Foam glass prepared from fly ash as well as preparation method and application thereof

A foam glass and fly ash technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of fly ash polluting the environment and achieve the effects of avoiding environmental hazards, reducing pore content, and reducing pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

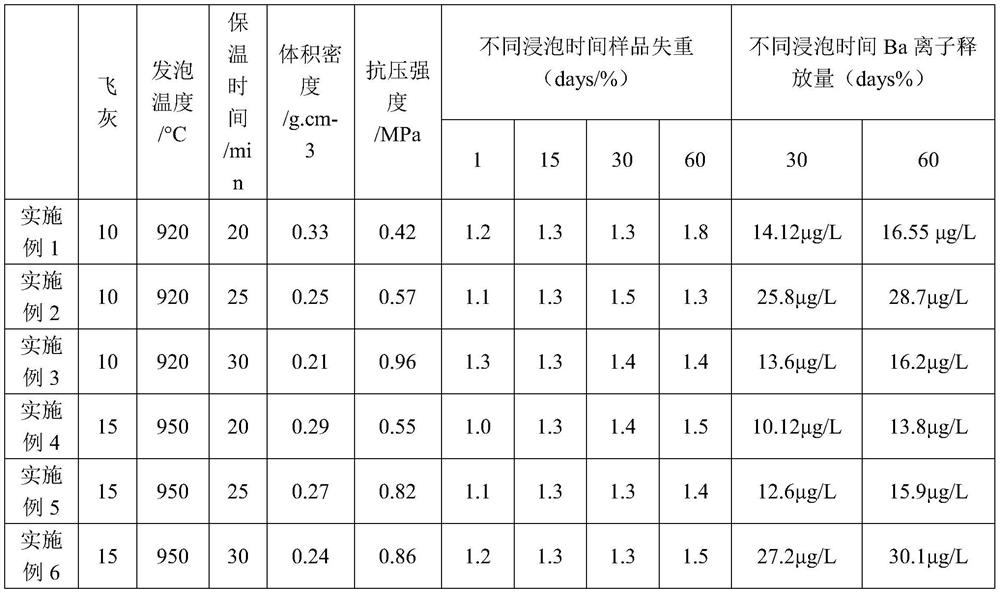

[0028] 1) The fly ash was mixed with glass powder and silicon carbide for 30 minutes using a planetary dry ball mill to obtain a mixture. The mass fraction of fly ash in the mixture was 15%, and the mass fraction of silicon carbide in the mixture was 1%. Add PVB alcohol solution with a mass concentration of 10% to the mixture. The mass of PVB alcohol solution is 5% of the mixture. After granulation, carry out semi-dry pressing molding with a molding pressure of 20 tons to obtain a green body with a specification of φ30×10mm ;

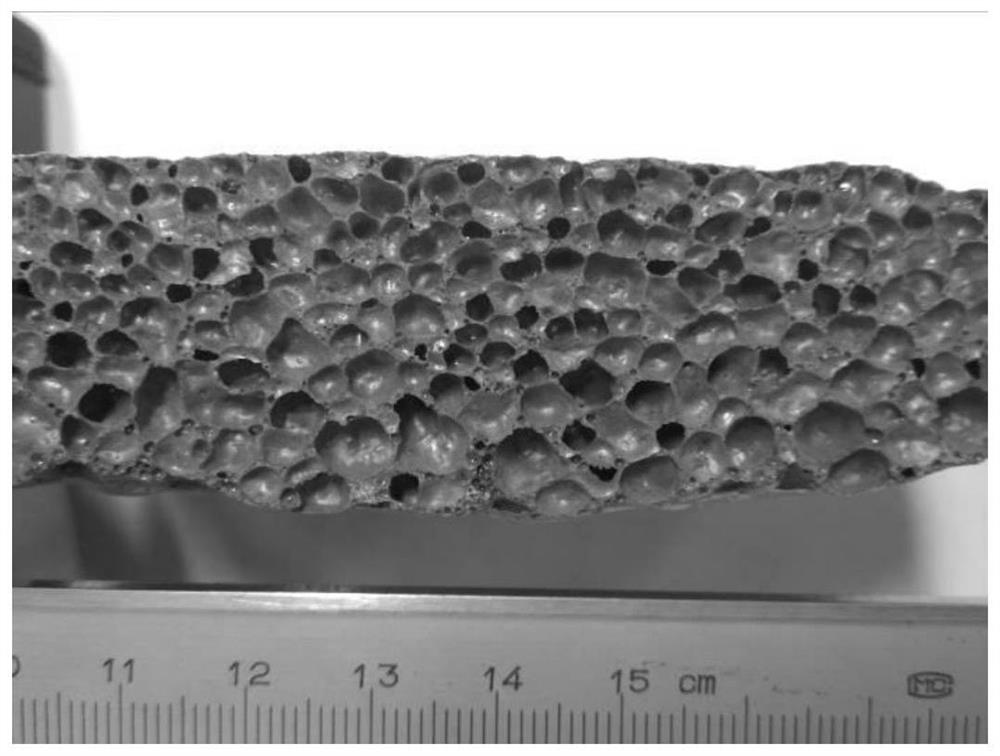

[0029] 2) Heat the green body at 120°C for 12 hours, then raise the temperature to 720°C for 4 hours, then raise the temperature to 950°C for 30 minutes at a heating rate of 4°C / min for foaming, and finally cool down to 560°C for 4 hours and then The temperature of the furnace is lowered, and the foam glass prepared by using fly ash is obtained, such as figure 1 , 2 As shown in the figure, it can be seen that the product has typical closed-cell foam g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com