Metal-coated fuel and preparation method thereof

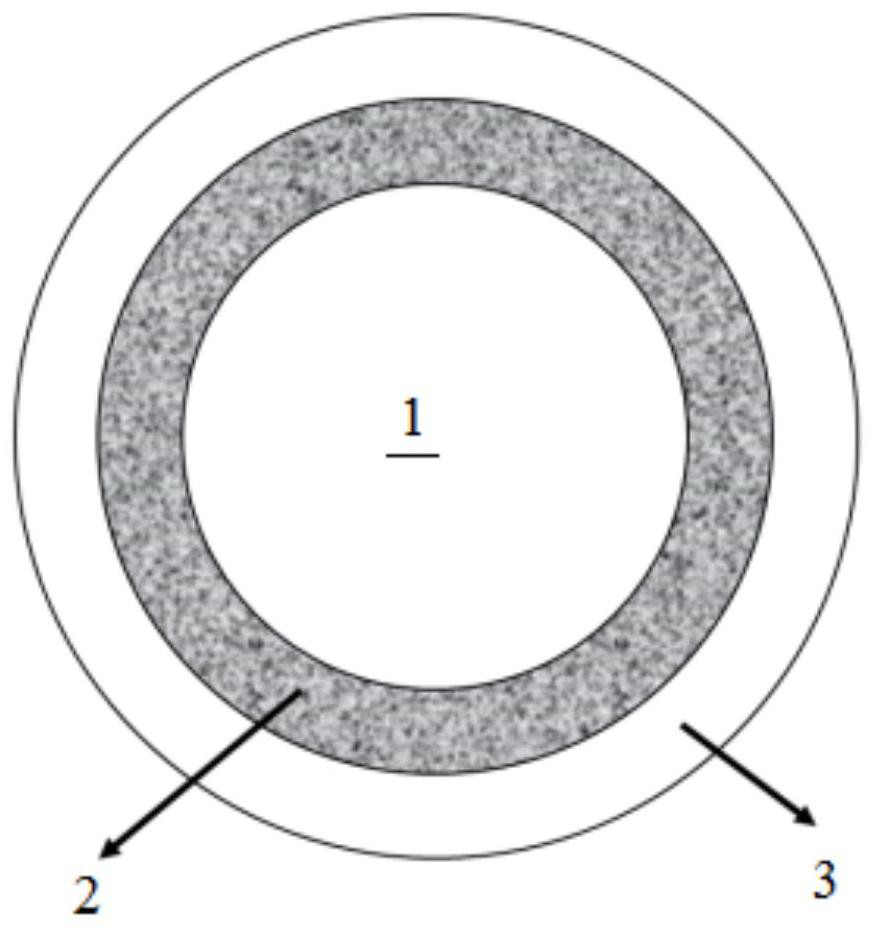

A metal cladding and fuel technology, which is applied in the fields of reactor fuel material, reactor manufacturing, and greenhouse gas reduction, etc., can solve the problems of poor performance of TRISO particles and endanger the safety of reactor operation, and achieve the effect of improving anti-oxidation performance and increasing melting point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

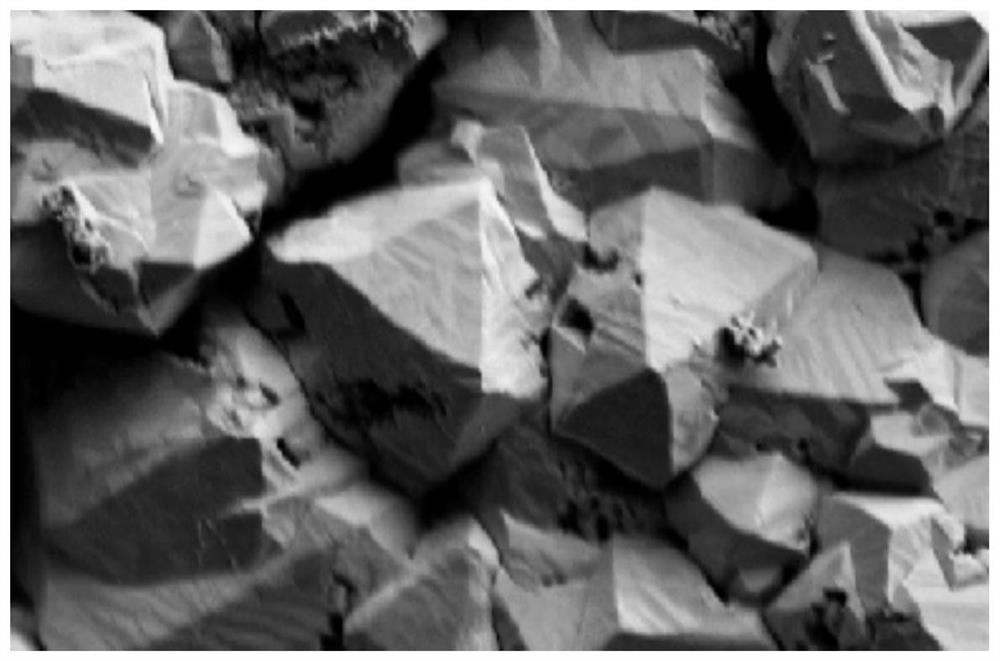

[0028] Example 1: Coated fuel particles with metallic niobium coating.

[0029] 1) The establishment of the relationship between the carrier concentration of the precursor and the temperature of the evaporation tank and the flow rate of the carrier gas: the tank temperature of niobium pentachloride is set at 150°C, 160°C, 170°C, 180°C, 190°C, 200°C, 210°C At different temperatures such as ℃, control the flow rate of hydrogen or argon carrier gas at 1L / min, 2L / min, 3L / min, 4L / min, 5L / min, 6L / min, etc., and control two factors to do parallel experiments , to establish the relationship between carrier gas concentration, tank temperature and carrier gas flow rate.

[0030] 2) Establish the relationship between the porosity of the metal coating and the carrier concentration of the precursor, and study the porosity of the coating and the tank body of the carrier concentration of the precursor at different concentrations. The precursor loading concentrations of the loose niobium coa...

Embodiment 2

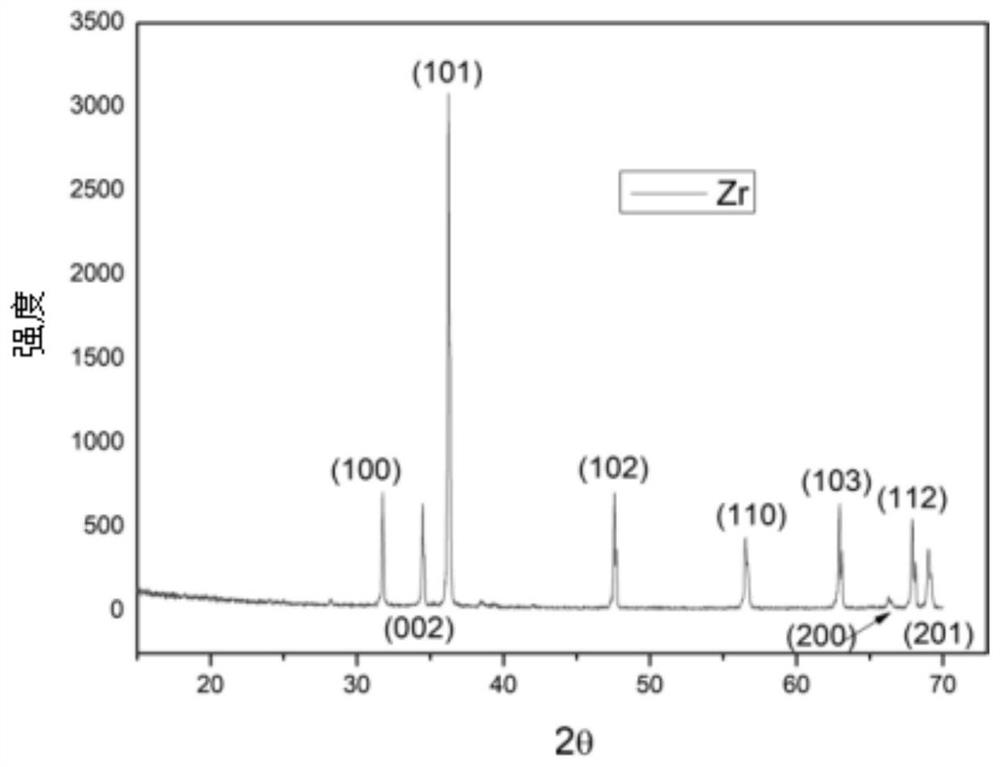

[0036] Example 2: Coated fuel particles with metallic zirconium coating.

[0037]1) The establishment of the relationship between the carrier concentration of the zirconium precursor and the problem of the evaporation tank and the flow rate of the carrier gas: set the temperature of the tank containing zirconium tetraiodide at 300°C, 310°C, 320°C, 330°C, 340°C, 350°C ℃, 360℃, 370℃ and other different temperatures, control the flow rate of hydrogen or argon carrier gas at 1L / min, 2L / min, 3L / min, 4L / min, 5L / min, 6L / min, etc. Parallel experiments were carried out on two factors to establish the relationship between the concentration of zirconium tetraiodide carrier gas, the temperature of the tank and the flow rate of the carrier gas.

[0038] 2) Establish the relationship between the porosity of the zirconium metal coating and the concentration of the precursor, and study the porosity of the zirconium coating and the tank of the precursor concentration at different concentration...

Embodiment 3

[0046] Example 3: Coated fuel particles with metallic tungsten coating.

[0047] 1) Establishment of the relationship between the carrier concentration of the precursor and the problem of the evaporation tank and the flow rate of the carrier gas: set the temperature of the tank containing tungsten hexachloride at 190°C, 200°C, 210°C, 220°C, 230°C, 240°C , 250°C, 260°C, 270°C and other different temperatures, control the flow rate of hydrogen or argon carrier gas at 1L / min, 2L / min, 3L / min, 4L / min, 5L / min, 6L / min and other different flow rates , control the two factors to do parallel experiments, and establish the relationship between the concentration of tungsten hexachloride carrier gas, the temperature of the tank and the flow rate of the carrier gas.

[0048] 2) Establish the relationship between the porosity of the tungsten metal coating and the concentration of the precursor, and study the porosity of the tungsten coating and the tank of the precursor concentration at diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com