High-capacity lithium ion battery negative electrode plate and preparation method thereof

A technology for lithium-ion batteries and negative pole pieces, which is applied in the direction of electrode manufacturing, battery electrodes, and secondary batteries. Effects of cycle performance, improvement of electronic conductivity, and improvement of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

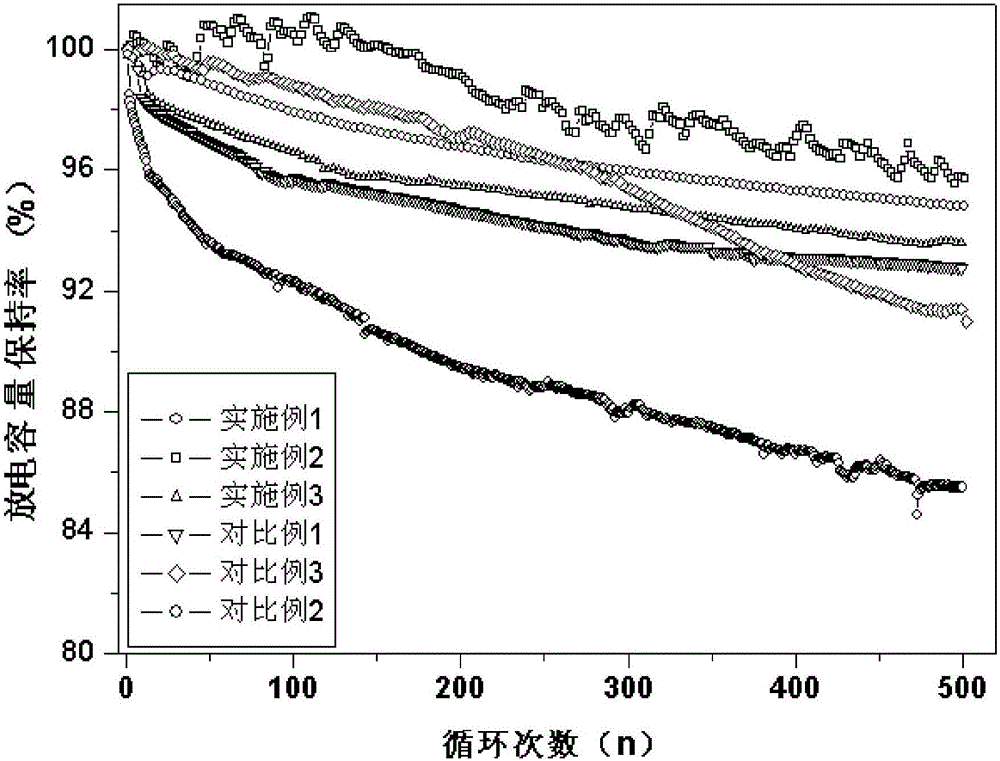

Examples

Embodiment 1

[0029] 1) Mix 93g of artificial graphite, 3g of conductive agent SP, 4g of LA132 binder and 200g of double distilled water to obtain negative electrode slurry;

[0030] At the same time, 43g of lithium hexafluoroaluminate, 43g of aluminum oxide, 7g of carbon nanotubes, 7g of polyvinylidene fluoride and 200g of N-methylpyrrolidone solvent were mixed uniformly to obtain a conductive composite slurry;

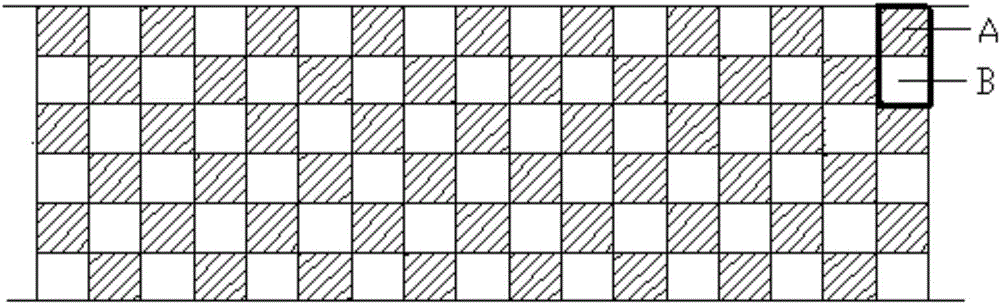

[0031] By vapor deposition method, methane gas is deposited on part A (the side length of which is 2 mm) of the surface of current collector copper foil (roughness 0.4 μm) by plasma chemical vapor deposition to obtain current collector A1, and then SiB4 is deposited by vapor phase method The current collector B1 (with a side length of 2 mm) is deposited on the part B of the surface of A1, and its deposition thickness is 1.0 μm.

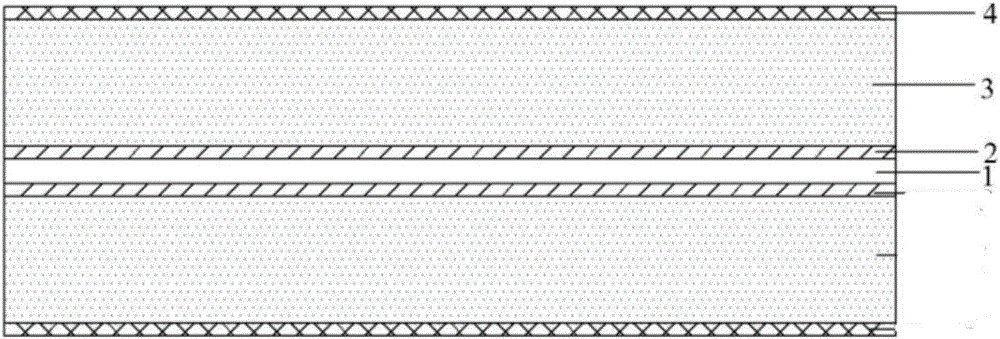

[0032] After drying, apply the negative electrode slurry on the surface of B1 through a coating machine (the coating thickness is 120 μm), and obtain the...

Embodiment 2

[0034] 1) Mix 93g of artificial graphite, 3g of conductive agent SP, 4g of LA132 binder and 200g of double distilled water to obtain negative electrode slurry;

[0035] At the same time, 40g of lithium hexafluoroaluminate, 40g of aluminum oxide, 10g of graphene, 10g of polyvinylidene fluoride and 200g of N-methylpyrrolidone solvent were mixed uniformly to obtain a conductive composite slurry;

[0036] By vapor deposition method, ethane gas is deposited on part A (side length 0.1 mm) of the current collector copper foil (roughness 0.5 μm) by plasma chemical vapor deposition to obtain current collector A1, and then the Mg2Si Part B (with a side length of 0.1 mm) deposited on the surface of A1 is deposited to obtain a current collector B1, and its deposition thickness is 0.5 μm.

[0037] After drying, apply the negative electrode slurry on the surface of B1 by a coating machine (the coating thickness is 80 μm), and obtain the pole roll C after drying, and then coat the conductive...

Embodiment 3

[0039] 1) Mix 93g of artificial graphite, 3g of conductive agent SP, 4g of LA132 binder and 200g of double distilled water to obtain negative electrode slurry;

[0040] At the same time, 45g of lithium hexafluoroaluminate, 45g of alumina, 5g of vapor-grown carbon fiber, 5g of polyvinylidene fluoride and 200g of N-methylpyrrolidone solvent were mixed uniformly to obtain a conductive composite slurry;

[0041] By vapor deposition method, natural gas is deposited on part A (side length 2 mm) of the surface of current collector copper foil (roughness 1.0 μm) by plasma chemical vapor deposition to obtain current collector A1, and then the particle size is obtained by gas phase method. 200nm of silicon powder is deposited on part B of the surface of A1 (with a side length of 2 mm) to obtain a current collector B1 with a deposition thickness of 2 μm.

[0042] After drying, apply the negative electrode slurry on the surface of B1 through a coating machine (the coating thickness is 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com