Preparation method of different morphologies of cobalt monoxide nanometers loaded with foam nickel

A technology of cobalt monoxide and nanomaterials, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of not meeting high-capacity power batteries, affecting ion and electron transmission, poor conductivity, etc. problems, to achieve a wide pore size distribution, shorten the transmission path, and improve the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

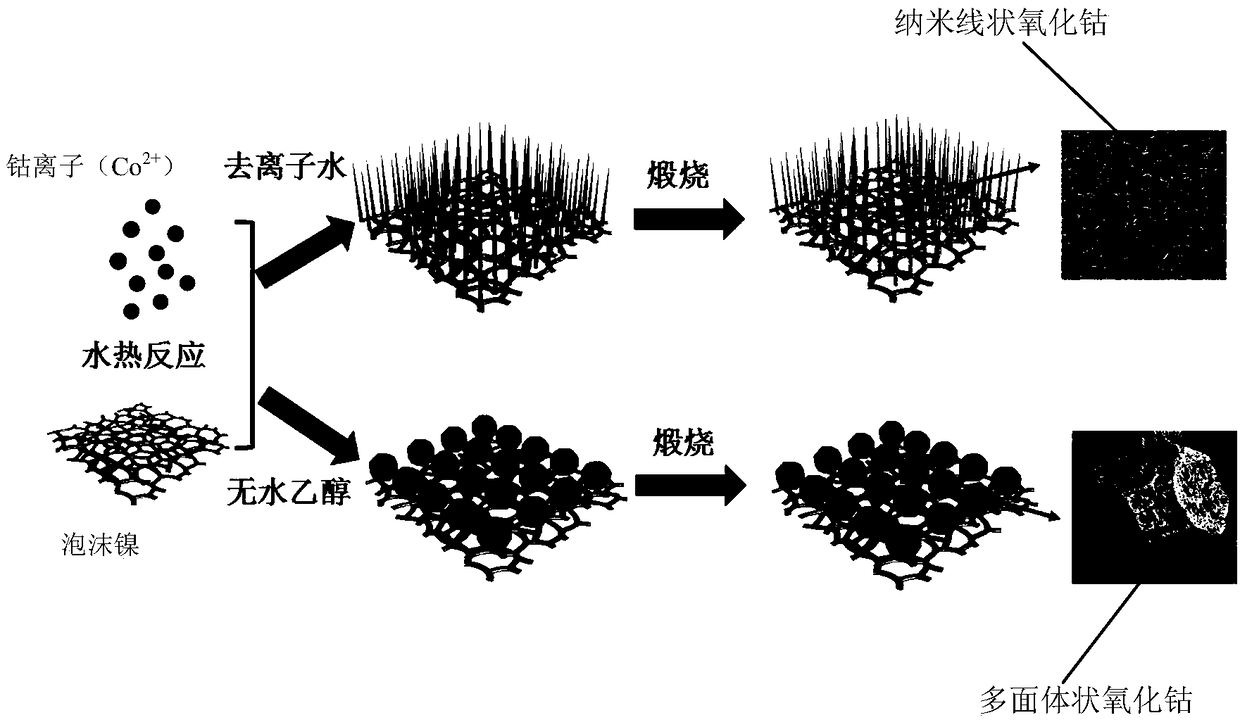

[0051] According to a non-limiting embodiment of the present invention, there is provided a method for preparing nickel foam supported cobalt monoxide nanomaterials with different shapes, the method comprising the following steps.

[0052] (1) The flaky nickel foam is placed in an ultrasonic cleaning machine for cleaning, and the cleaned foam nickel is placed in a drying oven for drying.

[0053] (2) Disperse the cobalt chloride hexahydrate powder into the dispersing solvent added with urea, and magnetically stir at room temperature for 0.5 to 1.5 hours to form a suspension at a stirring speed of 300 to 400 RPM, wherein the concentration of cobalt chloride hexahydrate and urea The quality is 2:3~8.

[0054] (3) Transfer the suspension in step (2) to the high-pressure hydrothermal reaction kettle, and put the dried sheet-shaped nickel foam into the high-pressure hydrothermal reaction kettle obliquely in the step (1), and seal the high-pressure For the hydrothermal reactor, set...

Embodiment 1

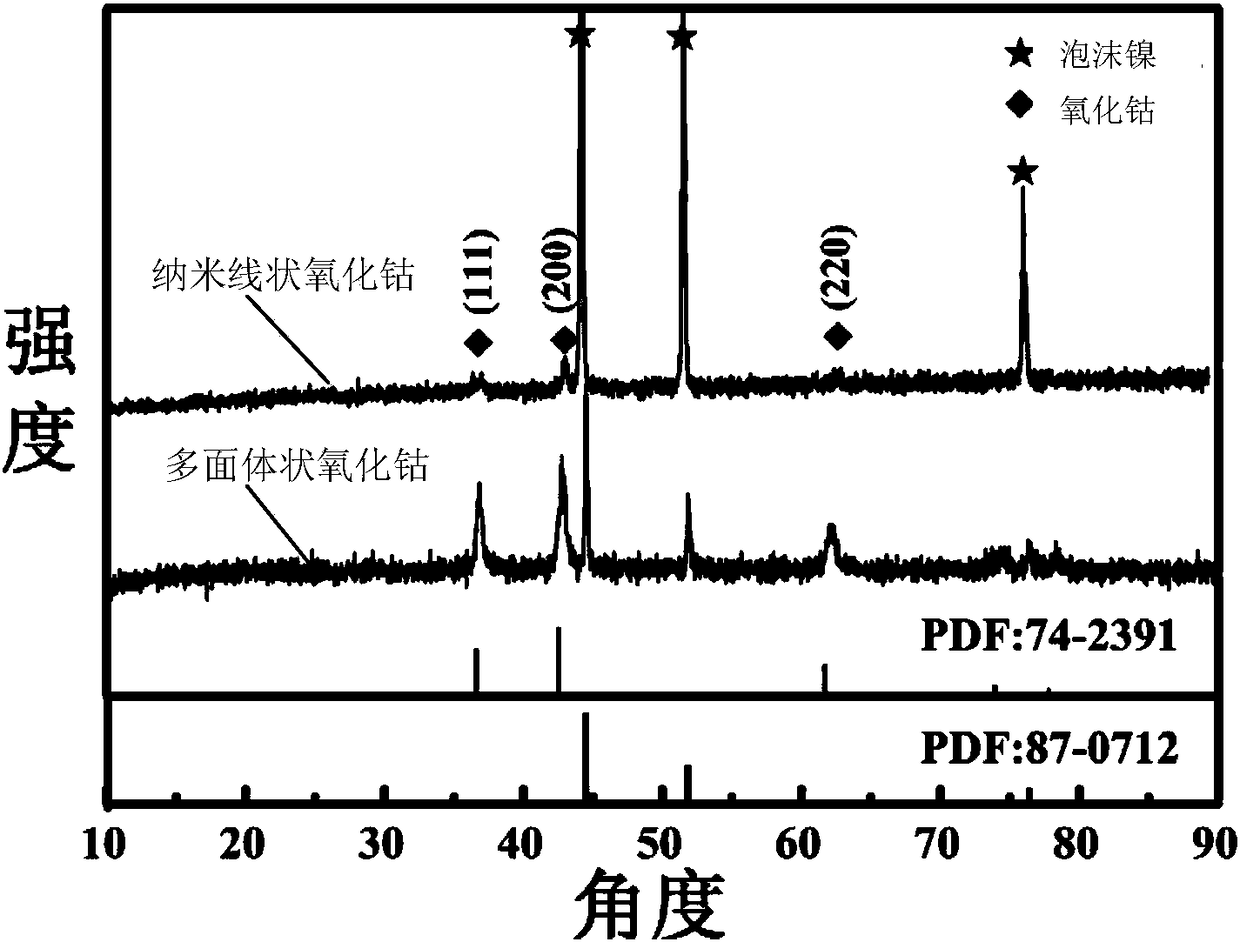

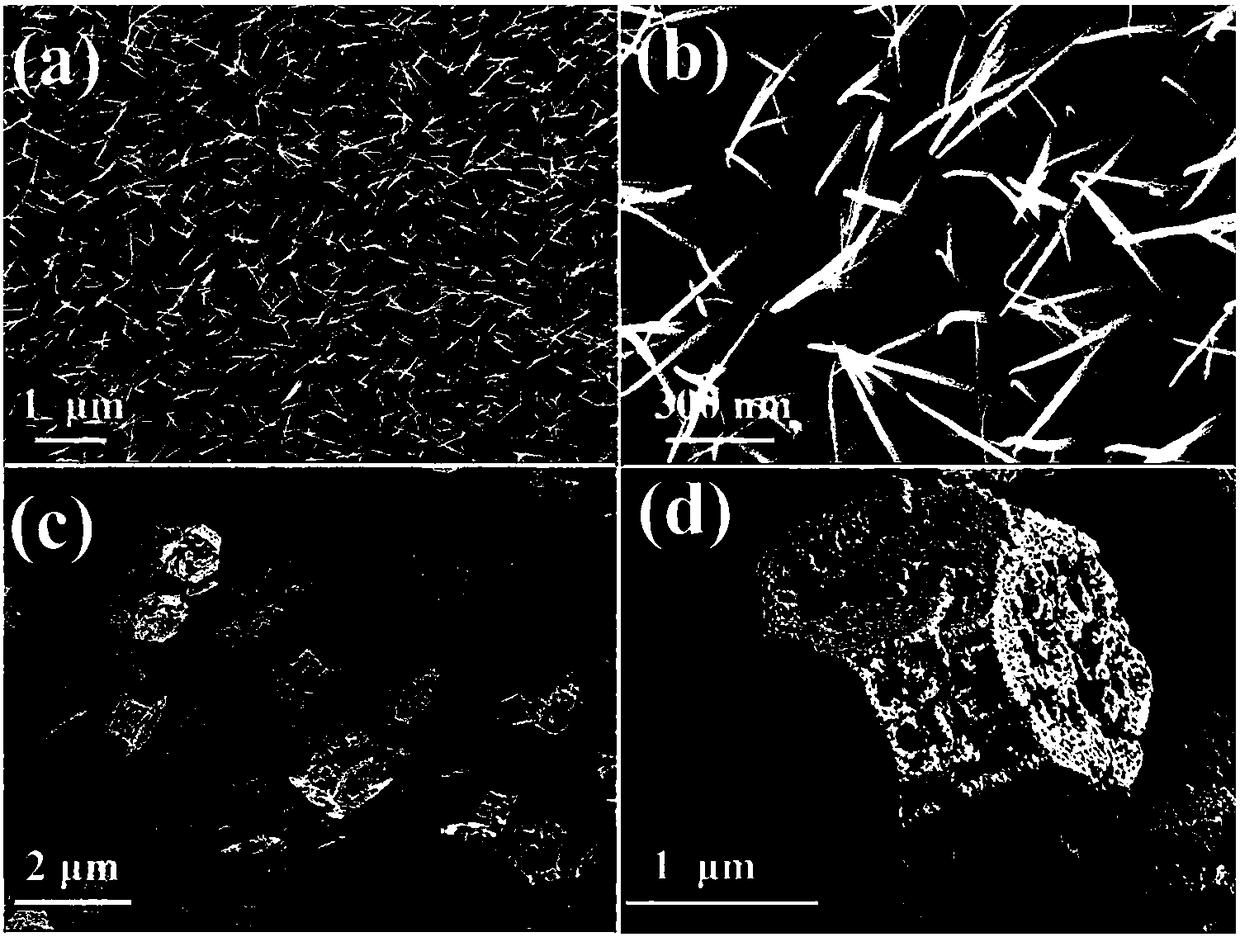

[0059] The preparation method of the CoO nanomaterials of two different shapes specifically comprises the following steps:

[0060] First, in step 1, the nickel foam with a specification of 280ppm and a thickness of 0.5mm is cut into a uniform size of 3 × 4 square centimeters, and cleaned with 3mol / L hydrochloric acid, acetone, absolute ethanol and deionized water in sequence. Wash in the machine for 30 minutes, 20 minutes, 15 minutes and 15 minutes, and then dry in a drying oven at a temperature of 60°C for 8 hours.

[0061] Next, in step 2, the CoCl 2 ·6H 2 The O powder is dispersed into deionized water with urea added, the mass ratio of urea to deionized water is 0.55:29, and magnetically stirred at a stirring speed of 350RPM for 1 hour at room temperature to form a suspension, wherein, CoCl 2 ·6H 2 The mass ratio of O to urea is 2:5.

[0062] Then, in step 3, the suspension is transferred to the high-pressure hydrothermal reactor, the dried nickel foam is tilted into t...

Embodiment 2

[0066] In addition to step 2, the CoCl 2 ·6H 2 O powder is dispersed in the dehydrated alcohol that has added urea, and the mass ratio of urea and dehydrated alcohol is 0.55:23, other steps are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com