A silicon nanowire, its preparation method and its application for preparing carbon-coated silicon nanowire anode material

A technology of silicon nanowires and cathode sheets, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of high energy consumption and unfavorable energy-saving production, and achieve the effects of low energy consumption, low production cost and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

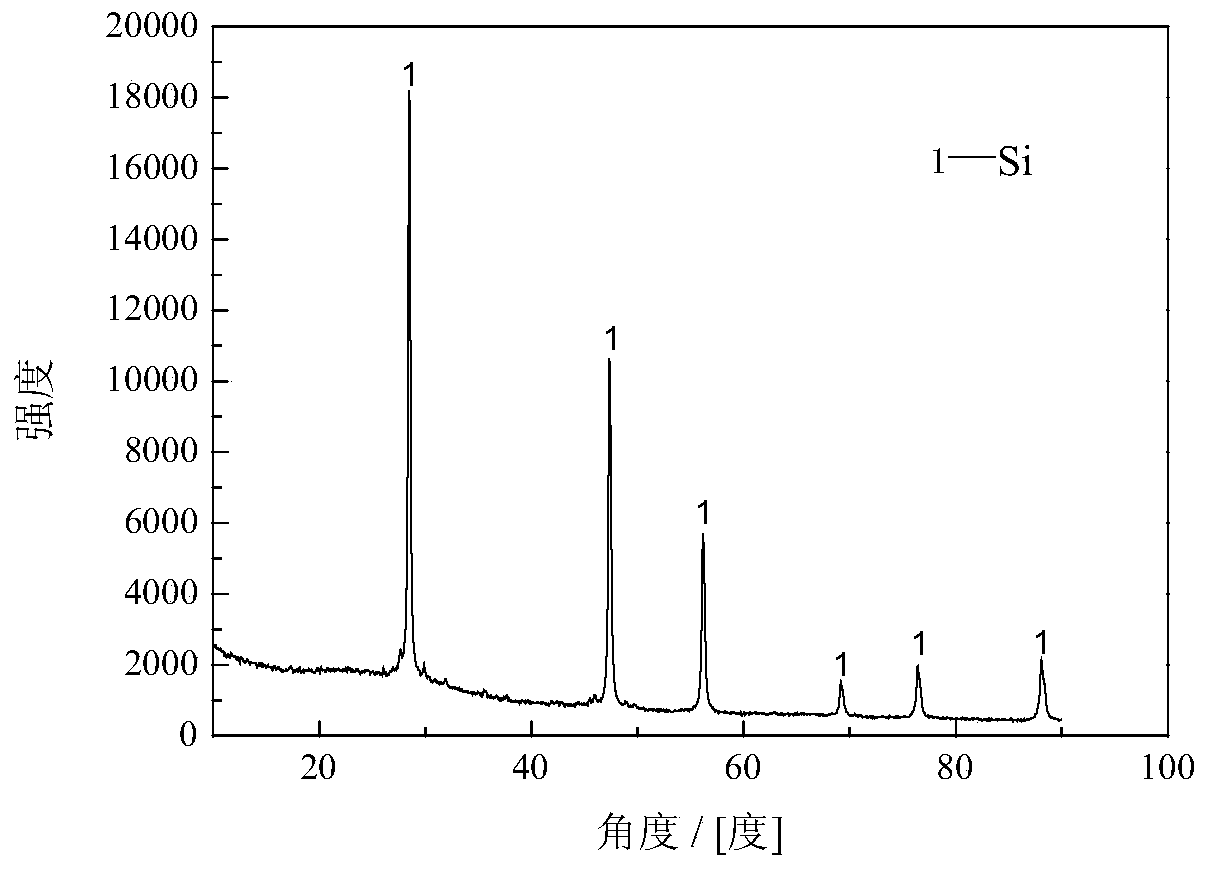

[0067] Preparation of silicon nanowires:

[0068] (1) Take 95g of silicon dioxide granules and 5g of sodium chloride granules and grind them into powder, sieve with a 200-mesh sieve and press the cathode sheet;

[0069] (2) Put the cathode sheet into a tube furnace for low-temperature sintering, the sintering temperature is 320°C, and the sintering time is 2h;

[0070] (3) The obtained cathode sheet is fixed on the iron-chromium-aluminum wire as the cathode, and the high-purity graphite is used as the anode. 2 In the molten salt system, DC voltage electrolysis was carried out under the atmosphere of high-purity argon, the electrolysis voltage was 2.8V, the electrolysis temperature was 500°C, and the electrolysis time was 4.5h;

[0071] (4) The obtained cathode sheet is taken out after soaking in water for 5 hours, washed with hydrofluoric acid, rinsed with deionization, and finally dried to obtain silicon nanowires.

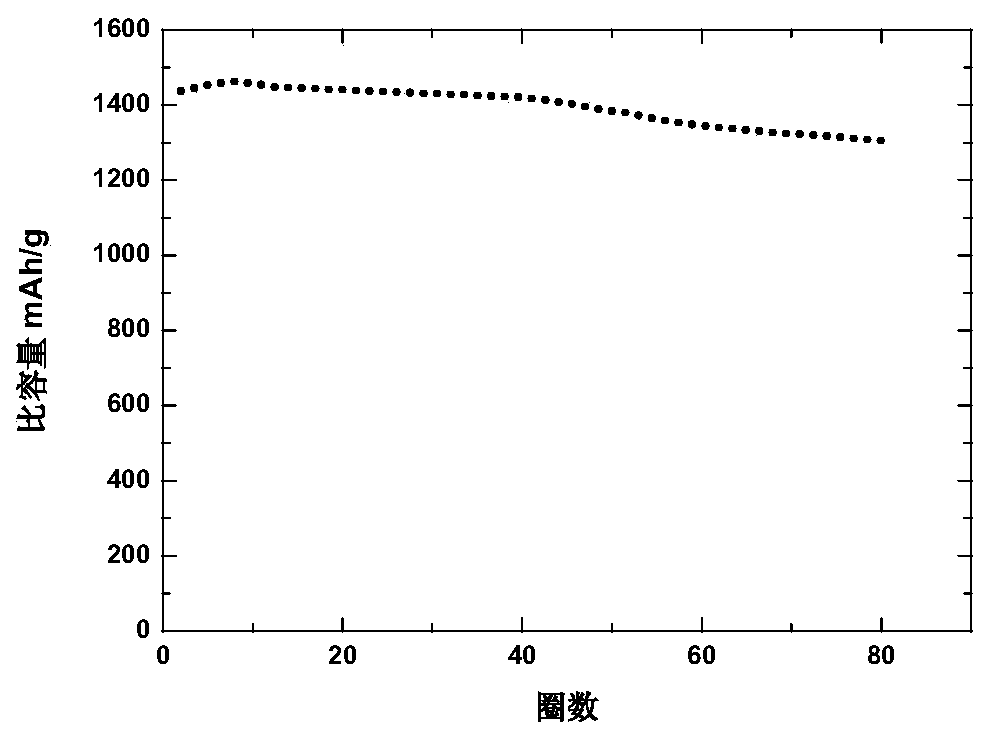

[0072] Preparation of carbon-coated silicon nanowire anod...

Embodiment 2

[0081] Preparation of silicon nanowires:

[0082] (1) Weigh 92g of silicon dioxide granules and 8g of sodium chloride granules and grind them into powder, sieve through a 200-mesh sieve and press the cathode sheet;

[0083] (2) Put the cathode sheet into a tube furnace for low-temperature sintering, the sintering temperature is 300°C, and the sintering time is 3h;

[0084] (3) The obtained cathode sheet is fixed on the iron-chromium-aluminum wire as the cathode, and the high-purity graphite is used as the anode. 2 In the molten salt system, DC voltage electrolysis was carried out under the atmosphere of high-purity argon, the electrolysis voltage was 2.5V, the electrolysis temperature was 530°C, and the electrolysis time was 6h;

[0085] (4) The obtained cathode sheet is taken out after soaking in water for 4 hours, washed with hydrofluoric acid, rinsed with deionization, and finally dried to obtain silicon nanowires;

[0086] Preparation of carbon-coated silicon nanowire an...

Embodiment 3

[0092] Preparation of silicon nanowires:

[0093] (1) Weigh 89g of silicon dioxide granules and 11g of sodium chloride granules and grind them into powder, sieve through a 200-mesh sieve and press the cathode sheet;

[0094] (2) Put the cathode sheet into a tube furnace for low-temperature sintering, the sintering temperature is 280°C, and the sintering time is 5h;

[0095] (3) The obtained cathode sheet is fixed on the iron-chromium-aluminum wire as the cathode, and the high-purity graphite is used as the anode. 2 In the molten salt system, DC voltage electrolysis was carried out under the atmosphere of high-purity argon, the electrolysis voltage was 2.0V, the electrolysis temperature was 560°C, and the electrolysis time was 10h;

[0096] (4) The obtained cathode sheet is taken out after being soaked in water for 3 hours, washed with hydrofluoric acid, rinsed with deionization, and finally dried to obtain silicon nanowires;

[0097] Preparation of carbon-coated silicon nanowi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com