Patents

Literature

79results about How to "Buffer volume effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of producing silicon carbon negative pole material of lithium ion battery

InactiveCN101153358ABuffer volume effectReduce the likelihood of reunionsElectrode manufacturing processesAdhesiveCarbonization

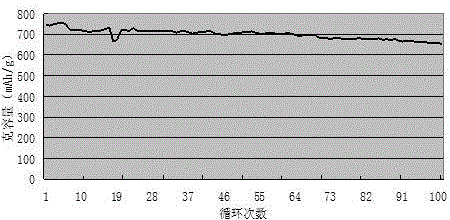

A preparation method of carbon / silicon cathode for ion lithium battery includes the procedures as follows: firstly a high-molecular polymer is used to treat the silicon powder with the nanometer fineness to form an electroconductive film over the surface of the silicon powder, secondly asphaltum as the adhesive is dissolved into an organic solvent, which is added into the silicon powder prepared in the step 1, mixed adequately and evenly, then added with spheric graphite, mixed evenly and then steamed to eliminate the solvent, to form a covering layer containing silicon on the surface of the spheric graphite, thirdly the material obtained in step 2 undergoes carbonization under the protection with the inert gas and, fourthly the asphaltum as the impregnant is dissolved into an organic solvent, and slowly added into the material obtained in step 3, which is mixed evenly and then steamed to eliminate the solvent, and the asphaltum as the impregnant is used to cover outside the silicon coverage layer, then the material obtained in step 4 undergoes carbonization under the protection with the inert gas to produce the final product. The present invention provides a preparation method of carbon / silicon cathode for ion lithium battery, which helps the active silicon carry out high capacity and is capable of good recycling efficacy at the same time.

Owner:SHENZHEN BAK BATTERY CO LTD

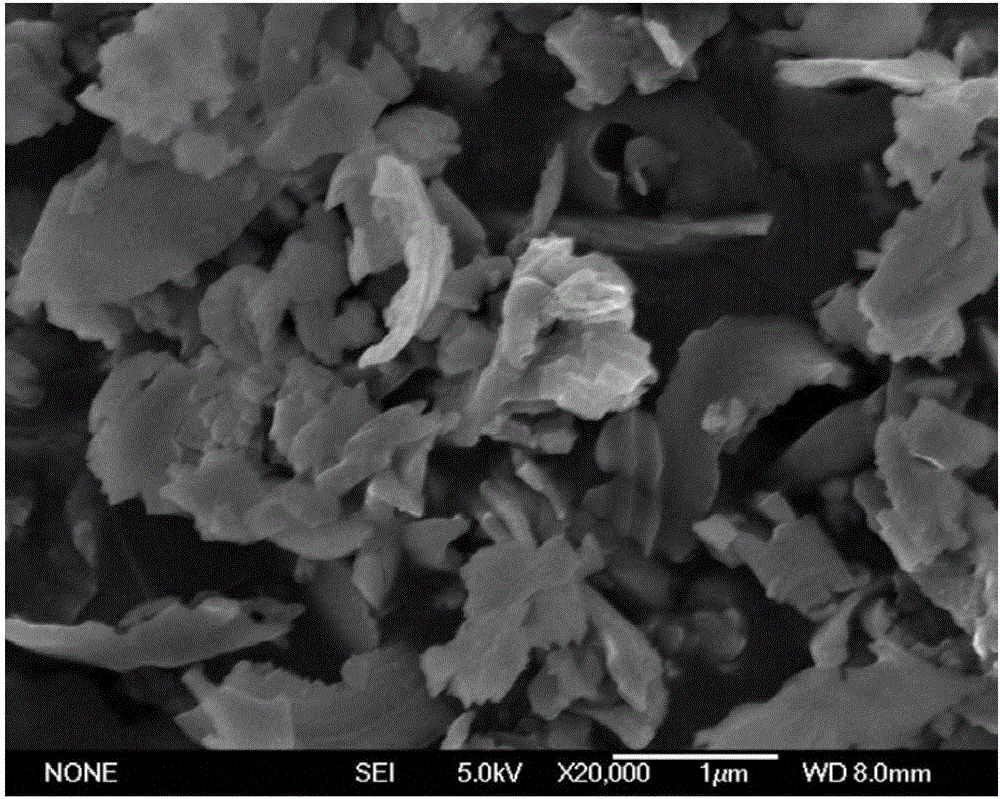

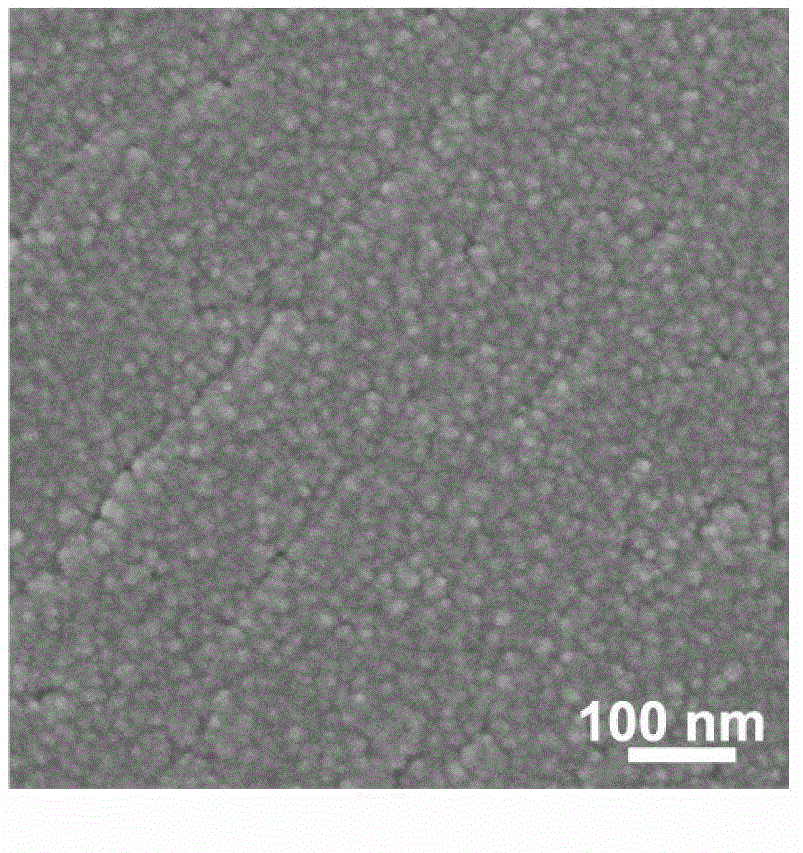

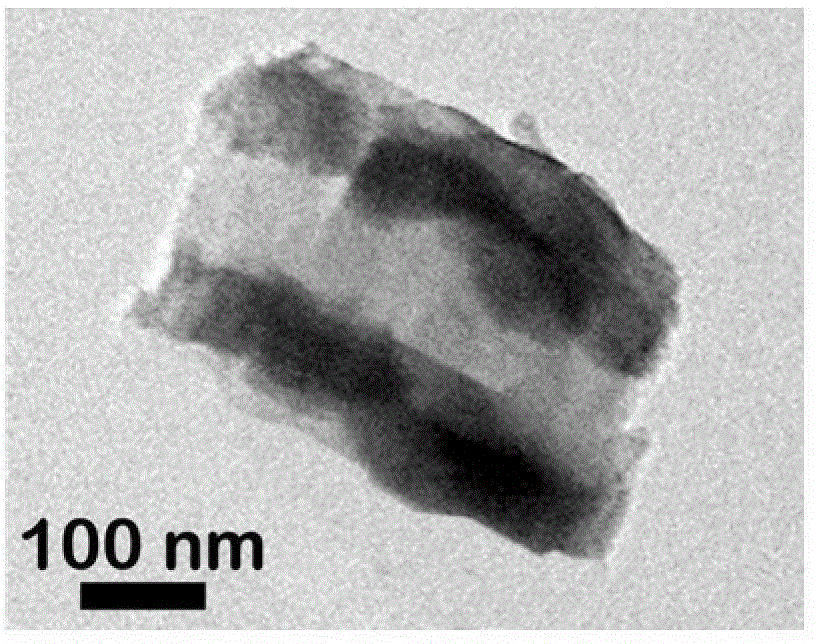

Silicon carbon composite material and preparation method thereof

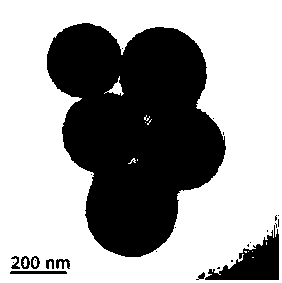

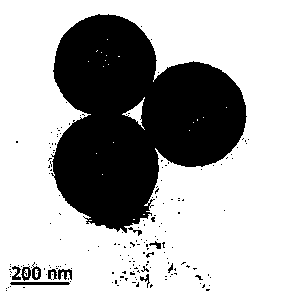

InactiveCN105140477AHigh electrochemical capacityImprove conductivityMaterial nanotechnologyCell electrodesCvd grapheneSilicon particle

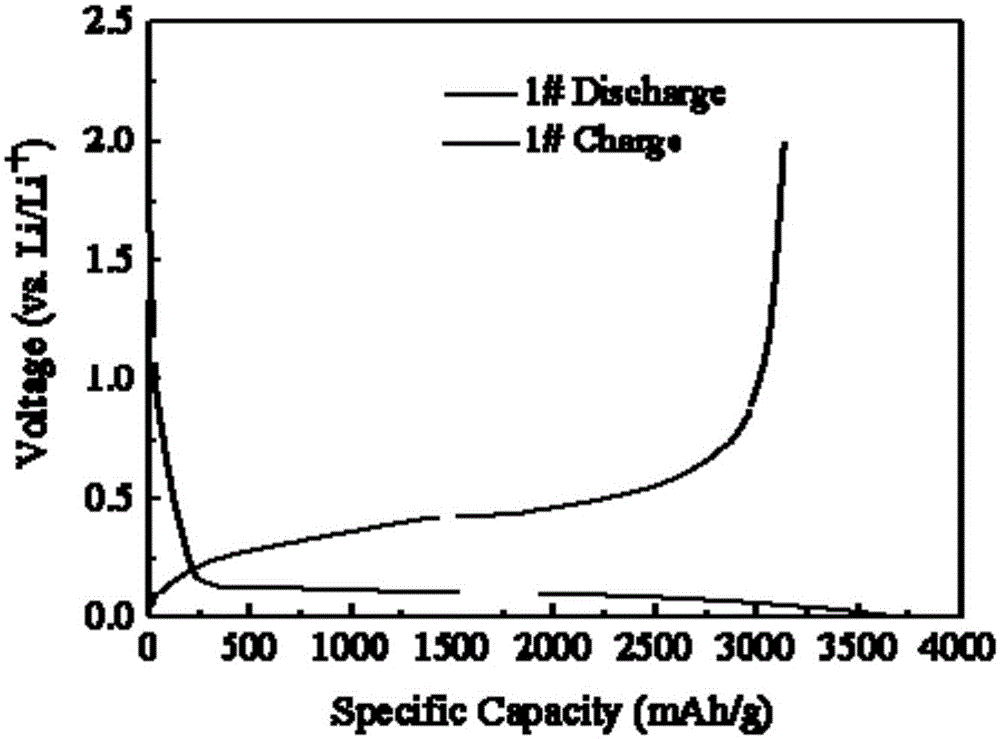

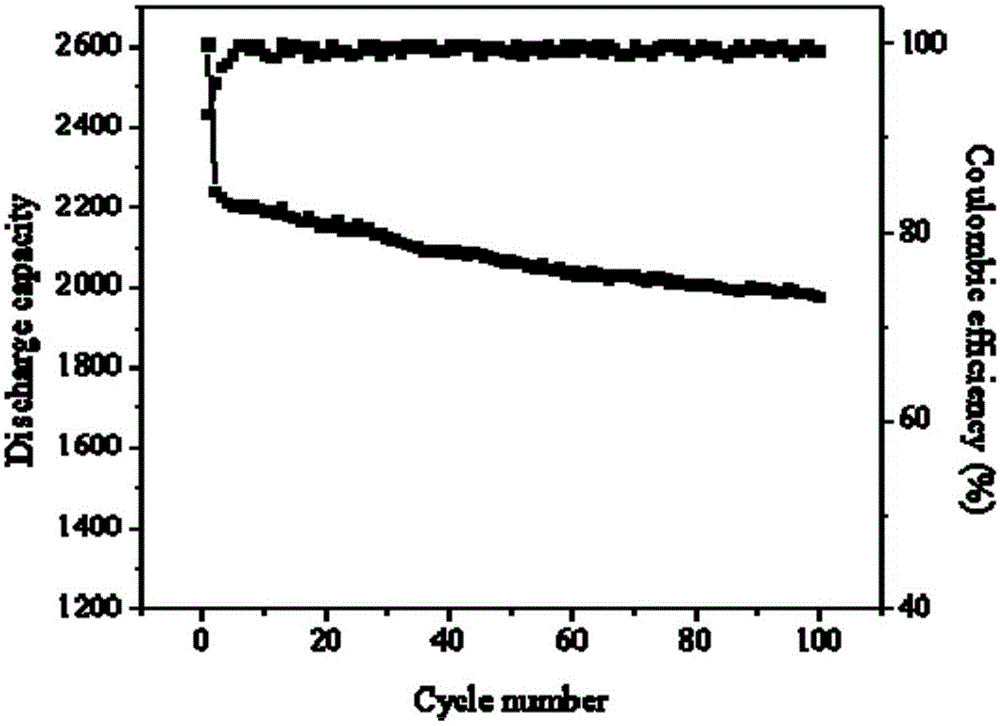

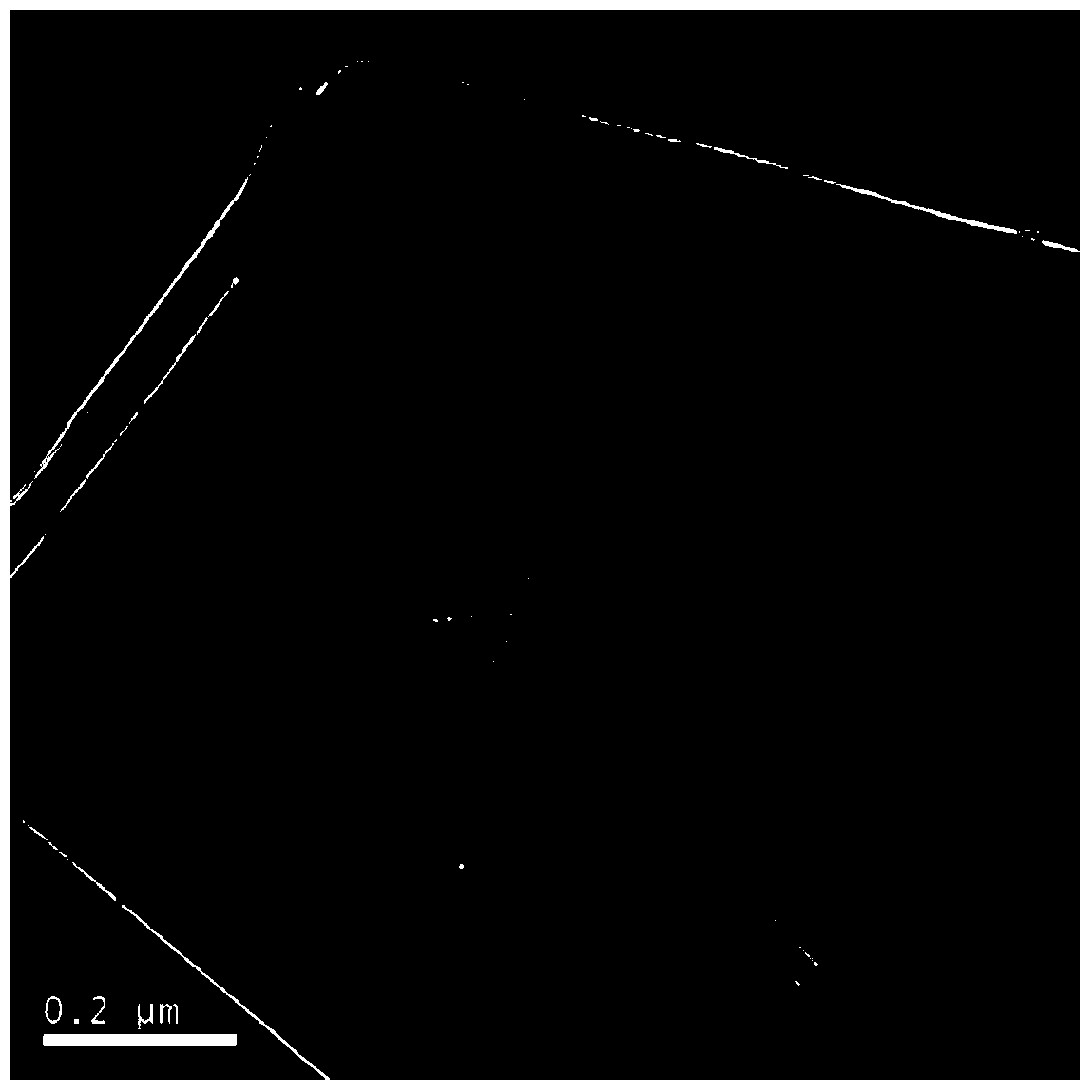

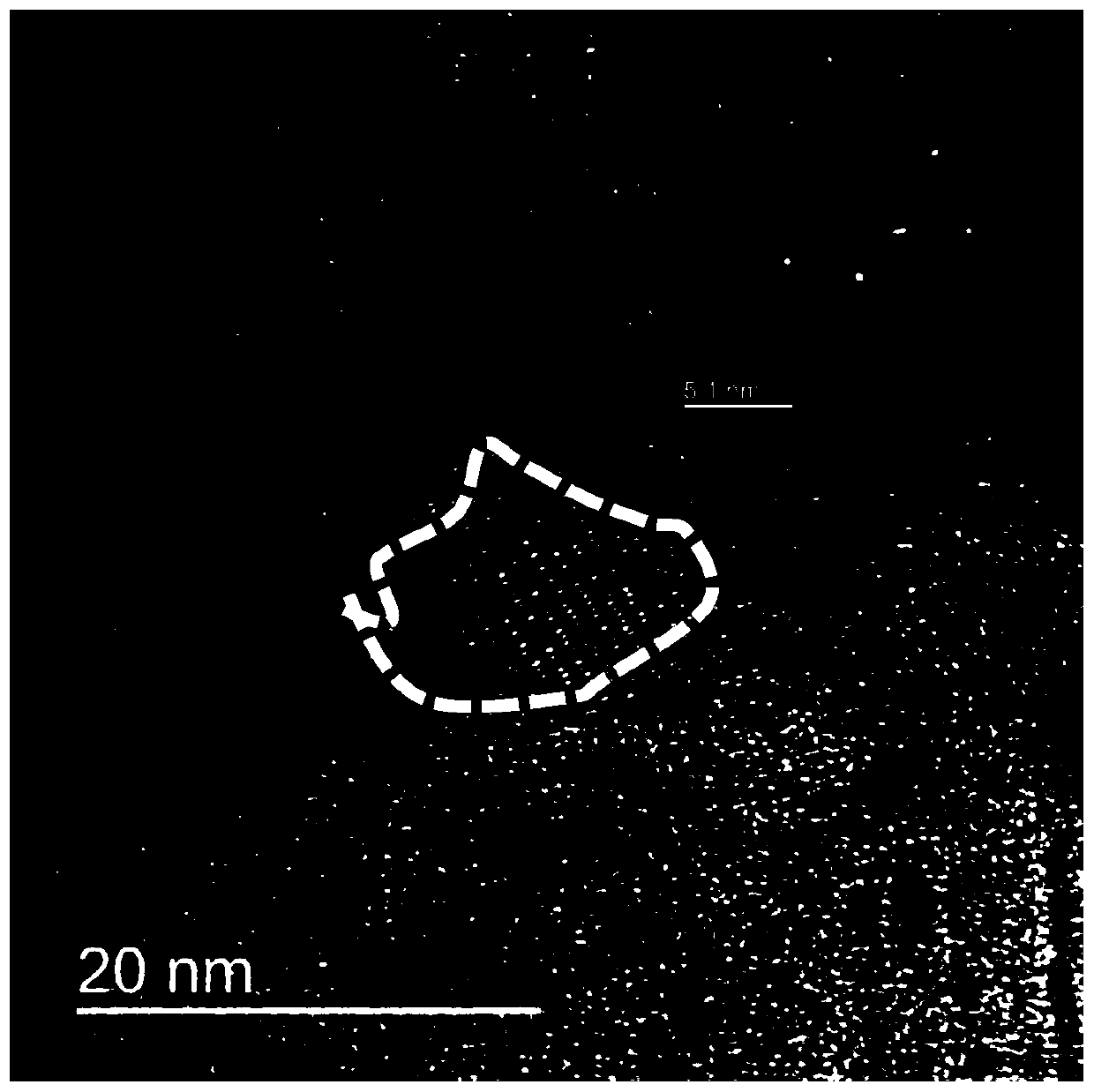

The invention discloses a silicon carbon composite material and a preparation method thereof. According to the preparation method, nano silicon powder particles are taken as a silicon substrate, a Si-C porous shell-core composite material is prepared, and the synergistic effect of silicon and carbon can be fully developed; the silicon material is high in electrochemical capacity, the carbon material is high in conductivity, and the flexible carbon material can be used for absorbing stress and buffering a volume effect of the silicon; meanwhile, the stable and firm shell-core structure can be used for maintaining the material stability; the porous structure can be used for increasing the contact structure of the silicon particles and an electrolyte and improving the compatibility of the silicon particles and the electrolyte; and the three-layer shell-core structure material is dispersed in a graphene material, the conductivity of the material can be further improved, and the capacity performance and the cycle life of an electrode material are improved.

Owner:HUBEI UNIV

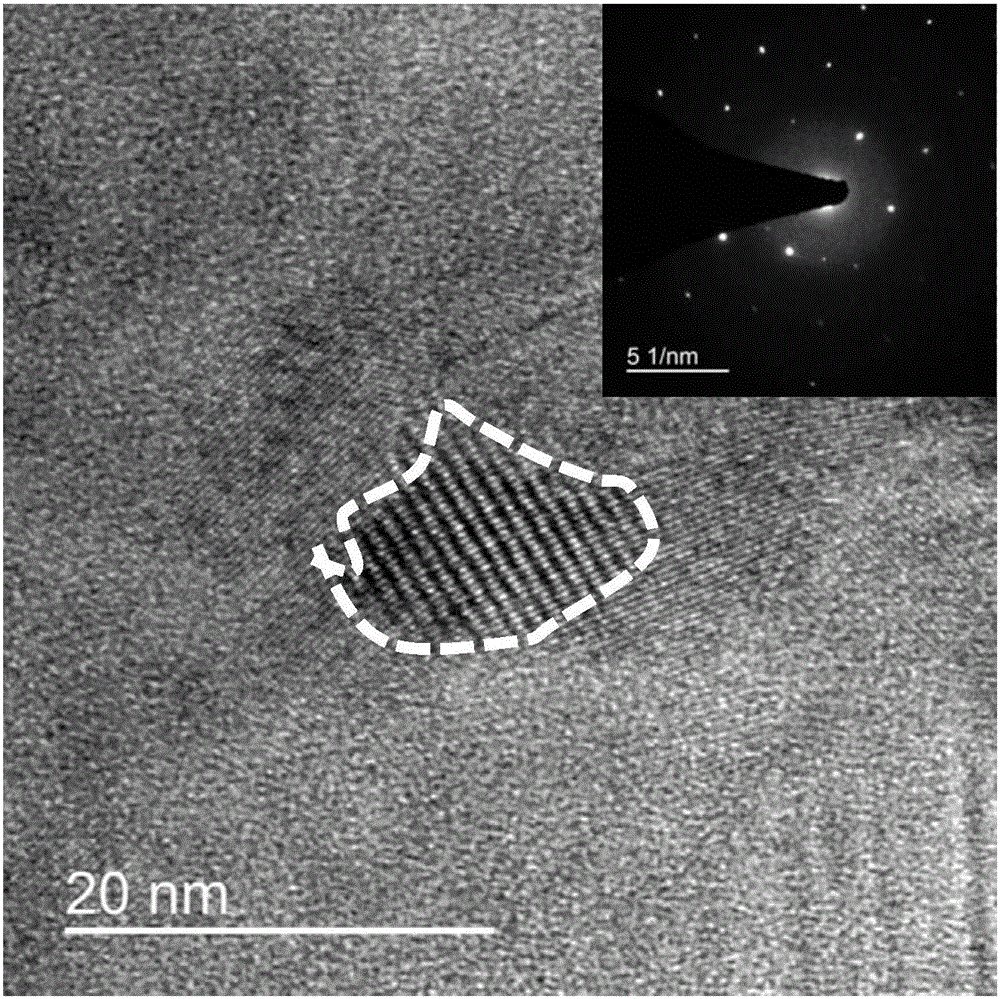

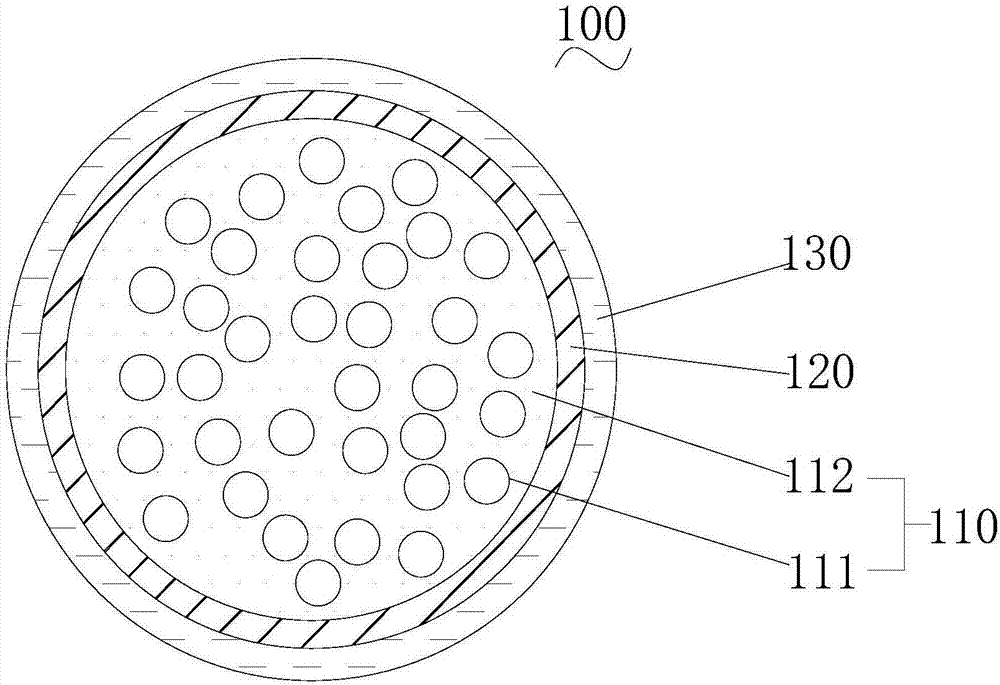

Silicon-carbon composite material and preparation method thereof, and lithium ion battery

ActiveCN103337613ABuffer volume effectImprove conductivityCell electrodesSecondary cellsCarbon compositesLithium-ion battery

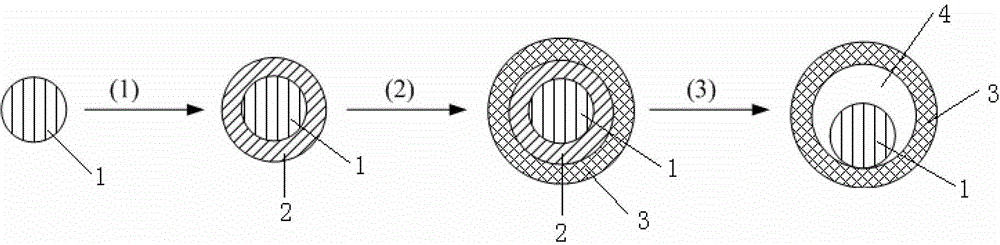

The invention discloses a silicon-carbon composite material and a preparation method thereof, and a lithium ion battery. The preparation method comprises following steps: (1) coating a silica-based material with a transition layer to obtain the transition layer-coated silica-based material; (2) coating the transition layer-coated silica-based material with carbon to obtain a carbon-transition layer-silicon based composite material; and (3) removing the transition layer to obtain the silicon-carbon composite material. The silicon-based material is coated with the transition layer, the transition layer is coated with the carbon, and the transition layer between the silicon-based material and the carbon is removed, so that a plurality of pores are formed between the silicon-based material and the carbon of the silicon-carbon composite material. The size of the pores between the silicon-based material and the carbon can be controlled precisely by setting the thickness of the transition layer according to micro-volume expansion theoretical value of the silicon-based material when lithium is embedded, so that volume effect of the silicon-carbon composite material is reduced effectively, and cycling performance of the lithium ion battery is further enhanced. The carbon of the silicon-carbon composite material is capable of increasing conductivity and rate capability of the composite material.

Owner:CHERY AUTOMOBILE CO LTD

Preparation method of high-capacity silicon-based negative electrode material of lithium-ion battery

InactiveCN106025211AImprove the reunion effectAvoid performance degradationCell electrodesSecondary cellsDispersitySlurry

The invention discloses a preparation method of a high-capacity silicon-based negative electrode material of a lithium-ion battery. The method comprises the preparation processes of: mixing nano silicon, graphite and a pyrolytic carbon organic matter precursor to obtain composite material precursor slurry; and carrying out spray drying to obtain precursor powder; and finally carrying out roasting treatment in an inert atmosphere and then carrying out grinding to obtain an organic matter pyrolytic carbon-coated nano silicon / graphite composite material. According to the preparation method, the dispersity of the nano silicon in the silicon-carbon negative electrode material can be improved; the structure stability of the material in a lithium intercalation and deintercalation process is improved; the condition that the material has relatively high conductivity is ensured; a pyrolytic carbon coating layer effectively coats the surfaces of material particles; the interface characteristic of the material can be effectively improved; and the electrochemical properties of the silicon-carbon negative electrode material are improved.

Owner:田东

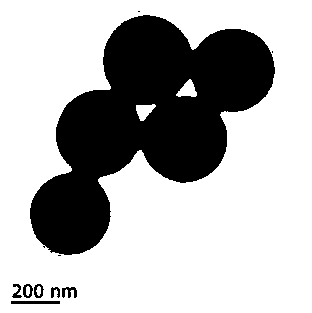

Preparation method for petal-shaped molybdenum disulfide hollow mesoporous carbon sphere by in-situ growth

InactiveCN107591527AUniform particle sizeStable structureMaterial nanotechnologyCell electrodesTetraethyl orthosilicateEnvironmental resistance

The invention relates to a preparation method for a petal-shaped molybdenum disulfide hollow mesoporous carbon sphere by in-situ growth, and belongs to the technical field of nanometer material production. The preparation method comprises the steps of mixing ethanol, deionized water, ammonia water, tetraethyl orthosilicate, resorcinol and formaldehyde for reaction; drying a solid phase and performing calcination in argon; etching the solid phase with a sodium hydroxide solution to obtain the solid phase, and drying the solid phase to obtain the hollow mesoporous carbon nanometer sphere; mixingsodium molybdate dihydrate, thiourea and the hollow mesoporous carbon nanometer sphere for hydrothermal reaction, performing centrifugal washing after hydrothermal reaction, drying the solid phase, and performing high-temperature calcination under protection of argon atmosphere to obtain the petal-shaped molybdenum disulfide hollow mesoporous carbon sphere by in-situ growth. The preparation method has the advantages that the raw material is low in cost, the process is environmental-friendly, high yield is achieved, and the prepared petal-shaped molybdenum disulfide hollow mesoporous carbon sphere by in-situ growth can be used as a lithium ion battery electrode material, a photocatalytic material or an electrocatalytic material.

Owner:YANGZHOU UNIV

High-capacity lithium ion battery negative electrode plate and preparation method thereof

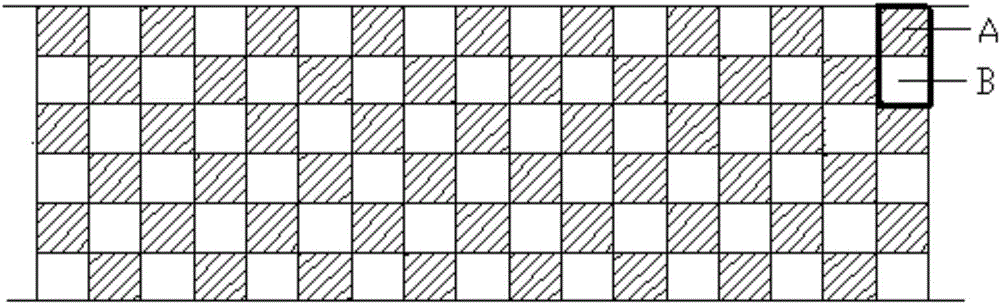

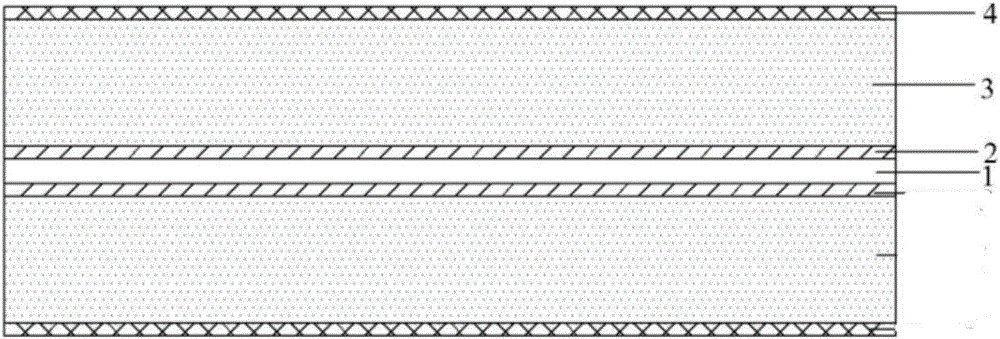

InactiveCN106374081ABuffer volume effectImprove conductivitySecondary cellsElectrode collector coatingExpansion rateSilicon

The invention discloses a high-capacity lithium ion battery negative electrode plate and a preparation method thereof. The negative electrode plate comprises a negative electrode current collector, and a base coat, an active substance layer and a conductive composite layer which are coated on the surface of the negative electrode current collector. The negative electrode plate is characterized in that the base coat makes a silicon material and a carbon material deposit on the surface of the current collector to form unit cells in the staggered directions through a vapor deposition method, and the silicon material and the carbon material are arranged in the unit cells in a staggered mode. The silicon material and the carbon material deposit on the surface of the current collector through the vapor deposition method and are high in density and large in adhesive force with the current collector, and the process is controllable; meanwhile, the carbon material deposits on the periphery of the silicon material, the electric conductivity of the electrode plate is improved, the expansion rate of the electrode plate is decreased, and therefore the energy density and cycle performance of a lithium ion battery are improved.

Owner:XIAMEN RIZHEN POWER TECH CO LTD

Carbon coated nanosilicon composite material as well as preparation method and application thereof

ActiveCN106784732AEasy to spreadImprove cycle stabilityMaterial nanotechnologySecondary cellsCarbon coatingUltrasound attenuation

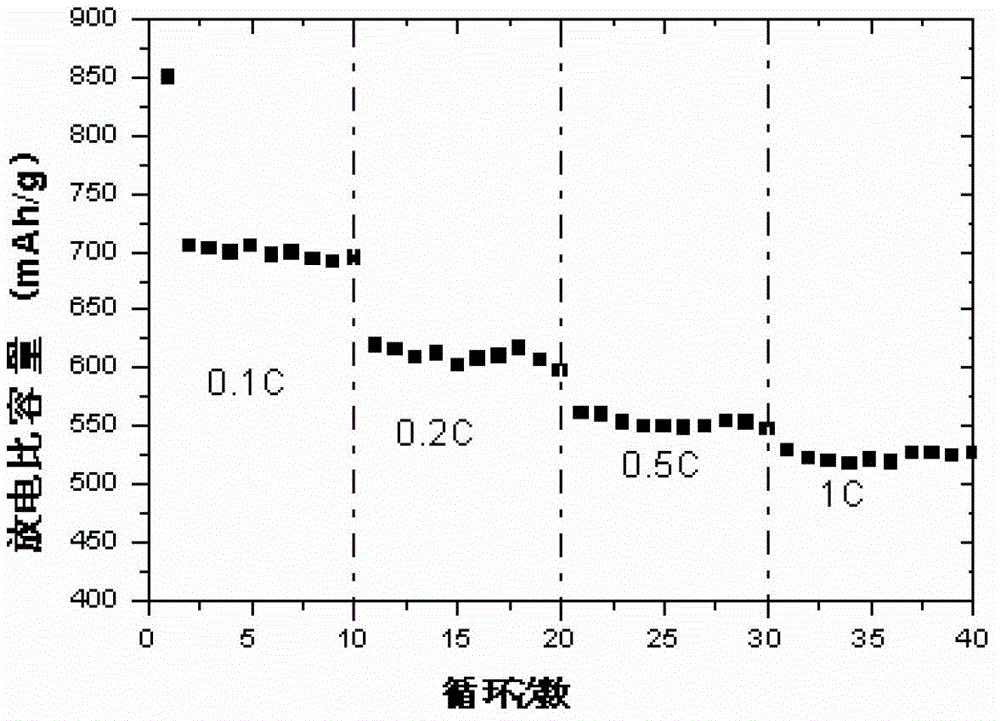

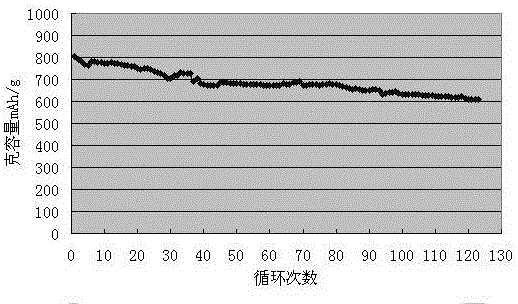

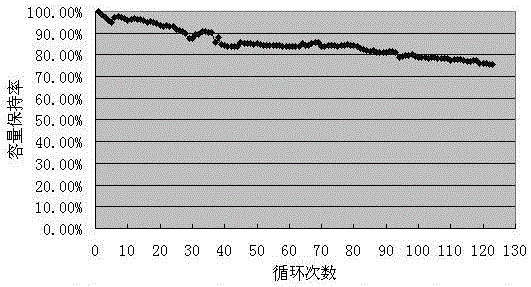

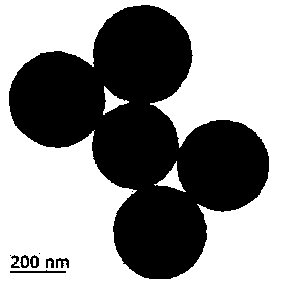

The invention relates to a carbon coated nanosilicon composite material as well as a preparation method and an application thereof. The invention relates to silicon composite powder as well as a preparation method and an application thereof. The invention aims to solve the technical problem that an existing method of reducing the volume effect of a silicon-based cathode material by virtue of nanocrystallization, alloying or porous forming is complex in preparation process and high in cost. The carbon coated nanosilicon composite material provided by the invention is powder of a core-shell structure taking nanosilicon particles as a content and carbon as a shell. The preparation method comprises the following steps: performing oxygen diffusion on nanoscale silicon micropowder with an oxidizing layer on the surface; then performing carbon coating treatment; and then soaking the same with a hydrofluoric acid solution to remove the component of silicon oxide to obtain the carbon coated nanosilicon composite material. The volume of the carbon coated nanosilicon composite material provided by the invention reaches 900mAh / g or above, attenuation after 150 times of cycles is smaller than 4%, and the material can be used as a lithium battery silicon cathode material.

Owner:吕铁铮

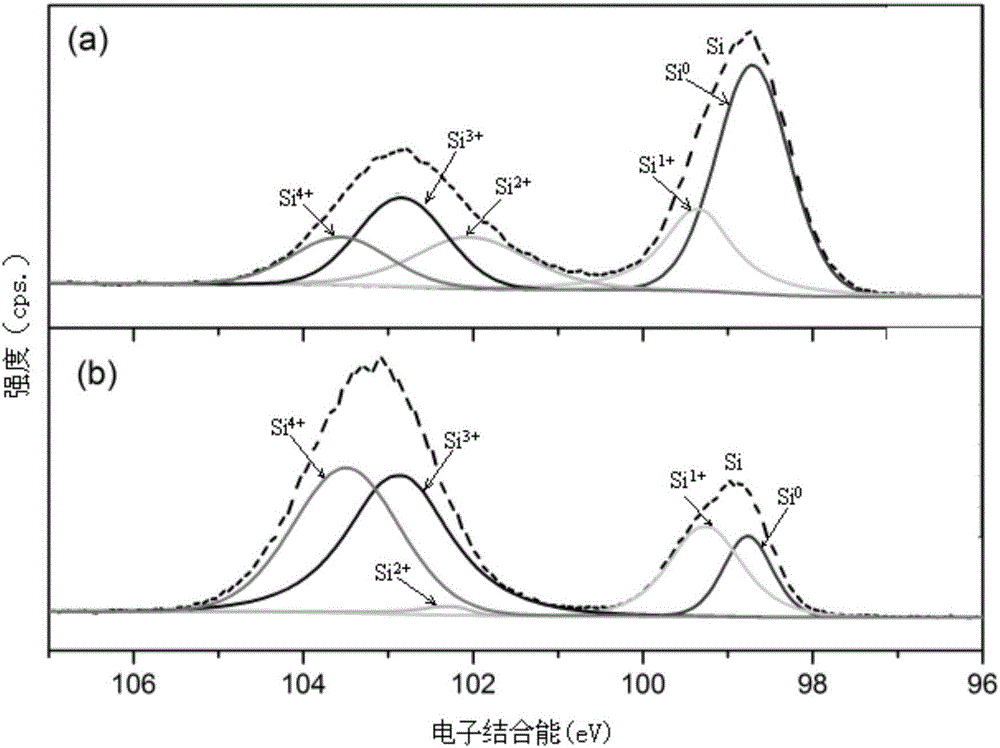

Single-layer/double-layer coated silicon oxide composite anode material and preparation method thereof

ActiveCN107959012AImprove cycle stabilityAlleviate the volume expansion effectCell electrodesCarbon layerSilicon oxide

The invention provides a single-layer / double-layer coated silicon oxide composite anode material and a preparation method thereof. The single-layer coated silicon oxide composite anode material is a two-layer composite material which has a core-shell structure, an inner core is a silica precursor, an outer layer is a lithium titanate layer, and the silica precursor is a material which is formed byuniformly dispersing and distributing silicon on silica. The double-layer coated silicon oxide composite anode material is a three-layer composite material which has a core-shell structure, an innercore is a silica precursor, a middle layer is a lithium titanate layer, and the outermost layer is a carbon layer which coats the outer surface of the lithium titanate layer. The double-layer coated silicon oxide composite anode material has the three-layer structure, the inner core is the silica precursor, the middle layer is the lithium titanate layer, the outermost layer is the carbon layer, the volume effect of silicon oxide can be buffered well, and thus, the double-layer coated silicon oxide composite anode material has high specific capacity and excellent cycle performance.

Owner:ETRUST POWER ETP GRP LTD

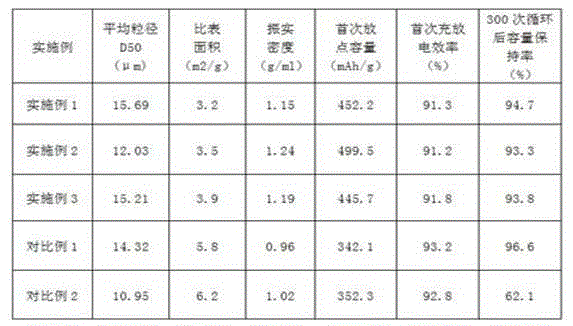

Preparation method of high-volume silicon-carbon negative electrode material

The invention relates to a method for preparing a modified graphite negative electrode material of a lithium ion power battery. The method particularly comprises the following steps: adding asphalt and resin into a kneading kettle with heating and stirring devices, heating until the asphalt and the resin are melted into liquid, continuously stirring, stopping heating after mixing uniformly and cooling to obtain a composite coating material block; performing coarse crushing on the composite coating material block and performing ultrafine crushing by using an airflow crushing machine or a cryogenic crushing machine to obtain composite coating material ultrafine powder; completely mixing the composite coating material ultrafine powder and graphite to obtain uniform powder; and performing heating, heat preservation and natural cooling on the uniform powder under the protection of inert gas, and sieving after cooling to obtain the modified graphite negative electrode material of the lithium ion power battery. The most outstanding innovation points are that the coating material precursor is subjected to compound treatment and coated by the graphite; the mixing uniformity of various coating material precursors is guaranteed, any solvents are not required, and environmental friendliness is realized; in addition, the process is simple, low in cost and easy in industrialized production.

Owner:SHENZHEN SINUO INDAL DEV

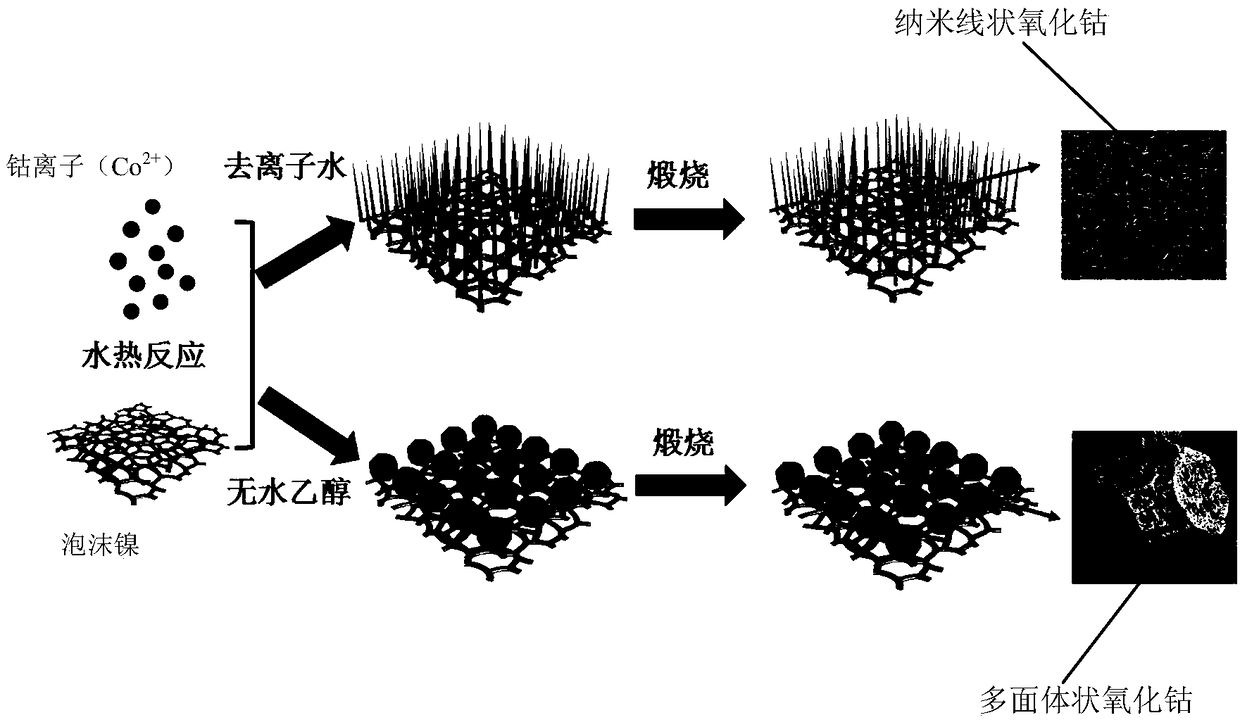

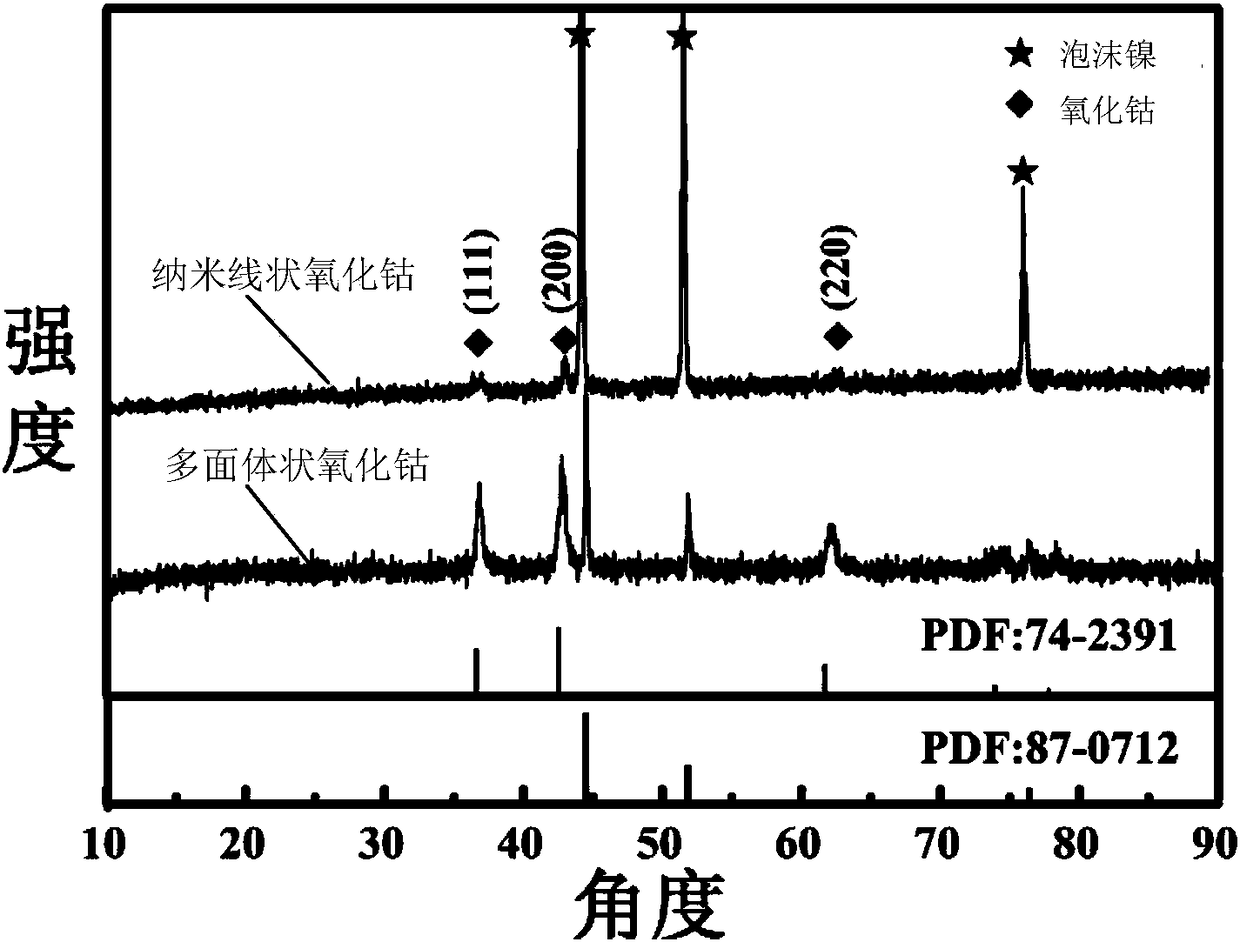

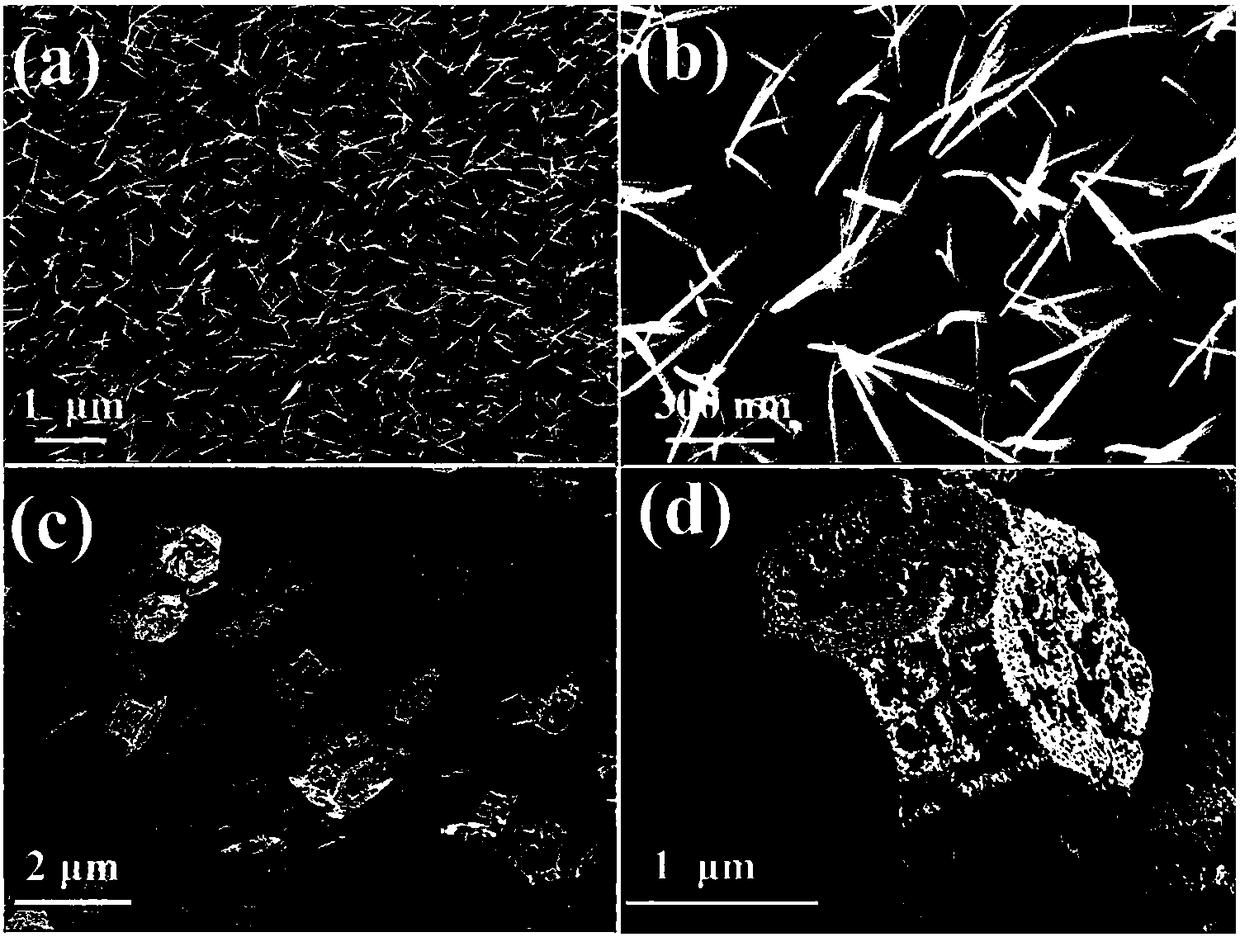

Preparation method of different morphologies of cobalt monoxide nanometers loaded with foam nickel

ActiveCN108390014AReduce usageQuality improvementMaterial nanotechnologyNegative electrodesThermal insulationSolvent

The invention discloses a preparation method of different morphologies of cobalt monoxide nanometers loaded with foam nickel. The preparation method comprises: placing sheet-like foam nickel in an ultrasonic washing machine, washing, placing the washed foam nickel in a drying box, and drying; dispersing cobalt chloride hexahydrate powder into a dispersion solvent added with urea, and magneticallystirring at a room temperature to form a suspension; transferring the suspension to a high-pressure hydrothermal reaction kettle, obliquely placing the dried sheet-like foam nickel into the high-pressure hydrothermal reaction kettle, sealing the high-pressure hydrothermal reaction kettle, placing the high-pressure hydrothermal reaction kettle into the drying box, carrying out thermal insulation for 15-18 h at a temperature of 160-200 DEG C, and naturally cooling to a room temperature; taking the foam nickel out of the high-pressure hydrothermal reaction kettle, placing into the ultrasonic washing machine, washing, placing into a vacuum drying box, and drying to obtain a precursor; and calcining the precursor for 3-4 h at a calcination temperature of 400-520 DEG C.

Owner:SOUTH CHINA NORMAL UNIVERSITY

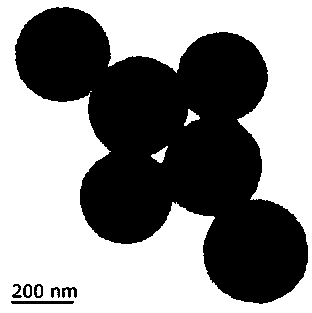

Preparation method of carbon-coated tungsten sulfide hollow nanosphere with shell layer with sandwich structure

InactiveCN107611388AUniform particle sizeStable structureCell electrodesSecondary cellsThioureaSulfide

The invention relates to a preparation method of a carbon-coated tungsten sulfide hollow nanosphere with a shell layer with a sandwich structure, and belongs to the technical field of production of anano material. The preparation method comprises the steps of: mixing alcohol, deionized water, ammonium hydroxide, ethyl orthosilicate, resorcinol and formaldehyde to perform a reaction, obtaining a solid phase to dry, and after calcining in argon, etching by aqueous solution of sodium hydroxide to obtain a hollow mesoporous carbon nanosphere; and after dissolving tungsten chloride and thiourea solid in the deionized water, adding the hollow mesoporous carbon nanosphere, after carrying out ultrasonic dispersion, performing a hydrothermal reaction, and after obtaining a solid phase to dry, calcining in the argon so as to obtain the carbon-coated tungsten sulfide hollow nanosphere of which the shell layer has the sandwich structure. The preparation method disclosed by the invention has the characteristics of cheap process raw material, simple and environmental-friendly process, high yield and excellent performance; the prepared carbon-coated tungsten sulfide hollow nanosphere of which the shell layer has the sandwich structure can be applied as a lithium ion battery electrode material, a photocatalysis material or an electro-catalysis material.

Owner:YANGZHOU UNIV

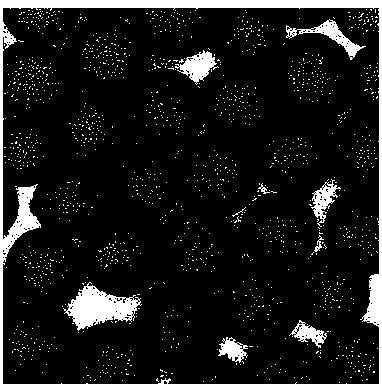

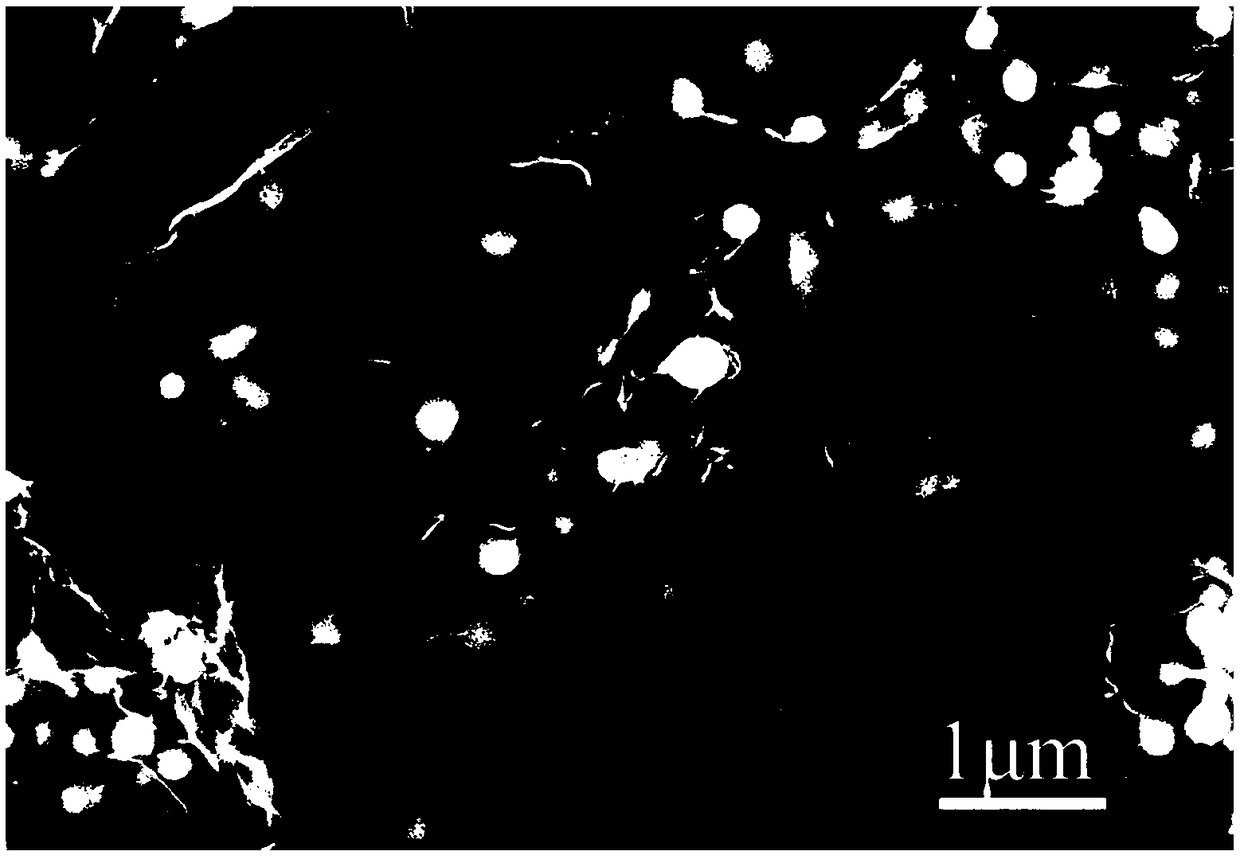

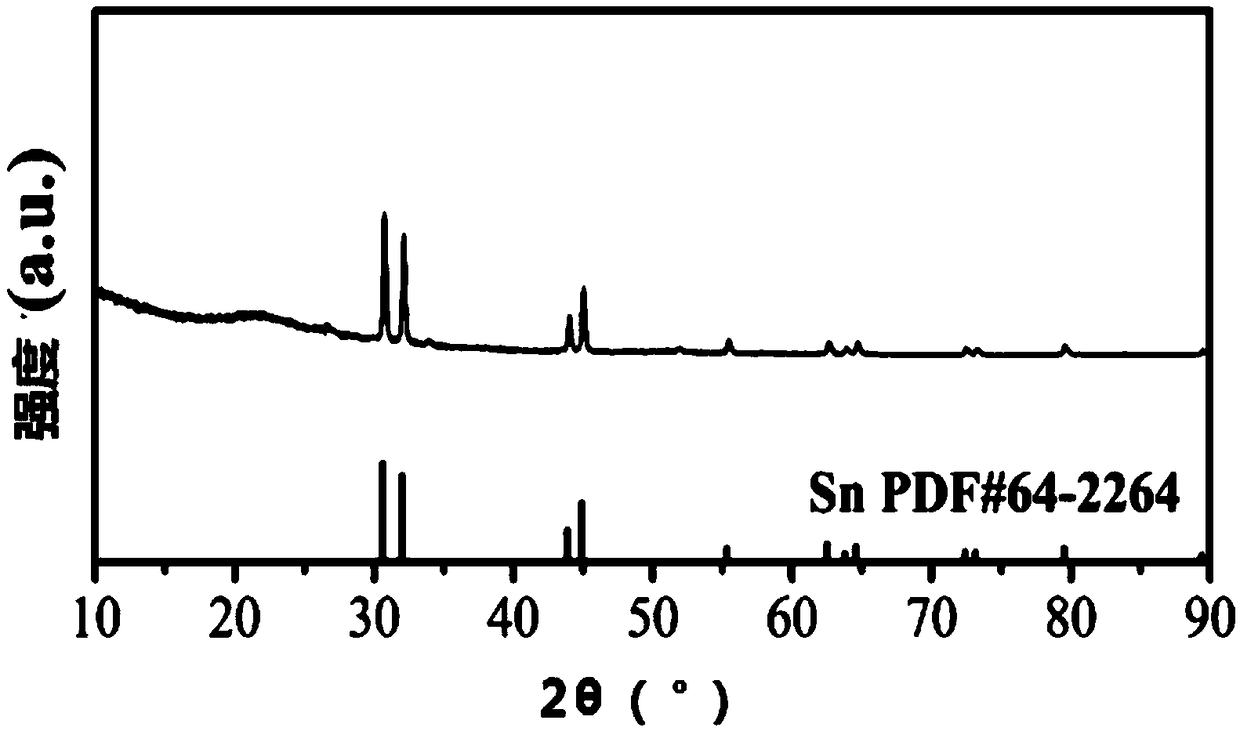

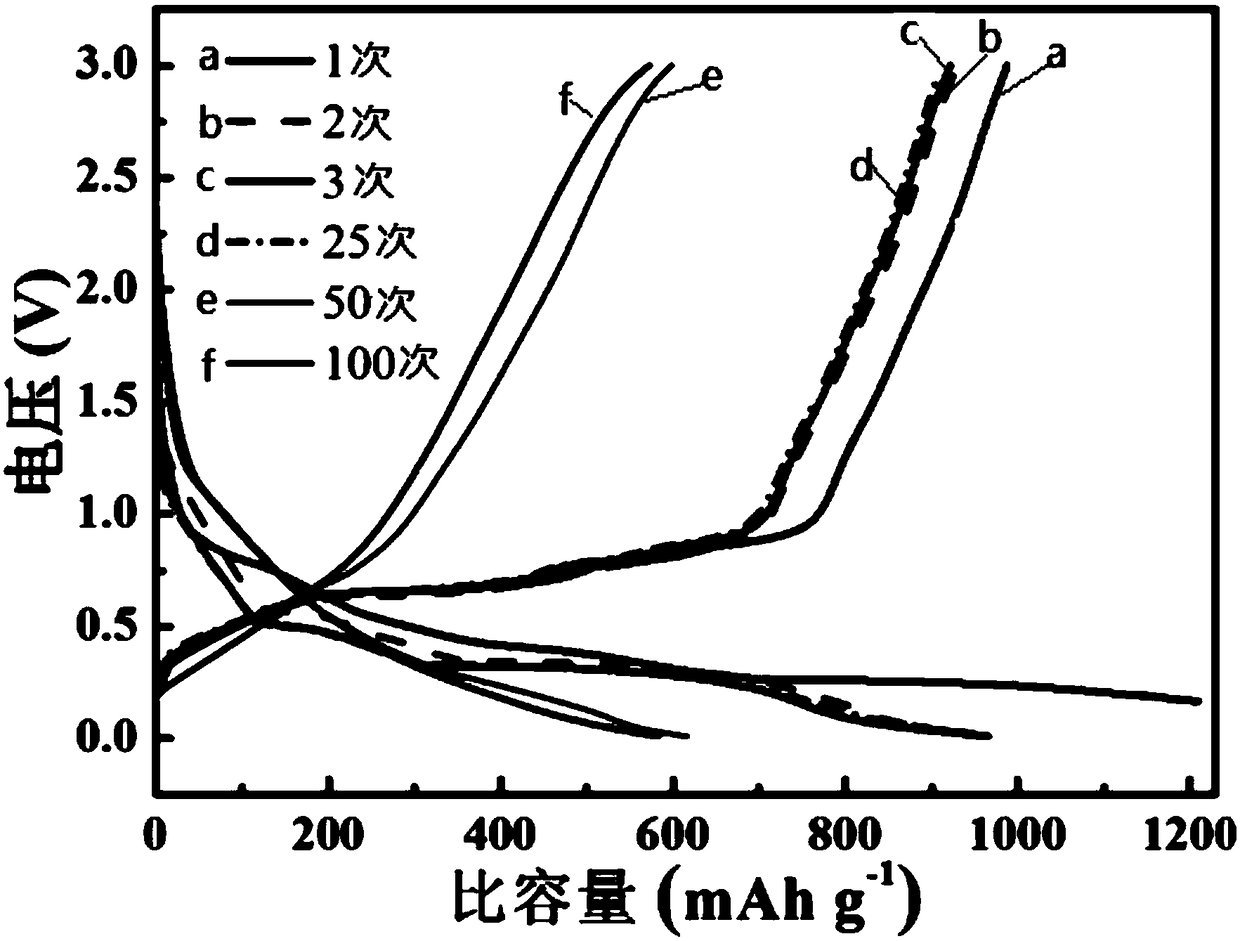

Tin @ hollow mesoporous carbon sphere material with yolk-egg shell structure and preparation method of tin @ hollow mesoporous carbon sphere material with yolk-egg shell structure

The invention discloses a tin @ hollow mesoporous carbon sphere material with a yolk-egg shell structure and a preparation method of the tin @ hollow mesoporous carbon sphere material with the yolk-egg shell structure. The material has the yolk-egg shell structure of taking elemental tin nanospheres as a yolk and hollow mesoporous carbon spheres as an egg shell; and the preparation method comprises the steps of taking the hollow mesoporous carbon spheres as nanoreactors and growing SnO2 particles in the nanoreactors; and reducing the SnO2 particles into elemental Sn at high temperature and forming the yolk-egg shell structure by the elemental Sn and the hollow mesoporous carbon spheres. According to the tin @ hollow mesoporous carbon sphere material with the yolk-egg shell structure, elemental Sn spheres are confined into the hollow mesoporous carbon spheres, a negative electrode material does not fall off in charging and discharging processes due to the unique yolk-egg shell structure, buffer space is provided for volume expansion of tin alloying through internal cavities, furthermore, the conductivity and the ion transfer rate of the material are improved through the hollow mesoporous carbon spheres, and improvement of the electrochemical properties of the composite material is facilitated.

Owner:YANGZHOU UNIV

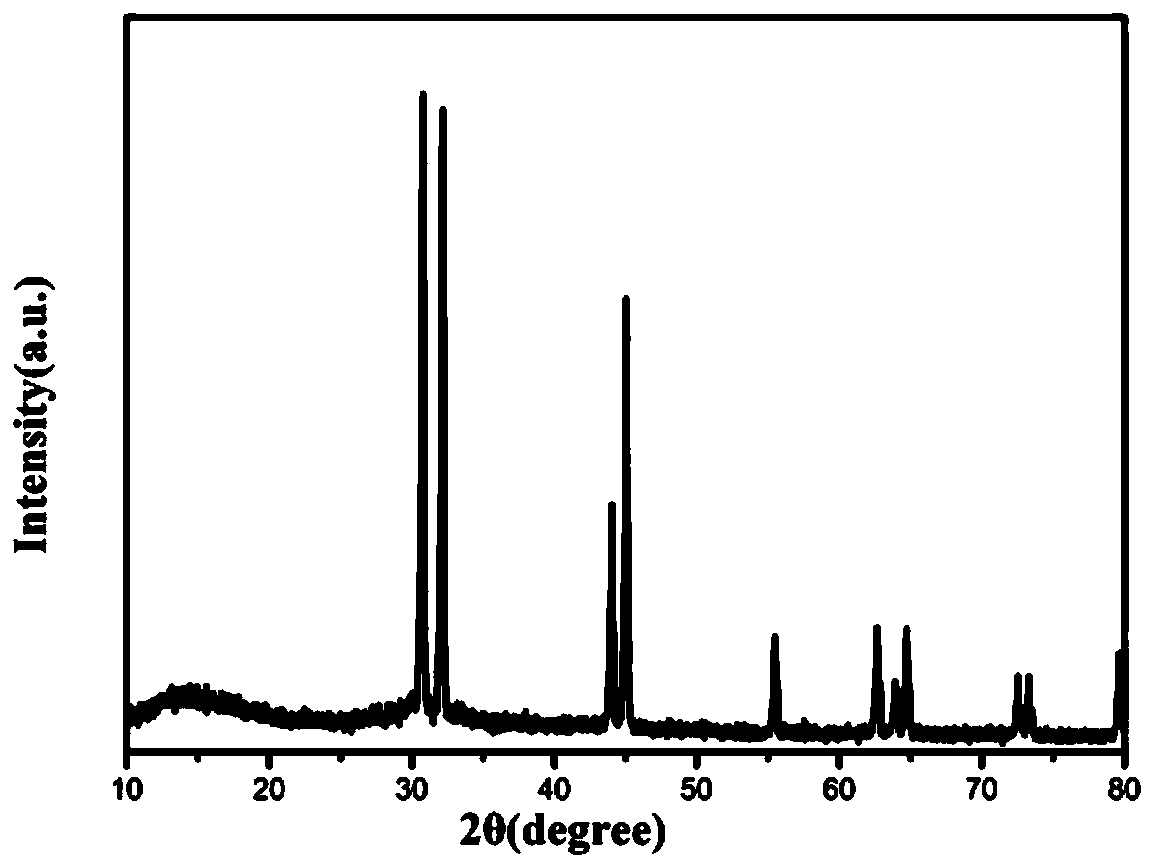

Preparation method and application of spherical tin sulfide consisting of nanorods

InactiveCN103915625ABuffer volume effectWill not cause mutual extrusion pulverizationTin compoundsCell electrodesCyclic processLithium-ion battery

The invention discloses a preparation method and application of spherical tin sulfide consisting of nanorods, belonging to the technical field of lithium ion battery materials. The invention further provides a preparation method of a negative electrode material. The method comprises the following steps: uniformly mixing a sulfur source, a tin source and a surfactant; heating a mixed solution by using a hydro-thermal method; filtering and drying the product to obtain a lithium battery negative electrode material of the spherical tin sulfide consisting of nanorods. Compared with spherical tin sulfide consisting of nanosheets, the spherical tin sulfide consisting of nanorods has the advantages that the cycle performance is improved, the stability of nanorods is higher than that of nanosheets in a circulating process, the volume change of an electrode material is suppressed effectively, the capacity fading of the electrode material is slowed down, and the cycle life of a battery is prolonged effectively.

Owner:JINAN UNIVERSITY

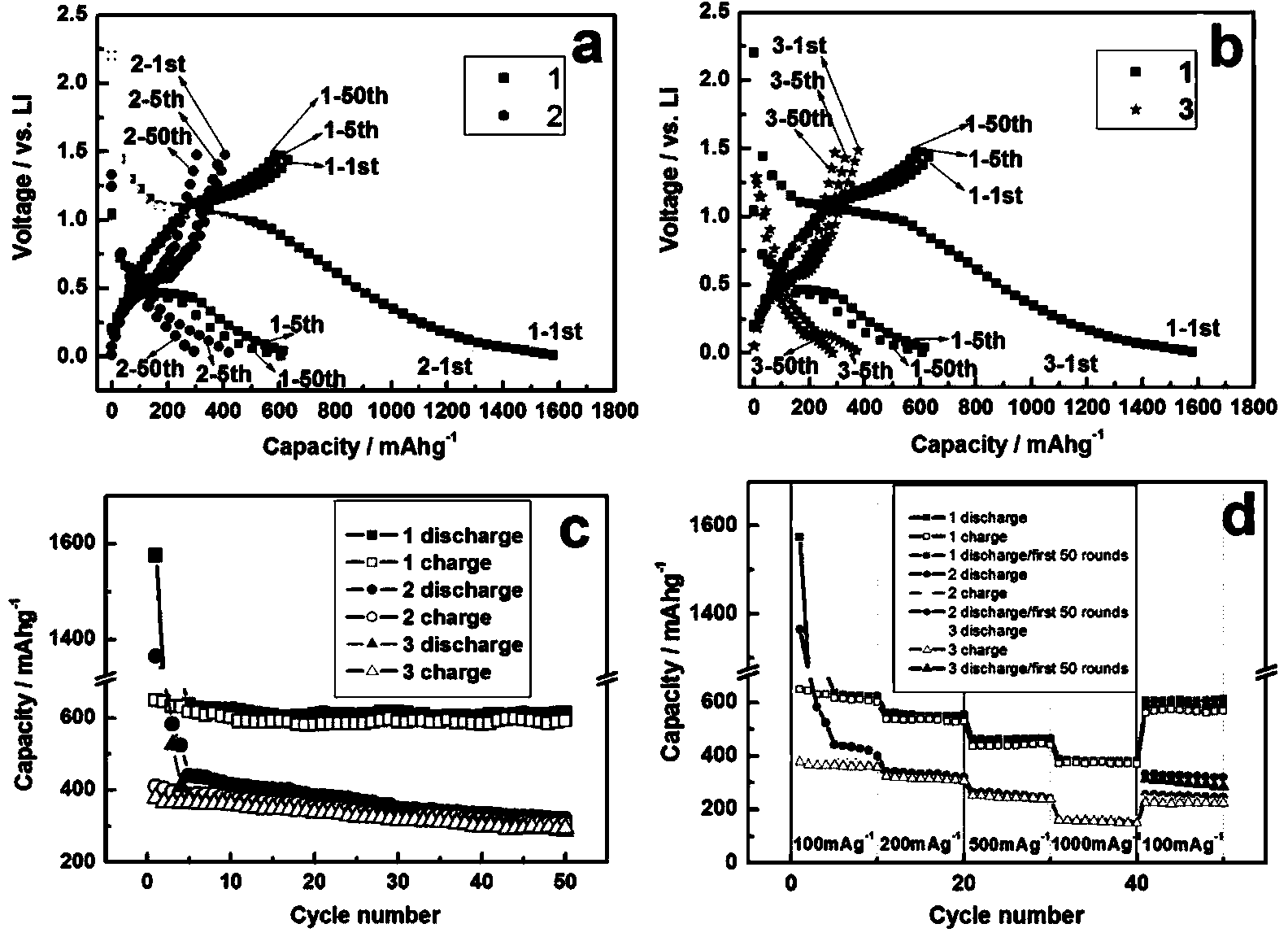

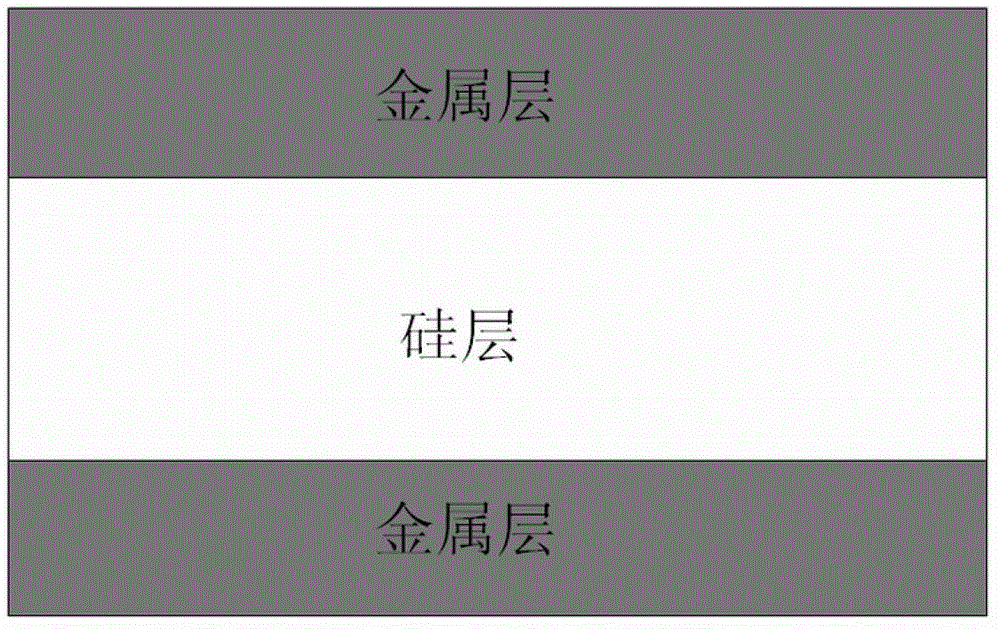

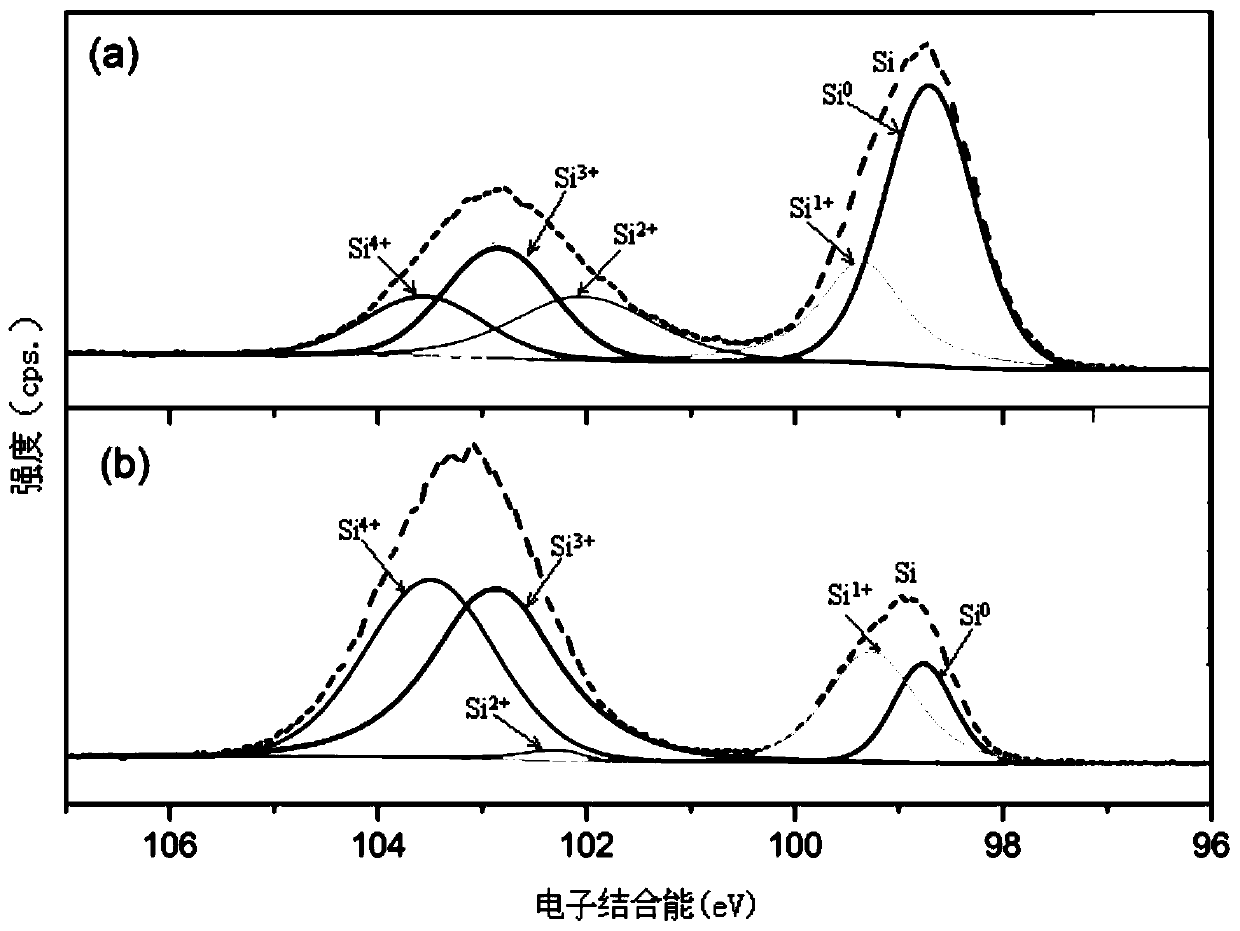

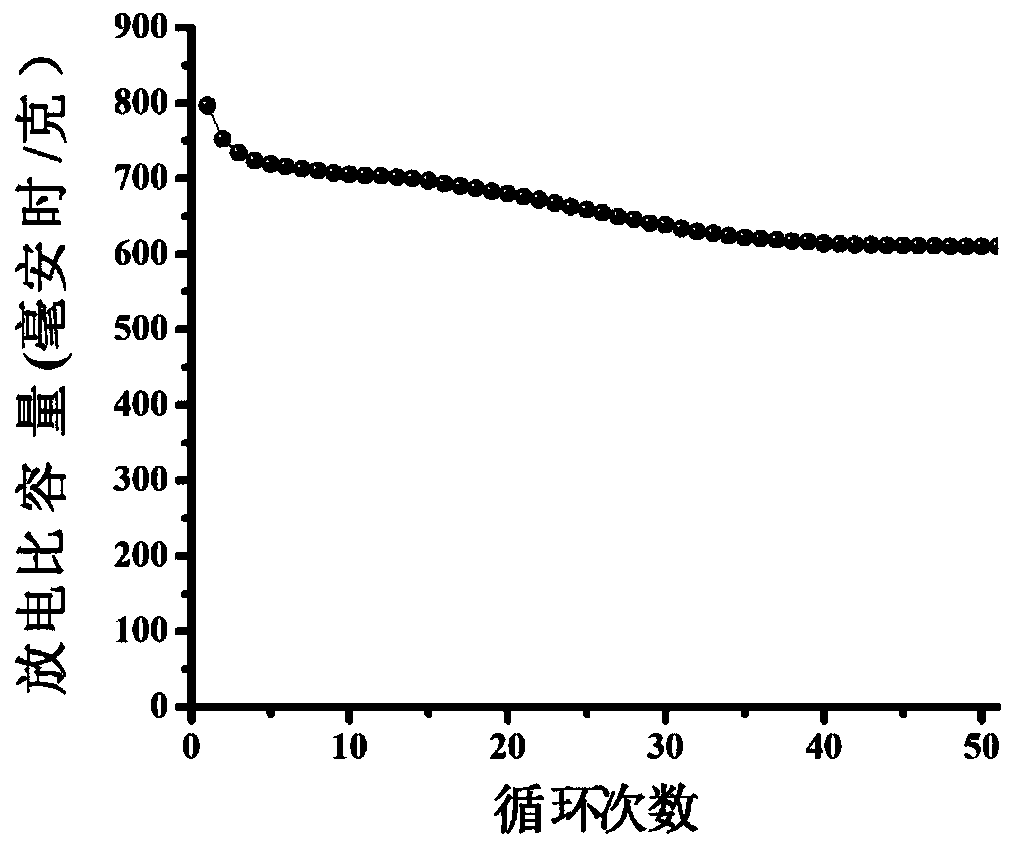

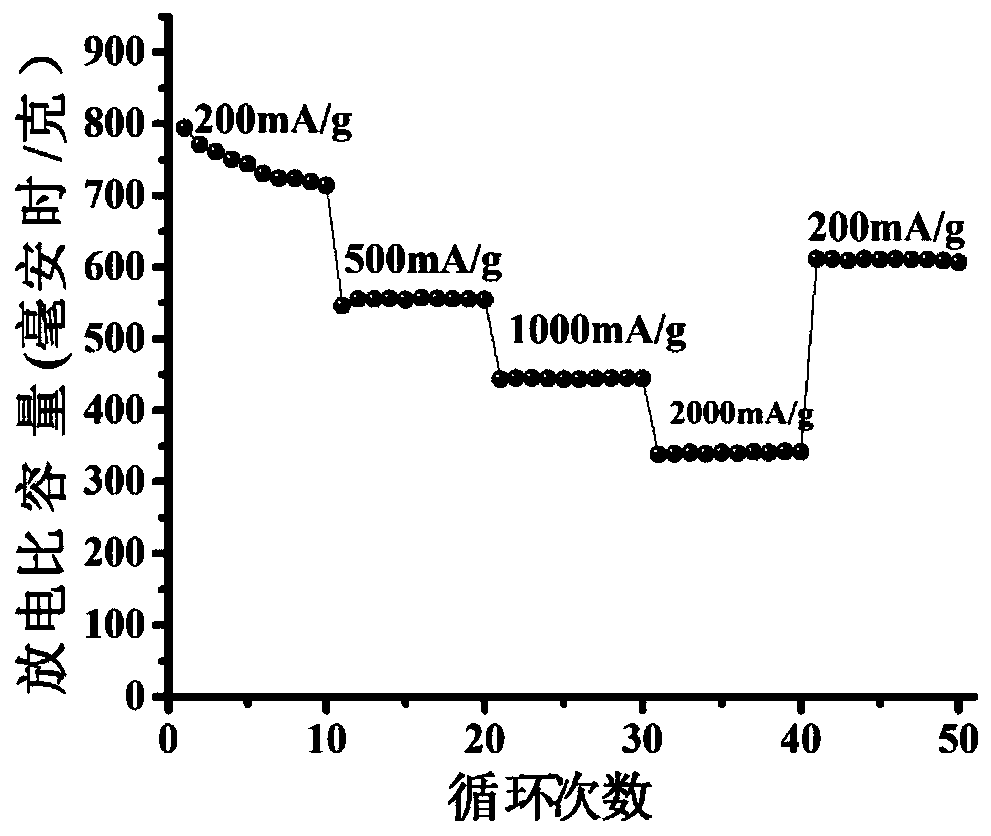

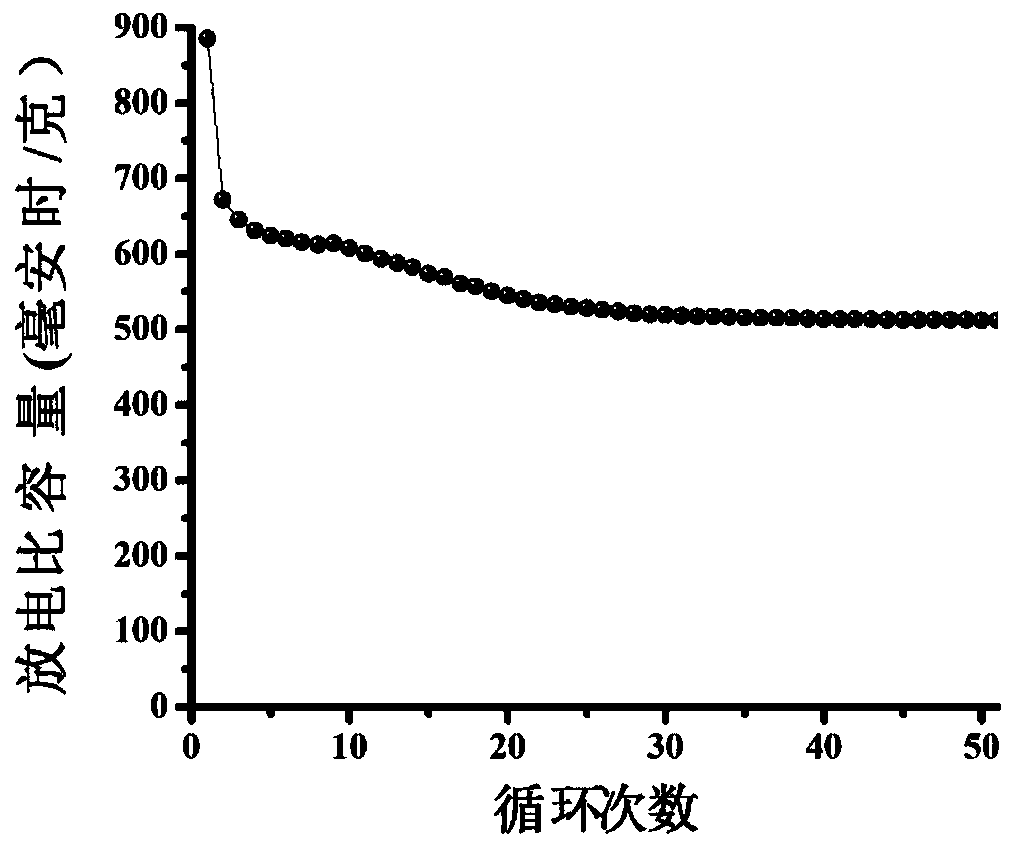

Silicon-based thin film material with sandwich structure and preparation method and application thereof

ActiveCN103144393AIncrease specific energyImprove cycle lifeLayered productsVacuum evaporation coatingHigh energyThin layer

The invention relates to a silicon-based thin film material with a sandwich structure. According to the silicon-based thin film material, a laminated sandwich structure consists of a metal layer, a silicon layer and a metal layer, wherein the metal layers have the thickness of 20-100 nm, and the Si layer has the thickness of 60 nm to 9.8 microns. According to a preparation method of the silicon-based thin film material, an alternate sputtering process for metallic targets of the metal layers and a silicon target of the Si layer is adopted, a metallic conductive attached-layer thin film is firstly prepared on a substrate, a Si thin film is then prepared, and a metallic thin layer finally covers the surface of the Si thin film, thereby forming the sandwich structure. The silicon-based thin film material and the preparation method of the silicon-based thin film material have the advantages that the silicon-based thin film material with the sandwich structure is used as a negative pole material of a lithium battery, and then, the larger volume change of the silicon-based thin film material during lithium ion deionizing / embedding is effectively inhibited, so that the lithium battery has higher energy density, cycle stability and multiplying factor performance; and the method is simple in process and lower in cost and is hopefully applied to high-energy and high-power thin-film batteries.

Owner:NANKAI UNIV

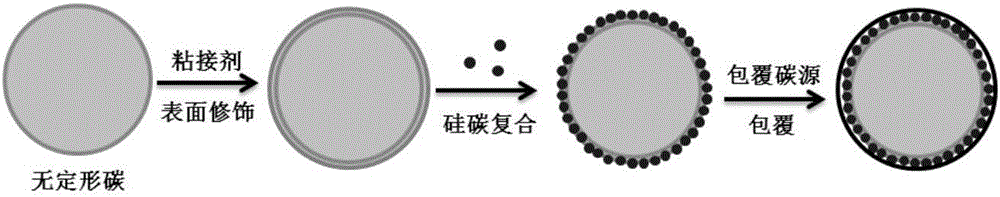

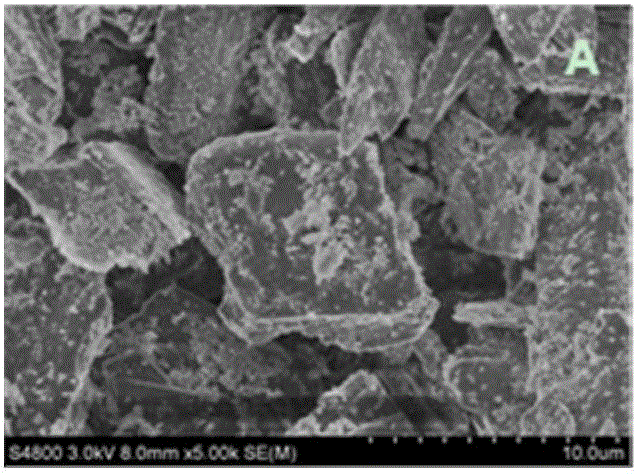

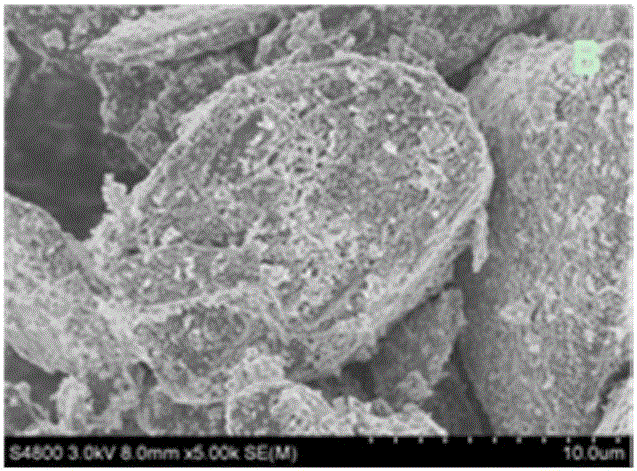

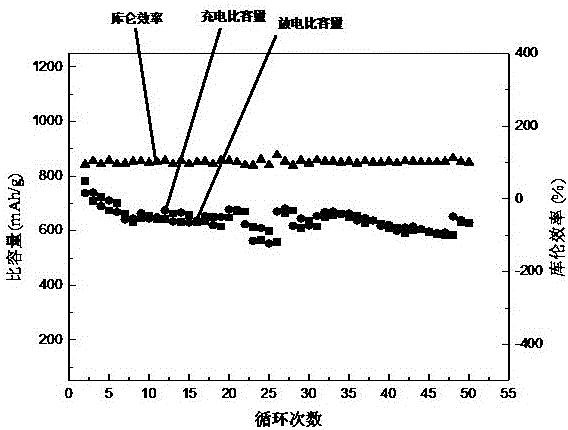

Carbon-silicon composite material and preparation method of carbon-silicon composite material as well as lithium-ion battery comprising composite material

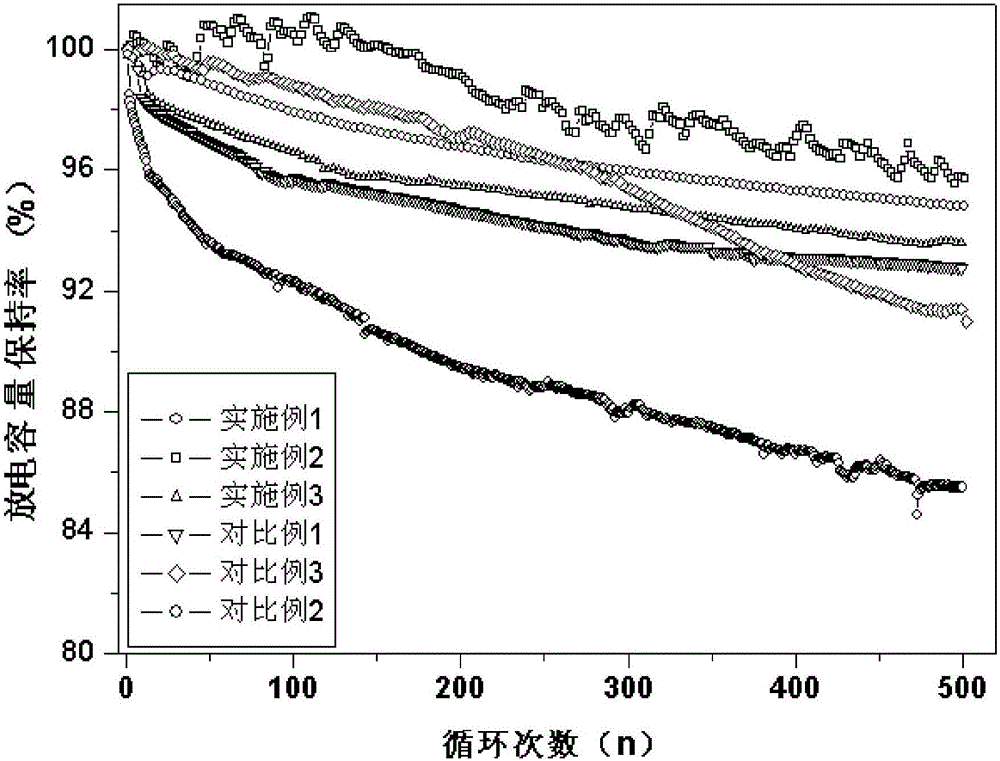

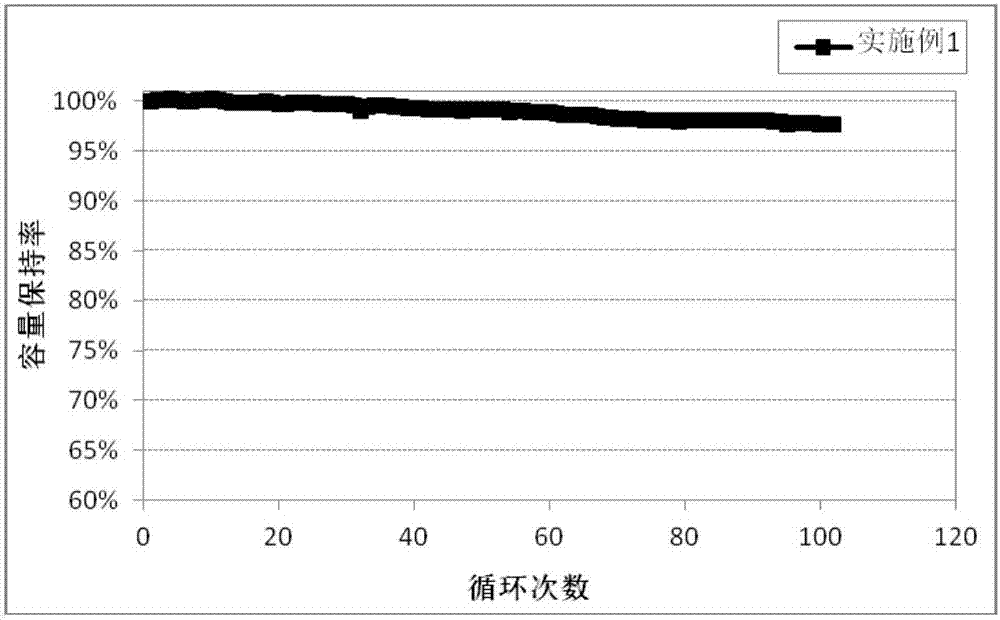

ActiveCN106784741AEasy to operateSuitable for large-scale productionMaterial nanotechnologyCell electrodesNano siliconCharge rate

The invention discloses a carbon-silicon composite material and a preparation method of the carbon-silicon composite material as well as a lithium-ion battery comprising the composite material. The carbon-silicon composite material comprises an amorphous carbon inner core and a shell which is formed by dispersing nano silicon into a pyrolytic carbon layer. The method is simple and easy to operate, is environmental-friendly and is suitable for large-scale production; the prepared carbon-silicon composite material has a stable structure, the nano silicon has good dispersibility and the coated degree of the nano silicon is very high; the carbon-silicon composite material is used as a negative electrode material of the lithium-ion battery and has a very high lithium removing specific capacity, a good circulating performance and an excellent rapid charging property; the lithium removing specific capacity is 391.7mAh / g or more, the capacity retention rate is 95.3 percent or more after the lithium-ion battery is charged and discharged at constant current of 1.0C for 50 times, and the charging rate of 10min can reach 90.2 percent.

Owner:深圳市贝特瑞新能源技术研究院有限公司

Preparation method for tin-carbon composite negative material

InactiveCN105161671AGuaranteed uniformitySimple processElectrode thermal treatmentSecondary cellsCarbon compositesGraphite

The invention provides a preparation method for a tin-carbon composite negative material. An outer layer of the tin-carbon composite negative material is a composite cladding layer jointly formed by asphalt, resin and tin powder, and an inner layer is the tin-carbon composite negative material which is composed of graphite and has a core-shell structure. In the tin-carbon composite material prepared according to the method, high specific capacity characteristic of tin is maintained, meanwhile, a modification effect on the graphite is played, the overall cyclic stability of the material is improved, the energy density of the negative material of a lithium ion battery is improved, thus, the negative material has higher specific capacity than the carbon negative material commonly used in the lithium ion battery in the current market, and the increasing energy density requirement of various portable electric devices on the battery is met.

Owner:田东

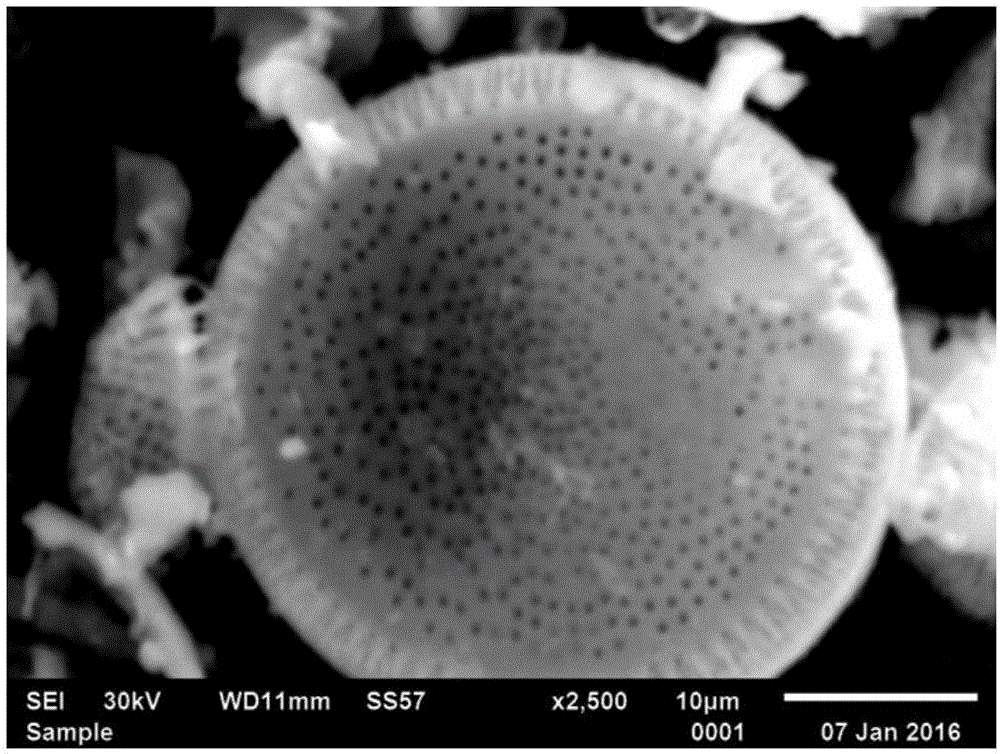

Method for preparing porous silicon/graphene composite lithium ion battery anode material using diatomite as raw material

InactiveCN106252631ARich reservesLow priceCell electrodesSecondary cellsCyclic processSocial benefits

This invention is a method for preparing a porous silicon / graphene composite lithium ion battery anode material using diatomite as a raw material. The method is characterized by comprising the preparation steps of diatomite purification, preparation of porous silicon and preparation of porous silicon / graphene composite lithium ion battery anode material. The first-time reversible capacity of the prepared porous silicon / graphene composite lithium ion battery anode material is up to 1275.3 mAh / g under the current density of 100 mA / g, the capacity is kept to be 885.7 mAh / g after 50 times of circulation, and then the capacity is almost kept the same in the almost remain the same process. Due to the fact that the diatomite is used as the raw material, sources are wide, the price is low, the volume effect of the silicon can be effectively inhibited and the electrical conductivity of the material can be also improved through porous silicon and graphene composition, and the method is scientific, reasonable, simple, convenient, easy to operate, excellent in electrochemical performance, good in effect and the like, is beneficial to popularization and application, makes industrialization easily achieved and has remarkable economic and social benefits.

Owner:NORTHEAST DIANLI UNIVERSITY

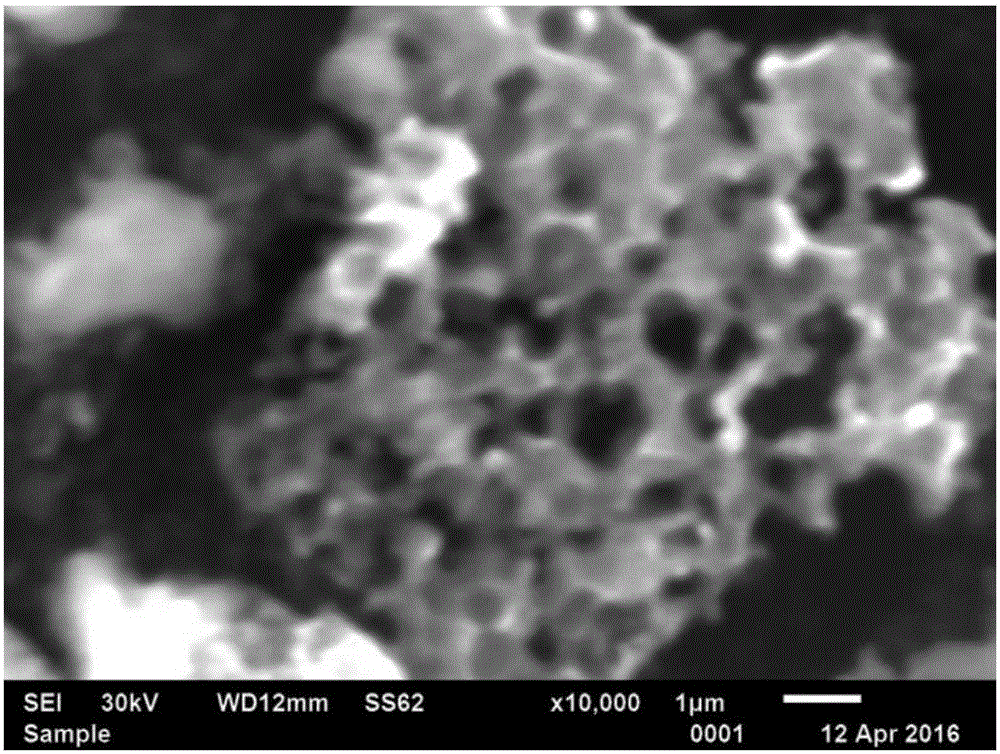

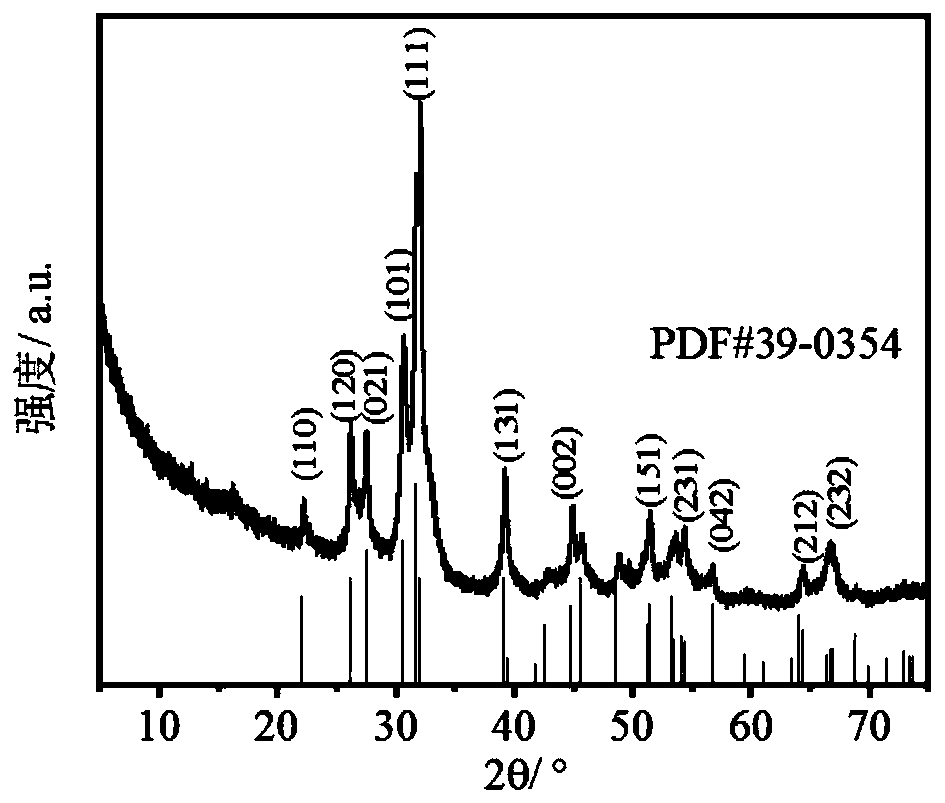

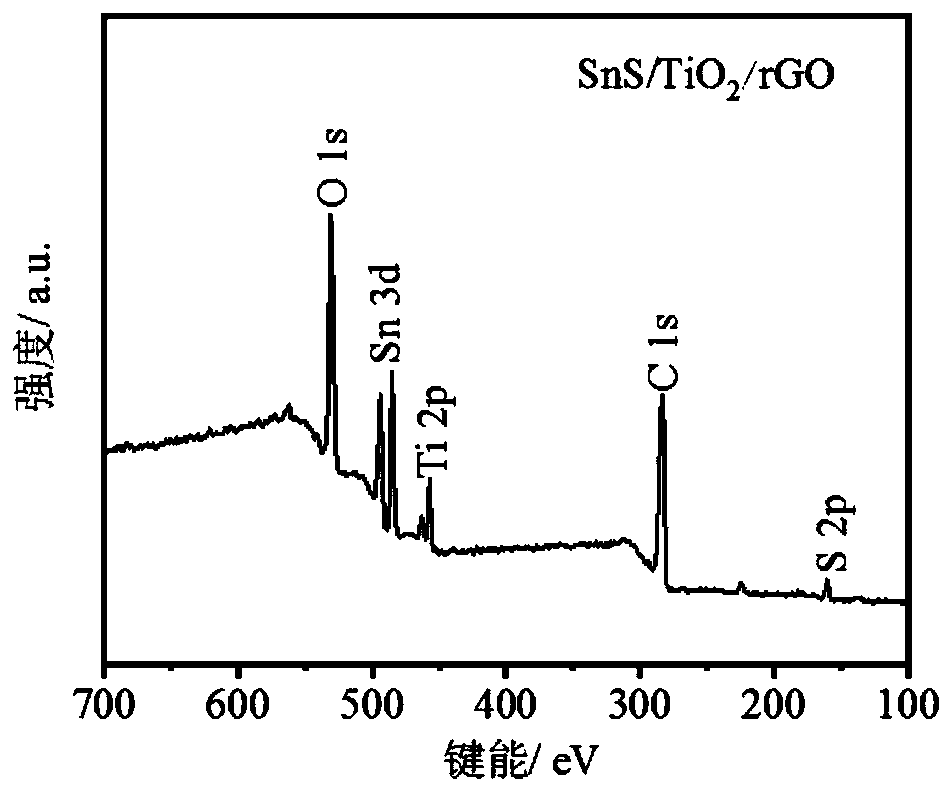

SnS/Ti02/rGO composite material for a potassium-ion battery negative electrode, preparation method thereof and matching electrolyte

InactiveCN110808368APlay a protective roleReduce negative impactSecondary cellsNegative electrodesElectrolytic agentElectrochemistry

The invention provides a SnS / Ti02 / rGO composite material for a potassium-ion battery negative electrode, a preparation method thereof and a matching electrolyte. In the SnS / Ti02 / rGO composite material, the SnS has a mass fraction of 80% or more, and the Ti02 has a mass fraction of 2% or less. The microstructure of the SnS / Ti02 / rGO composite material is that TiS-coated SnS nanoparticles are uniformly distributed on a reduced graphene oxide substrate, and have a particle size of 10-100 nm. The invention also provides a method for preparing the composite material and a matching electrolyte. The TiO2 coating has a protective effect on the SnS nanoparticles, and reduces the negative impact of the coating on material dynamics, provides the material with better electrochemical performance, and further improves the cyclic stable performance of the potassium-ion battery using the material through the optimization of the electrolyte.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

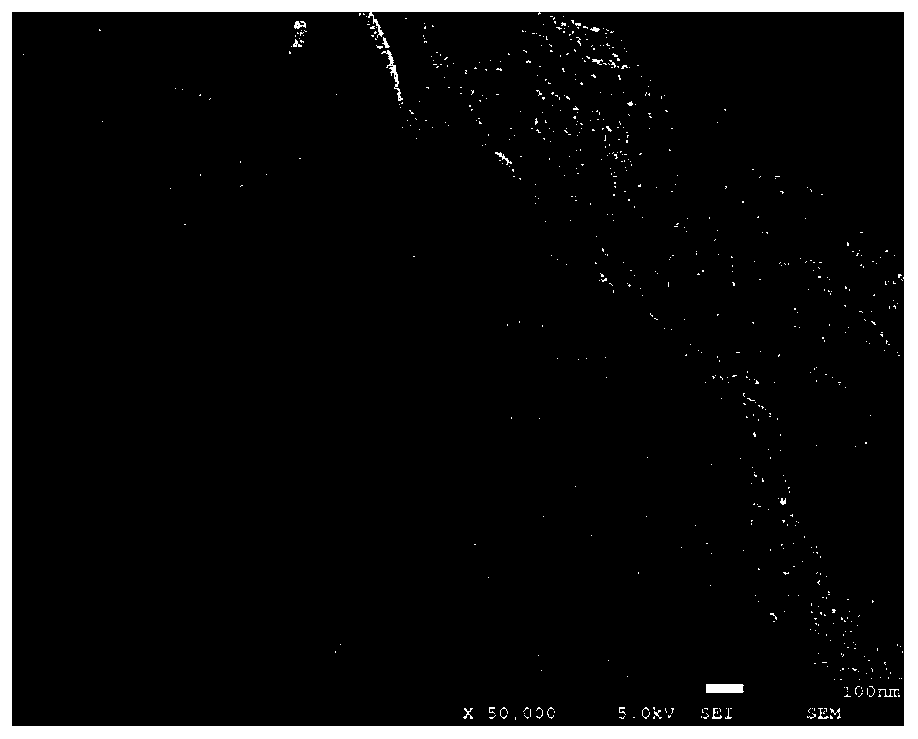

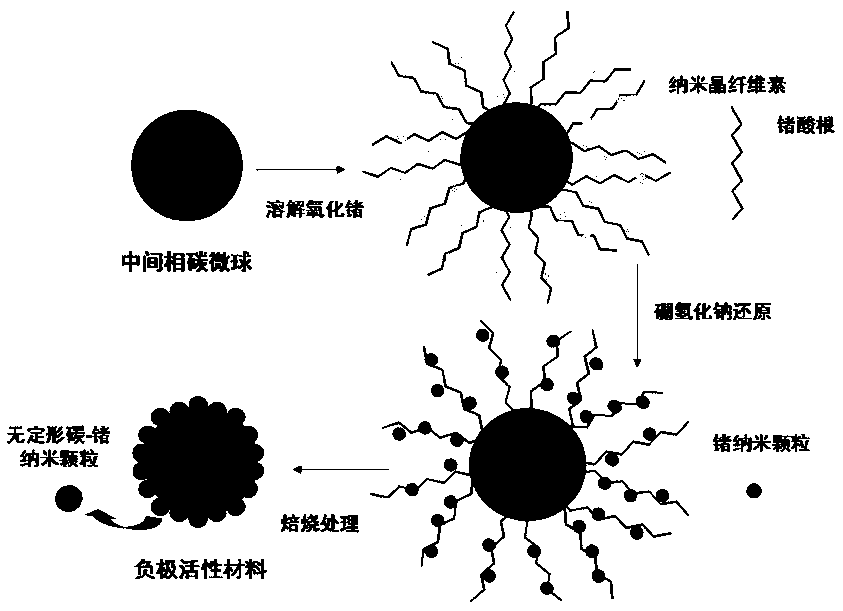

Lithium-ion battery germanium/carbon composite negative electrode material and preparation method and application thereof

ActiveCN110085847AImprove cycle stabilityAvoid reunionNegative electrodesSecondary cellsCelluloseCarbon composites

The invention discloses a lithium-ion battery germanium / carbon composite negative electrode material and a preparation method and an application thereof. The composite negative electrode material includes germanium nanoparticles, mesocarbon microbeads and amorphous carbon. The preparation method comprises the steps of (1) dissolving GeO2 in an alkaline solution, adding nanocrystalline cellulose, adjusting the pH-value of the obtained first suspension, adding the mesocarbon microbeads and stirring to form a second suspension, and transferring the second suspension to a water bath; (2) preparingan NaBH4 solution, adding the heated second suspension, stirring for reaction in the water bath, washing wafer vacuum filtration, then carrying out vacuum drying, roasting the dried solid in an inertgas or reducing atmosphere to obtain the product. The composite negative electrode material disclosed by the invention has high mass capacity and volume specific capacity, can effectively alleviate the volume change and pulverization of germanium, is high in cycle stability and good in compatibility with a propylene carbonate containing electrolyte, has the advantages of good low-temperature electrochemical performance and the like and can be applied to lithium-ion batteries.

Owner:NAT UNIV OF DEFENSE TECH

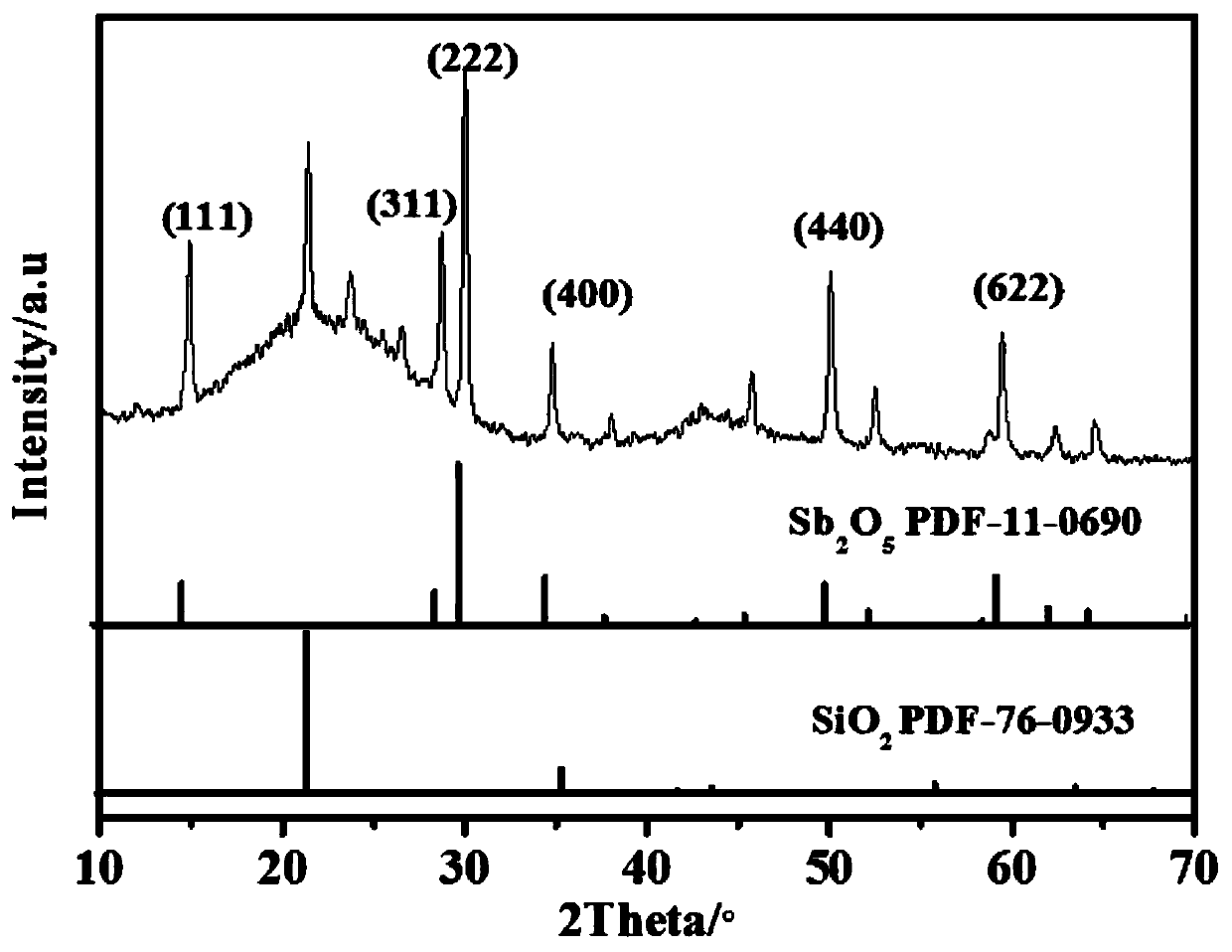

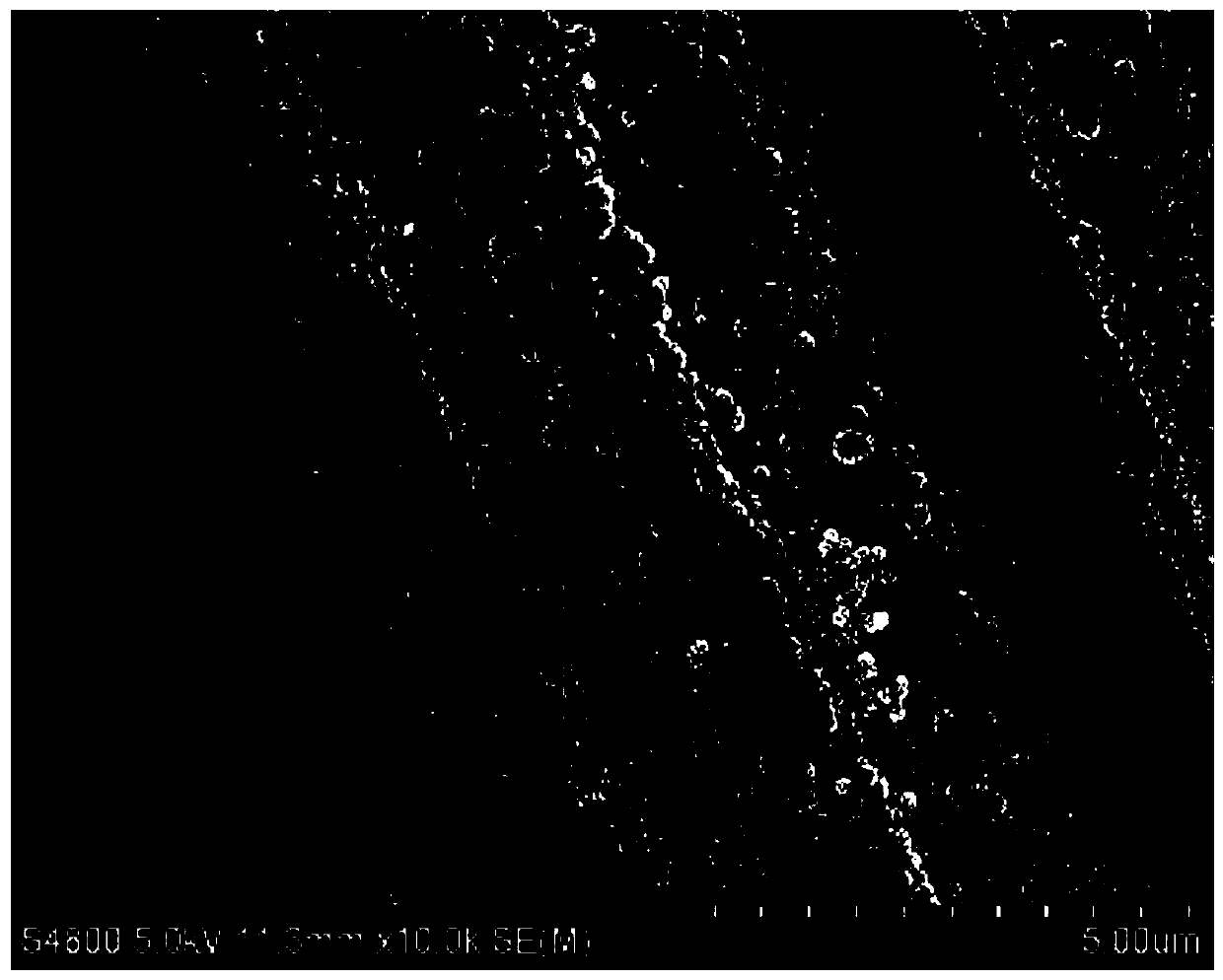

Preparation of antimony pentoxide/silicon dioxide/carbon cloth flexible material and application thereof as negative electrode of sodium-ion battery

The invention discloses preparation of an antimony pentoxide / silicon dioxide / carbon cloth flexible material and an application thereof as a negative electrode of a sodium-ion battery, which comprisesthe following steps: grinding silicon dioxide, adding the silicon dioxide into deionized water for dissolution to obtain a solution A; adding antimony trichloride into the ethanol solution for dissolution to obtain an antimony trichloride solution, and adding a sodium hydroxide aqueous solution into the antimony trichloride solution to adjust the pH value of the antimony trichloride solution to obtain a solution B; adding the solution A into the solution B and stirring to obtain a solution C; impregnating the activated carbon cloth in the solution C, transferring the solution C and the carboncloth into a reaction kettle for hydrothermal reaction, cooling the carbon cloth to room temperature, moving out the carbon cloth, and cleaning and drying the carbon cloth to obtain the antimony pentoxide / silicon dioxide / carbon cloth flexible sodium ion battery negative electrode material. The method is simple to operate and low in cost, and the silicon material can be applied to the negative electrode material of the sodium-ion battery.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of tin-based cathode material of high-capacity lithium-ion battery

InactiveCN105810921AGood dispersionImprove conductivityElectrode thermal treatmentSecondary cellsDispersityElectrical battery

The invention discloses a preparation method of tin-based cathode material of a high-capacity lithium-ion battery.The preparation method includes: mixing nano tin and graphite with a pyrolytic carbon organic matter precursor to obtain composite material precursor slurry, performing spraying drying to obtain precursor powder, calcining under inert atmosphere, and grinding to obtain nano tin / graphite composite material wrapped by organic matter pyrolytic carbon.By the preparation method, the dispersity of nano tin in the tin-carbon cathode material can be increased, the material stability during lithium getting off, high conductivity of the material is guaranteed, the pyrolytic carbon wrapping layer effectively wrap the surfaces of the particles of the material, the interface feature of the material can be improved effectively, and the electrochemical performance of the tin-carbon cathode material is increased.

Owner:田东

Anode material for lithium-ion battery and preparation method

ActiveCN101931077AImprove lithium intercalation spaceHigh reversible specific capacityCell electrodesCarbon compositesPore diameter

The invention provides an anode material for a lithium-ion battery and a preparation method thereof. The anode material is characterized in that the material is a composite of graphite and mesoporous carbons; the mesoporous carbons account for 1-60% of the composite by mass; the graphitization degree of the graphite ranges from 78% to 88%; the pore diameters of the mesoporous carbons are 2-50nm; and the through porosity is not lower than 85%. The carbon composite anode material is prepared by chemically compounding the graphite with low graphitization degree and the mesoporous carbons with high through porosity. The anode material is suitable for low-temperature power lithium-ion batteries, has mild preparation conditions and is beneficial to industrialization.

Owner:HUNAN SHINZOOM TECH

Method for preparing porous silicon/graphene composite lithium ion battery anode material by using diatomite as raw material

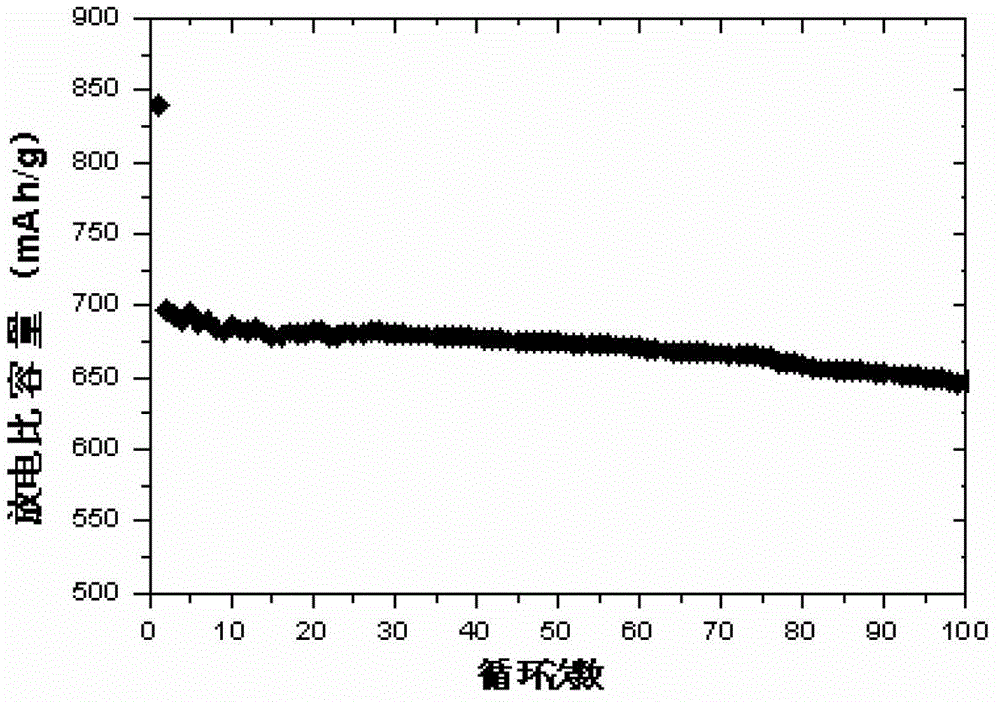

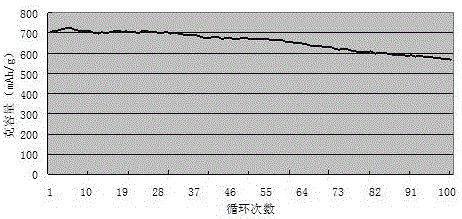

InactiveCN106532008AWide variety of sourcesLow priceCell electrodesSecondary cellsMaterials preparationPower flow

The invention discloses a method for preparing a porous silicon / graphene composite lithium ion battery anode material by using diatomite as a raw material. The method is characterized by comprising the steps of diatomite purification, porous silicon preparation and porous silicon / graphene composite material preparation. The preparation method is scientific and reasonable, simple, convenient and practicable, low in cost, environmentally-friendly and high in practicability, raw materials are wide in sources, excellent conductivity and good mechanical performance of graphene are sufficiently utilized, the problems such as electrical conductivity and volume effect of a silica-based material are effectively improved, the method is directly used for the lithium ion battery anode material, and the reversible capacity still can reach 609.4 mAh / g after 100 times of cycle under the current density of 100 mA / g.

Owner:NORTHEAST DIANLI UNIVERSITY

Preparation of Self-Supported Three-Dimensional Graphene/Tin Composite Anode Material for Lithium Ion Battery

InactiveCN109167047AStable structure and performanceImprove structural performanceNegative electrodesSecondary cellsTin dioxideCarbon nanotube

A method for prepare a self-supporting three-dimensional graphene / tin composite lithium ion battery negative electrode material relates to a preparation method of a lithium ion battery negative electrode material. The invention solves the technical problems of high mobility and poor multiplicity of the existing three-dimensional graphene and tin composite materials. 11) mix graphene oxide dispersion liquid and nanometer tin dioxide into a mixed liquid; Or mixing graphene oxide dispersion, nano tin dioxide and acidified carbon nanotubes into a mixed liquid; 2, dry after hydrothermal reaction toobtain an electrode precursor; 3, the precursor is reduced in H2 / Ar mixed gas atmosphere at high temperature to obtain the material. The specific discharge capacity of the material of the first cycleat current density of 200mA g<-1> is 1089.4 mAh g<-1> - 1098.9 mAh g<-1>. The capacity retention rate was above 53.1% in the 100th cycle. The cycle performance is stable and it can be used as the material of lithium ion battery.

Owner:HARBIN INST OF TECH

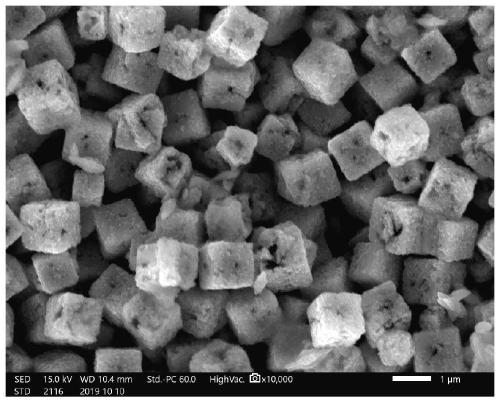

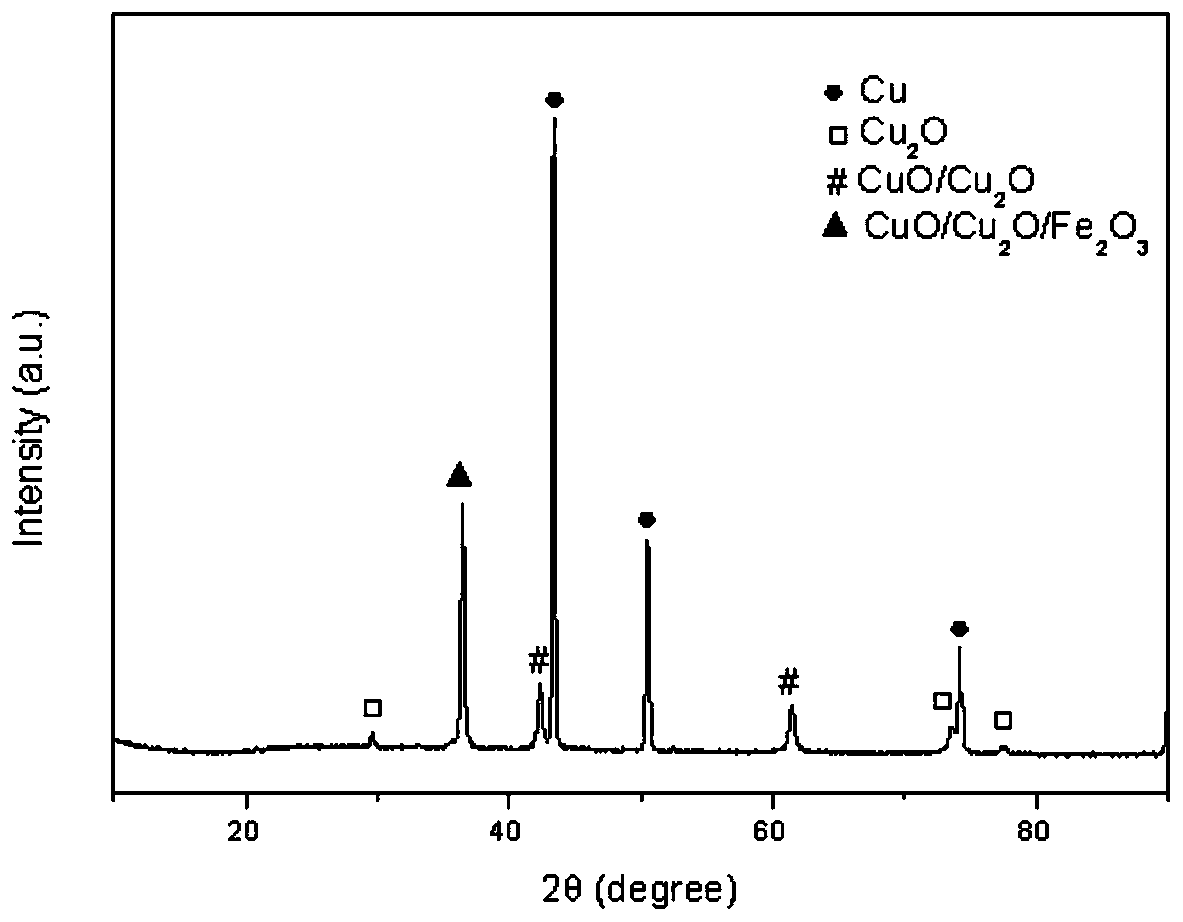

Hollow porous cuprous oxide-copper oxide-ferric oxide cubic lithium ion battery anode and one-step preparation method thereof

ActiveCN111193012AAlleviate volume changesLarge specific surface areaNegative electrodesSecondary cellsCopper oxide nanoparticlesNanoparticle

The invention provides a hollow porous cuprous oxide-copper oxide-ferric oxide cubic lithium ion battery anode based on three-dimensional porous copper skeleton in-situ growth. The battery anode is composed of a three-dimensional porous copper skeleton and hollow porous cuprous oxide-copper oxide-ferric oxide cubes, the hollow porous cuprous oxide-copper oxide-ferric oxide cubes are cubes which are of a hollow porous structure and is formed by assembling cuprous oxide nanoparticles and copper oxide nanoparticles, wherein the cuprous oxide nanoparticles and the copper oxide nanoparticles are formed by partially oxidizing the surfaces of ferric oxide nanoparticles and the three-dimensional porous copper skeleton in situ. The hollow porous cuprous oxide-copper oxide-ferric oxide cubes are uniformly distributed on the surface of the three-dimensional porous copper skeleton. The invention also provides a one-step preparation method of the anode. The lithium ion battery anode provided by theinvention can effectively buffer the volume change of the lithium ion battery in the charge-discharge process, prevent the active component from falling off in the charge-discharge process of the lithium ion battery, and significantly improve the specific capacity and cycle performance of the lithium ion battery anode.

Owner:SICHUAN UNIV

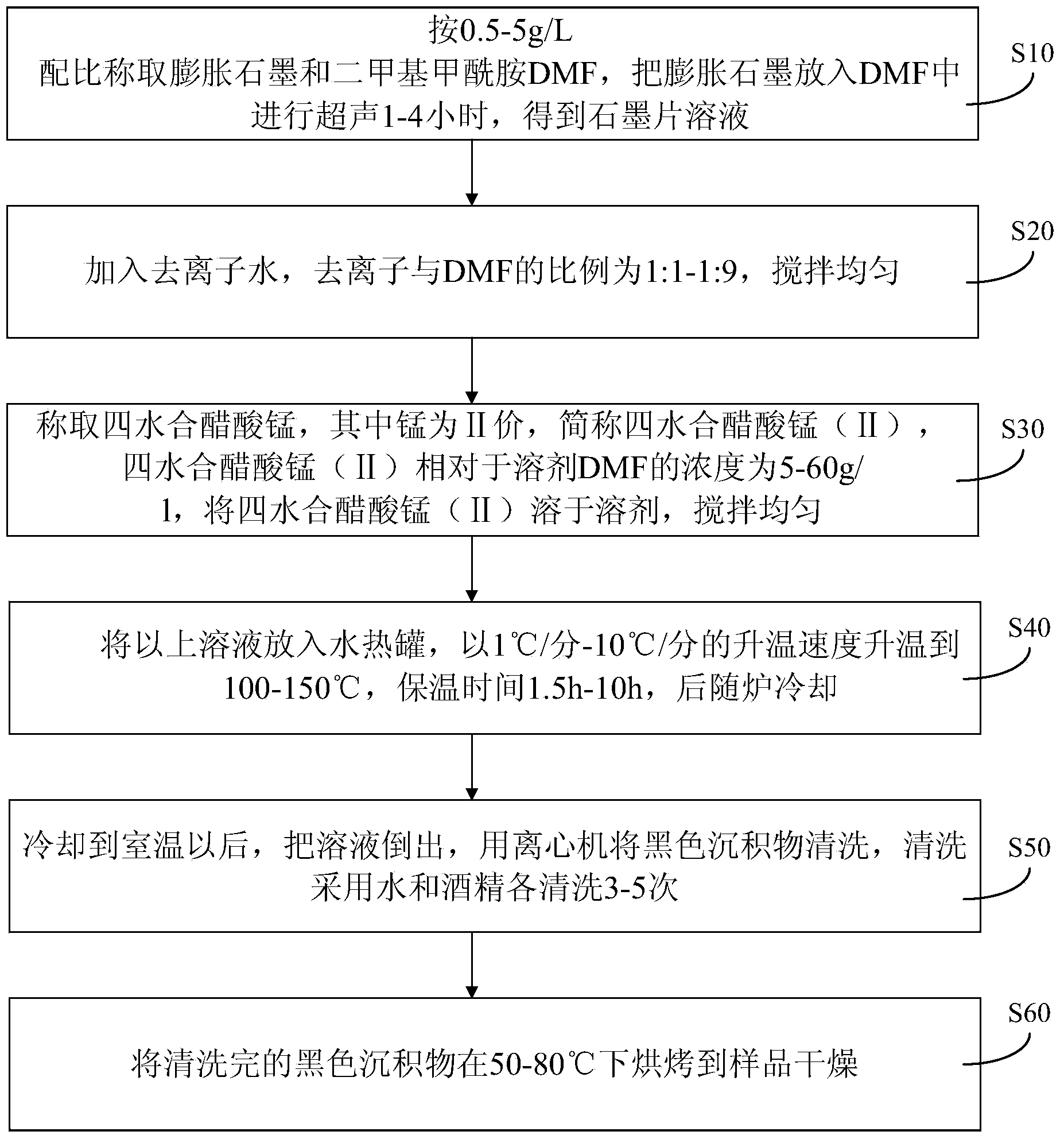

Graphite flake /trimanganese tetroxide composite nano-material with sandwich structure, its preparation method, and lithium ion battery using it

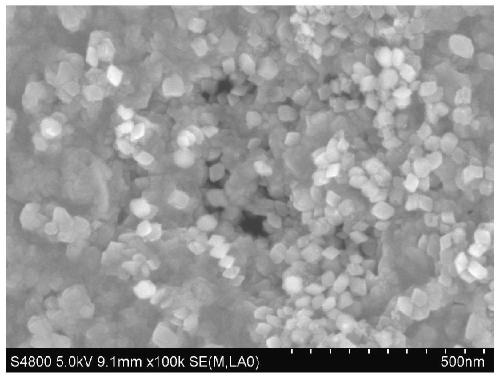

ActiveCN104167532AAvoid re-stackingAvoid reunionMaterial nanotechnologyCell electrodesMANGANESE ACETATE TETRAHYDRATERoom temperature

The invention discloses a graphite flake / trimanganese tetroxide composite nano-material with a sandwich structure, its preparation method, and a lithium ion battery using it. The method comprises the following steps: weighing expanded graphite and DMF according to a ratio of 0.5-5g / L, putting the expanded graphite in the DMF, and carrying out ultrasonic treatment for 1-4h to obtain a graphite flake solution; adding deionized water according to a ratio of deionized water to the DMF of 1:1-1:9, and uniformly stirring; weighing manganese (II) acetate tetrahydrate according to a ratio of the manganese acetate tetrahydrate to the solvent DMF of 5-60g / L, dissolving the manganese acetate tetrahydrate in the solvent, and uniformly stirring; adding the above obtained solution into a hydrothermal tank, heating, carrying out heat insulation, and carrying out furnace cooling; cleaning a black sediment by using a centrifuge after the above obtained material is cooled to room temperature; and baking the cleaned black sediment at 50-80DEG C until the obtained sample is dry. The method for obtaining a uniform Mn3O4 nanoparticle film on the surface of a non-oxidized graphite flake is simple, and is suitable for mass production.

Owner:浙江东信昆辰科技股份有限公司

Preparation method for modified graphite anode material

InactiveCN104868159AGuaranteed stabilityImprove co-embedding performanceCell electrodesSecondary cellsHigh energyCyclic stability

The invention discloses a preparation method for a modified graphite anode material. The preparation method comprises the following steps: (1) preparing a slurry precursor; (2) drying the precursor; (3) performing heat treatment. The prepared graphite anode material has higher specific capacity; the material is modified, so that the electrical conductivity of the material is effectively improved, and the cyclic stability of the material is improved; therefore, when the anode material is used for a lithium ion battery, higher energy density and good cyclic stability are achieved.

Owner:田东

A carbon-coated nano-silicon composite material and its preparation method and application

ActiveCN106784732BEasy to spreadImprove cycle stabilityMaterial nanotechnologySecondary cellsCarbon coatingNano silicon

The invention relates to a carbon coated nanosilicon composite material as well as a preparation method and an application thereof. The invention relates to silicon composite powder as well as a preparation method and an application thereof. The invention aims to solve the technical problem that an existing method of reducing the volume effect of a silicon-based cathode material by virtue of nanocrystallization, alloying or porous forming is complex in preparation process and high in cost. The carbon coated nanosilicon composite material provided by the invention is powder of a core-shell structure taking nanosilicon particles as a content and carbon as a shell. The preparation method comprises the following steps: performing oxygen diffusion on nanoscale silicon micropowder with an oxidizing layer on the surface; then performing carbon coating treatment; and then soaking the same with a hydrofluoric acid solution to remove the component of silicon oxide to obtain the carbon coated nanosilicon composite material. The volume of the carbon coated nanosilicon composite material provided by the invention reaches 900mAh / g or above, attenuation after 150 times of cycles is smaller than 4%, and the material can be used as a lithium battery silicon cathode material.

Owner:吕铁铮

Lithium ion battery anode material and preparation method thereof

ActiveCN109768265AObvious structural advantagesRelieve swellingMaterial nanotechnologyCell electrodesZinc selenideSodium-ion battery

The present invention relates to a lithium ion battery anode material with high specific capacity and a preparation method thereof. The lithium ion battery anode material is a zinc sulfide-zinc selenide composite material based on a zinc sulfide hollow nanosphere structure. The preparation method comprises the steps of: preparing a zinc sulfide hollow nanosphere, and adding selenium powder, grinding and heating the mixture of the zinc sulfide hollow nanosphere and the selenium powder to perform selenylation of the surface of the zinc sulfide hollow nanosphere. The zinc sulfide is introduced asan anode material, and a zinc sulfide-zinc selenide composite material is obtained by employing a simple selenylation reaction. The lithium ion battery anode material has obvious structure advantages, can provide more oxidation active sites to obtain higher specific capacity, and has good mechanical properties and a good cycle life. The zinc sulfide and the zinc selenide are taken as anode material active materials, and the electrochemical properties of the lithium ion battery are improved through the synergistic effect of the zinc sulfide and the zinc selenide.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Sodium-ion battery negative electrode material and preparation method thereof

ActiveCN109755543AImprove electrochemical performanceRelieve swellingMaterial nanotechnologyCell electrodesHigh current densitySodium-ion battery

The invention relates to a sodium-ion battery negative electrode material compounded by a nickel oxide-nickel sulfide composite and graphene and a preparation method thereof. The composite material has a double-layer hollow sphere structure. The preparation process includes the following steps: firstly, preparing a nickel oxide double-layer hollow sphere, partially vulcanizing the hollow sphere toobtain the nickel oxide-nickel sulfide composite, and then compounding the nickel oxide-nickel sulfide composite with graphene to prepare the negative electrode material by using a spray drying method. The composite material of the invention can provide more oxidation active sites, obtains higher specific capacity under high current density, shortens the transmission path of electrons and charges, relieves the expansion of materials during charging and discharging, and achieves good cycle life due to good mechanical properties. According to the scheme of the invention, graphene and the nickeloxide-nickel sulfide hollow sphere are compounded, so that the conductivity of the negative electrode material can be enhanced, the volume expansion of active substances in the charging and discharging process can also be alleviated, and the electrochemical performance of the sodium-ion battery can be improved.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com