN111540843AGood particle coating abilityWrap implementationSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceInorganic layer

The invention discloses a display panel and a display device. The display panel comprises: an array substrate, a light-emitting functional layer positioned on the array substrate, and a packaging structure covering the light-emitting function layer, wherein the packaging structure comprises a first inorganic layer tightly combined with the light-emitting function layer, and the first inorganic layer at least comprises a coating sub-layer used for coating particles on the surface of the light-emitting function layer. The light-emitting device is especially sensitive to water and oxygen in the air; particles or defects can be formed in the evaporation process of the light-emitting device. Water and oxygen invasion is caused by particles and defects; therefore, the failure of the light-emitting device can be caused by long-time exposure in the air; according to the display panel, the problems that the service life of the device is influenced due to the fact that the first inorganic layeris coated with the coating sub-layer are solved, the coating sub-layer of the packaging structure has good particle coating capacity and certain water-oxygen blocking capacity, water-oxygen invasion caused by the existence of particles of the first inorganic layer can be well prevented, packaging failure is caused, and then the service life of the display panel is prolonged.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Nickel battery positive active material and preparation method thereof and nickel-metal hydride battery

InactiveCN102760874AGuaranteed capacityGuaranteed high temperature performanceAlkaline accumulator electrodesNickel accumulatorsSelf-dischargeNanotechnology

The invention provides a nickel battery positive active material. The nickel battery positive active material comprises a core and a dense layer covering the core, wherein the core is spherical nickel hydroxide, and the dense layer is calcium carbonate. The invention further provides a preparation method of the nickel battery positive active material and a nickel-metal hydride battery containing the nickel battery positive active material. The nickel battery positive active material is applied to the nickel-metal hydride battery, can effectively weaken the self-discharge process inside the battery, and ensures the capacity and high-temperature performance of the battery. The preparation method of the nickel battery positive active material provided by the invention is simple and easy to implement.

Owner:BYD CO LTD

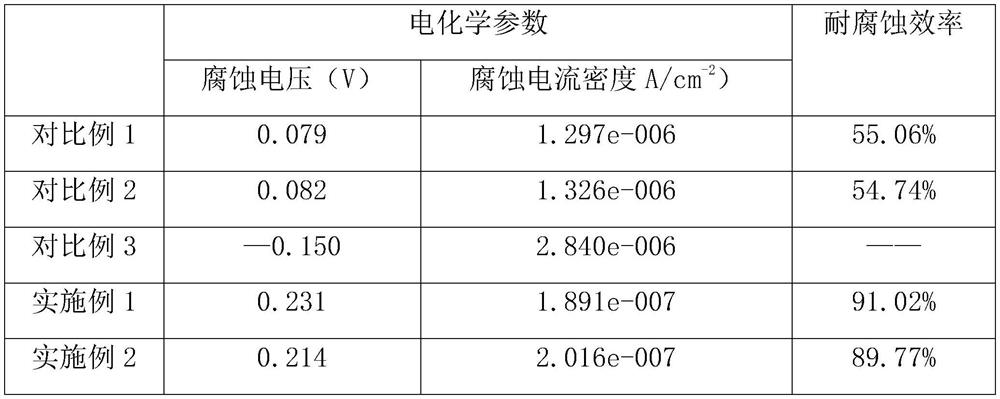

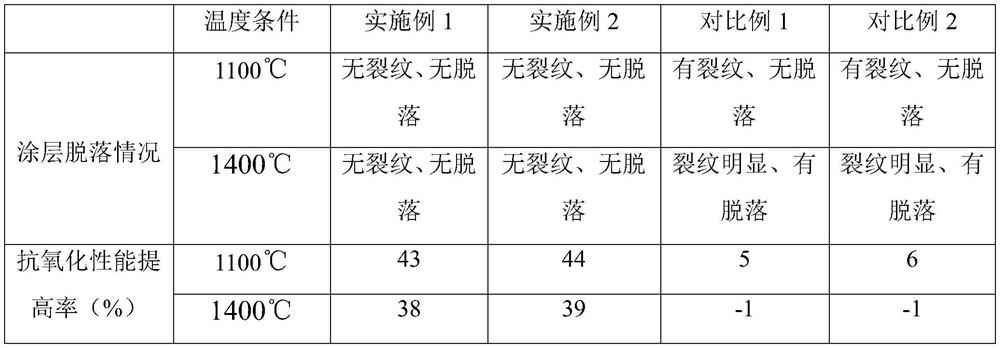

Graphene oxide coated ceramic particle corrosion-resistant gradient coating and preparation method thereof

PendingCN114477965AWrap implementationOvercome the problem of easy reunionHeat inorganic powder coatingCeramic coatingAdhesive

The invention discloses a preparation method of a graphene oxide coated ceramic particle corrosion-resistant gradient coating. The preparation method comprises the following steps: preparing graphene oxide coated Cr3C2 ceramic particles, carrying out dispersion reaction on the graphene oxide coated Cr3C2 ceramic particles and metal oxide powder to generate a hybrid reactant, finally mixing the hybrid reactant with ceramic aggregate and an adhesive, and curing and sintering to prepare the corrosion-resistant ceramic coating. The core-shell structure of the ceramic particles and the graphene oxide is favorable for improving the bonding strength of the graphene oxide and a ceramic matrix, avoiding gaps on an interface, improving the compactness of the coating, reducing the generation of cracks of the coating and improving the high-temperature corrosion resistance of the coating; and meanwhile, the core-shell structure is beneficial to improving the oxidation resistance of the coating and prolonging the service life of the coating.

Owner:ZHAOSHAN TECH BEIJING CO LTD

Full-automatic infusion device packaging machine with material lacking reminding function

PendingCN108045642AAvoid wastingAvoid breakingWrapping material feeding apparatusPackaging automatic controlFixed frameEngineering

The invention discloses a full-automatic infusion device packaging machine with a material lacking reminding function. The full-automatic infusion device packaging machine with the material lacking reminding function comprises an operation table, a fixing frame, a bracket and a bottom film fixing column; the fixing frame is fixed to one side of the operation table; the bracket is fixed to one endof the operation table; the bottom film fixing column is fixed to the other side of the operation table; an upper film fixing column is fixed to one side of the fixing frame; a tensioning adjusting rod is fixed to one side of the upper film fixing column; a power supply panel is fixed to the top of the fixing frame through a rotating rod; an alarming device is fixed to the top of the rotating rod;a discharging port is fixed to one side of the bracket; a conveying belt is fixed to the surface of the operation table; and an infrared sensor is fixed to one side of the conveying belt and locatedon the surface of the operation table. The full-automatic infusion device packaging machine with the material lacking reminding function is reasonable and novel in deign, convenient to operate and useand high in infusion device packaging efficiency, an operator can be reminded in time during material lacking, waste of upper films and bottom films is wasted, high practicability is achieved, and the full-automatic infusion device packaging machine with the material lacking reminding function is suitable for wide use and popularization.

Owner:浙江圣利机械设备有限公司

Metal-coated fuel and preparation method thereof

ActiveCN111916227AImprove antioxidant capacityHigh melting pointNuclear energy generationReactors manufactureLithium-ion batteryMixed gas

The invention provides a metal-coated fuel and a preparation method thereof. The metal-coated fuel sequentially comprises a nuclear fuel core, a loose metal layer and a compact metal layer from insideto outside. The method comprises the following steps: S1, providing a nuclear fuel core, loading the nuclear fuel core into a high-temperature spouted bed, and introducing argon to enable the nuclearfuel core to be in a fluidized state; S2, introducing hydrogen or argon or a mixed gas of hydrogen and argon, and controlling the proportion of the precursor of the loose metal layer in the carrier gas to be 5-10% V / V, so as to coat the loose metal layer on the surface of the nuclear fuel core; S3, controlling the proportion of the precursor of the compact metal layer in the carrier gas to be 0.2-2% V / V so as to further coat the compact metal layer; and S4, stopping introducing the precursor, introducing argon, and cooling the fuel to obtain the lithium ion battery positive electrode material. The metal-coated fuel provided by the invention has the advantages of good thermal conductivity, strong fission product retention capacity, low breakage rate and the like, and can effectively improve the safety and economy of nuclear fuel.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI +1

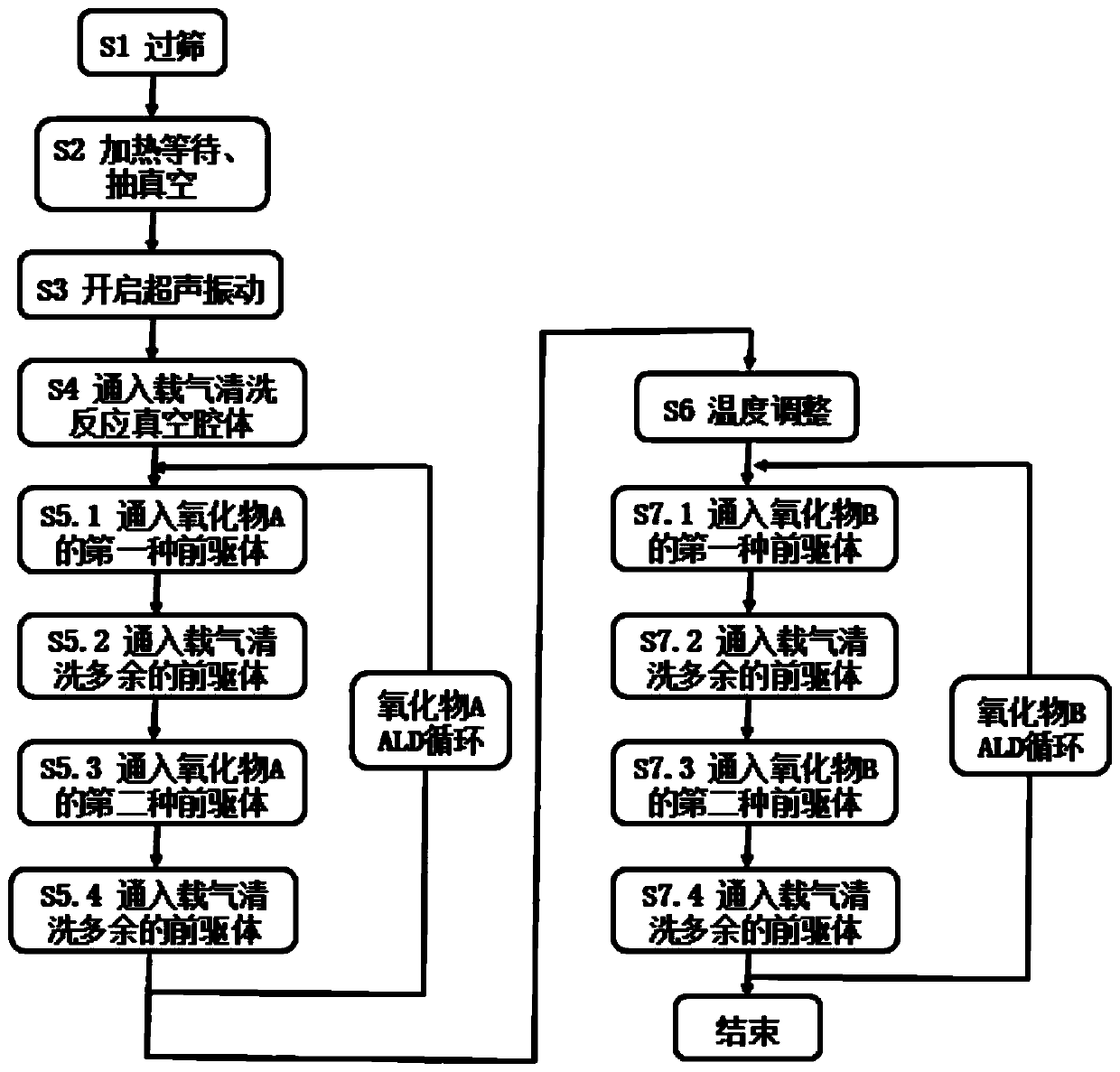

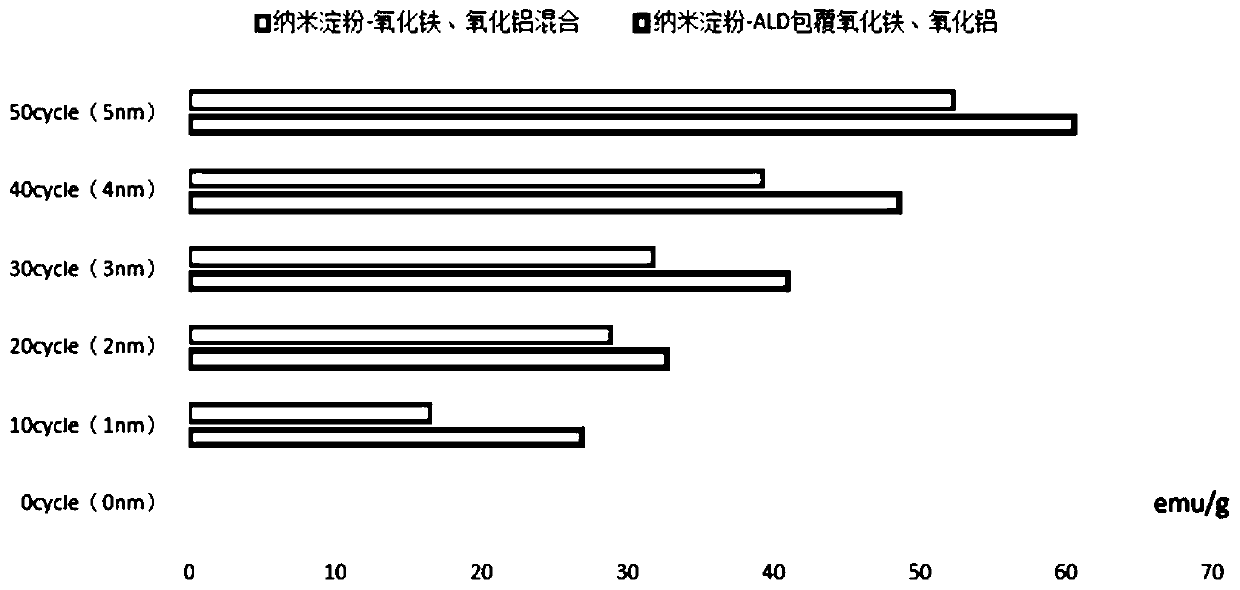

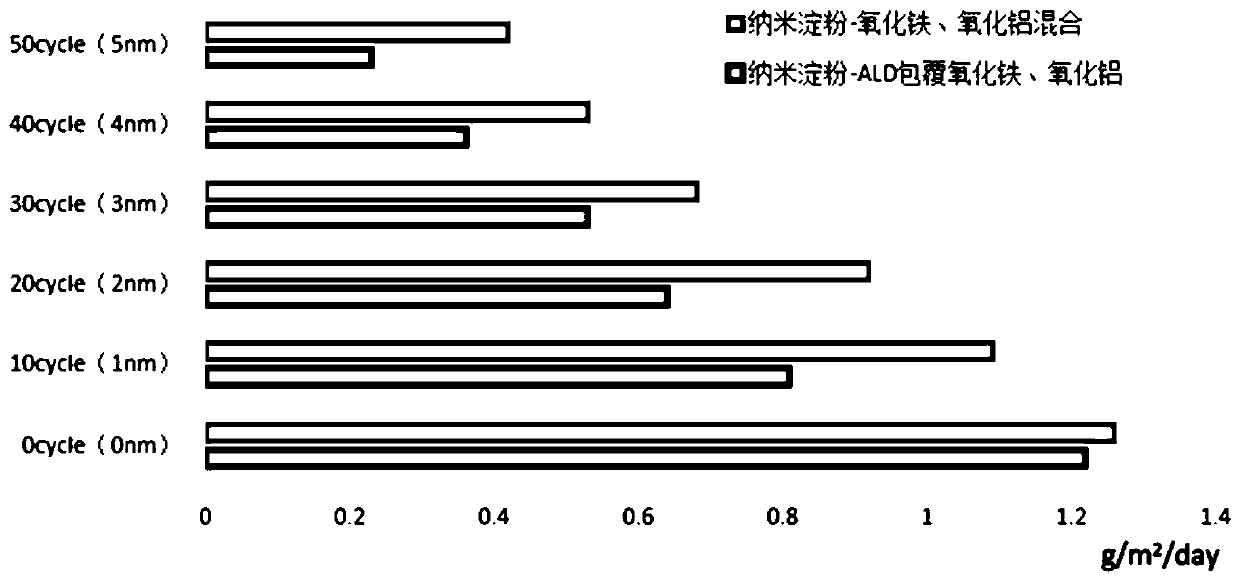

Method for cladding nanometer starch microspheres through atomic layer deposition

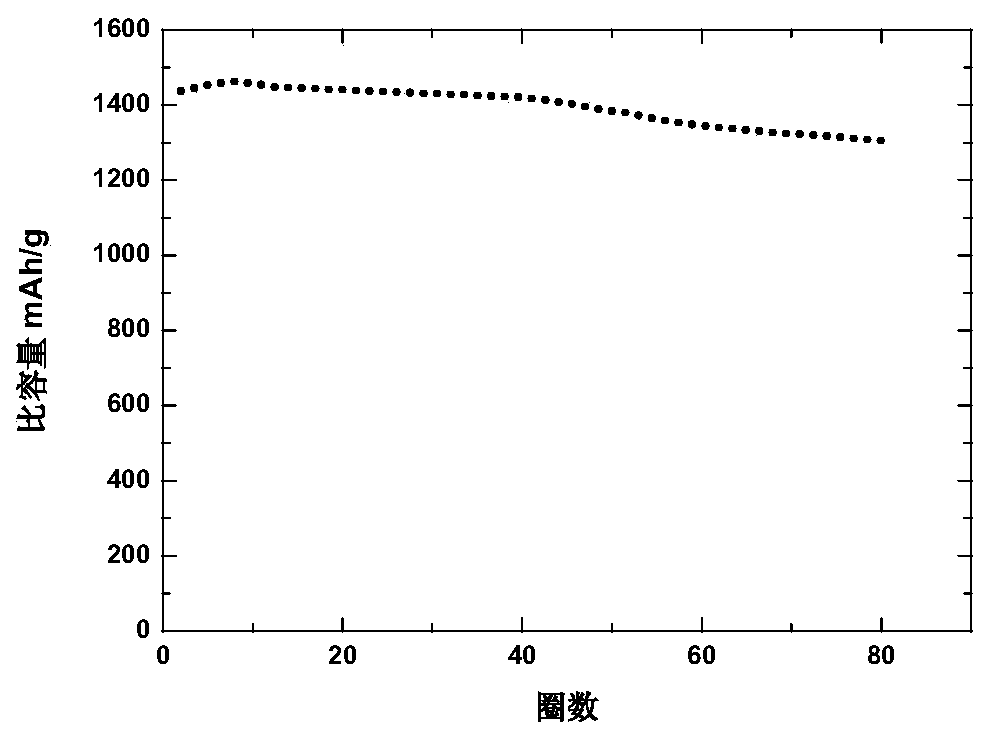

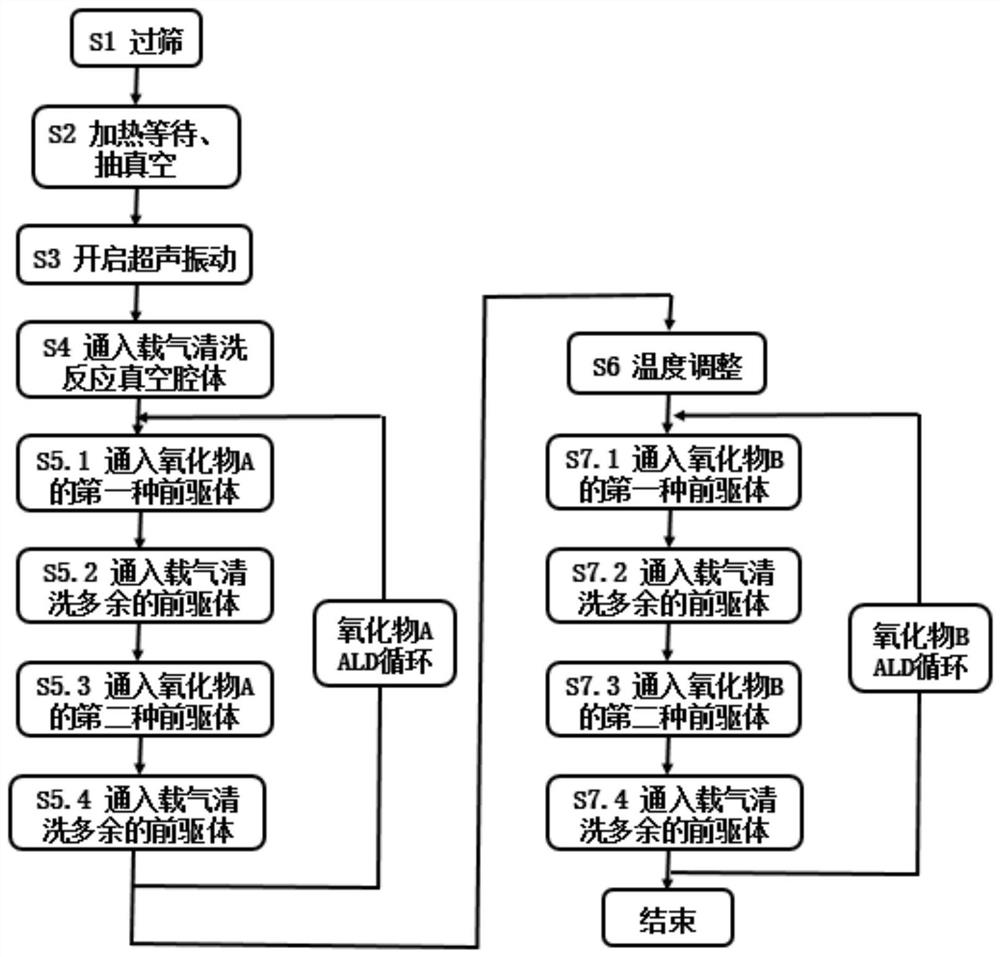

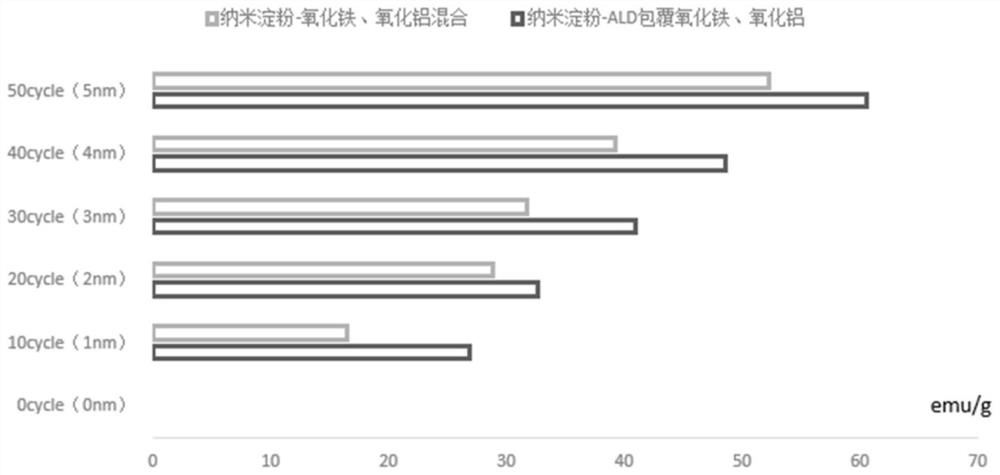

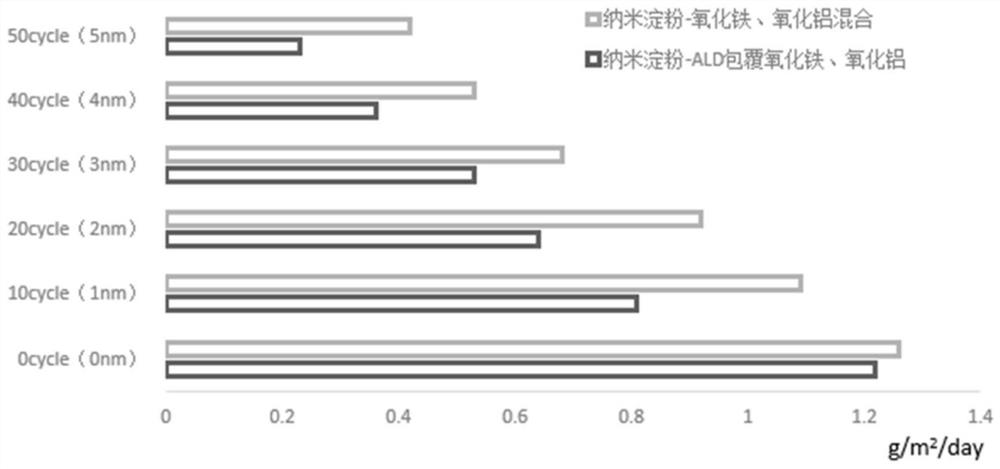

ActiveCN111304634AWrap implementationDense coatingMaterial nanotechnologyNanomagnetismStarch MicrospheresChemical adsorption

The invention belongs to the technical field of nanometer starch microsphere modification, and particularly relates to a method for cladding nanometer starch microspheres through atomic layer deposition. The nanometer starch microspheres are placed into an ultrasonic vertical fluidizing atomic layer deposition device, ultrasonic vibration is started, under a proper reaction temperature and pressure, properly-active and vapor-pressure precursors are selected to be alternately introduced, a single layer of chemical adsorption is formed and self-limiting chemical semi-reaction is completed on thesurfaces of the nanometer starch microspheres through exchanging of active functional groups to generate compact thin films, and cladding is performed on all the parts of the surfaces through the thin films with uniform and consistent thickness. The nanometer thin films generated through an atomic layer deposition technology are high in cladding uniformity, especially uniform cladding can be performed on the small-grained nanometer starch microspheres, the formed nanometer thin films are compact in structure and have the uniform thickness and excellent consistency, and due to the characteristics of a reacting mechanism of the thin films, the cladding of the nanometer starch microspheres of different grain sizes can be realized.

Owner:HUST WUXI RES INST

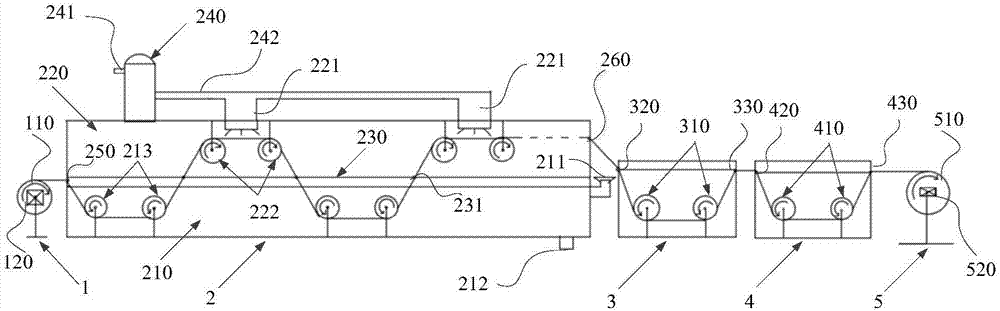

Continuous manufacturing machine capable of synchronously realizing polymer wire coating and metalizing

ActiveCN107999331AWrap implementationControl thicknessPretreated surfacesCoatingsAgricultural engineeringAirflow

The invention provides a continuous manufacturing machine capable of synchronously realizing polymer wire coating and metalizing. The continuous manufacturing machine is sequentially equipped with a pay-off device, a coating device, an oxidization-reduction device, a cleaning device and a take-up device from left to right, wherein the coating device comprises a solution slot in the lower part anda gas flow reaction chamber positioned on the upper part; the solution slot is separated from the gas flow reaction chamber through a baffle plate; a gas flow compression heater is arranged on the outer part of the coating device; the left side of the coating device is equipped with a wire inlet hole and the right side of the coating device is equipped with a wire outlet; a plurality of sets of circulating roller groups are arranged in the coating device from left to right; each set of circulating roller groups comprises a roller group arranged in the solution slot and a roller group which isarranged in the gas flow reaction chamber in an adjacent mode; a wire inlet is formed in the left side wall of each of the oxidization-reduction device and the cleaning device, a wire outlet is formed in the right side wall of each of the oxidization-reduction device and the cleaning device, and a roller wheel used for supporting the polymer wire is arranged inside each of the oxidization-reduction device and the cleaning device. The continuous manufacturing machine has the characteristics of simple coating equipment and a simple coating method, a short coating process, good coating and metalizing effect, and the like.

Owner:WUHAN UNIV OF TECH

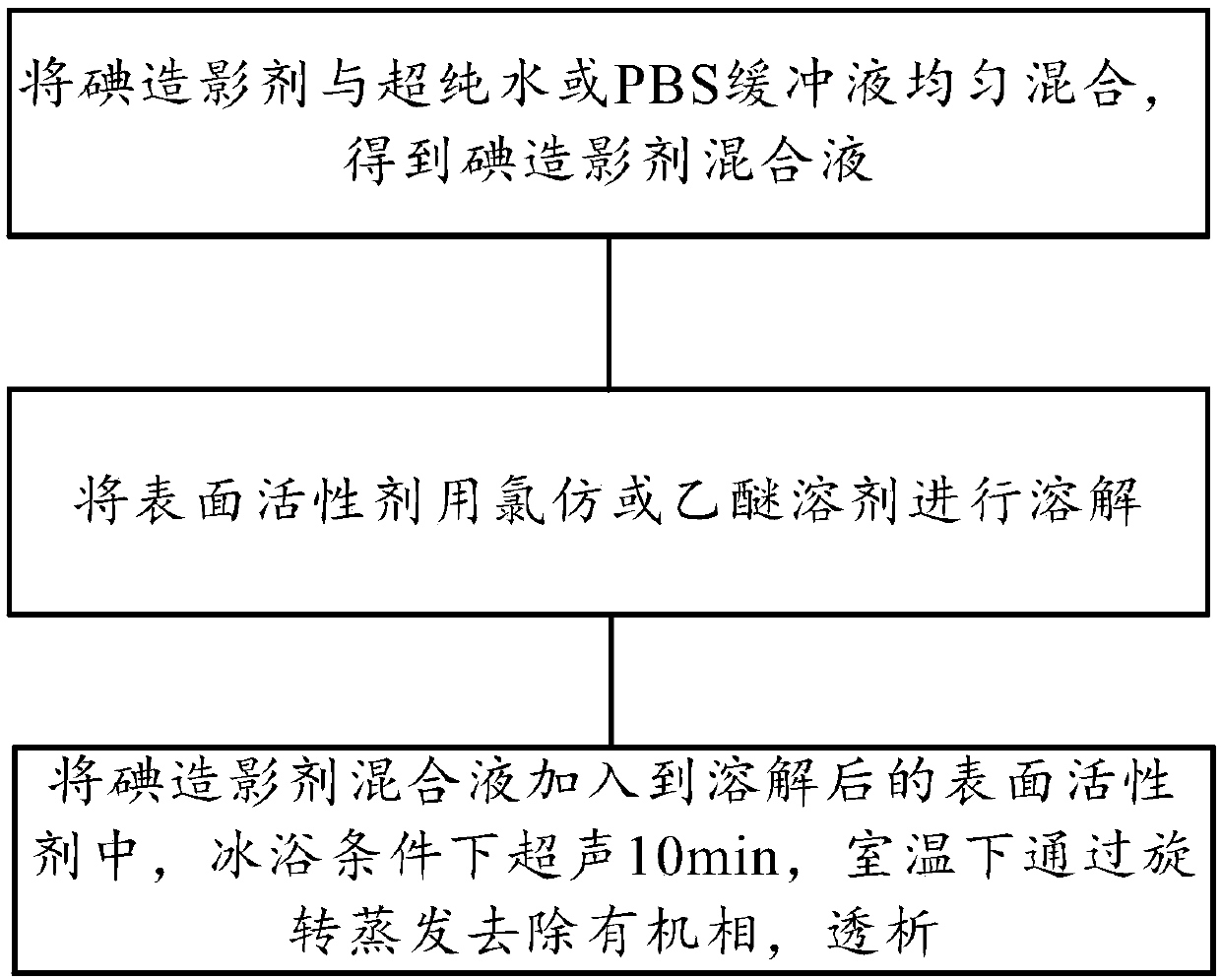

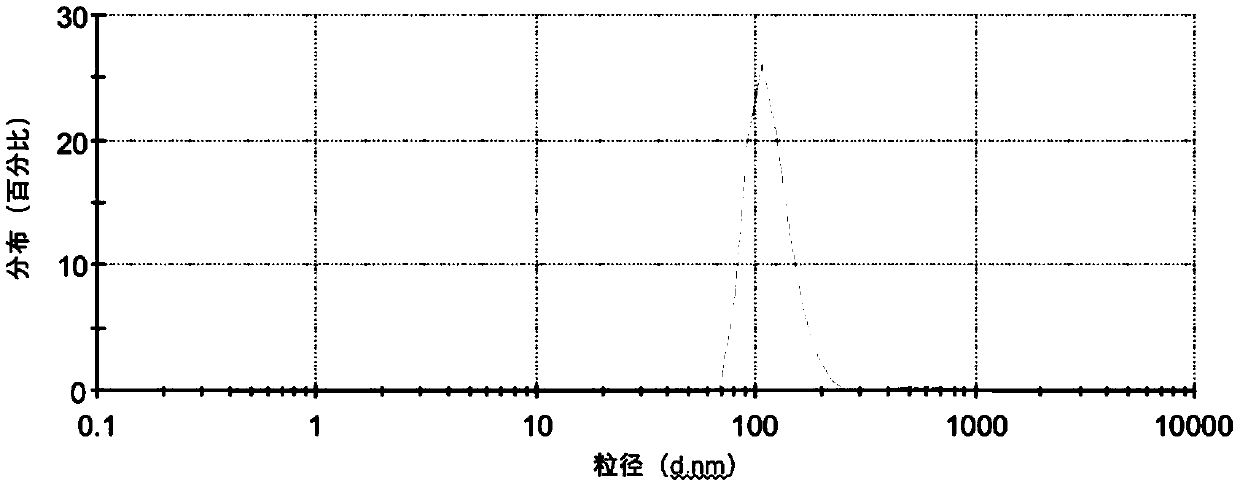

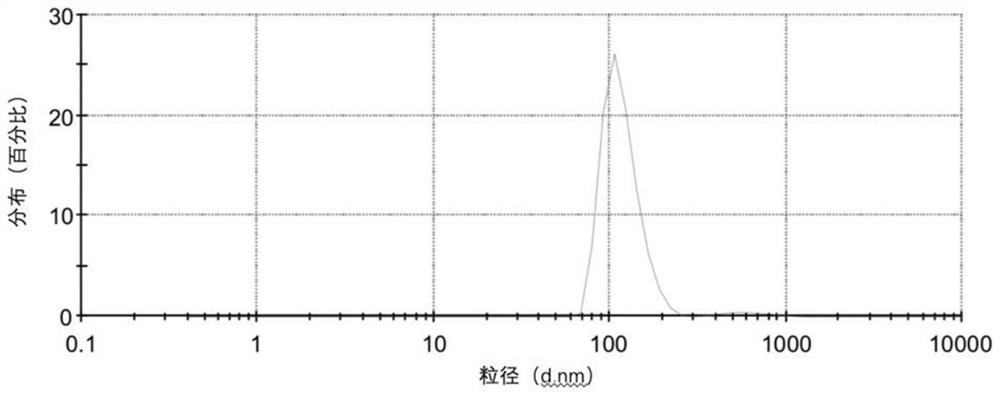

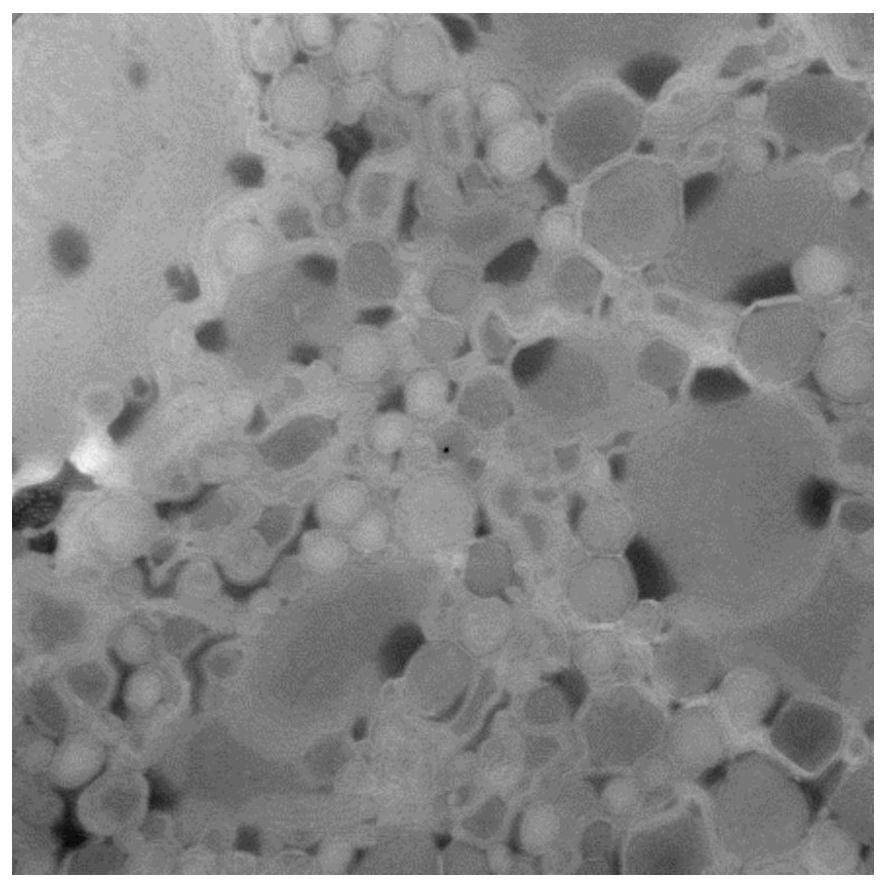

Chemical exchange saturation transfer contrast agent as well as preparation method and application thereof

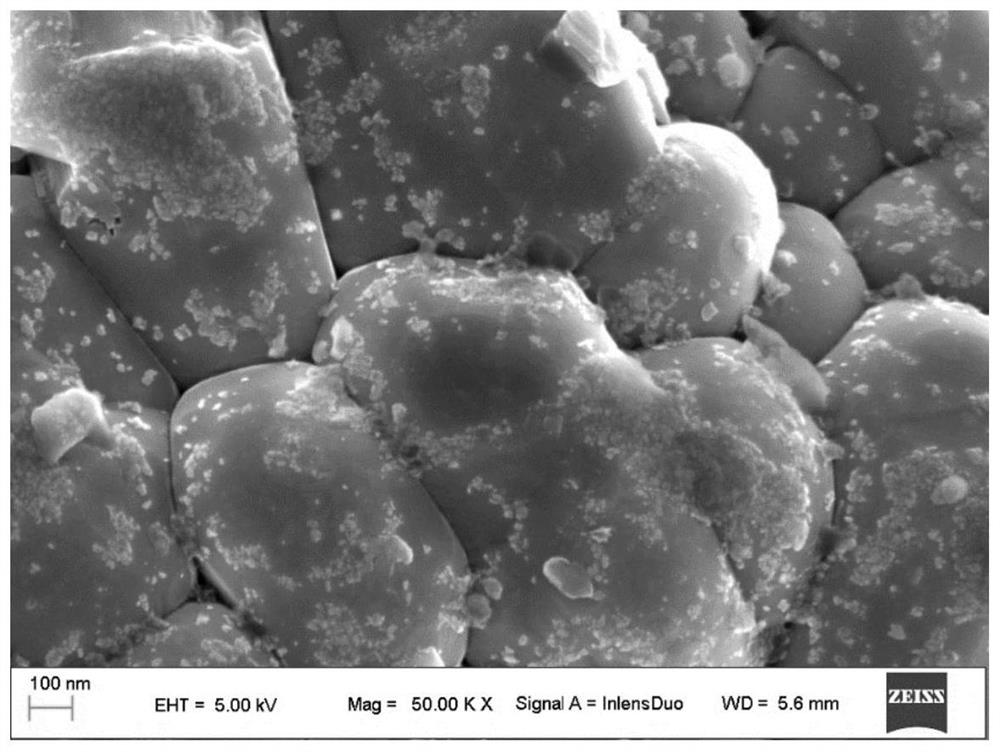

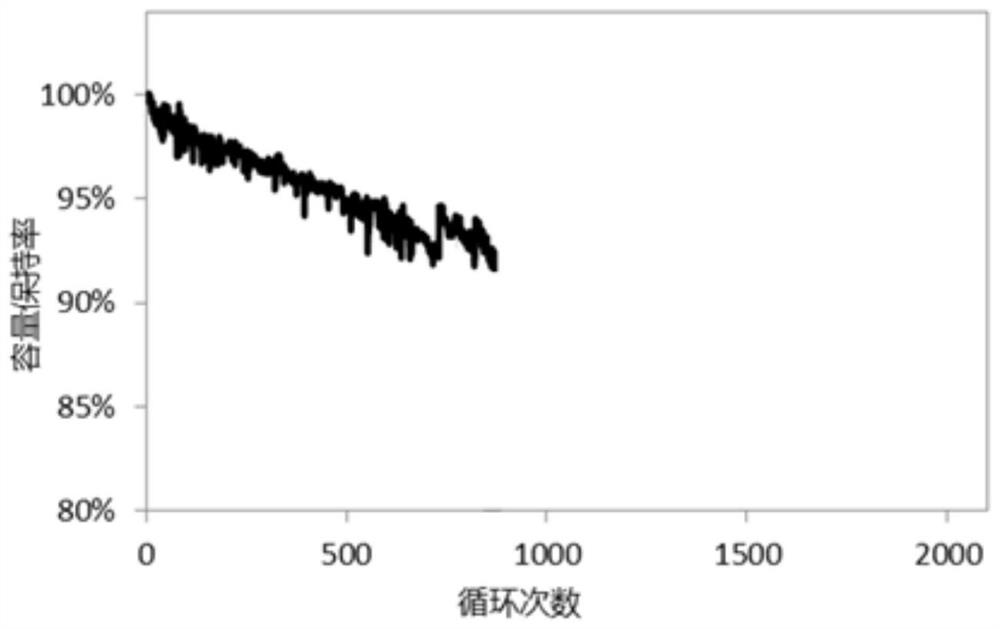

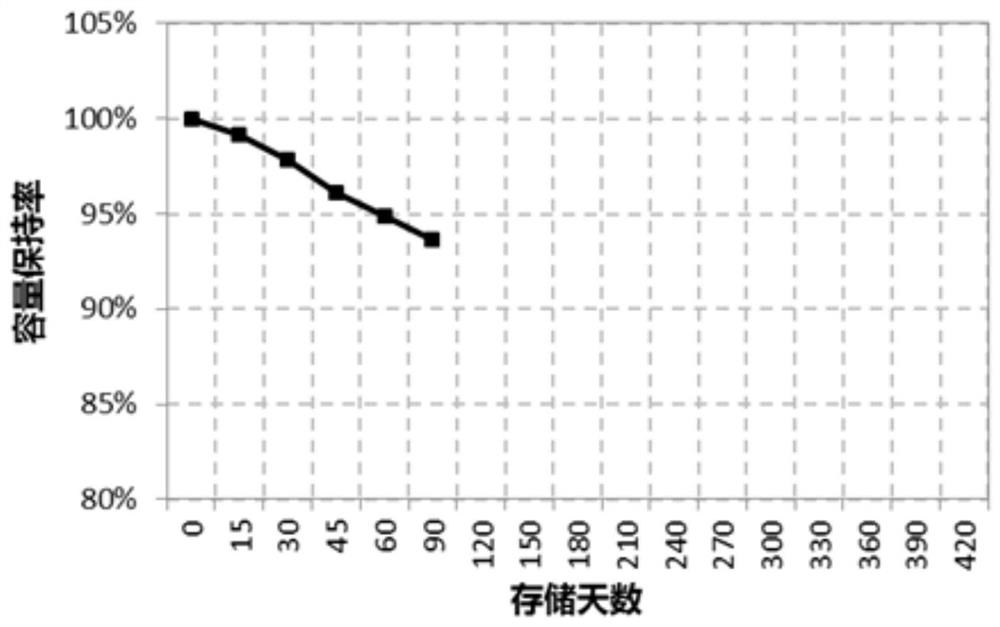

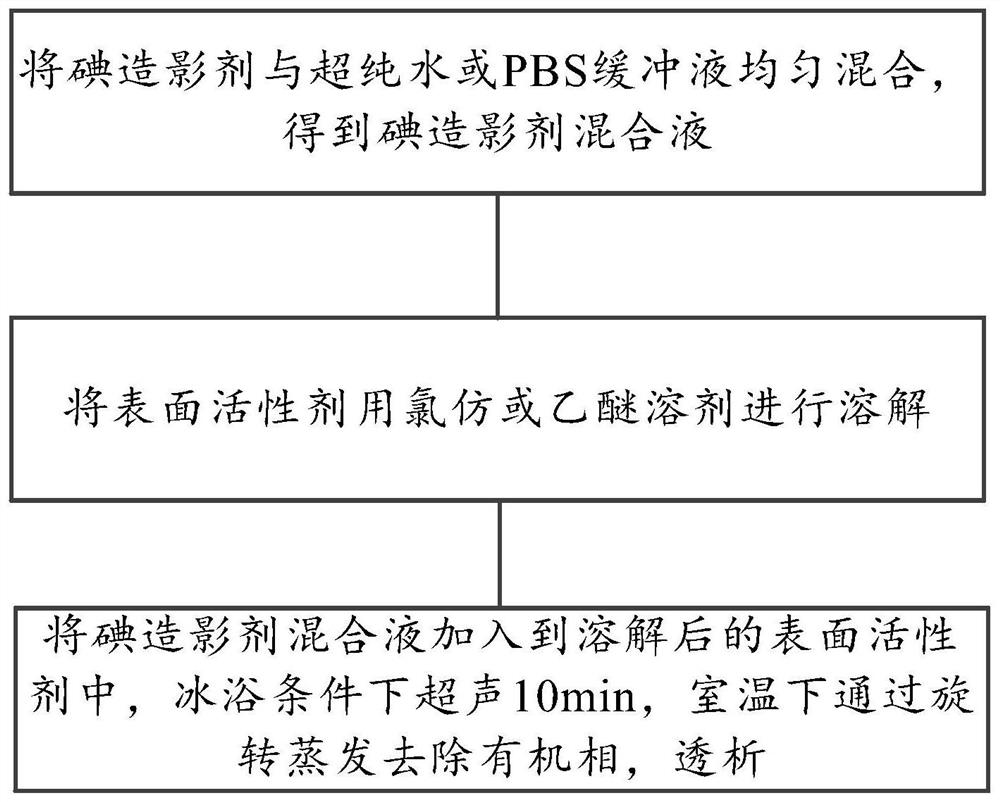

ActiveCN109568609AIncreased sensitivityGood biocompatibilityDispersion deliveryEmulsion deliveryCholesterolBiocompatibility Testing

The invention provides a chemical exchange saturation transfer contrast agent as well as a preparation method and application thereof, and belongs to the technical field of nuclear magnetic resonanceimaging. The contrast agent is a novel LipoCEST contrast agent; on the basis of keeping the advantages of high sensitivity and the like of the original iodine CEST contrast agent, high biocompatibility and safety are realized; the defects of fast discharge in the tumor region, low retention rate and the like of a conventional CEST contrast agent such as iohexol can be overcome; the EPR effect of the tumor region is improved. The contrast agent is formed by coating an iodine contrast agent with a surfactant; the surfactant is one or a mixture of more of phosphatidylcholine liposomes, phosphatidyl ethanolamine liposomes, phosphatidylserine, lecithin or cholesterol. The contrast agent is used for nuclear magnetic resonance imaging.

Owner:HARBIN MEDICAL UNIVERSITY

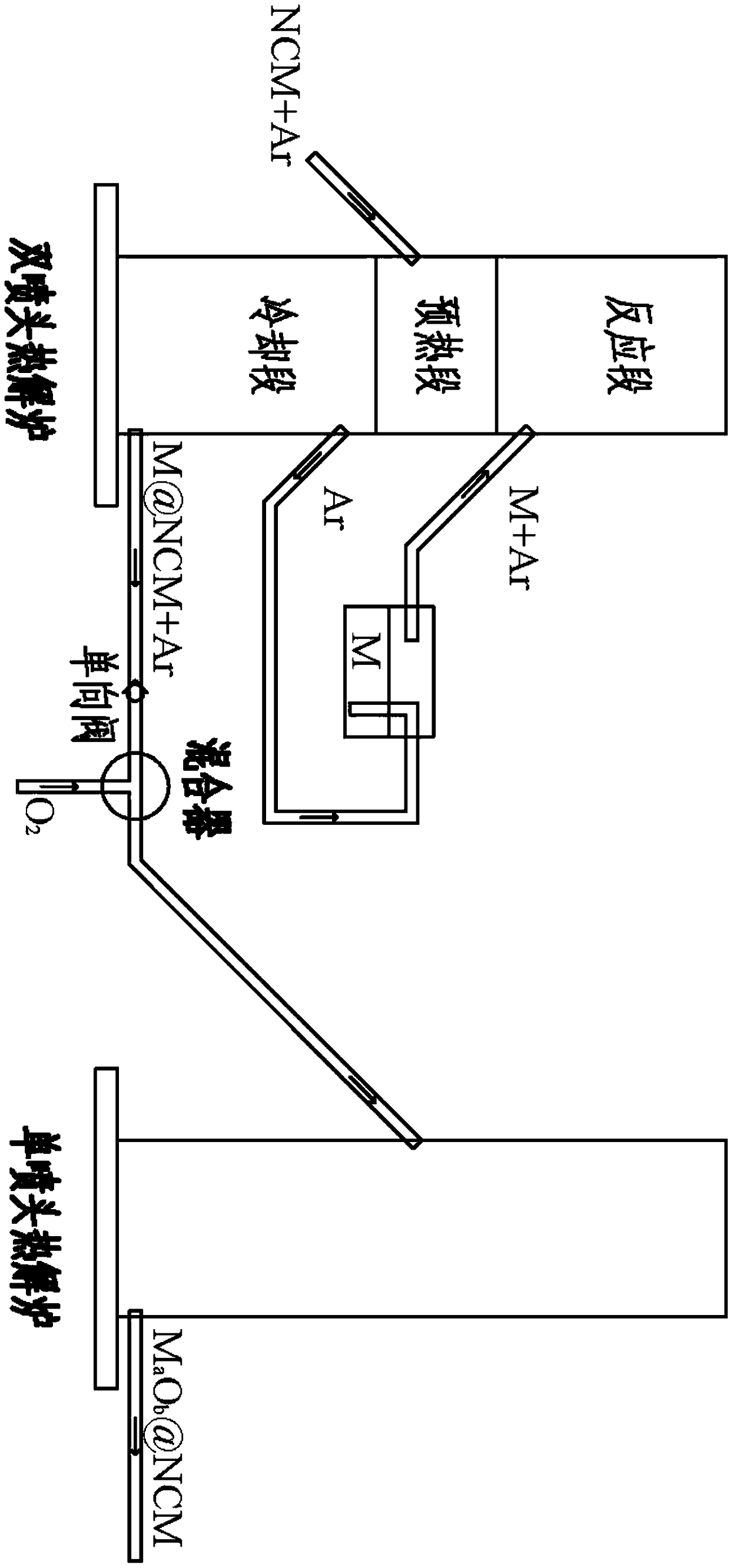

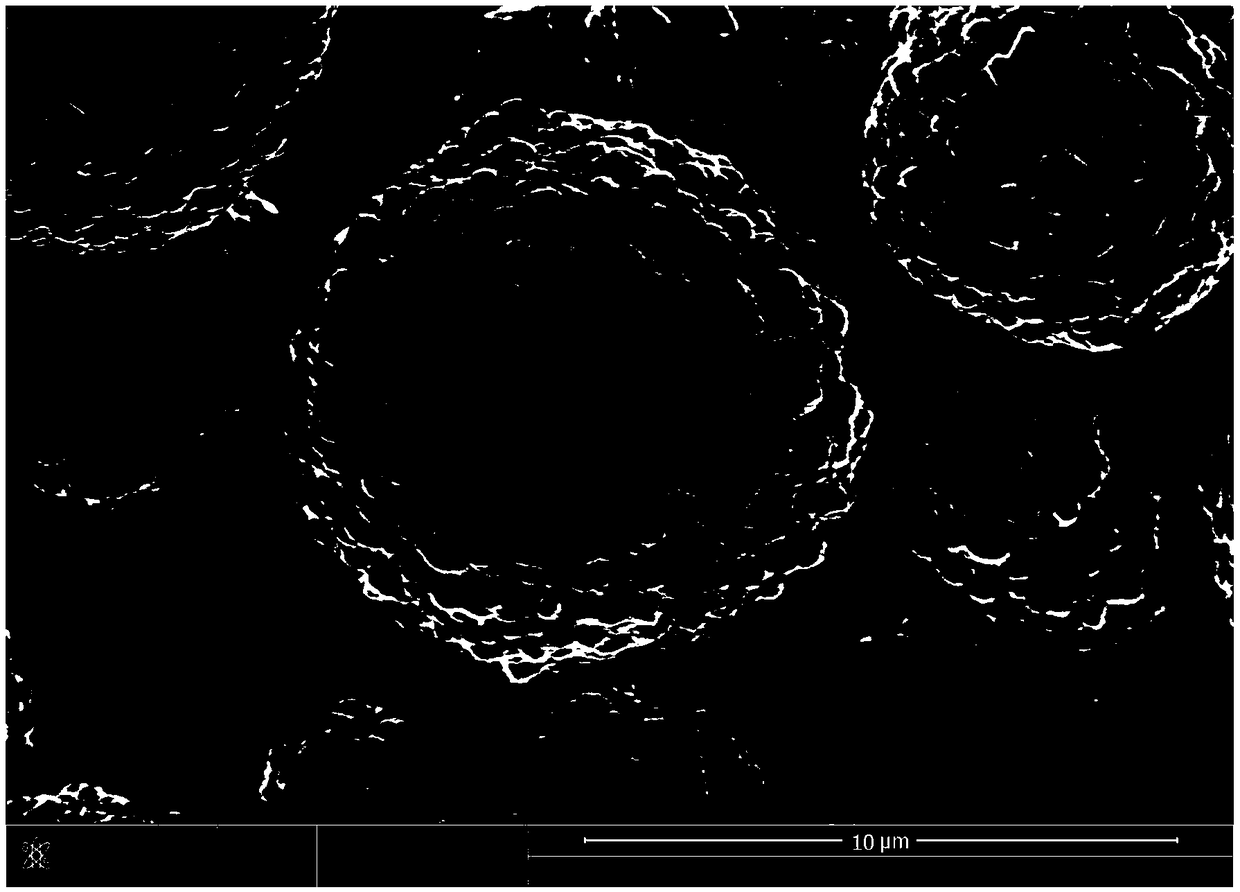

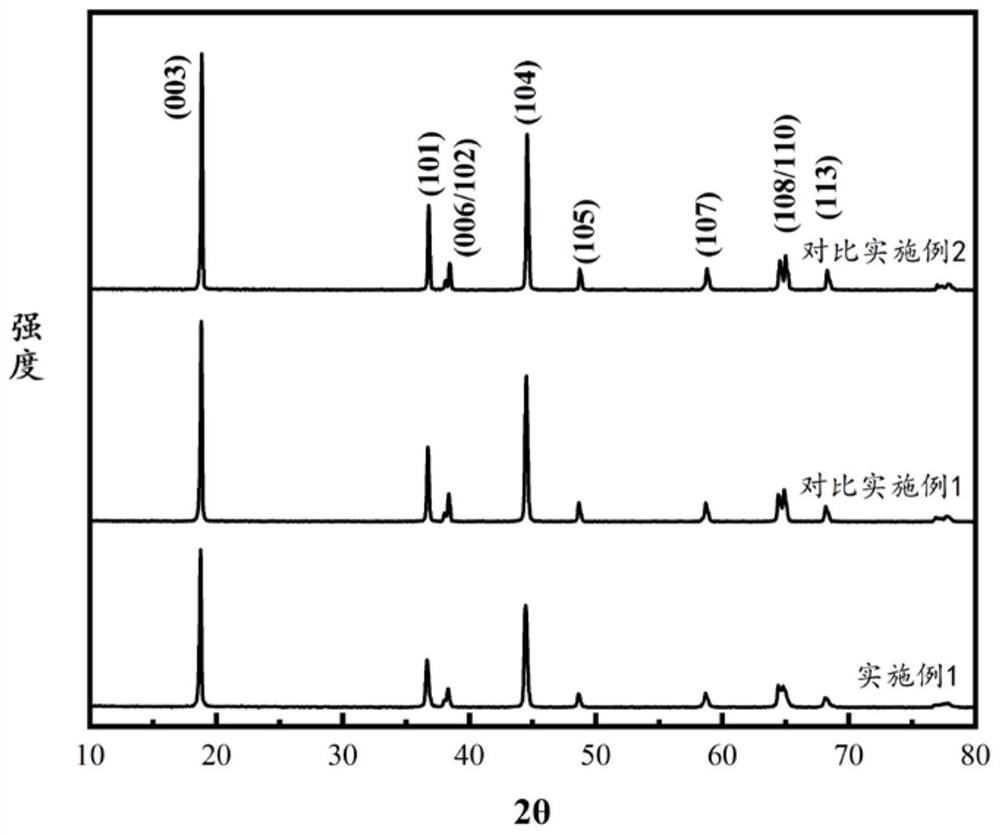

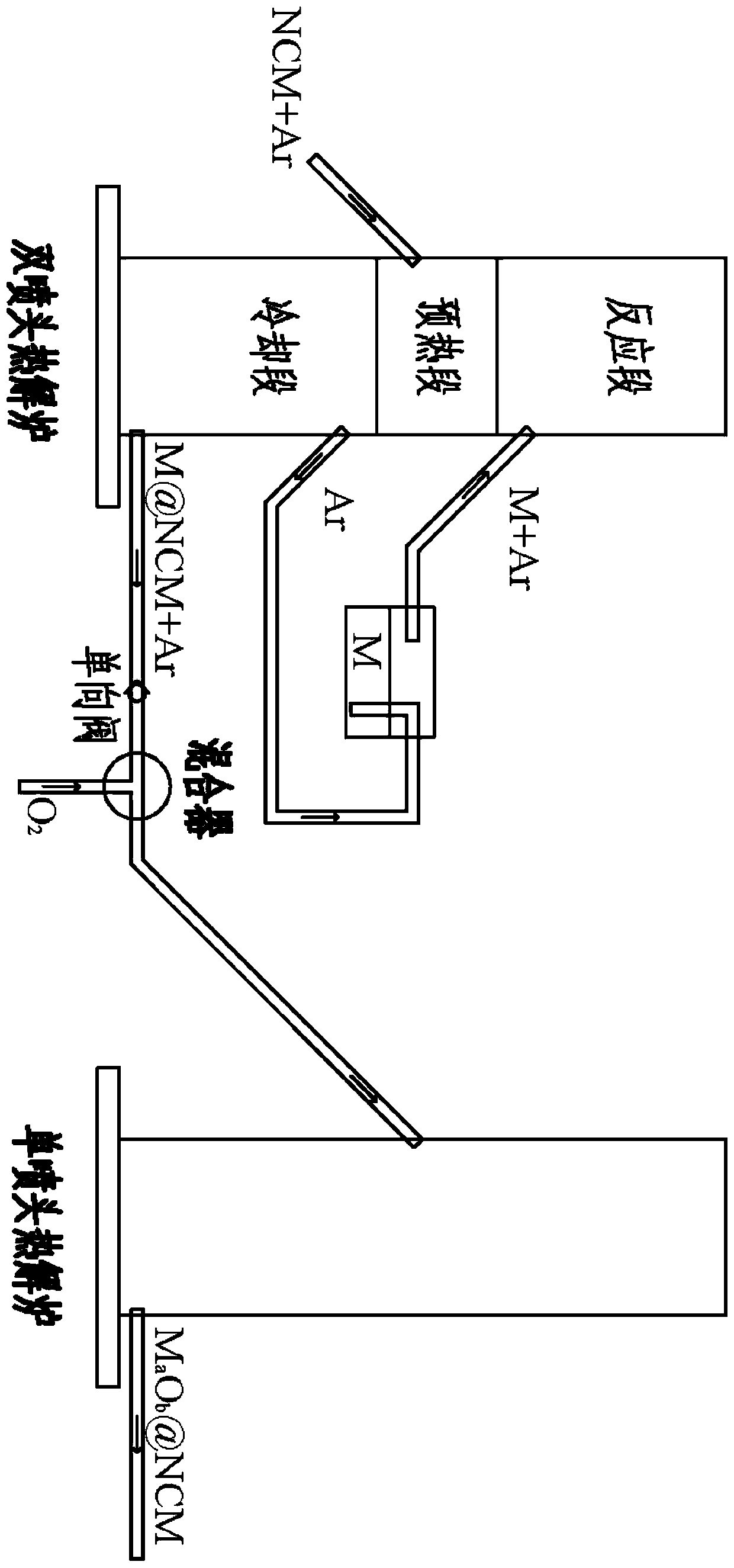

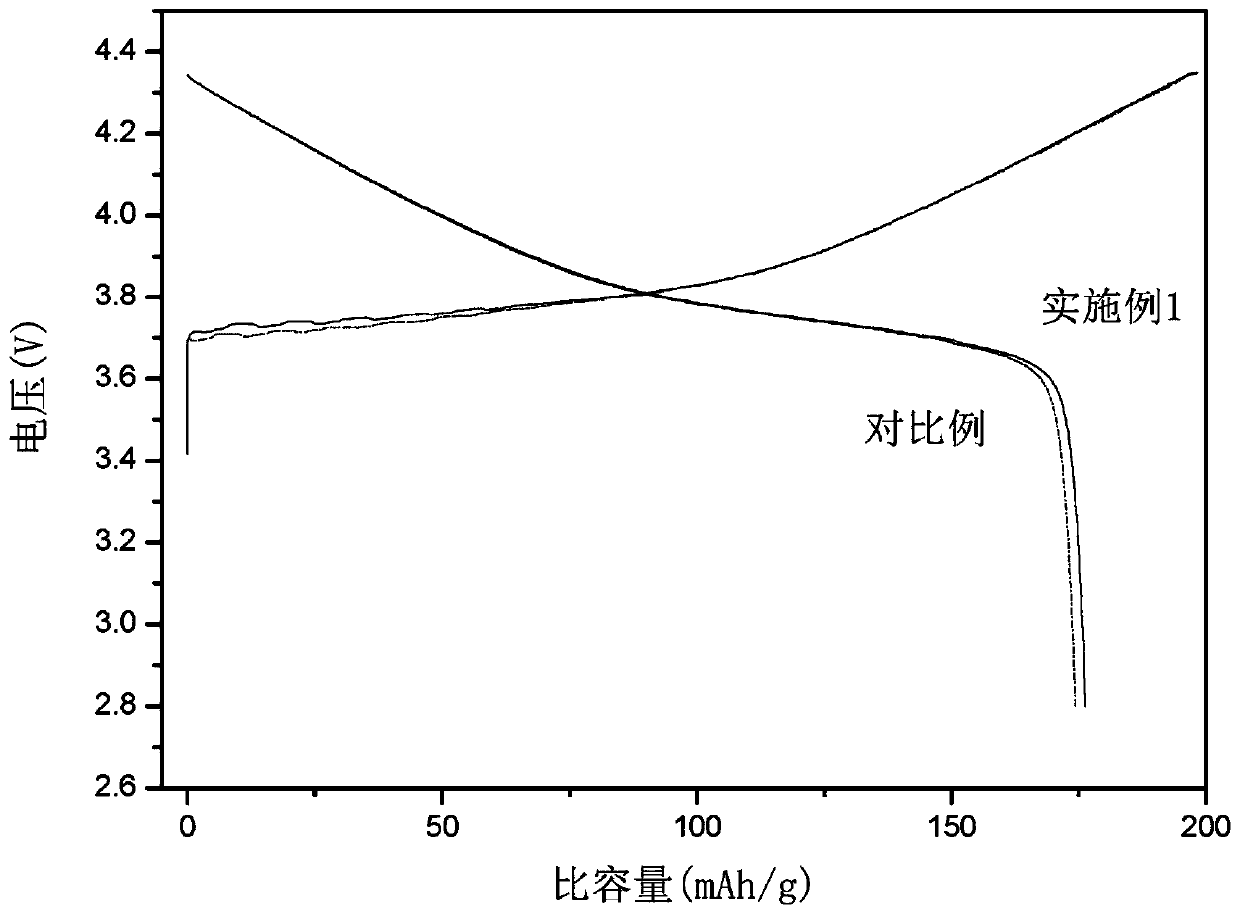

Preparation method of lithium nickel cobalt manganate for coated power battery.

ActiveCN108832083AWrap implementationImprove bindingCell electrodesSecondary cellsManganateMetal particle

The invention discloses a preparation method of lithium nickel cobalt manganate for coated power battery. The method comprises the following steps: 1) preheating the lithium nickel cobalt manganate particles; 2) heating the metal to be coated to boiling under an inert gas atmosphere to obtain metal vapor; 3) blowing the preheated lithium nickel cobalt manganate particles into a pyrolysis furnace with an inert gas, and simultaneously blowing metal vapor into the pyrolysis furnace for reaction with the inert gas; 4) the obtained particles are sent to a mixer through an inert gas, and mixed withan oxygen-containing mixed gas to form a solid-gas mixture; 5) the solid-gas mixture is sent to a pyrolysis furnace for reaction. The invention adopts the method of molten metal vapor to coat the lithium nickel cobalt manganate, the metal particles can be uniformly adhered on the surface of the lithium nickel cobalt manganate particles by the fine particles, the coating of the ultra-thin layer isrealized, the molten metal is firmly combined with the cathode material, is not easy to fall off, the coating stability is good, and the performance of the lithium nickel cobalt manganate cathode material can be remarkably improved.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Environment-friendly ink-jet printing dye ink for artificial cotton and preparation method of environment-friendly ink-jet printing dye ink

The invention discloses a preparation method of environment-friendly inkjet printing dye ink for artificial cotton, which comprises the following steps: adding water and a benzyl vinyl trimethyl ammonium chloride solution into a reactor, adding styrene and butyl acrylate, adding a 2, 2 '-azobis [2-methylpropylamidine]-dihydrochloride solution, and stirring for reaction to prepare a polymer microsphere dispersion liquid; adding caffeic acid, copper chloride and sodium perborate into the polymer microsphere dispersion liquid, heating, stirring and reacting to obtain modified dispersion liquid; adding a reactive dye solution and water into a reactor, adding the modified dispersion liquid, and purifying the mixed liquid through dialysis to prepare a reactive dye / polymer microsphere compound; the reactive dye / polymer microspheres, a dispersing agent, a defoaming agent and water are mixed and added into a mixer for grinding treatment, a viscosity regulator and a pH regulator are added, and the environment-friendly ink-jet printing dye ink for artificial cotton is prepared through stirring. The prepared ink is good in dispersity, high in degree of dyeing and good in color fastness when being used for artificial cotton printing.

Owner:绍兴舜锦纺织品有限公司

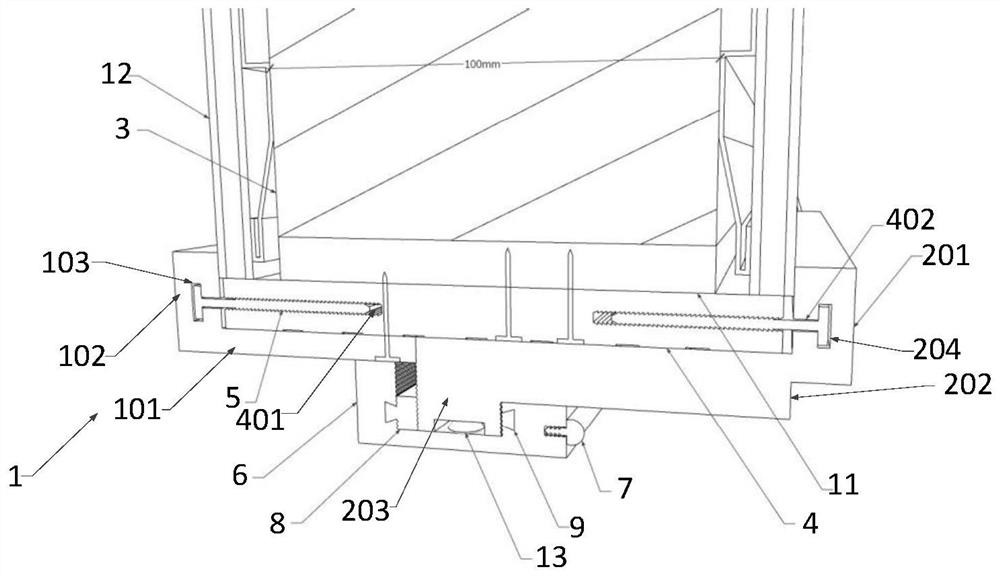

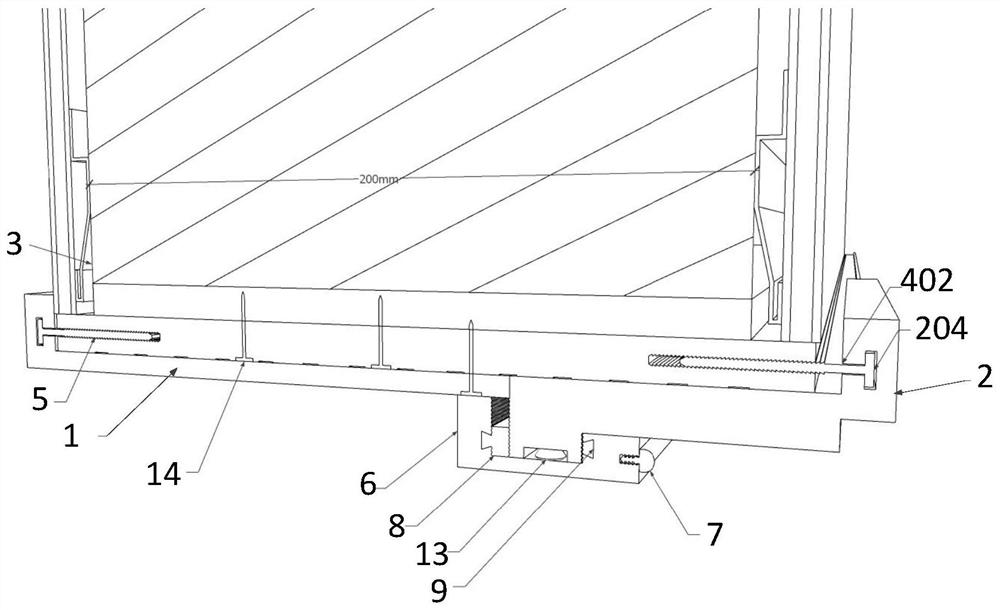

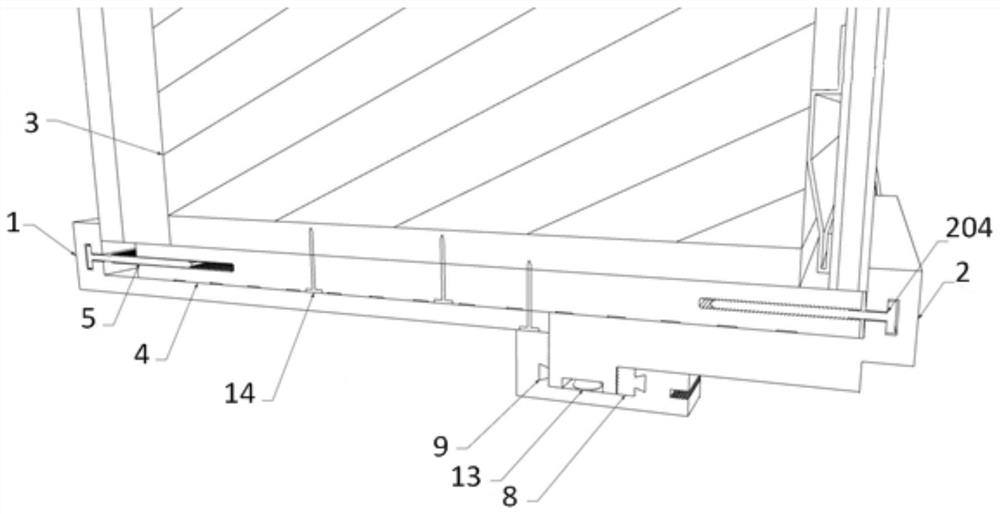

Quick door pocket installation system

InactiveCN111809835AWrap implementationRealize forceBuilding constructionsStructural engineeringMechanical engineering

The invention provides a quick door pocket installation system. The quick door pocket installation system can be subjected to mass production and can adapt to different situations through overall cooperation to form a door pocket after installation. The quick door pocket installation system comprises a first mounting plate, a second mounting plate, lining plates, a door stop strip and a door stopcushion pad, wherein the first mounting plate and the second mounting plate are oppositely arranged on two sides of a wall; the lining plates are arranged between the first mounting plate and the walland between the second mounting plate and the wall respectively and are connected to the first mounting plate and the second mounting plate through plug-in pieces separately; the door stop strip abuts against the first mounting plate and the second mounting plate, and one end of the second mounting plate is placed in the door stop strip; and the door stop cushion pad is arranged on one side of the door stop strip. The quick door pocket installation system can meet the on-site requirements after being cut according to the on-site size, the cost is reduced while the construction efficiency is shortened, and the decoration period is further shortened.

Owner:变形积木(北京)科技有限公司

Metal fluoride coated ternary material and preparation method thereof

ActiveCN108232131BImprove cycle performanceIncrease storage capacityMaterial nanotechnologyCell electrodesPhysical chemistryFluoride

The invention proposes a metal fluoride-coated ternary material and a preparation method thereof. The ternary material is combined with a metal fluoride by multiple ball milling to form a metal fluoride-coated ternary material. The invention avoids the use of a wet process for fluoride coating, does not need to use a fluoride precipitant, does not cause corrosion to positive electrode materials, and has relatively low requirements for equipment corrosion protection. By adopting the preparation method of the metal fluoride-coated ternary material of the present invention, the coating of the ternary positive electrode material with nanoscale metal fluoride particles can be realized. The preparation method is simple, efficient, operable and suitable for large-scale industrial production. The obtained metal fluoride-coated ternary material improves the cycle performance and storage performance of the cathode material.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

A chemical exchange saturation transfer contrast agent and its preparation method and application

ActiveCN109568609BIncreased sensitivityGood biocompatibilityDispersion deliveryEmulsion deliveryActive agentCholesterol

The disclosure provides a chemical exchange saturation transfer contrast agent and its preparation method and application, belonging to the technical field of nuclear magnetic resonance imaging. The contrast agent is a new type of LipoCEST contrast agent. On the basis of retaining the advantages of high sensitivity of the original iodine-based CEST contrast agent, it also has high biocompatibility and safety, and solves the problem of traditional CEST contrast agents such as iohexol. The disadvantages such as fast excretion in the tumor area and low retention rate improve the EPR effect in the tumor area. The contrast agent is formed by wrapping an iodine contrast agent with a surfactant, and the surfactant is selected from one or more of phosphatidylcholine liposomes, phosphatidylethanolamine liposomes, phosphatidylserine, lecithin or cholesterol. mixture of species. This contrast agent is used in magnetic resonance imaging.

Owner:HARBIN MEDICAL UNIVERSITY

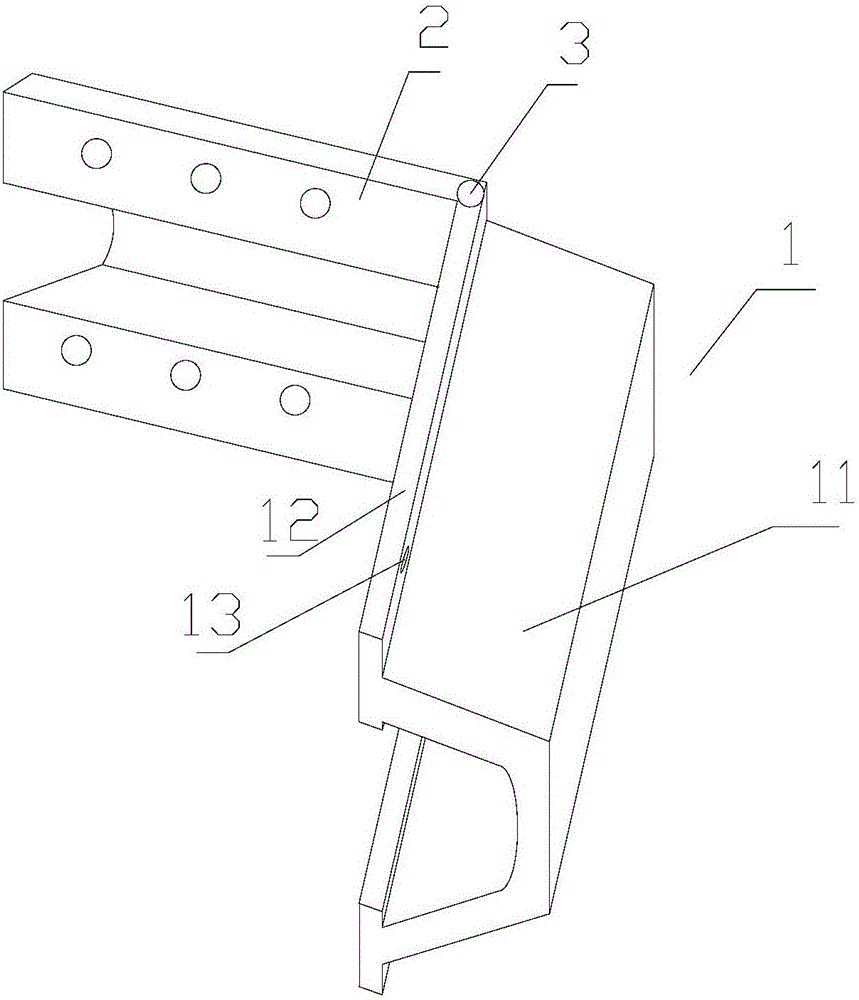

Cornerite type fender

InactiveCN106759120AAdjust in timeWrap implementationClimate change adaptationShipping equipmentEngineering

The invention discloses a cornerite type fender which comprises a first fender body (1), a second fender body (2) and a hinge part (3). One end of the first fender body (1) is hinged to one end of the second fender body (2) through the hinge part (3), and the included angle formed between the first fender body (1) and the second fender body (2) can be adjusted. By adoption of the cornerite type fender, the problem that in the prior art, a corner on a wharf is inconvenient to wrap and indeterminate in angle, and consequentially a fender needs to be re-customized is solved, and multi-angle corner wrapping is achieved.

Owner:安徽澎柏橡胶制品有限公司

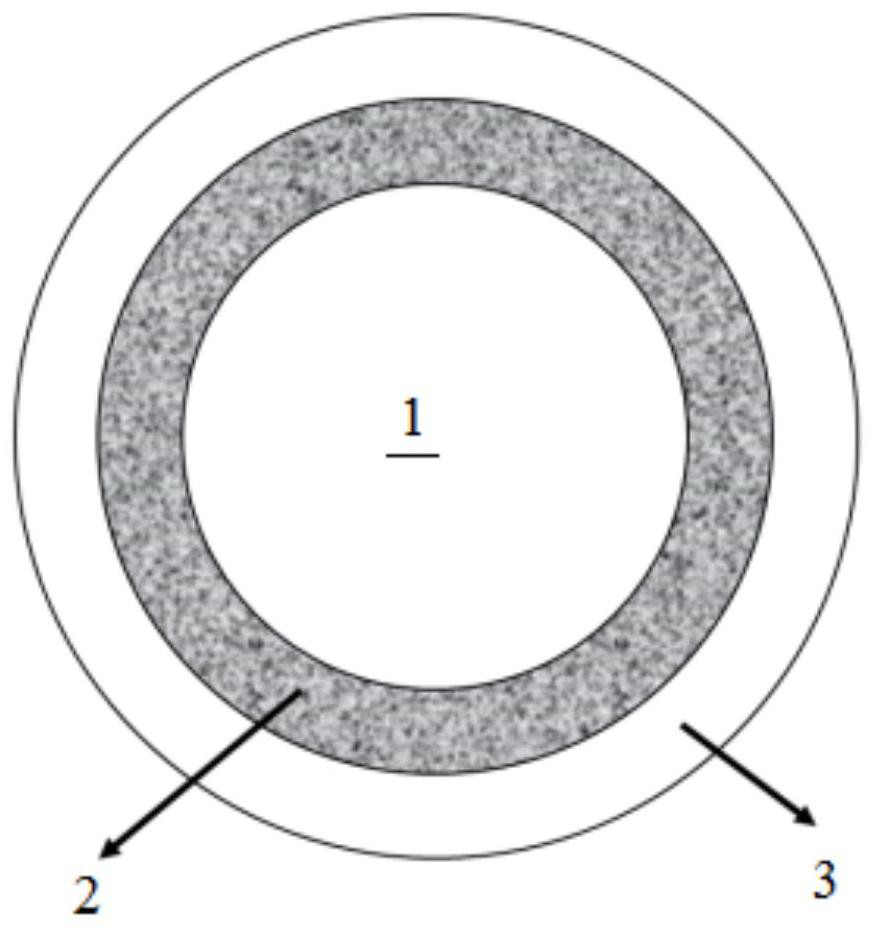

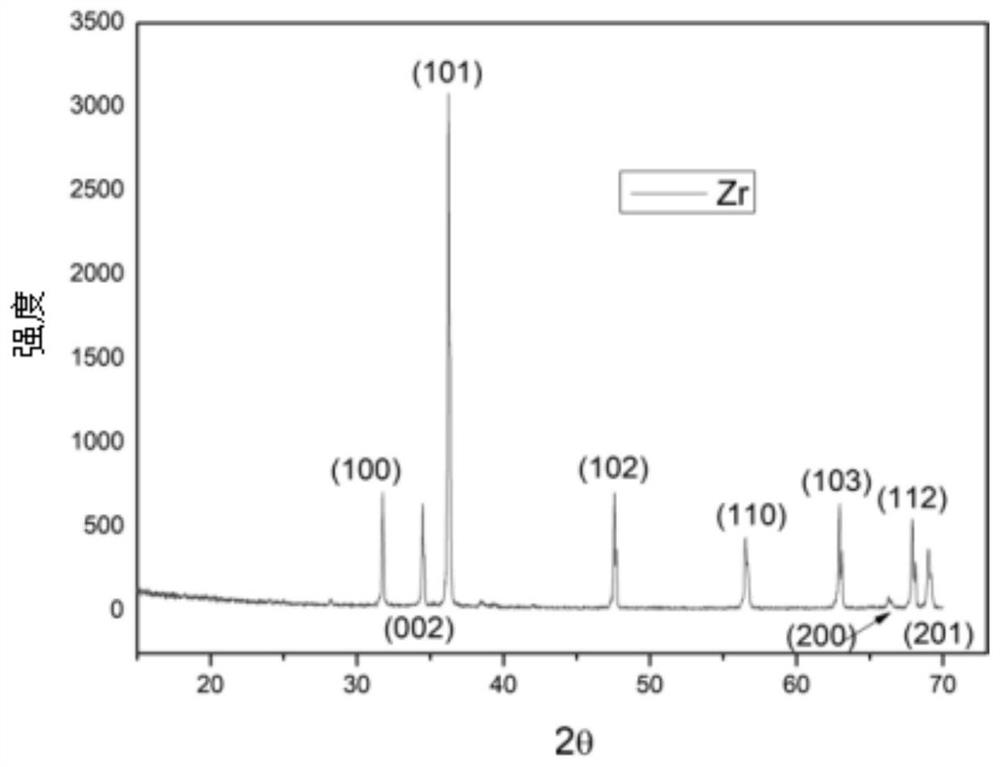

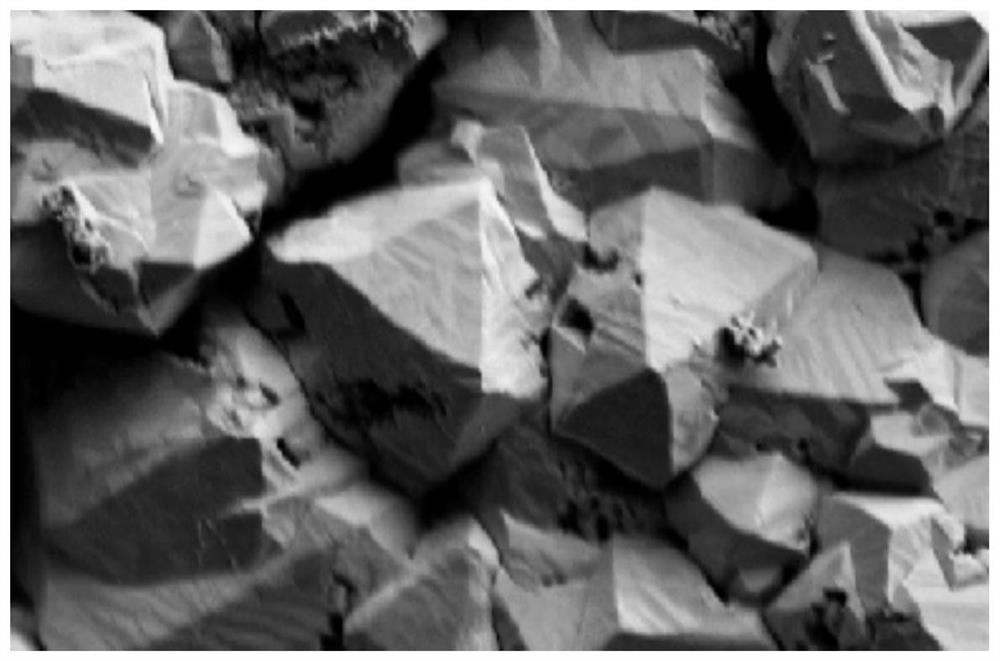

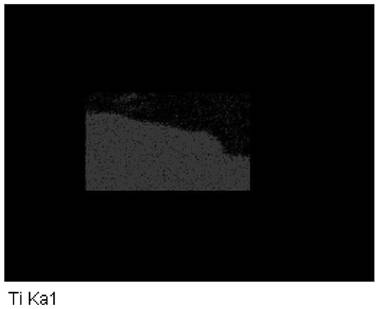

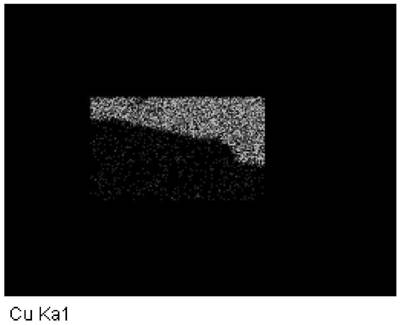

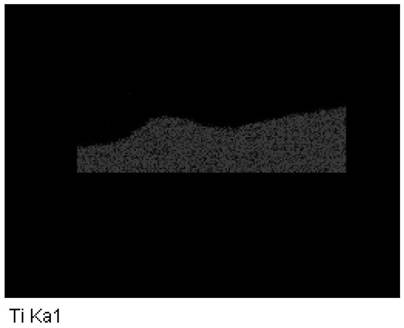

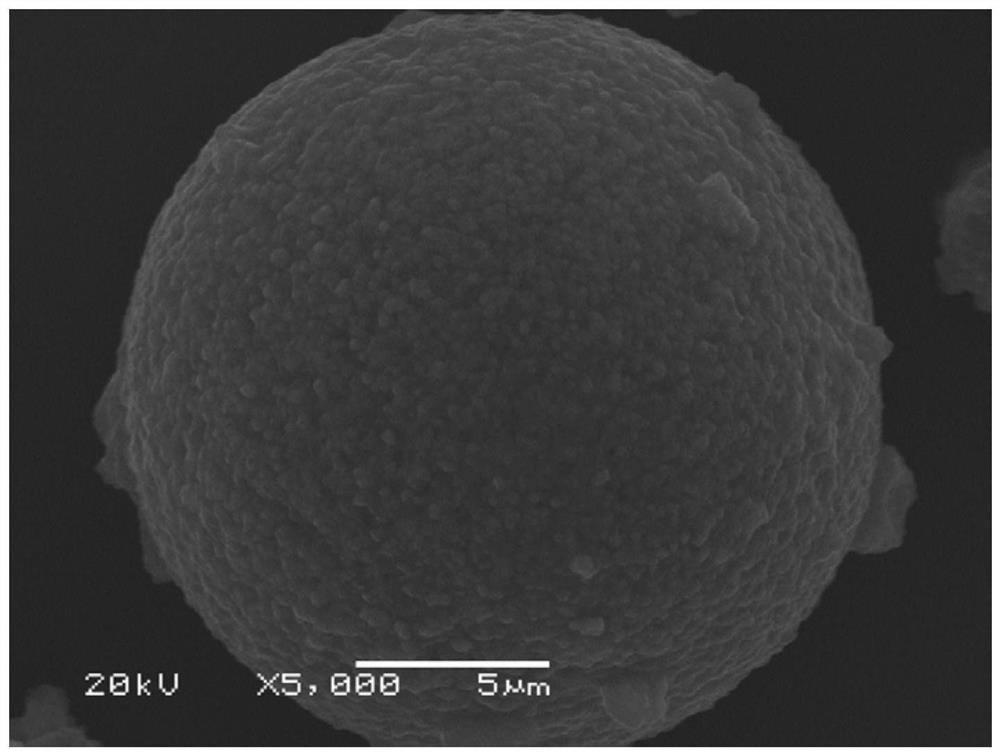

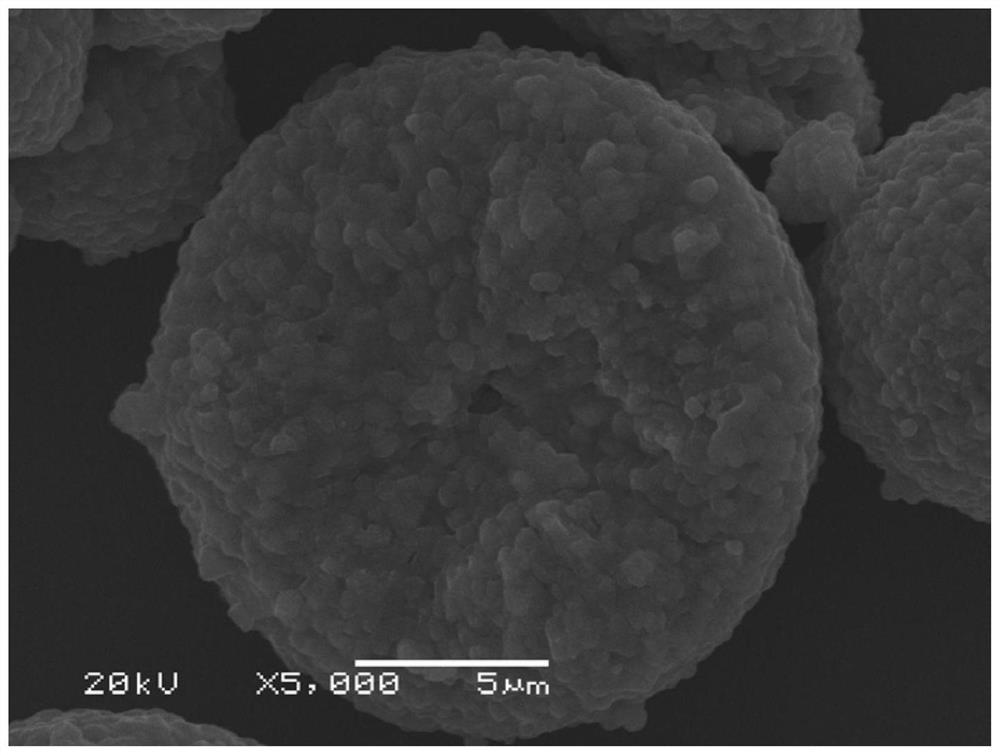

Titanium and titanium alloy particles coated with low-hardness metal on the surface and preparation method thereof

ActiveCN110238389BIsolated contactAffect mechanical propertiesTransportation and packagingMetal-working apparatusTitanium matrix compositesTitanium

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

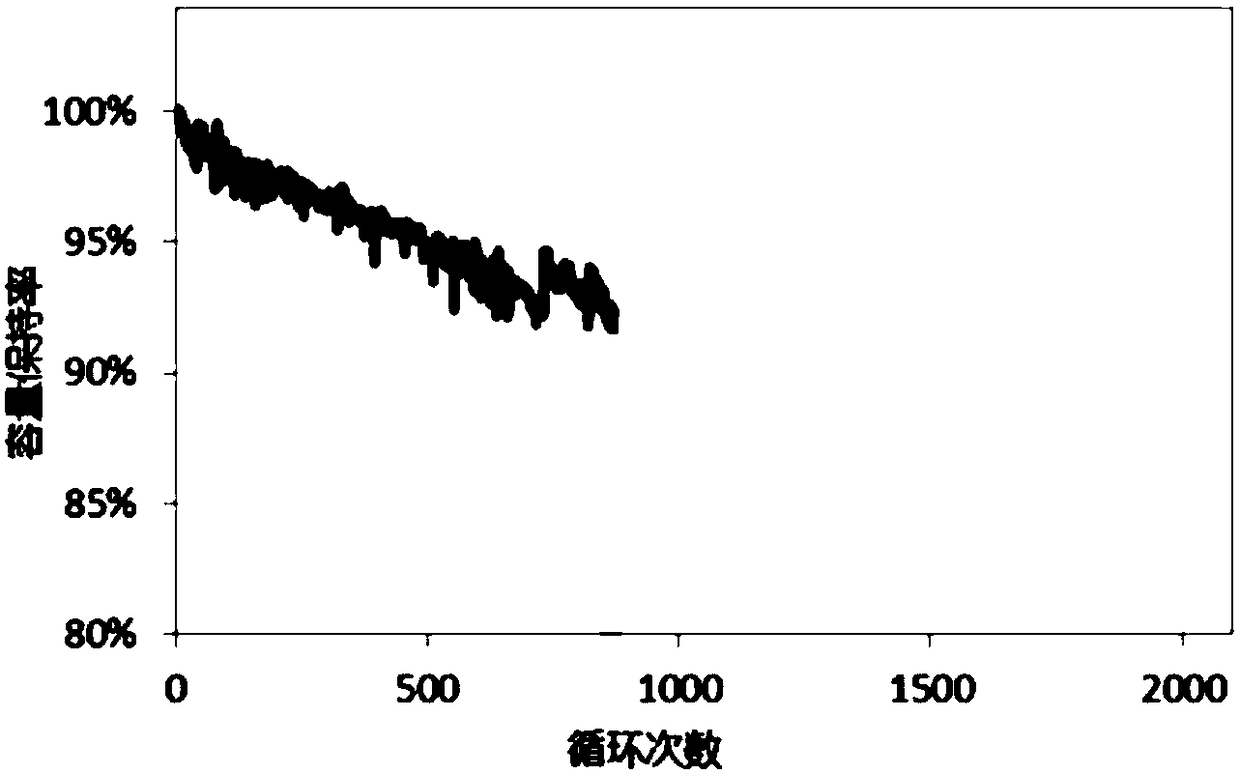

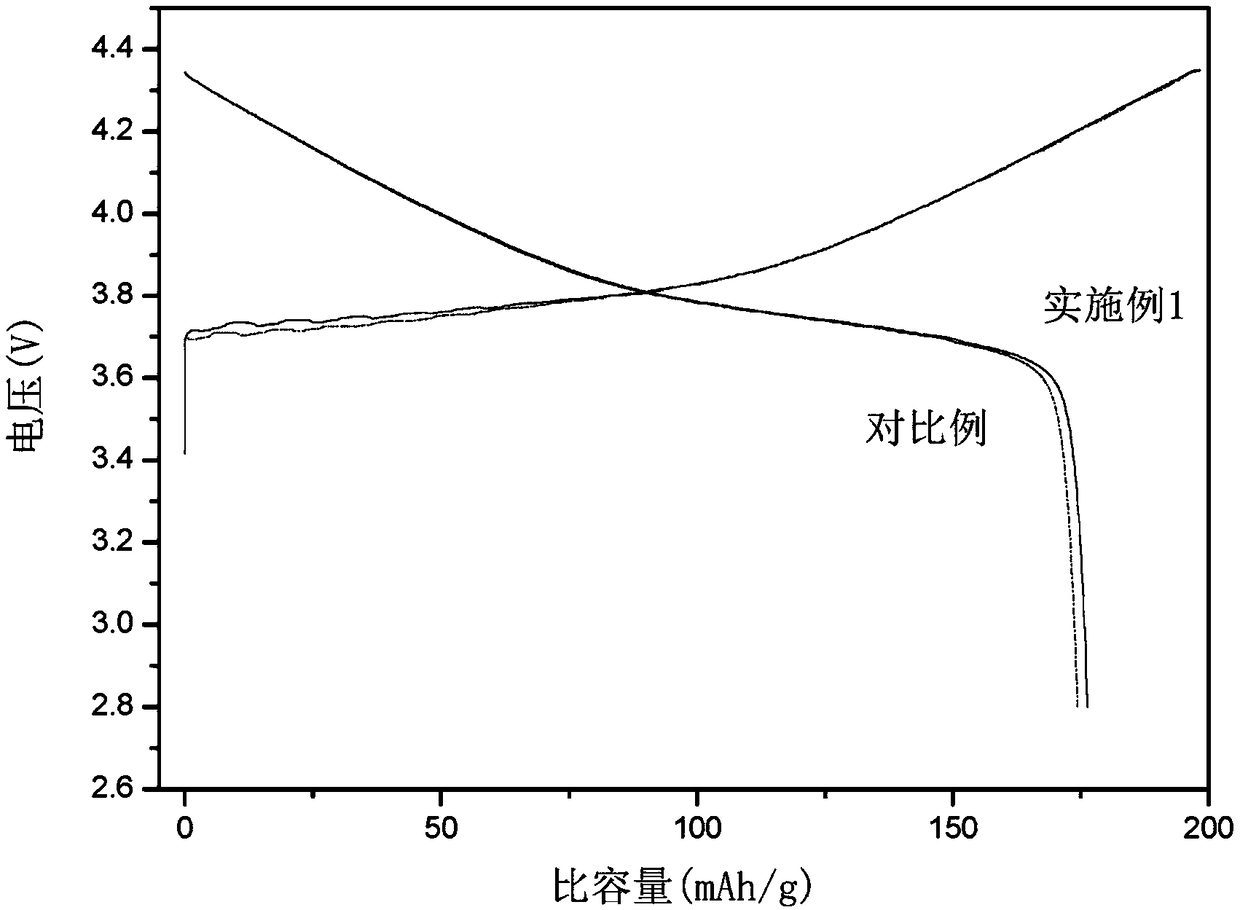

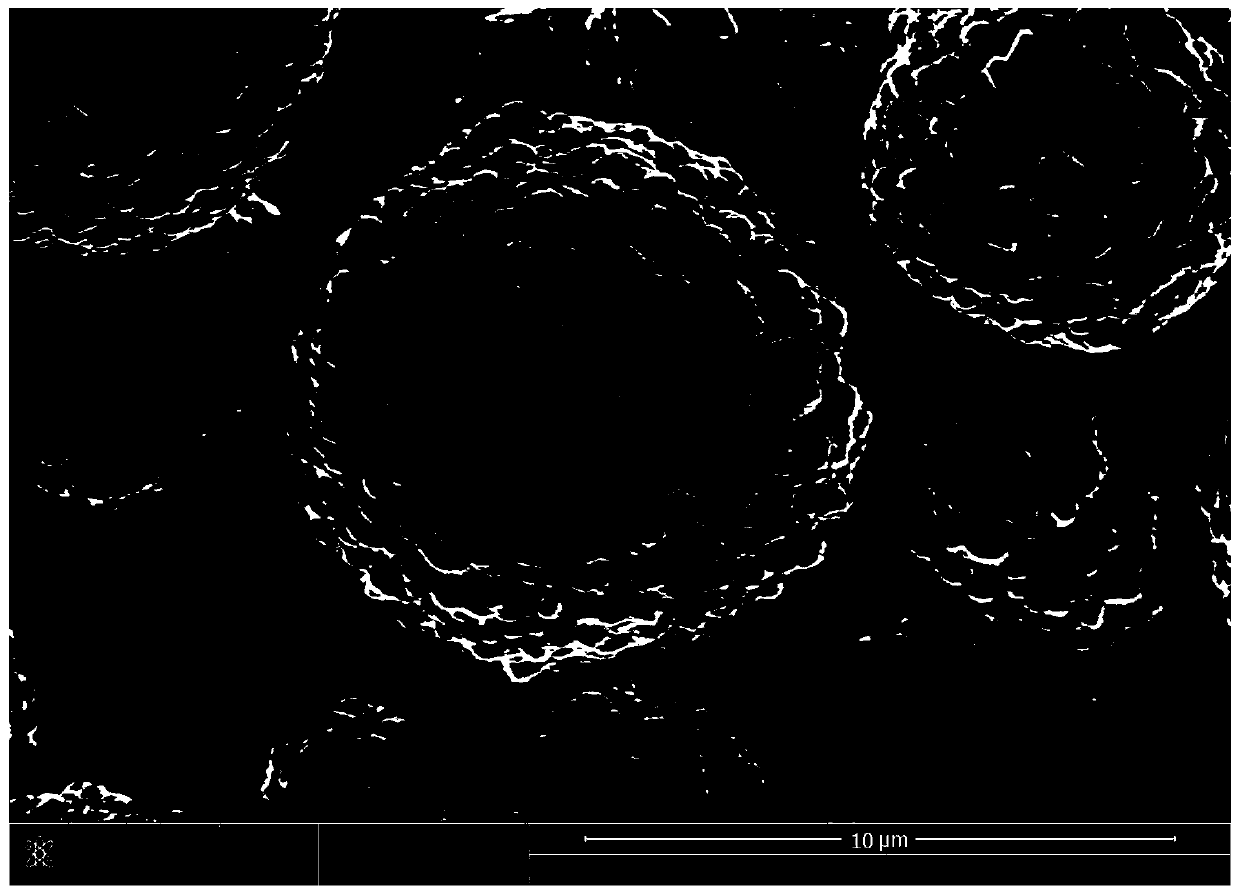

A kind of nickel-cobalt-manganese ternary positive electrode material and its preparation method and application

ActiveCN110247045BImprove cycle performanceLower impedanceSecondary cellsPositive electrodesElectrical batteryManganese

The invention provides a nickel-cobalt-manganese ternary positive electrode material and a preparation method and application thereof. The nickel-cobalt-manganese ternary positive electrode material is LiNi<0.8>Co<0.1>Mn<0.2>O<2>, and the surface with primary particles of the nickel-cobalt-manganese ternary positive electrode material is coated with lithium boron oxide. The preparation method comprises the following steps: dispersing a nickel-cobalt-manganese ternary precursor into an alcohol solution, and performing stirring and mixing to form a solution A; adding boric acid into water, and stirring until the boric acid is completely dissolved to form a solution B; adding the solution B into the solution A, stirring, heating and drying by distillation to obtain solid powder; and mixing the solid powder with lithium salt, and calcining to obtain the nickel-cobalt-manganese ternary positive electrode material. The coating substance H3BO3 is dissolved in an aqueous solution, enters gaps of secondary particles of the ternary precursor, is separated out among the primary particles in the solvent evaporation drying process, and is then fired, so that coating of the primary particles is realized, generation of microcracks of the primary particles can be effectively inhibited, and the cycle stability of a battery is improved.

Owner:CENT SOUTH UNIV

A kind of preparation method of nickel-cobalt lithium manganese oxide for coated power battery

ActiveCN108832083BWrap implementationImprove bindingCell electrodesSecondary cellsPower batteryManganate

The invention discloses a preparation method of lithium nickel cobalt manganate for coated power battery. The method comprises the following steps: 1) preheating the lithium nickel cobalt manganate particles; 2) heating the metal to be coated to boiling under an inert gas atmosphere to obtain metal vapor; 3) blowing the preheated lithium nickel cobalt manganate particles into a pyrolysis furnace with an inert gas, and simultaneously blowing metal vapor into the pyrolysis furnace for reaction with the inert gas; 4) the obtained particles are sent to a mixer through an inert gas, and mixed withan oxygen-containing mixed gas to form a solid-gas mixture; 5) the solid-gas mixture is sent to a pyrolysis furnace for reaction. The invention adopts the method of molten metal vapor to coat the lithium nickel cobalt manganate, the metal particles can be uniformly adhered on the surface of the lithium nickel cobalt manganate particles by the fine particles, the coating of the ultra-thin layer isrealized, the molten metal is firmly combined with the cathode material, is not easy to fall off, the coating stability is good, and the performance of the lithium nickel cobalt manganate cathode material can be remarkably improved.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

A preparation method of highly ordered mesoporous carbon-coated magnetic nanoparticles

ActiveCN104134504BWrap implementationAvoid exposureMaterial nanotechnologyInorganic material magnetismMagnetite NanoparticlesCarbonization

A method for preparing highly ordered mesoporous carbon-coated magnetic nanoparticles. The method uses magnetic nanoparticles as the core, and uses electrostatic or hydrophobic interactions to fully coat the organic template agent on the outer layer of the magnetic core. Through the formation of mesoporous The organic polymer precursor of the porous carbon and the self-assembly coating of the organic template on the surface of the magnetic core are carbonized at a high temperature to form a highly ordered mesoporous carbon-coated magnetic nanomaterial; the highly ordered mesoporous carbon coating prepared by the present invention The coated magnetic nanoparticles can be applied to bioseparation, drug delivery, nuclear magnetic resonance imaging, catalysis and other fields.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A silicon nanowire, its preparation method and its application for preparing carbon-coated silicon nanowire anode material

ActiveCN106207144BGood lookingEvenly distributedNon-aqueous electrolyte accumulatorsCell electrodesElectrolysisArgon atmosphere

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com