Patents

Literature

30results about How to "Avoid re-stacking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three dimensional graphene/hollow carbon sphere/sulfur composite material, preparation method thereof, and application in lithium-sulfur batteries

ActiveCN104916828AHigh specific capacityImprove cycle performanceMaterial nanotechnologyCell electrodesLithium–sulfur batteryLithium sulfur

The invention discloses a three dimensional graphene / hollow carbon sphere / sulfur composite material, a preparation method thereof, and an application in lithium-sulfur batteries. The three dimensional graphene / hollow carbon sphere / sulfur composite material comprises nanometer elemental sulfur and a three dimensional graphene-hollow carbon sphere nano-compound, and the nanometer elemental sulfur is distributed in the three dimensional graphene-hollow carbon sphere nano-compound. The preparation method comprises the following steps: dispersing the three dimensional graphene-hollow carbon sphere nano-compound in an alcohol and water mixed solvent to obtain a suspension; and adding an aqueous solution of Na2S.9H2O and Na2SO3 into the suspension, adding an acidic solution, and reacting to obtain the three dimensional graphene / hollow carbon sphere / sulfur composite material. The composite material has the advantages of high specific capacity, stable cycle performances, and excellent rate performance and coulombic efficiency, the preparation method has the advantages of simplicity, convenience and good effect, and the composite material can be applied in the preparation of lithium-sulfur battery positive electrode materials.

Owner:NAT UNIV OF DEFENSE TECH

Graphene metal compound super capacitor electrode material and preparation method thereof

ActiveCN105185597AKeep high specific powerReduce usageHybrid capacitor electrodesHybrid/EDL manufactureConductive polymerMetal alloy

The invention provides a graphene metal compound super capacitor electrode material. The material is a compound product obtained by compounding sheet-like graphene and sheet-like nano metals and / or sheet-like nano metal alloys and conductive polymers, and the conductive polymers are embedded into adjacent sheet metal layers and sheet graphene layers. The preparation method involves adding expanded graphite flakes, the metals and / or the metal alloys, the conductive polymers and meltable polymers in certain proportions into a graphene stripping machine, grinding for 10 to 16 hours at a vacuum state and preparing a mixed powder material of the sheet-like graphene, the sheet-like nano metals and / or the sheet-like nano metal alloys and granular high-molecular polymers; and pressurizing or vacuumizing the mixed powder material in a reactor, increasing the temperature to the melting point temperature of the meltable polymers, performing insulation for 2 to 4 hours, then reducing the temperature to a room temperature and obtaining the combined electrode material. When the material and method are implemented, graphene aggregation and accumulation can be prevented, the available surface area of graphene is improved, and the electrochemical performance is high.

Owner:深圳市来源新材料科技有限公司

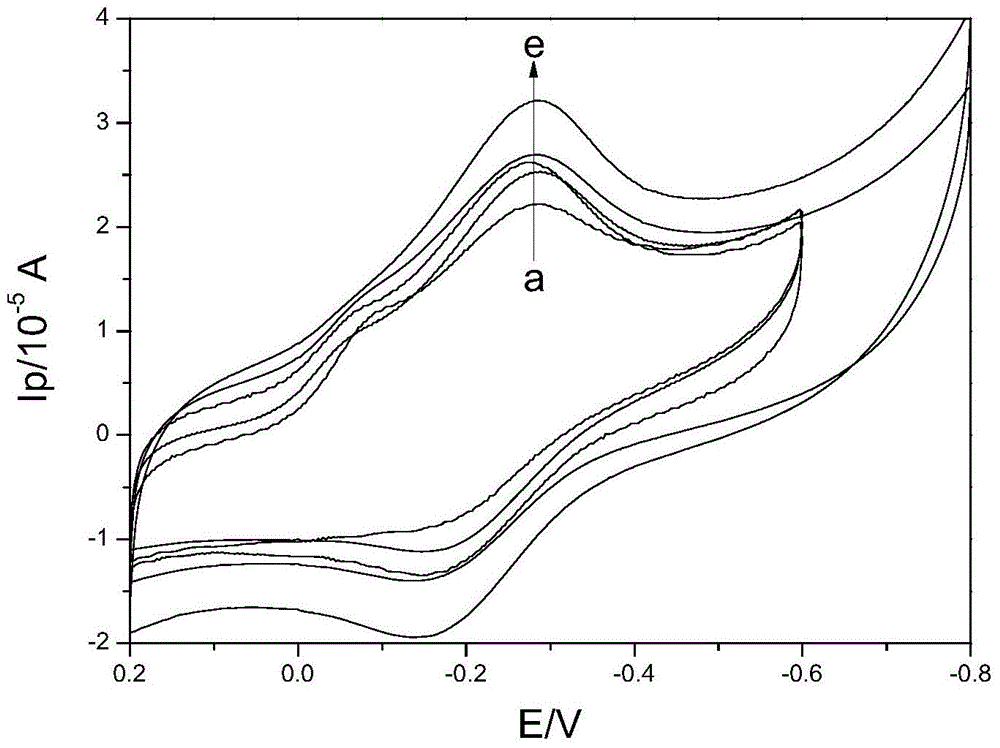

Graphene-hydrotalcite-like compound-graphite phase carbon nitride composite material immobilized protein modified electrode, production method and application thereof

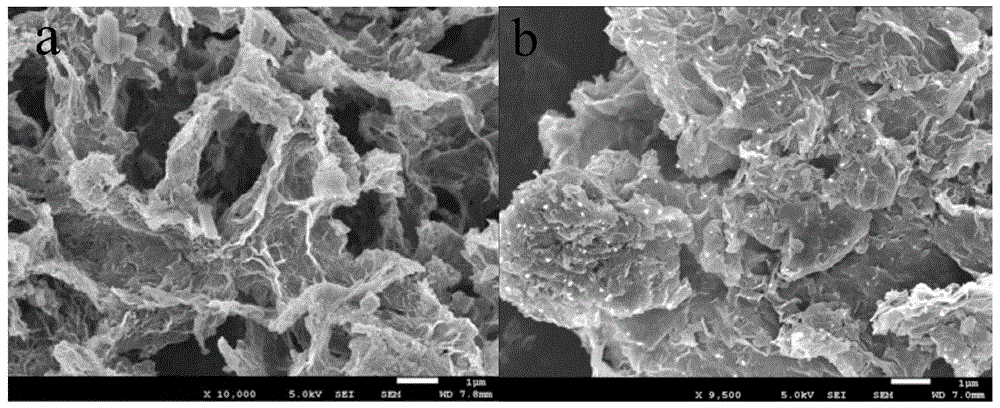

InactiveCN104977341ASuppress restackingLarge specific surface areaMaterial analysis by electric/magnetic meansElectrochemical responseCarbon composites

The invention discloses a graphene (GR)-hydrotalcite-like compound (LDH)-graphite phase carbon nitride (g-C3N4) composite material immobilized protein modified electrode, a production method and an application thereof. The method comprises the following steps: compounding an exfoliation hydrotalcite-like compound with negatively charged exfoliation graphene oxide nanosheets, mixing the obtained material with melamine, roasting, and adding water to recover in order to prepare a GR-LDH-g-C3N4 hybrid; and adding a GR-LDH-g-C3N4 and Hb mixed solution to an ionic liquid modified carbon paste electrode in a dropwise manner in order to produce the GR-LDH-g-C3N4 composite material immobilized protein modified electrode. The graphene-hydrotalcite-like compound-graphite phase carbon nitride composite material immobilized protein modified electrode fully displays advantages of a gel method and an integrating, merging and layering method, increases the specific surface area, the conductivity and the biocompatibility of the hybrid material, and inhibits the afresh stacking of GR sheets; and a roasting method allows g-C3N4 to grow on the surface of a GR sheet layer, increases the specific surface area of the hybrid material, and improves the electron transfer rate of an electrochemical reaction process. A constructed CTS / GR-LDH-g-C3N4-Hb composite film-based third-generation trichloroacetic acid sensor has the advantages of low detection limit, wide detection range and small Michaelis constant.

Owner:上海铭煦新材料有限公司

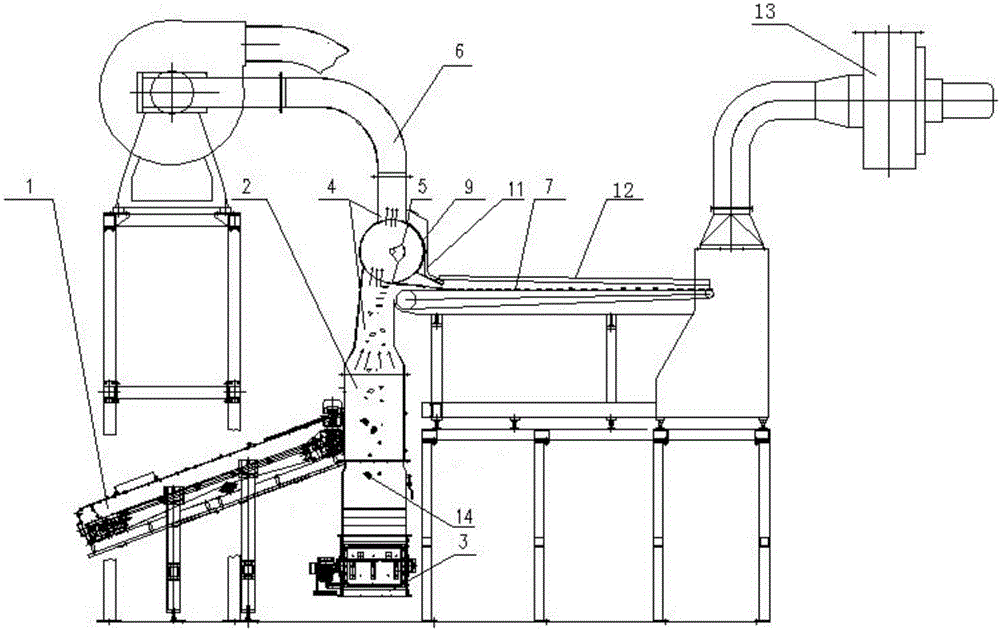

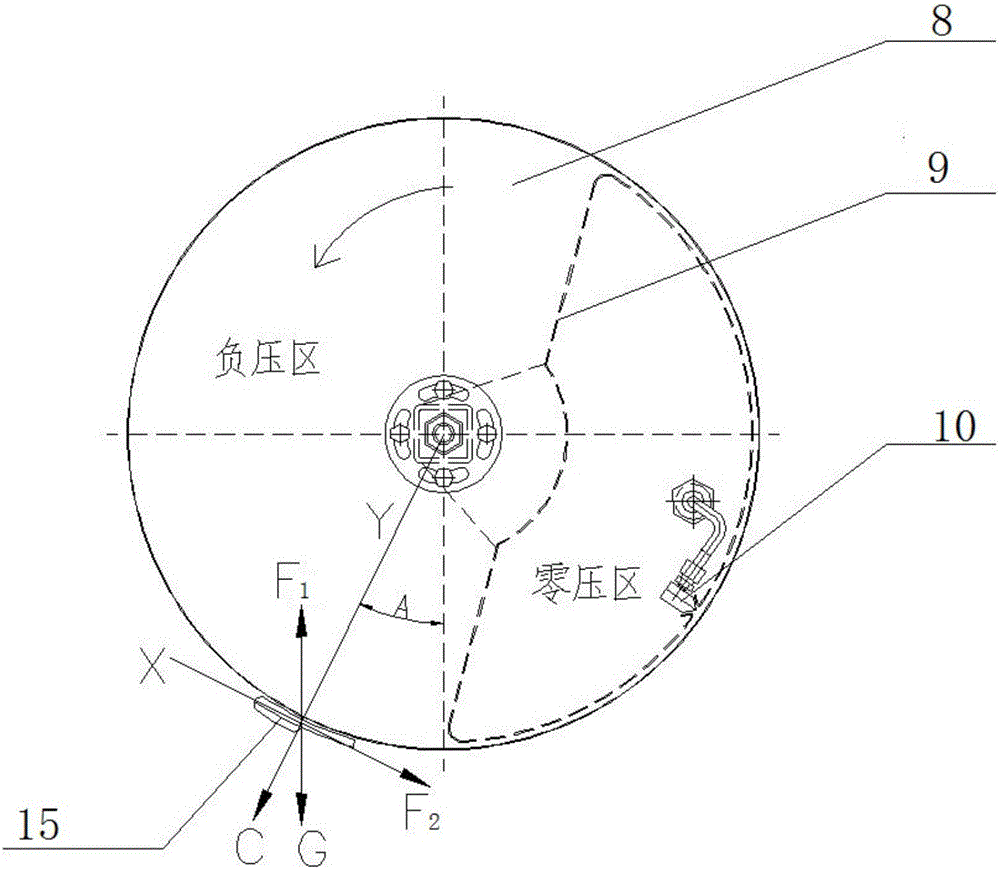

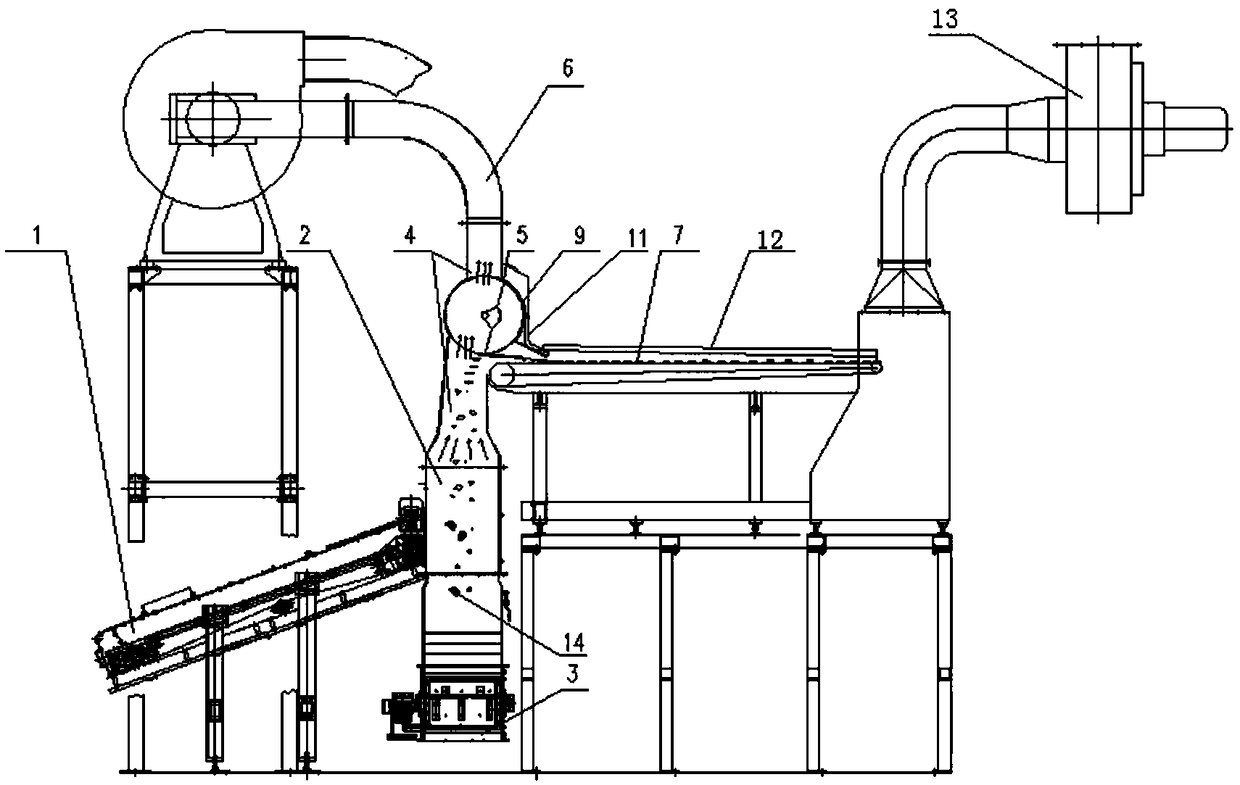

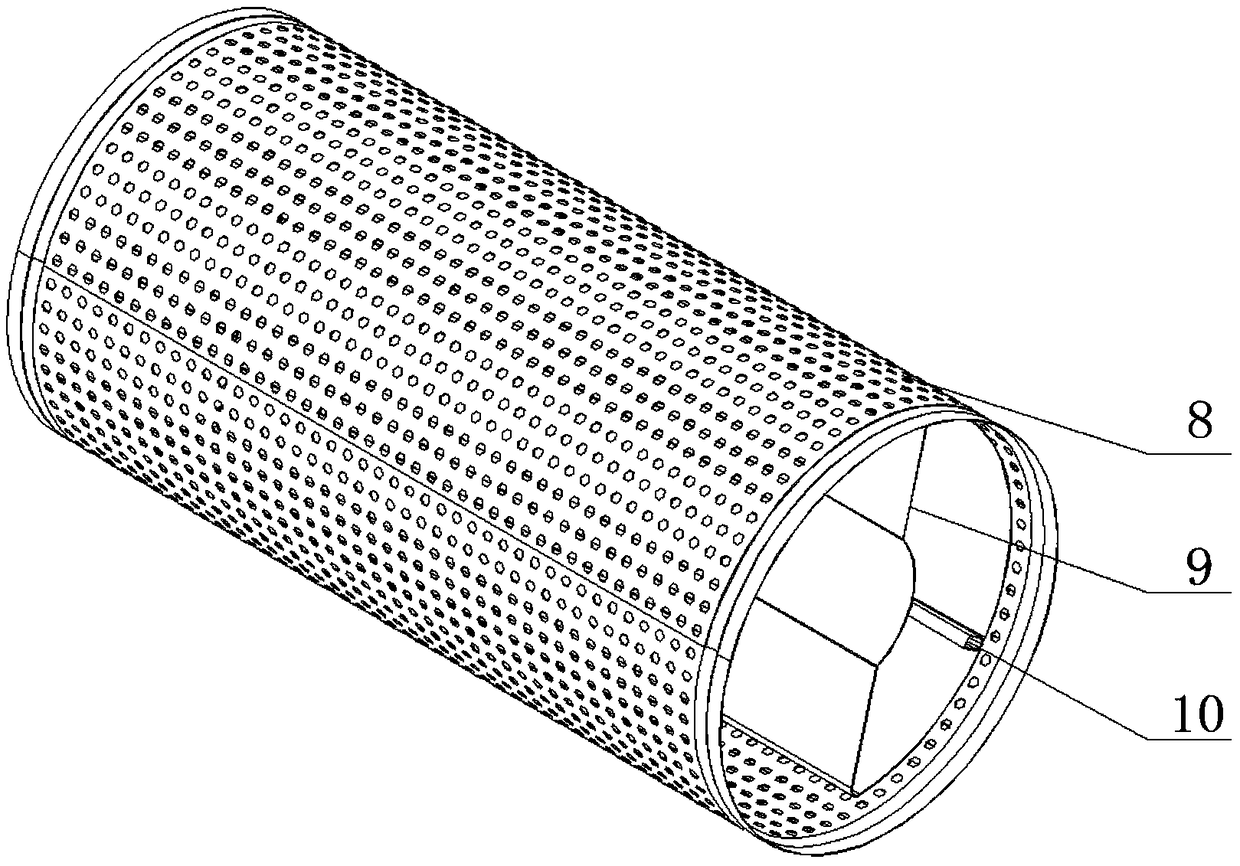

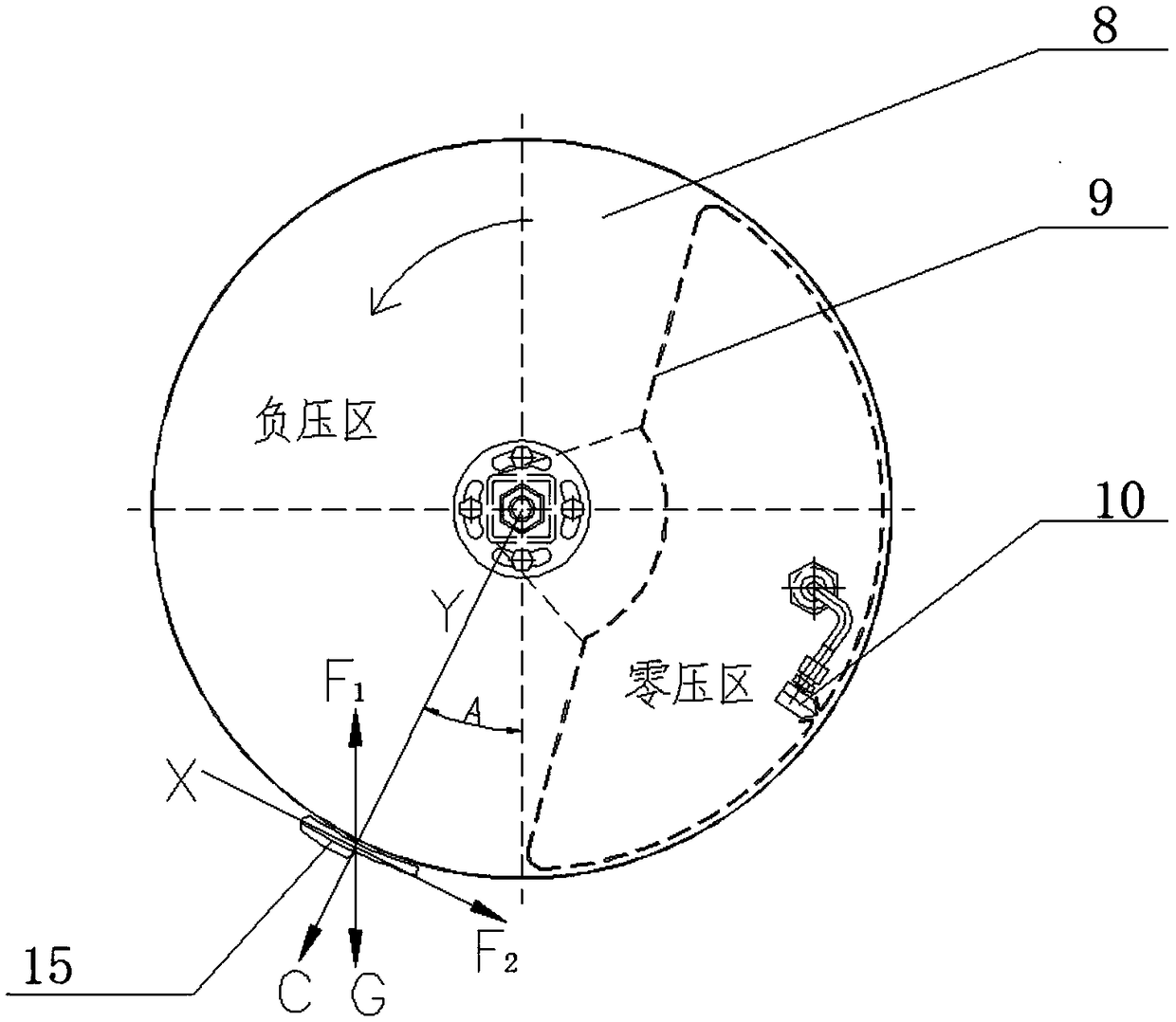

Tobacco paving, flattening and monolayer-conveying method and device

ActiveCN106690398AAvoid re-stackingAvoid Undetectable DefectsTobacco preparationAcute angleAir separation

The invention relates to the field of tobacco processing, and relates to the control technology of the tobacco form, in particular to a tobacco online spreading, flattening and monolayer-conveying method and equipment. Tobacco is accelerated in a material-air separation air duct, then the overlapped and wrapped tobacco is spread and flattened through positive pressure and zero pressure conversion of a negative pressure monolayer screen drum, the tobacco is handed over to a high-speed belt conveyor, and the belt speed of the high-speed belt conveyor is larger than or equal to the discharge speed of the screen drum in order to prevent the monolayer tobacco from being overlapped again; after the tobacco is handed over to the high-speed belt conveyor, by applying equal-belt-speed compressed air, the tobacco is attached to the belt surface of a high-speed belt and conveyed to a link needing tobacco detection along with the high-speed belt, wherein the angle between the equal-belt-speed compressed air and the belt running direction is an acute angle. According to the omni-bearing dead-angle-free method for exposing debris, green blocks and mildew spots in the tobacco under a detection device, the defect that in traditional photoelectric detection, during tobacco conveying, the debris, the green blocks and the mildew spots cannot be detected due to tobacco wrapping and overlapping can be avoided.

Owner:KUNMING SHIPBUILDING EQUIP

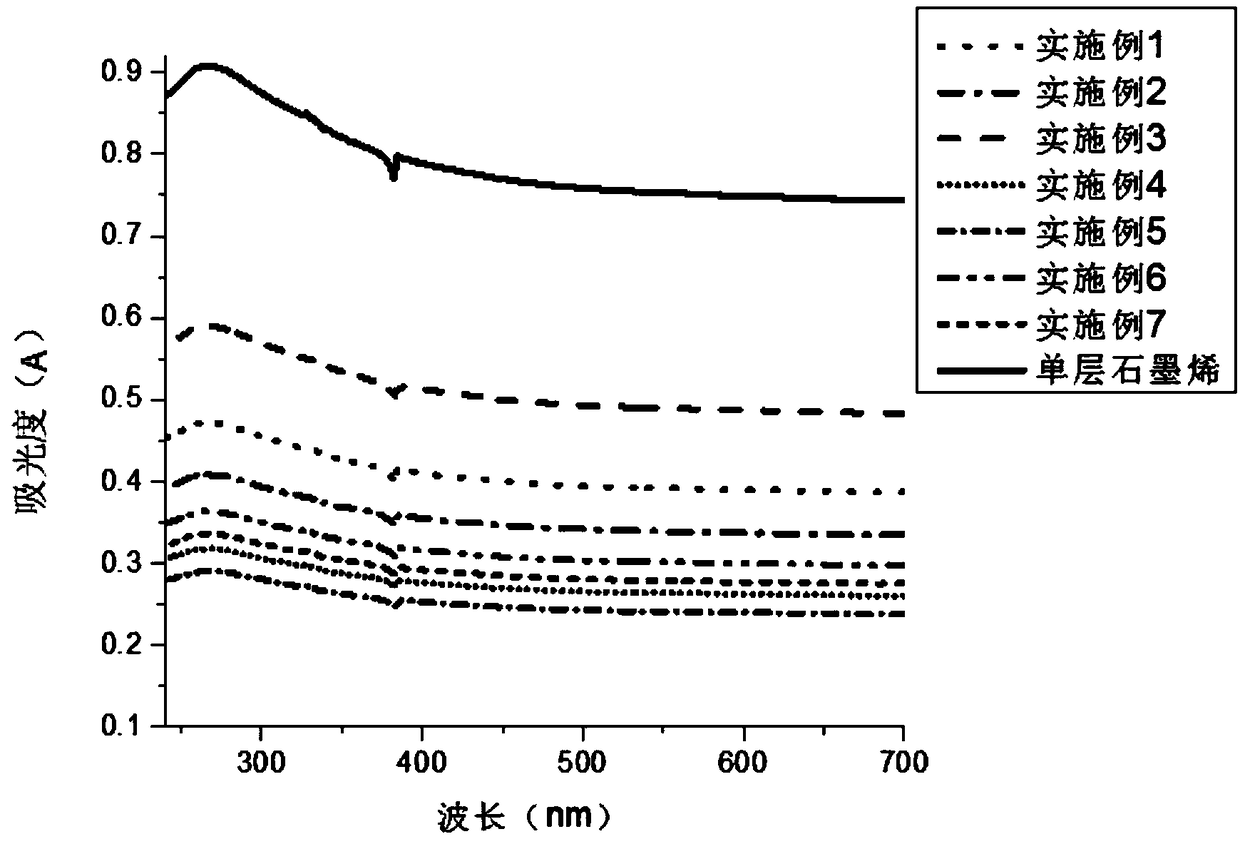

Method for preparing ultra-dispersible graphene through liquid nitrogen cold quenching

ActiveCN104692364AAvoid re-stackingShorten the cycle time of freeze-drying in situFreeze-dryingMaterials science

The invention discloses a method for preparing ultra-dispersible graphene through liquid nitrogen cold quenching. Oxidized graphene with different sizes is prepared by adopting a chemical method, an oxidized graphene solution is heated and then cold-quenched in liquid nitrogen, and thus ultra-dispersible oxidized graphene is prepared; and then, the ultra-dispersible oxidized graphene is reduced by a heating or chemical reduction way, to obtain the ultra-dispersible graphene. The method has the advantages of low cost and simple flow path, can shorten the preparation period (mainly shortens the period of sample freeze drying), and is suitable for mass preparation of the ultra-dispersive graphene.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

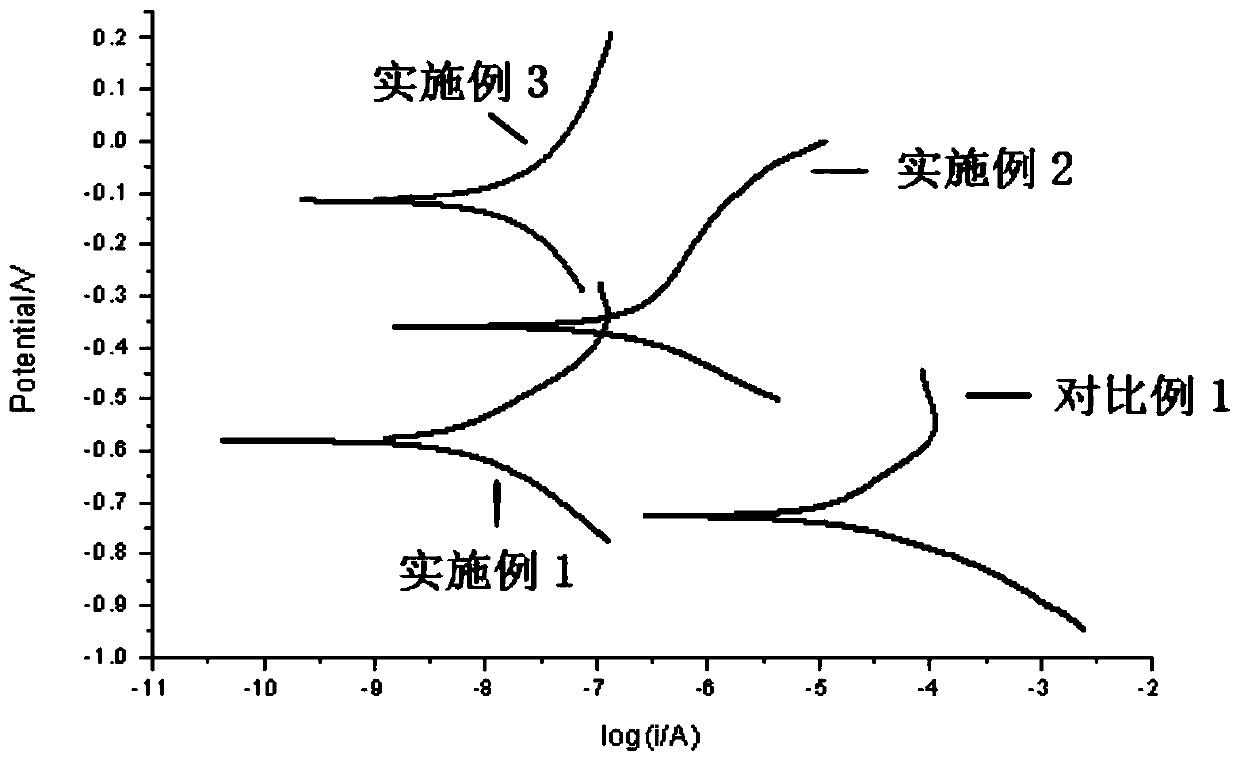

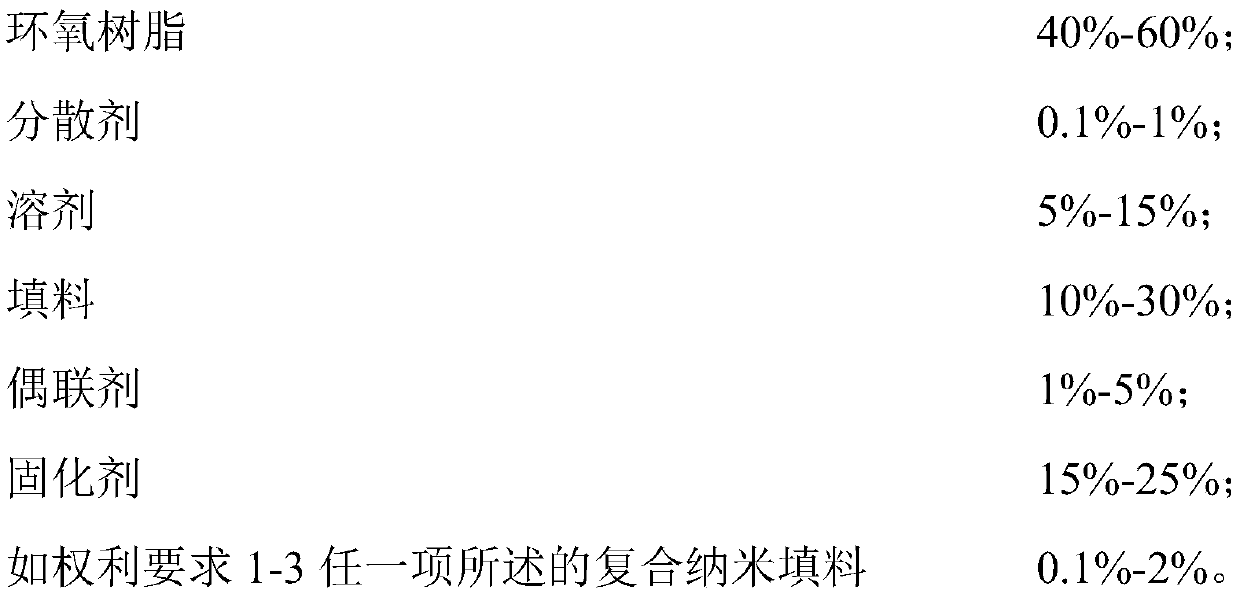

Graphene conductive anticorrosive coating for grounding grid and preparation method thereof

InactiveCN110713743AImprove conductivityImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGrounding grid

The invention relates to graphene conductive anticorrosive coating for a grounding grid and a preparation method thereof. Epoxy resin is used as a base material, and a composite nanofiller is added into the epoxy resin, so that the conductivity and the corrosion resistance of the epoxy resin can be greatly improved, the defects of a pure organic coating and a pure inorganic coating are overcome, and the graphene conductive anticorrosive coating has the comprehensive quality of an organic material, an inorganic material and a nano material. By adding the composite nanofiller, the corrosion resistance and conductivity of a coating are improved, the service lifetime of the coating is effectively prolonged, and the hardness, durability, acid and alkali resistance and the like of the coating are improved.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Graphene-molybdenum disulfide composite conductive paste for lithium battery and preparation method thereof

InactiveCN106384827AGood dispersionIncreased Surface Area UtilizationCell electrodesHigh pressureSolvent

The invention provides graphene-molybdenum disulfide composite conductive paste for lithium battery and a preparation method thereof. The method comprises the following steps of: blending a lithium ion or magnesium ion salt, molybdenum disulfide and graphite particles, heating at a high temperature, so that the lithium ion or magnesium ion is intercalated between the graphite and molybdenum disulfide layers; cooling to room temperature, fusing into a solvent, ultrasonically precrushing, thereby obtaining a mixture; ejecting the mixture through a jet nozzle of a high voltage pulse jet machine, and performing further crushing and stripping on the graphite and molybdenum disulfide by utilizing the mechanical shearing and high-speed collision effects of particles, thereby obtaining the graphene-molybdenum disulfide composite conductive paste. According to the composite conductive paste and the preparation method thereof provided by the invention, nanolayers can be effectively prevented from being stacked again, the surface area utilization rate of the electrode material is improved, and the electrical conductivity of the positive and negative poles of the lithium ion battery is greatly improved.

Owner:张家口龙驰科技有限公司

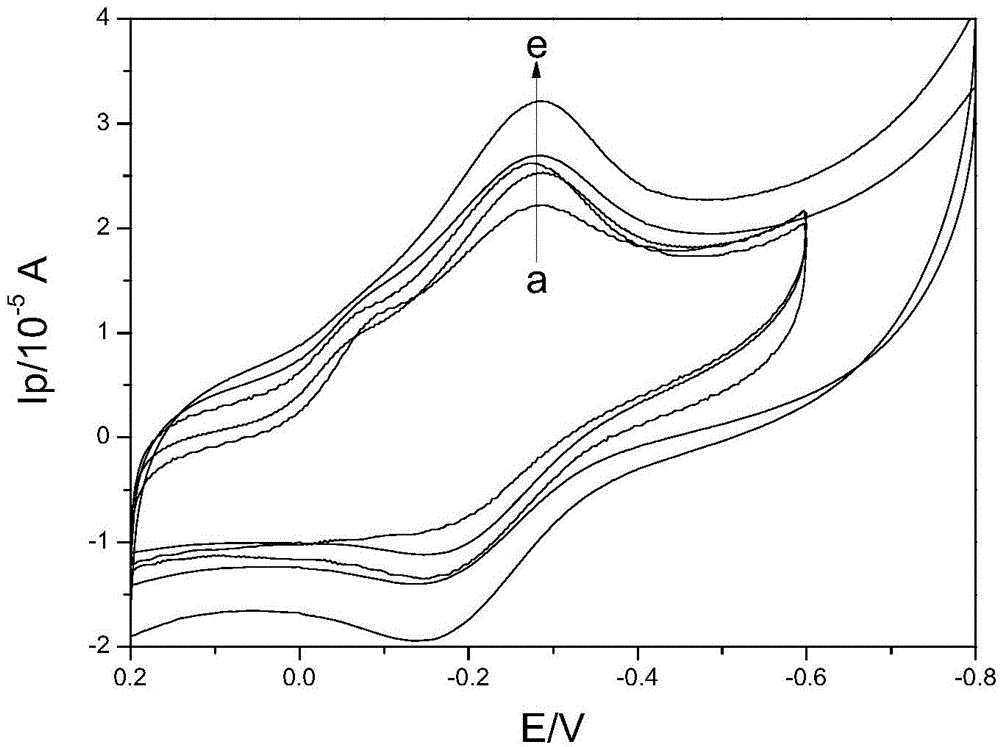

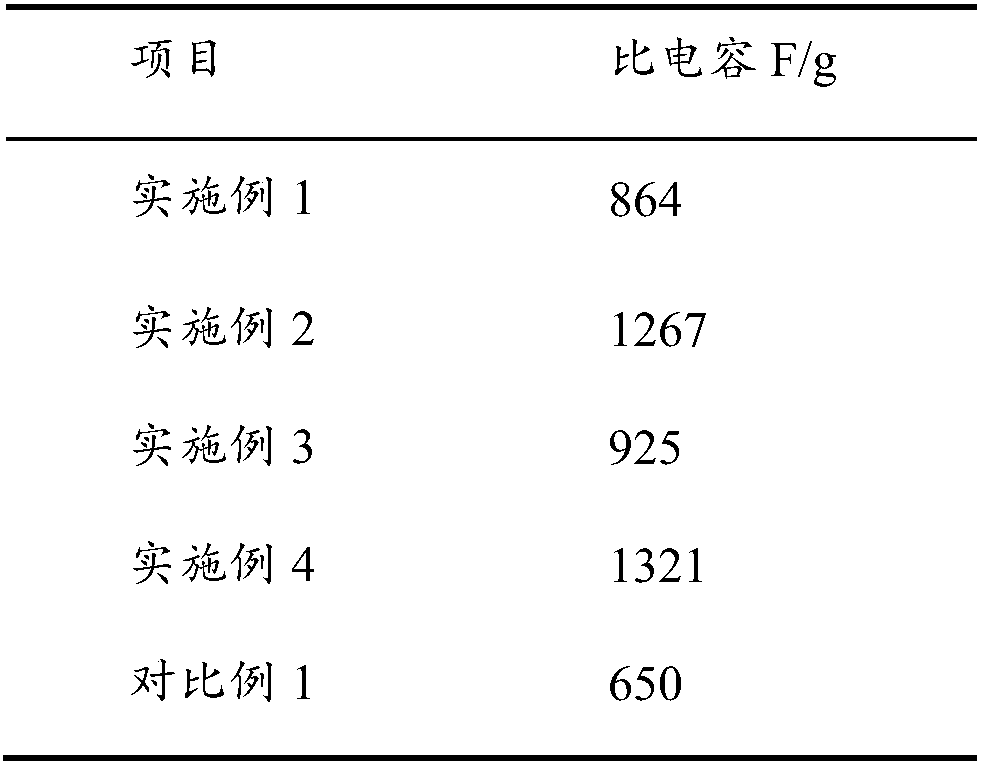

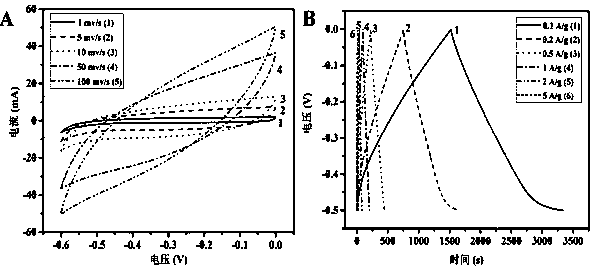

Graphene doped metallic oxide electrode material and preparation method thereof

ActiveCN108022760AEasy to prepareEasy to operateMaterial nanotechnologyHybrid capacitor electrodesCapacitanceElectrolysis

The invention provides a graphene doped metallic oxide electrode material and a preparation method thereof, and relates to the technical field of electrochemical materials. According to the graphene doped metallic oxide electrode material, graphene is firstly prepared through an electrolysis method, then the graphene is mixed with a mixed salt solution of Ru, Sn and Co, and the mixture is calcinedat the temperature of 220 to 300 DEG C after drying, so that the graphene and metallic oxide composite electrode material is obtained. According to the graphene doped metallic oxide electrode material, metallic oxide and graphene are introduced for compounding, so that metal nanoparticles are embedded into adjacent graphene sheets, a double electric layer electrode material and a faradaic pseudocapacitance electrode material are reasonably compounded, and the material is good in electrical conductivity and chemical stability and has ideal specific capacitance.

Owner:XIAMEN UNIV OF TECH

Graphene/zinc oxide coated solid carbon sphere lithium ion battery negative electrode material and preparation method thereof

The invention relates to the technical field of lithium ion negative electrode materials, and discloses a graphene / zinc oxide coated solid carbon sphere lithium ion battery negative electrode materialand a preparation method thereof. The preparation method includes the following steps of S1, preparing a solid carbon sphere; S11, preparing an aqueous glucose solution, adding the solution to a reactor for hydrothermal reaction, after the reaction, naturally cooling, centrifuging to pH of 7, then drying, and calcining the dried product to obtain the solid carbon sphere; S2, dissolving graphene in deionized water, adding a dispersant, performing ultrasonic dispersion to obtain a graphene solution, then successively adding zinc nitrate and ammonia water to the graphene solution, stirring uniformly for 2-6 h in a 90 DEG C water bath, then adding the solid carbon sphere, stirring uniformly, transferring to an autoclave, performing hydrothermal reaction for 6-24 h at 90-120 DEG C, and after the reaction, centrifuging and drying; S3, calcining the dried product to obtain the graphene / zinc oxide coated solid carbon sphere lithium ion battery negative electrode material.

Owner:林荣铨

Graphene/zinc oxide wrapped solid carbon sphere lithium ion negative electrode plate and preparing method of buckle type lithium ion battery thereof

InactiveCN107959016AReduce reunionSimple preparation processCell electrodesFinal product manufactureCvd grapheneComposite structure

The invention relates to the technical field of lithium ion negative electrode materials, and discloses a graphene / zinc oxide wrapped solid carbon sphere lithium ion negative electrode plate and a preparing method of a buckle type lithium ion battery thereof. A solid carbon sphere is introduced into a graphene / zinc oxide material, and the excellent electric conductivity of graphene and the rich porosity structure of the solid carbon sphere are combined and have a synergistic effect; on one hand, polymerization reaction can happen between graphene oxide and the solid carbon sphere, and therefore the bonding effect is achieved between the solid carbon sphere and graphene, and a uniform graphene-solid carbon sphere composite structure can be formed; on the other hand, due to the existence ofthe solid carbon sphere, graphene sheet layers are prevented from being stacked again, and the agglomeration of graphene is effectively reduced.

Owner:林荣铨

Graphene enhanced ceramic coating and preparation method thereof

InactiveCN108383500AImprove mechanical propertiesImprove conductivityClaywaresHeat conductingCeramic coating

The invention discloses graphene enhanced ceramic coating and a preparation method thereof. The graphene enhanced ceramic coating is mainly prepared from the following raw materials in percentage by weight: 0.5 percent to 20 percent of modified graphene, 30 percent to 50 percent of negative ion powder, 10 percent to 60 percent of ceramic powder and 5 percent to 15 percent of sintering auxiliary agent. The graphene enhanced ceramic coating disclosed by the invention has semiconductor performance and has the advantages of bacterium inhibition and sterilization and strong mechanical properties; the graphene enhanced ceramic coating can be widely applied to sensors, heat-conducting materials and capacitive materials.

Owner:FOSHAN RUNHUIHE CHEM CO LTD

Graphene and metallic oxide composite electrode material and preparation method thereof

ActiveCN108022763AEasy to prepareEasy to operateHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceElectrolysis

The invention provides a graphene and metallic oxide composite electrode material and a preparation method thereof, and relates to the technical field of electrochemical materials. According to the graphene and metallic oxide composite electrode material, graphene is firstly prepared through an electrolysis method, then the graphene is mixed with a mixed salt solution of Ru, Mn and Co, and the mixture is calcined at the temperature of 220 to 300 DEG C after drying, so that the graphene and metallic oxide composite electrode material is obtained. According to the graphene and metallic oxide composite electrode material, metallic oxide and graphene are introduced for compounding, so that metal nanoparticles are embedded into adjacent graphene sheets, a double electric layer electrode material and a faradaic pseudocapacitance electrode material are reasonably compounded, and the material is good in electrical conductivity and chemical stability and has ideal specific capacitance.

Owner:XIAMEN UNIV OF TECH

Intercalation agent for rapidly stripping graphite for mass production of high-quality graphene

ActiveCN108640107AImprove stripping efficiencyAchieving delaminationOrganic chemistryGrapheneChemical reactionReaction temperature

The invention relates to an intercalation agent for rapidly stripping graphite for mass production of high-quality graphene. The intercalation agent is prepared from transitional metal halogen salt, anitrogen source substance and an organic solvent; and a mass ratio of the transitional metal halogen salt to the nitrogen source substance to the organic solvent is (1 to 10): 1: (2 to 10). The transitional metal halogen salt can form eutectic crystals with the nitrogen source substance or the organic solvent, a melt point of the eutectic crystal is lower than the melt point of each component, the mixed intercalation agent is liquid at room temperature, the intercalation agent is intercalated into the graphite to form a graphite interlayer compound, so that the reaction temperature, the preparation cost and the difficulty are reduced; and meanwhile, the nitrogen source substance can also form a hydrogen bond with the organic solvent, so that a combined body of the nitrogen source substance and the organic solvent exists stably among the layers of the graphene, the interlayer accumulation of the prepared graphene can be avoided, and the stripping efficiency and the product quality canbe improved. The intercalation agent does not have chemical reaction in the ball milling process, and can be separated from the graphite interlayer compound in a centrifuging manner, and the separatedintercalation agent can be recycled, so that energy can be saved, and the environment can be protected.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

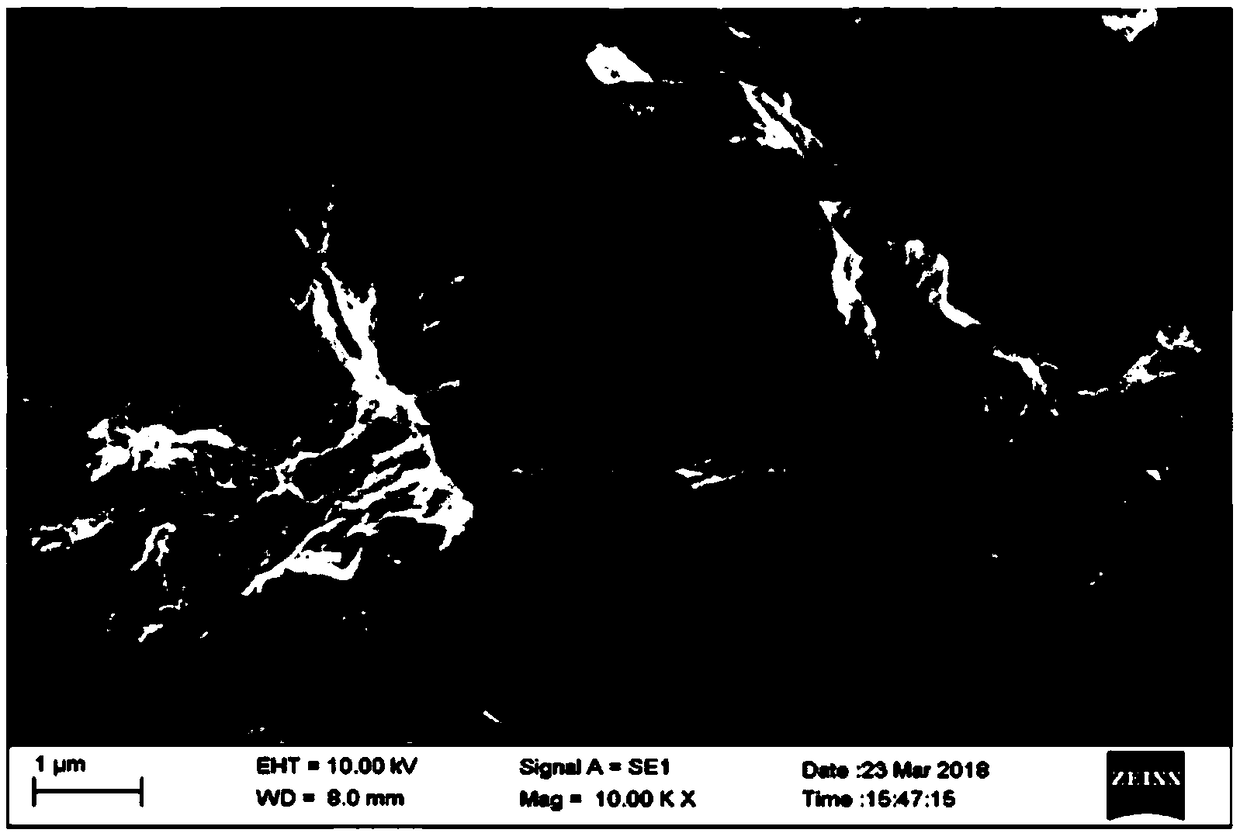

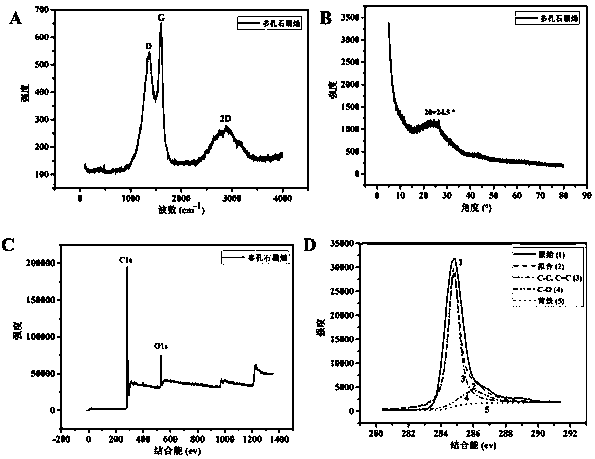

Aperture-controllable porous graphene nanometer material preparation method

InactiveCN108439379AReduce manufacturing costAvoid re-stackingHybrid capacitor electrodesGraphenePorous grapheneFiltration

The invention discloses an aperture-controllable porous graphene nanometer material preparation method. The method comprises the steps that graphene oxide is subjected to ultrasonic dispersion in water to form a graphene oxide suspension which is mixed with a nearly saturated zinc nitrate solution, ultrasonography continues to be conducted to make the mixture mixed to be uniform; extraction filtration is conducted, graphene oxide and zinc nitrate are intercepted on filter paper, and a defective zinc salt template covers the surface of graphene oxide; the filter paper loaded with graphene oxideand zinc nitrate is dried and placed in a muffle furnace to be burned, exposed graphene oxide in a defective hole is burned completely in the high-temperature environment, zinc nitrate is subjected to thermal decomposition in the high-temperature environment to be zinc oxide, zinc oxide is removed by means of hydrochloric acid, and then porous graphene is obtained successfully. Accordingly, by means of control over the burning temperature, time and salt content in the muffle furnace, porous graphene nanometer materials with different apertures are obtained, and then the preparation cost of porous graphene is greatly lowered, and the utilization efficiency is improved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Polydopamine nanosphere/boron nitride quantum dot/graphene solid lubricant, and preparation method, application and composite material thereof

The invention discloses a polydopamine nanosphere / boron nitride quantum dot / graphene solid lubricant, a preparation method and application thereof, and a composite material. The preparation method comprises the following steps: uniformly mixing and stirring ethanol, deionized water and ammonia water to obtain a mixed solution; dissolving dopamine hydrochloride into deionized water, dropwise adding into the mixed solution, sequentially stirring, centrifuging, washing with water, and drying to obtain PDA NS; uniformly mixing and stirring the PDA NS and GO, then adding hydrazine hydrate for reflux condensation to obtain a PDA NS / RGO composite particle product system, and after the PDA NS / RGO composite particle product system is cooled, washing and freeze-drying the product system to obtain PDA NS / RGO composite particles; adding boric acid into ionized water, adding ammonia water, magnetically stirring uniformly, and cooling in a reaction kettle to obtain BNQDS; and carrying out magnetic stirring on the BNQDS and the PDA NS / RGO composite particles, and carrying out freeze drying to obtain the PDA NS / BNQDS / RGO solid lubricant. The obtained solid lubricant can reduce and stabilize the friction coefficient of a matrix material and improve the wear resistance of the matrix material.

Owner:SHAANXI UNIV OF SCI & TECH

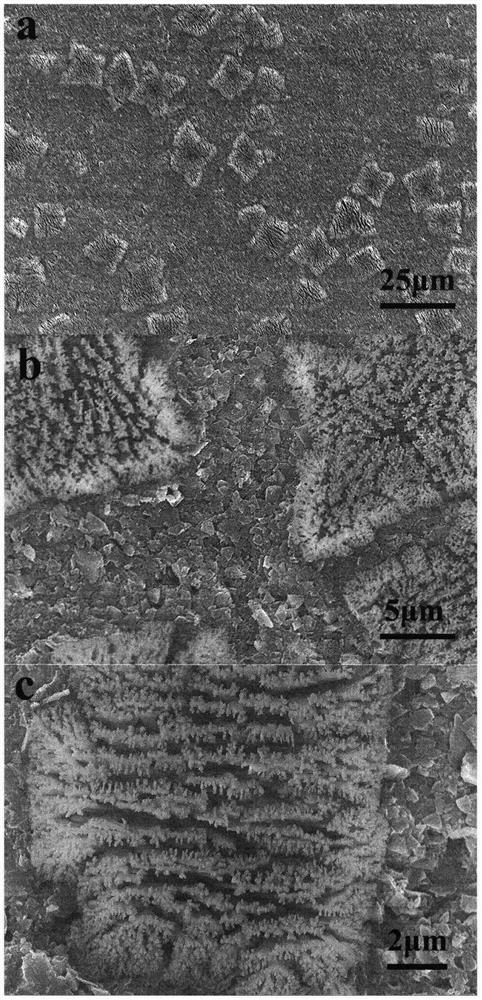

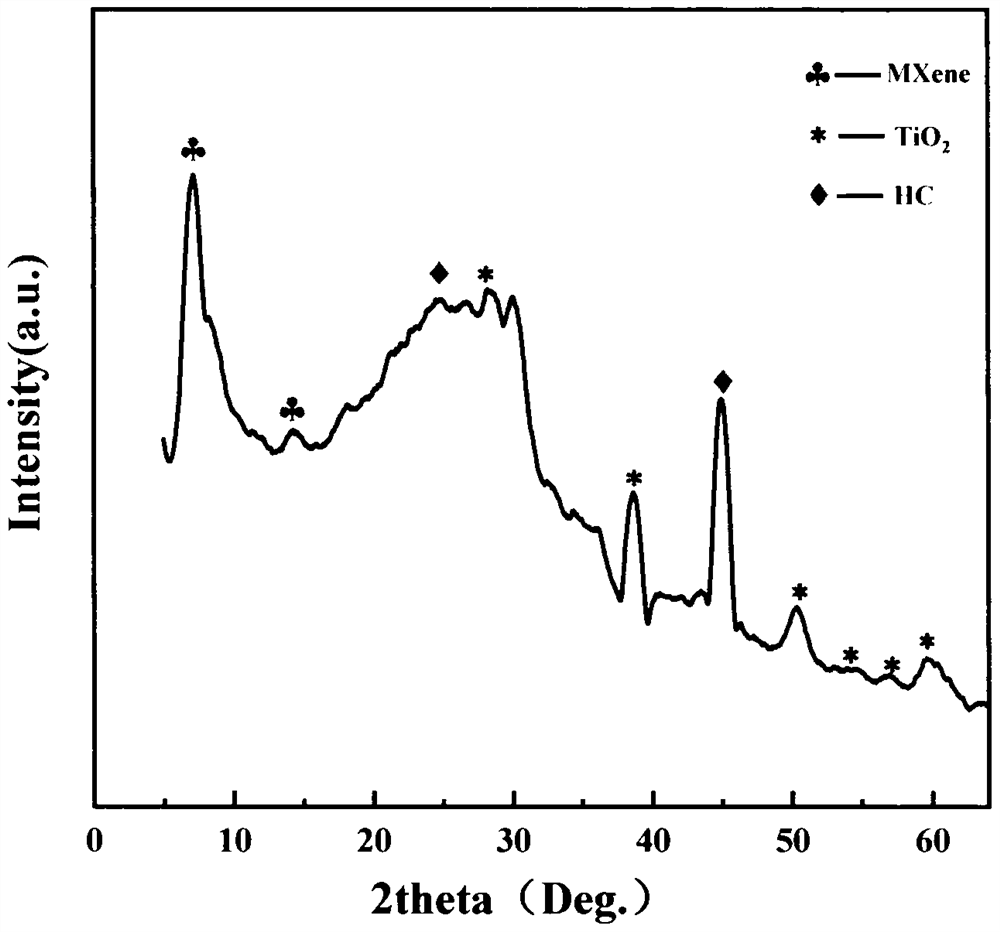

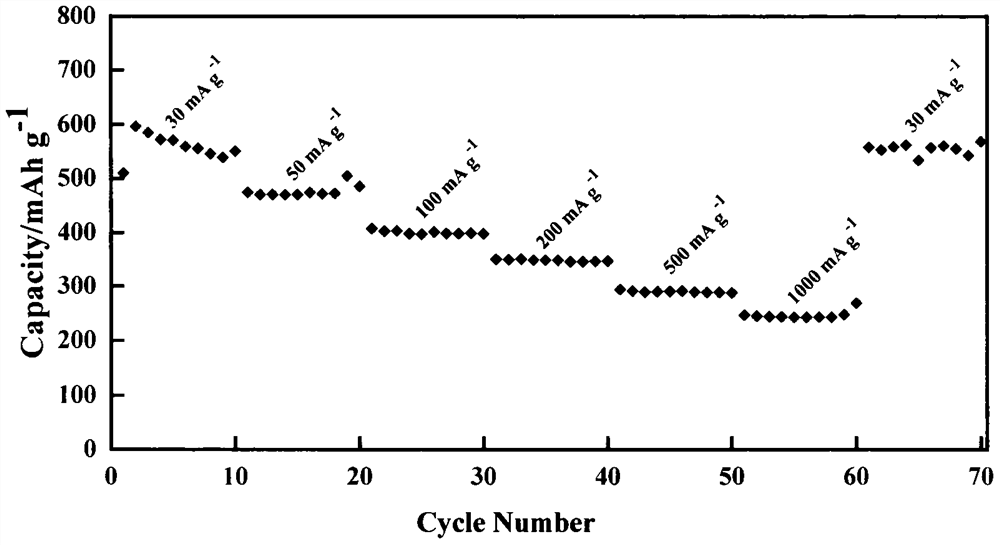

Preparation method of in-situ oxidation growth flower-like structure TiO2/MXene/hard carbon sodium ion battery negative electrode material

PendingCN113314705ALow costEasy to manufactureSecondary cellsNegative electrodesCarbon compositesElectrical battery

The invention belongs to the technical field of sodium ion batteries, and particularly relates to a preparation method of an in-situ oxidation growth flower-like structure TiO2 / MXene / hard carbon sodium ion battery negative electrode material. The method comprises the following steps: (1) in an air atmosphere, heating popcorn to 230-280 DEG C, and carrying out pre-oxidation treatment; (2) putting the pre-oxidized popcorn into an atmosphere furnace, and carbonizing at 800-1400 DEG C for 2-3 hours to obtain popcorn hard carbon; (3) grinding and sieving the popcorn hard carbon to obtain hard carbon powder with a particle size of less than 48 [mu] m; and (4) mixing the sieved hard carbon powder with multiple layers of MXene, and carrying out ball milling in an air environment by taking water as a solvent. Under the action of huge energy generated by collision of ball-milling beads, the multiple layers of MXene are stripped and react with air to generate TiO2 nanorods through in-situ oxidation at the same time, so that a TiO2 / MXene / hard carbon composite material with a flower-shaped structure, namely the sodium ion battery negative electrode material, is formed. A unique flower-shaped structure is formed through ball milling regulation and control, and the sodium storage performance of the material is improved. When the composite material is used as a negative electrode of a room-temperature sodium-ion battery, the specific capacity of the battery can be effectively improved, and the cycle performance is enhanced. Meanwhile, the method is simple and feasible to operate, pollution-free to environment and suitable for popularization and application.

Owner:TIANJIN POLYTECHNIC UNIV

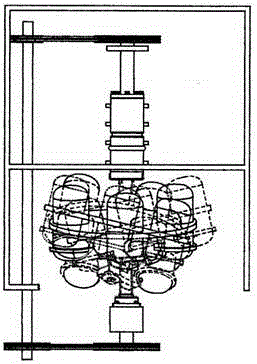

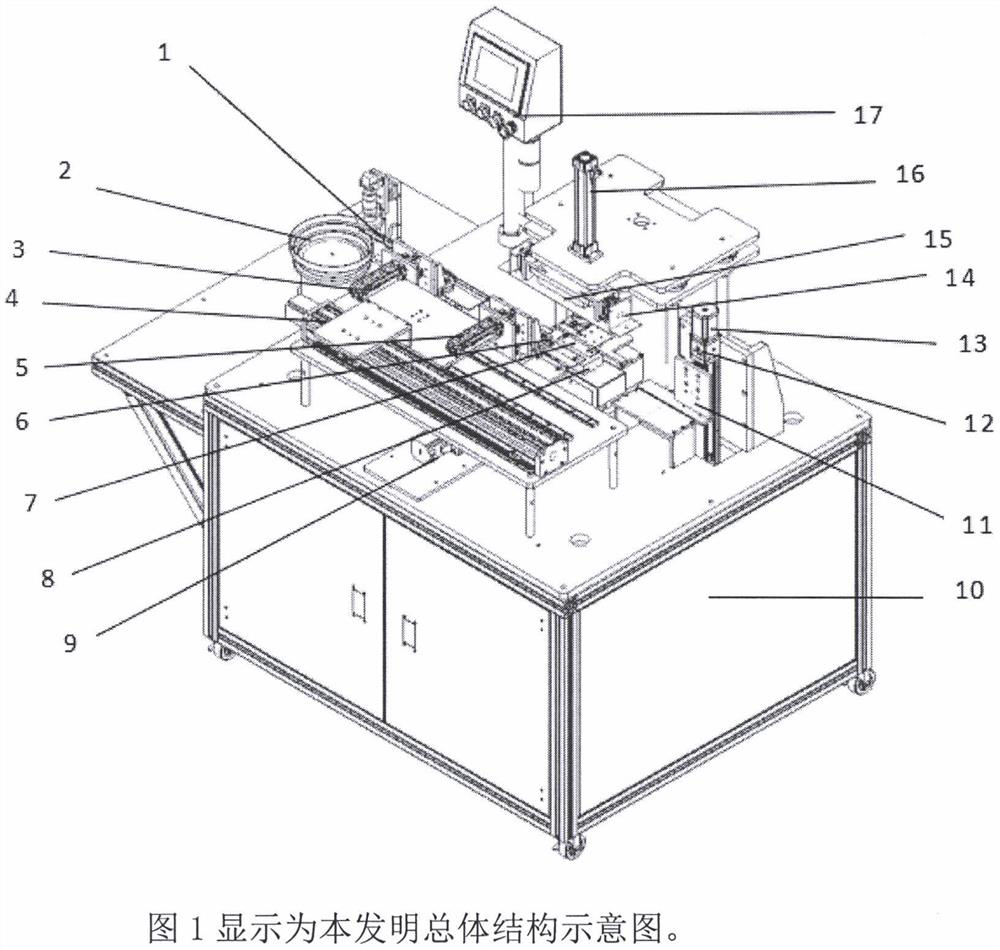

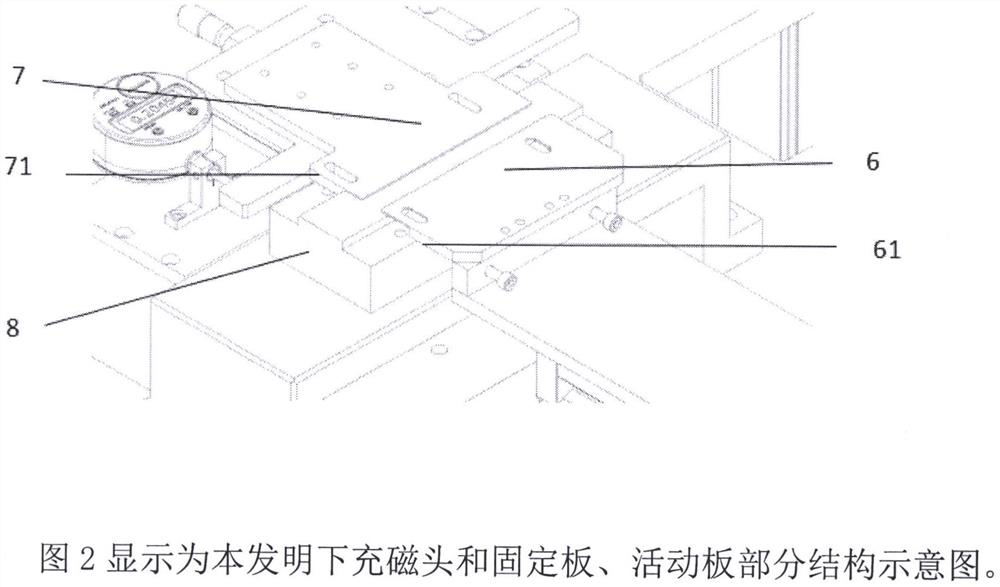

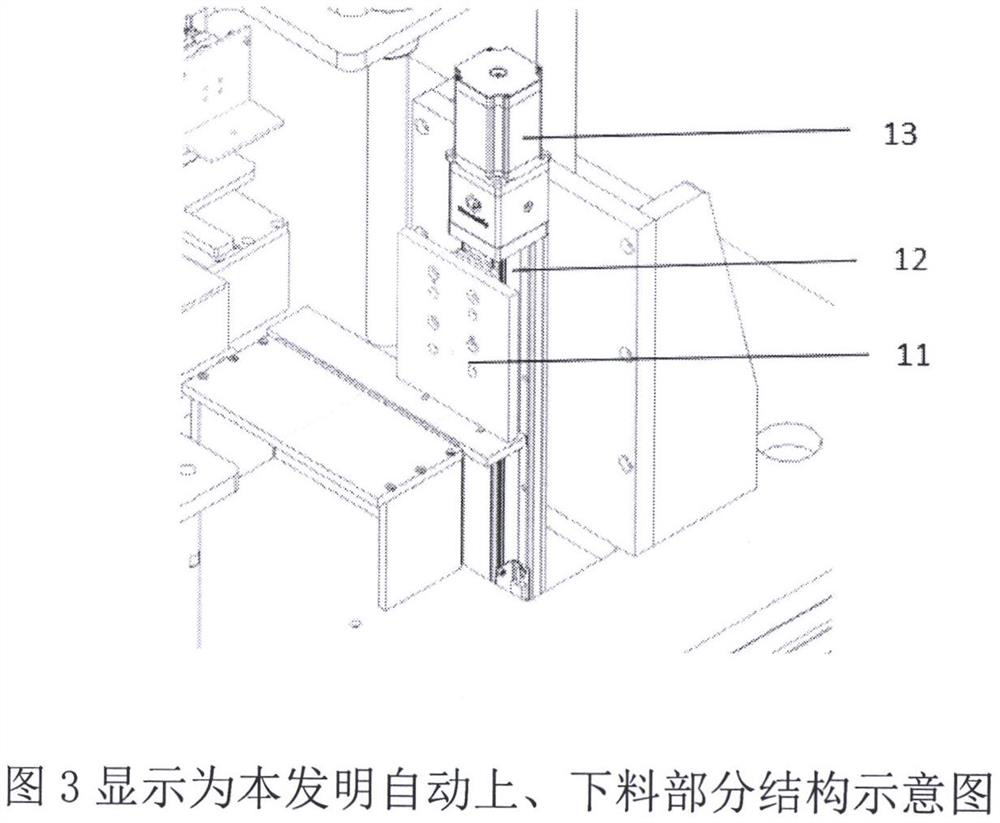

Full-automatic bipolar magnetizing equipment

The invention provides full-automatic bipolar magnetizing equipment, belongs to the field of magnetic materials, and realizes full-automatic magnetizing by digitally controlling the whole process of feeding, magnetizing and discharging. Surface magnetic parameters and symmetry of NS poles of the magnet can be accurately controlled; the double manipulators are adopted to complete the feeding and discharging processes at the same time, and compared with the prior art, the efficiency can be doubled. A vacuum suction nozzle is adopted to complete grabbing and releasing of the magnet, and the magnet is accurately positioned. And an improved magnetizing head structure is adopted, so that the positioning plate cannot deform. And the magnets are adopted for vertical collection and automatic stacking, the subsequent process can be directly used, re-stacking in the subsequent process is avoided, and the efficiency of the whole process is improved.

Owner:天津博雅全鑫磁电科技有限公司

A kind of graphene/metal oxide composite electrode material and preparation method thereof

ActiveCN108022763BImprove conductivityGood chemical stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceElectrolysis

The invention provides a graphene and metallic oxide composite electrode material and a preparation method thereof, and relates to the technical field of electrochemical materials. According to the graphene and metallic oxide composite electrode material, graphene is firstly prepared through an electrolysis method, then the graphene is mixed with a mixed salt solution of Ru, Mn and Co, and the mixture is calcined at the temperature of 220 to 300 DEG C after drying, so that the graphene and metallic oxide composite electrode material is obtained. According to the graphene and metallic oxide composite electrode material, metallic oxide and graphene are introduced for compounding, so that metal nanoparticles are embedded into adjacent graphene sheets, a double electric layer electrode material and a faradaic pseudocapacitance electrode material are reasonably compounded, and the material is good in electrical conductivity and chemical stability and has ideal specific capacitance.

Owner:XIAMEN UNIV OF TECH

A kind of graphene metal composite supercapacitor electrode material and preparation method thereof

ActiveCN105185597BKeep high specific powerReduce usageHybrid capacitor electrodesHybrid/EDL manufactureParticulatesConductive polymer composite

Owner:深圳市来源新材料科技有限公司

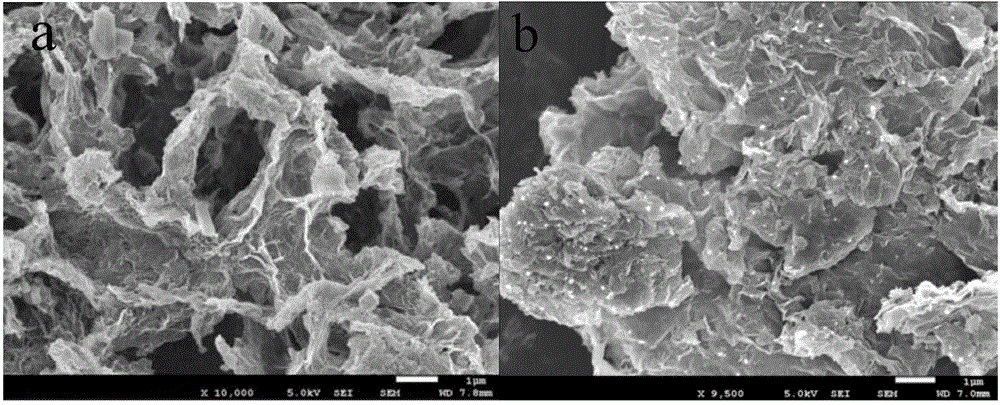

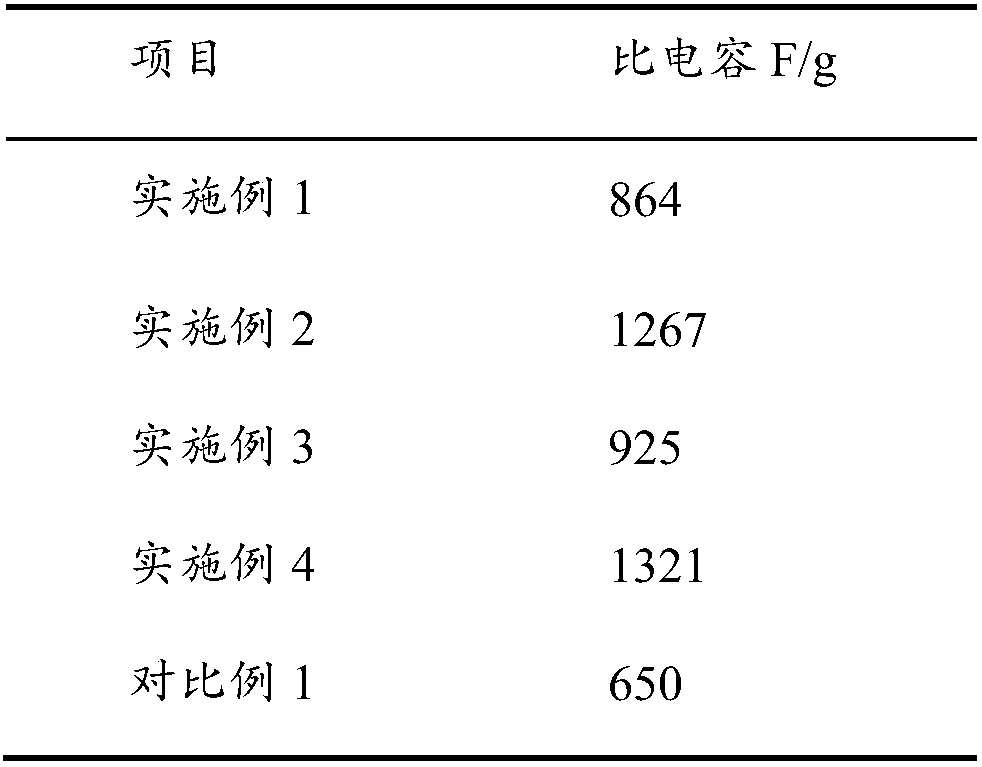

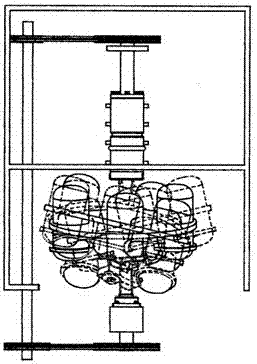

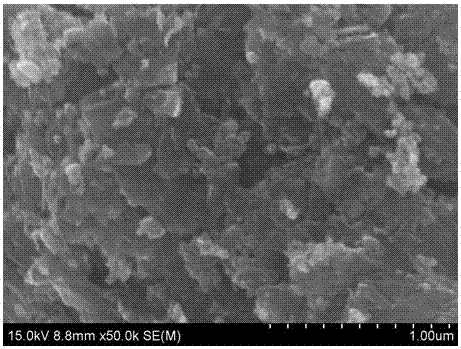

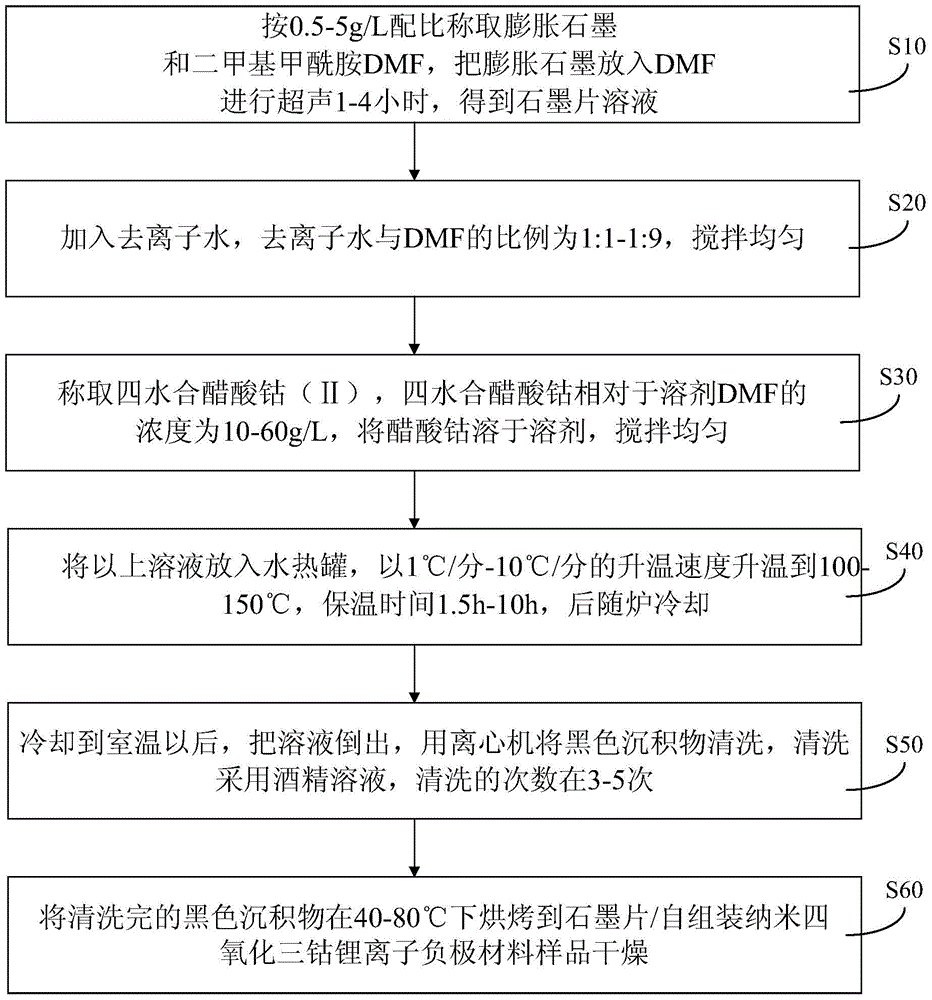

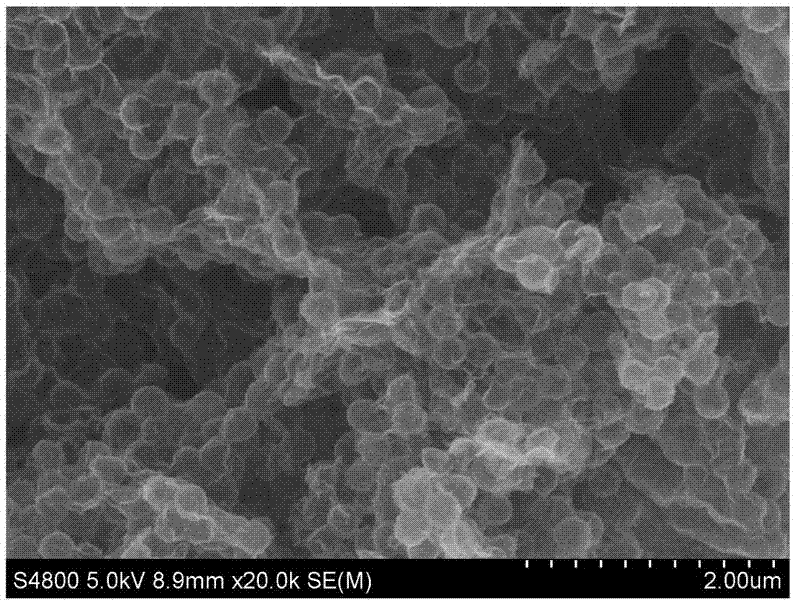

A graphite sheet/self-assembled nanometer cobalt tetraoxide lithium ion negative electrode material, preparation method and lithium battery using the same

InactiveCN104167543BTightly evenly distributedEvenly distributedMaterial nanotechnologyCell electrodesSolventLithium-ion battery

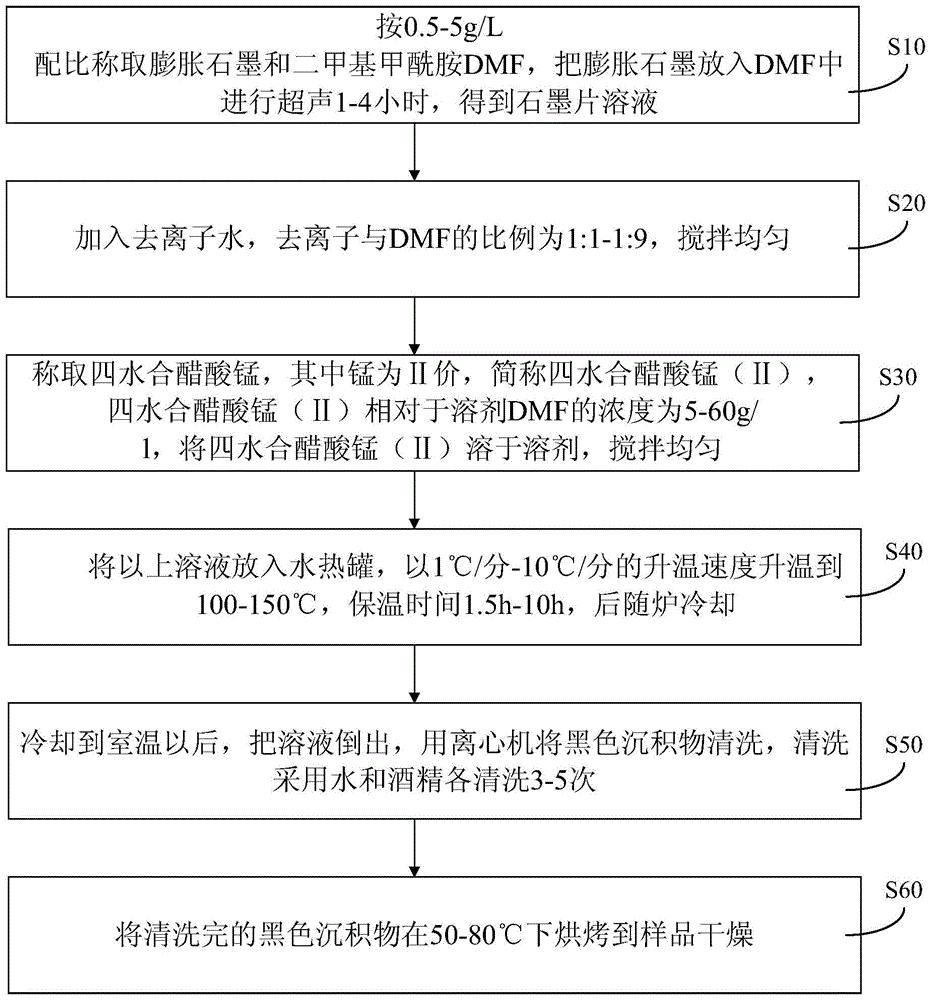

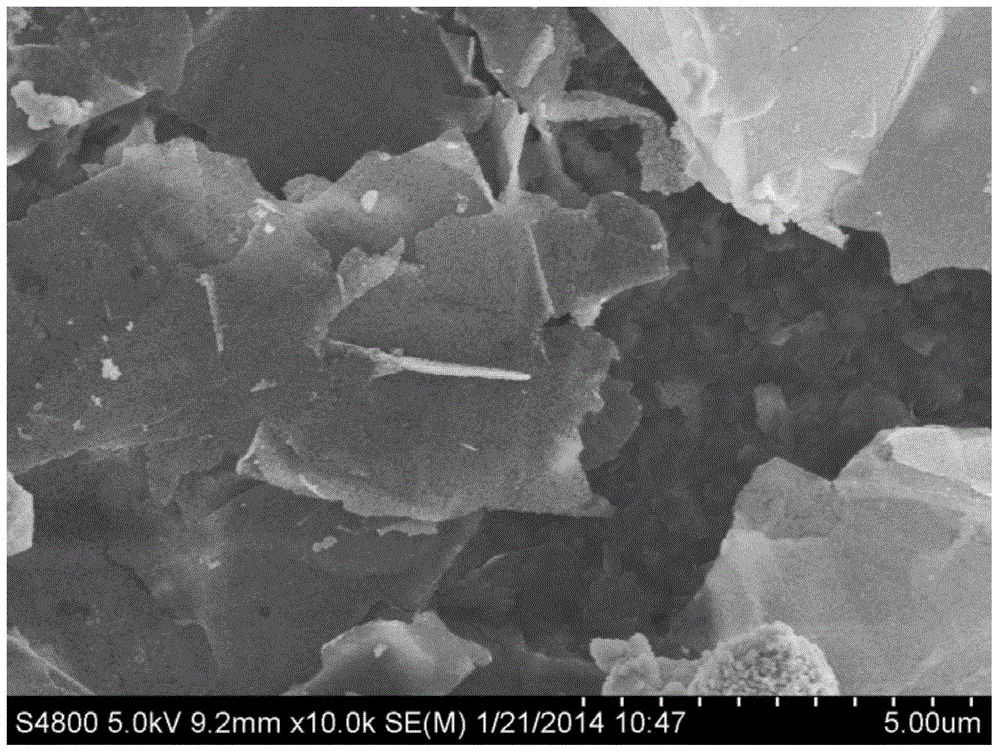

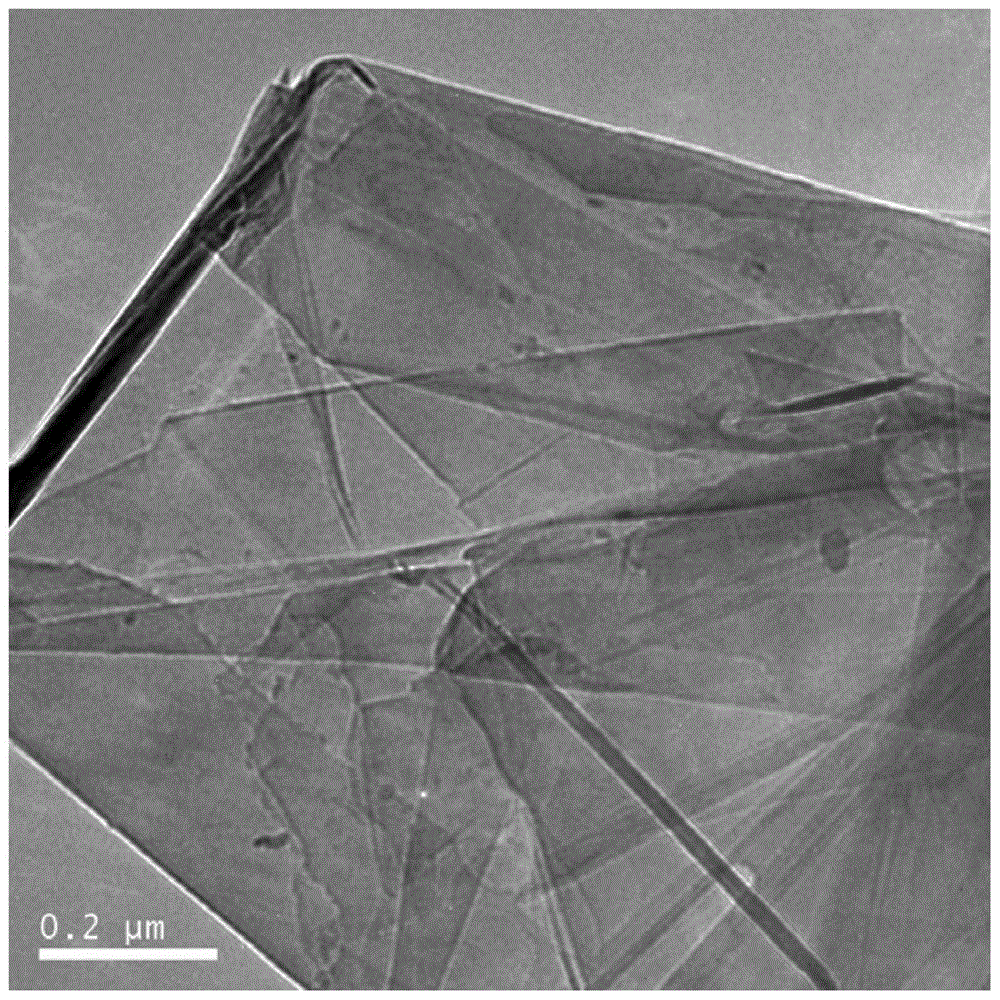

The embodiment of the invention discloses a graphite flake / self-assembled nanometer cobaltosic oxide lithium ion negative electrode material, its preparation method and a lithium battery using it. The preparation method comprises the following steps: weighing expanded graphite and DMF according to a ratio of 0.5-5g / L, and carrying out ultrasonic treatment to obtain a graphite flake solution; adding a proper amount of deionized water; weighing cobalt acetate tetrahydrate according to a ratio of the cobalt acetate tetrahydrate to the solvent DMF of 10-60g / L, and dissolving the cobalt acetate tetrahydrate in the solvent; stirring for dissolving, adding the above obtained solution into a hydrothermal tank, and carrying out heat insulation; and cooling to room temperature, cleaning the above obtained black sediment through using an alcohol solution by a centrifuge, and baking the cleaned black sediment until the obtained sample is dry. Co3O4 nanoparticles in the composite material prepared through the method are cubic particles with good crystallization and uniform size, the side length of the nanoparticles is about 4nm, the density of the nanoparticles is 2*10<13> / cm<2>, a gap between two adjacent nanoparticles is 1-10nm, and the nanoparticles are uniformly distributed on two surfaces of a graphite flake, so an extremely good lithium storage performance can be obtained.

Owner:HANGZHOU DIANZI UNIV

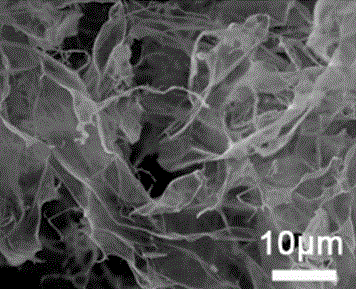

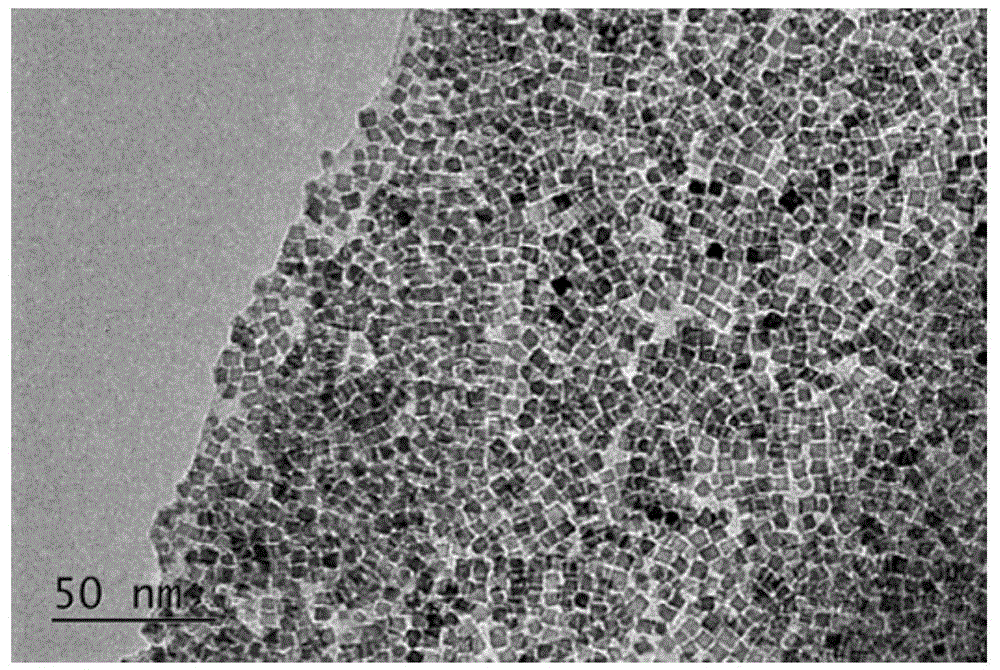

Three-dimensional graphene-hollow carbon sphere/sulfur composite material and its preparation method and application in lithium-sulfur batteries

ActiveCN104916828BHigh specific capacityImprove cycle performanceMaterial nanotechnologyCell electrodesAlcoholSulfur

The invention discloses a three dimensional graphene / hollow carbon sphere / sulfur composite material, a preparation method thereof, and an application in lithium-sulfur batteries. The three dimensional graphene / hollow carbon sphere / sulfur composite material comprises nanometer elemental sulfur and a three dimensional graphene-hollow carbon sphere nano-compound, and the nanometer elemental sulfur is distributed in the three dimensional graphene-hollow carbon sphere nano-compound. The preparation method comprises the following steps: dispersing the three dimensional graphene-hollow carbon sphere nano-compound in an alcohol and water mixed solvent to obtain a suspension; and adding an aqueous solution of Na2S.9H2O and Na2SO3 into the suspension, adding an acidic solution, and reacting to obtain the three dimensional graphene / hollow carbon sphere / sulfur composite material. The composite material has the advantages of high specific capacity, stable cycle performances, and excellent rate performance and coulombic efficiency, the preparation method has the advantages of simplicity, convenience and good effect, and the composite material can be applied in the preparation of lithium-sulfur battery positive electrode materials.

Owner:NAT UNIV OF DEFENSE TECH

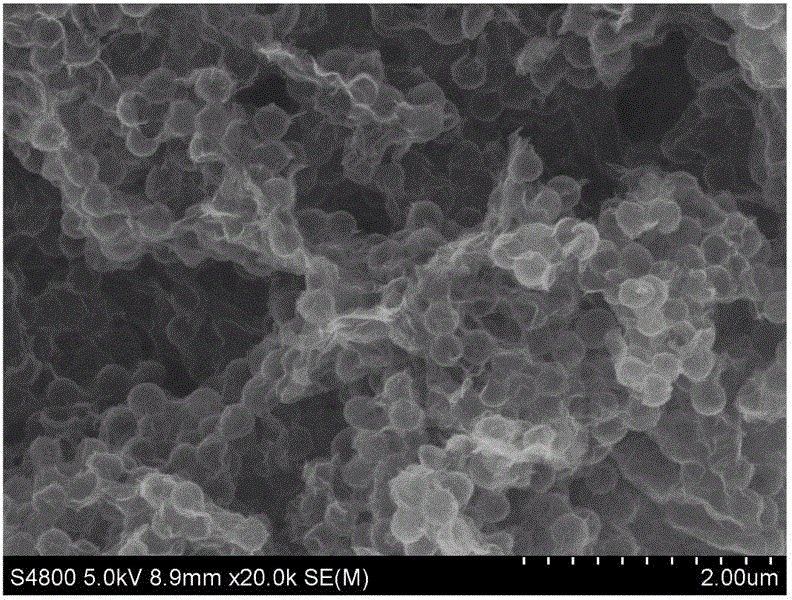

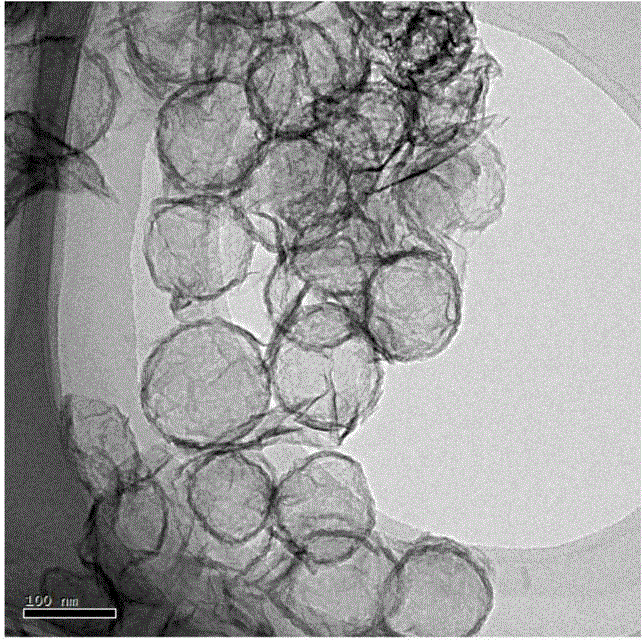

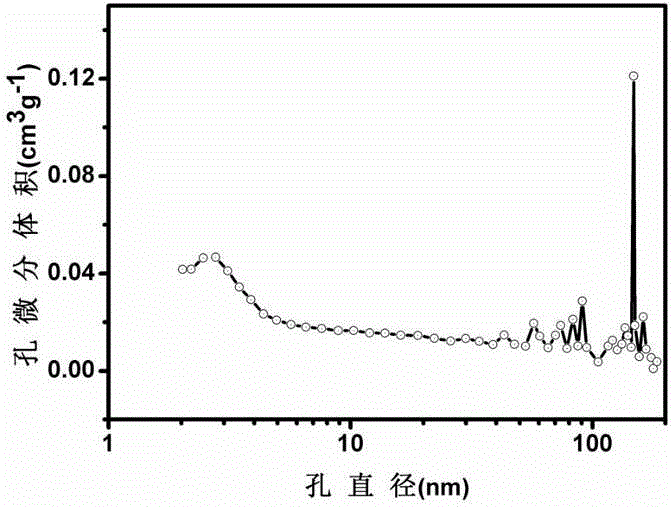

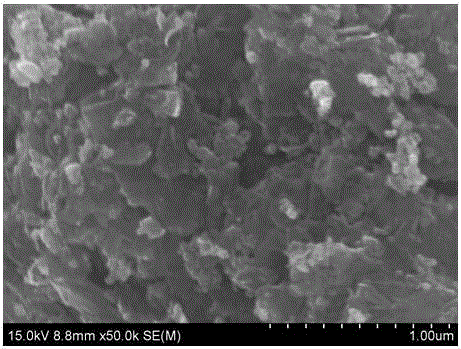

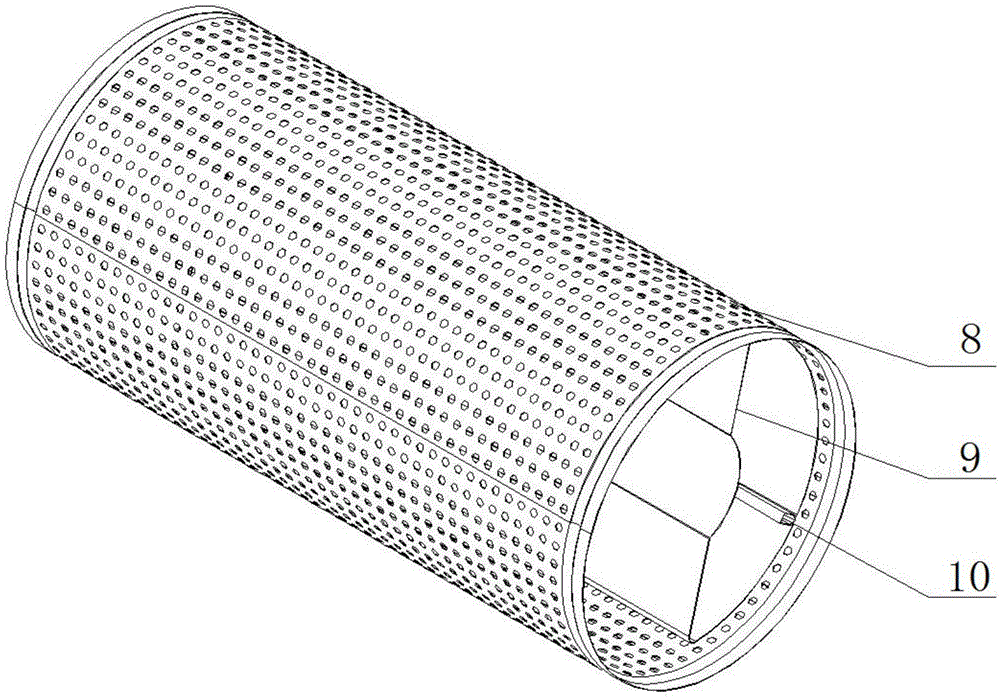

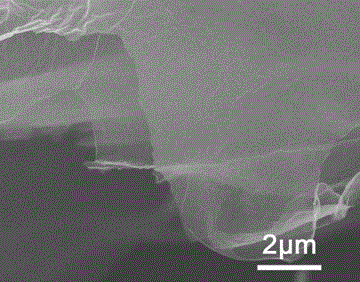

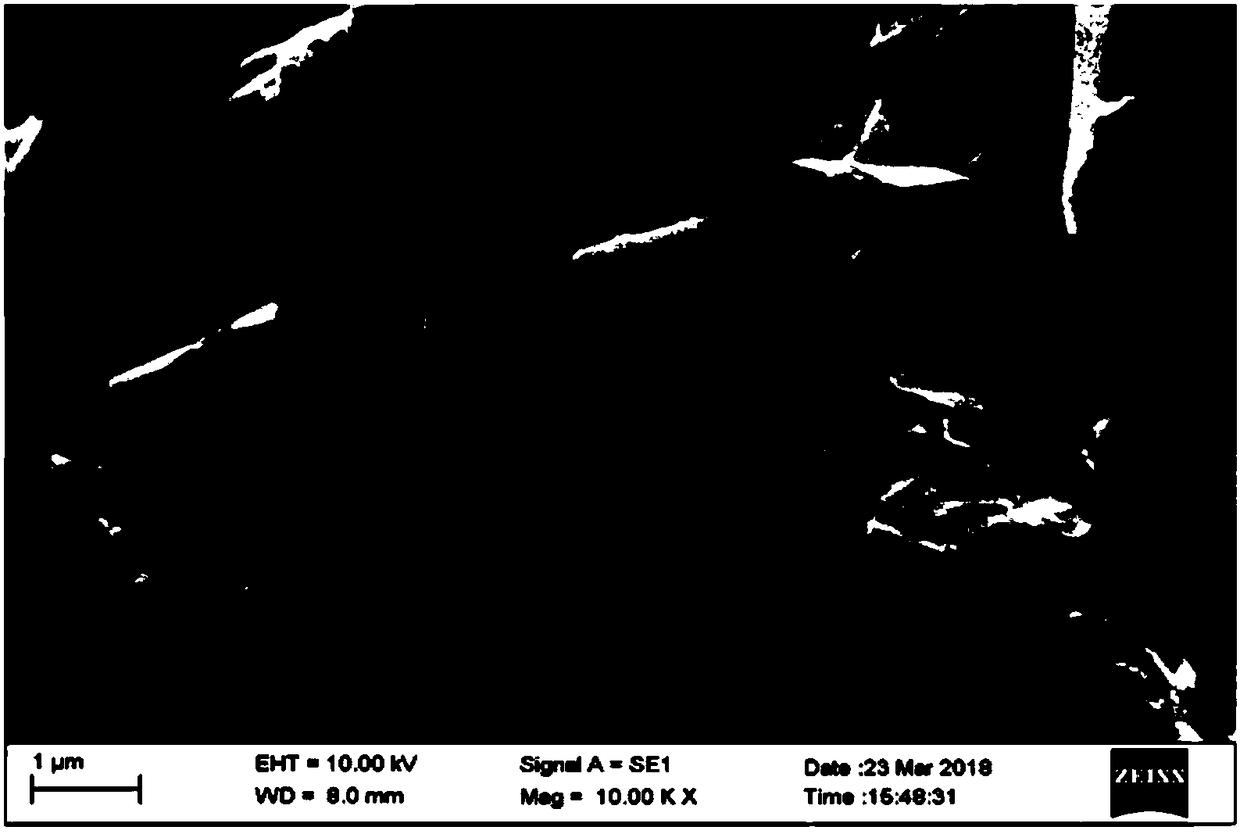

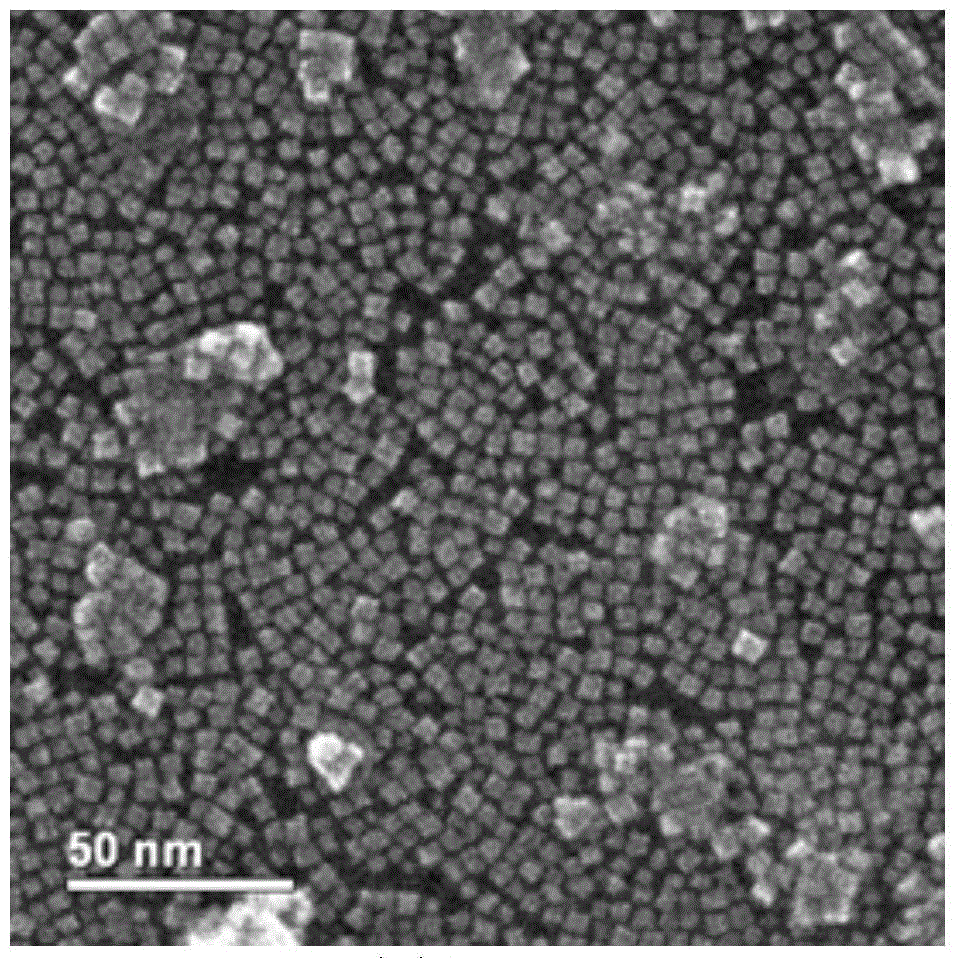

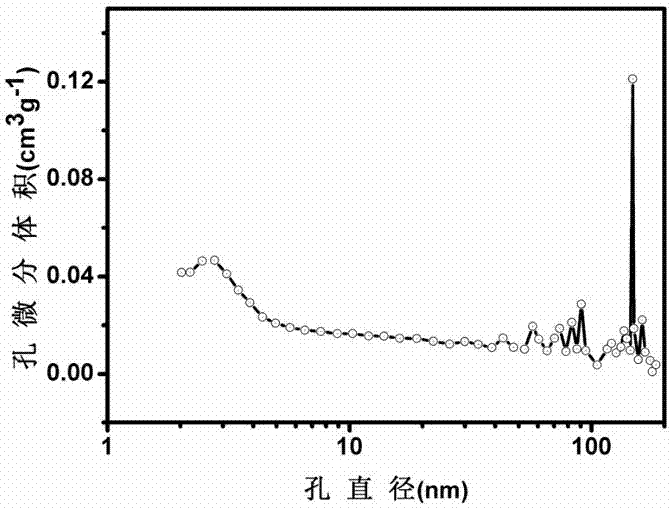

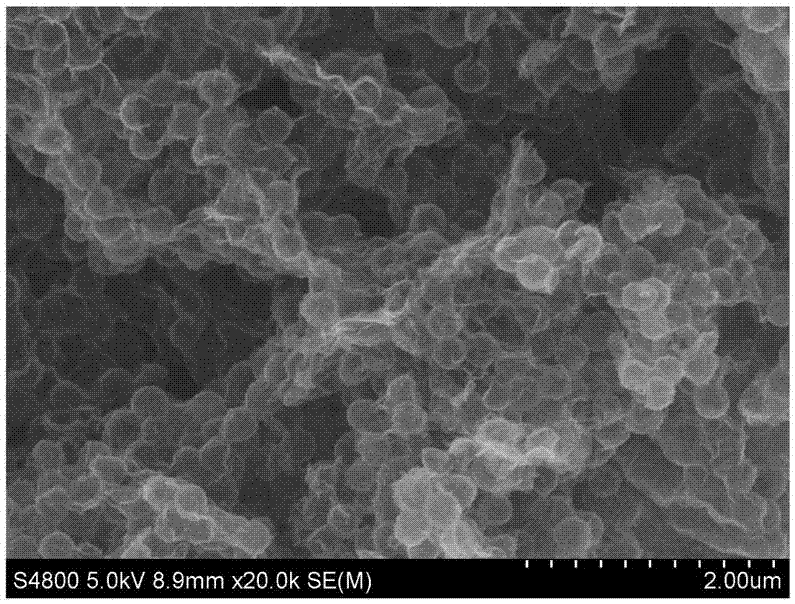

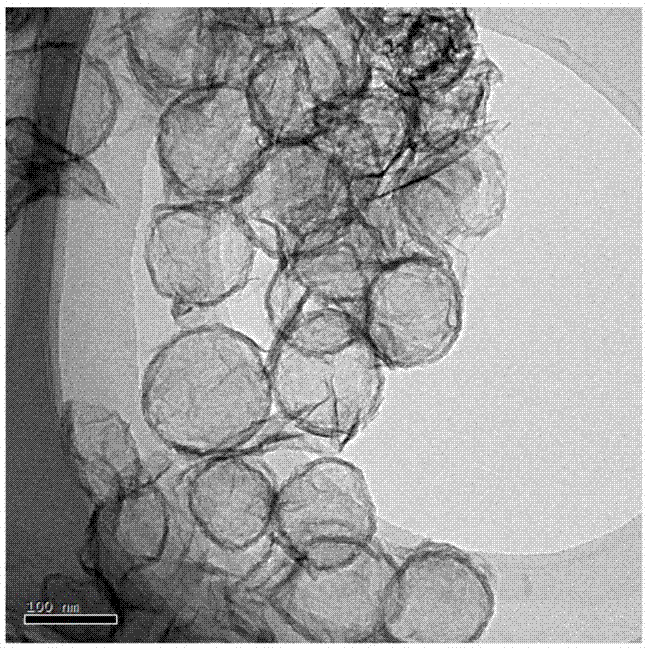

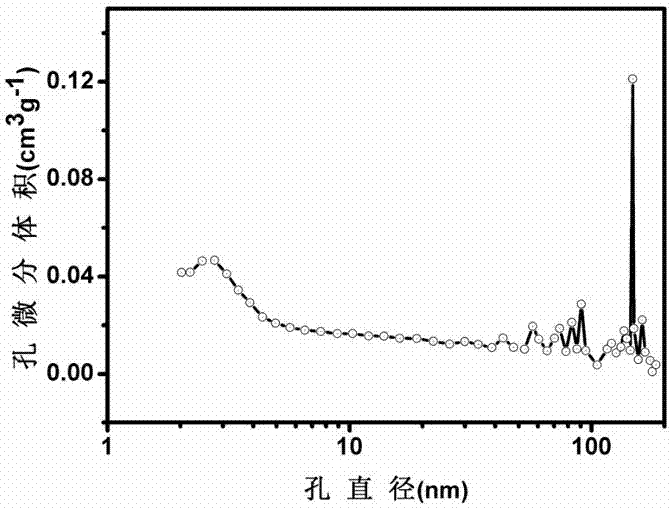

Three-dimensional graphene-hollow carbon sphere nanocomposite and preparation method thereof

ActiveCN104882594BImprove electronic conductivityFlexible and controllable mechanical flexibilityCell electrodesLi-accumulatorsCyclic processLithium

The invention discloses a three-dimensional graphene-hollow carbon sphere nano composite and a preparation method thereof. The three-dimensional graphene-hollow carbon sphere nano composite is prepared from hollow carbon spheres and graphene, wherein the hollow carbon spheres are distributed in a three-dimensional net structure formed by the graphene. The preparation method comprises the following steps: (1) preparing silicon dioxide microspheres coated with phenolic resin; (2) preparing three-dimensionalgraphene-microsphere hydrogel; (3) preparing a three-dimensional graphene-carbon sphere nano composite; and (4) preparing the three-dimensional graphene-hollow carbon sphere nano composite. The three-dimensional graphene-hollow carbon sphere nano composite is good in conductivity, is rich in graded hole structure, can be applied to a positive electrode material of a lithium-sulphur battery so as to supply rapid electron conduction, restrain dissolution and shuttle of polysulfide sulphur and alleviate the volume change of a sulphur positive electrode in a circulating process. The preparation method is simple and convenient and has a good effect.

Owner:NAT UNIV OF DEFENSE TECH

A sandwich-structured graphite sheet/manganese tetroxide composite nanomaterial, preparation method and lithium ion battery using the same

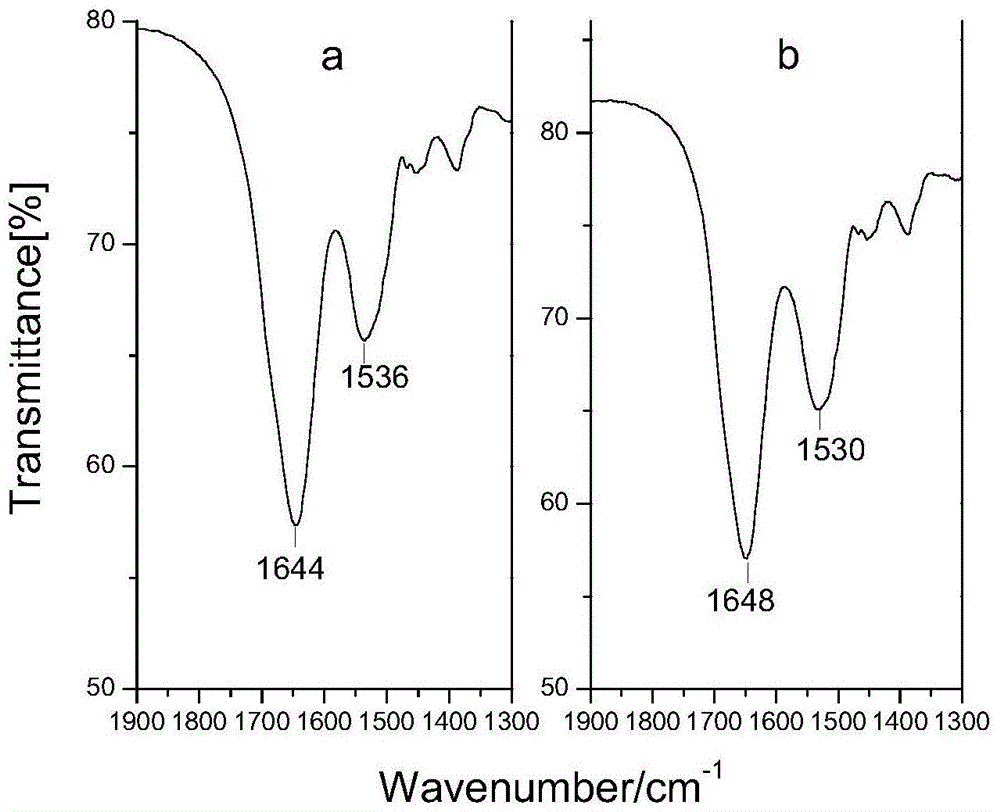

ActiveCN104167532BAvoid re-stackingAvoid reunionMaterial nanotechnologyCell electrodesMANGANESE ACETATE TETRAHYDRATERoom temperature

The invention discloses a graphite flake / trimanganese tetroxide composite nano-material with a sandwich structure, its preparation method, and a lithium ion battery using it. The method comprises the following steps: weighing expanded graphite and DMF according to a ratio of 0.5-5g / L, putting the expanded graphite in the DMF, and carrying out ultrasonic treatment for 1-4h to obtain a graphite flake solution; adding deionized water according to a ratio of deionized water to the DMF of 1:1-1:9, and uniformly stirring; weighing manganese (II) acetate tetrahydrate according to a ratio of the manganese acetate tetrahydrate to the solvent DMF of 5-60g / L, dissolving the manganese acetate tetrahydrate in the solvent, and uniformly stirring; adding the above obtained solution into a hydrothermal tank, heating, carrying out heat insulation, and carrying out furnace cooling; cleaning a black sediment by using a centrifuge after the above obtained material is cooled to room temperature; and baking the cleaned black sediment at 50-80DEG C until the obtained sample is dry. The method for obtaining a uniform Mn3O4 nanoparticle film on the surface of a non-oxidized graphite flake is simple, and is suitable for mass production.

Owner:浙江东信昆辰科技股份有限公司

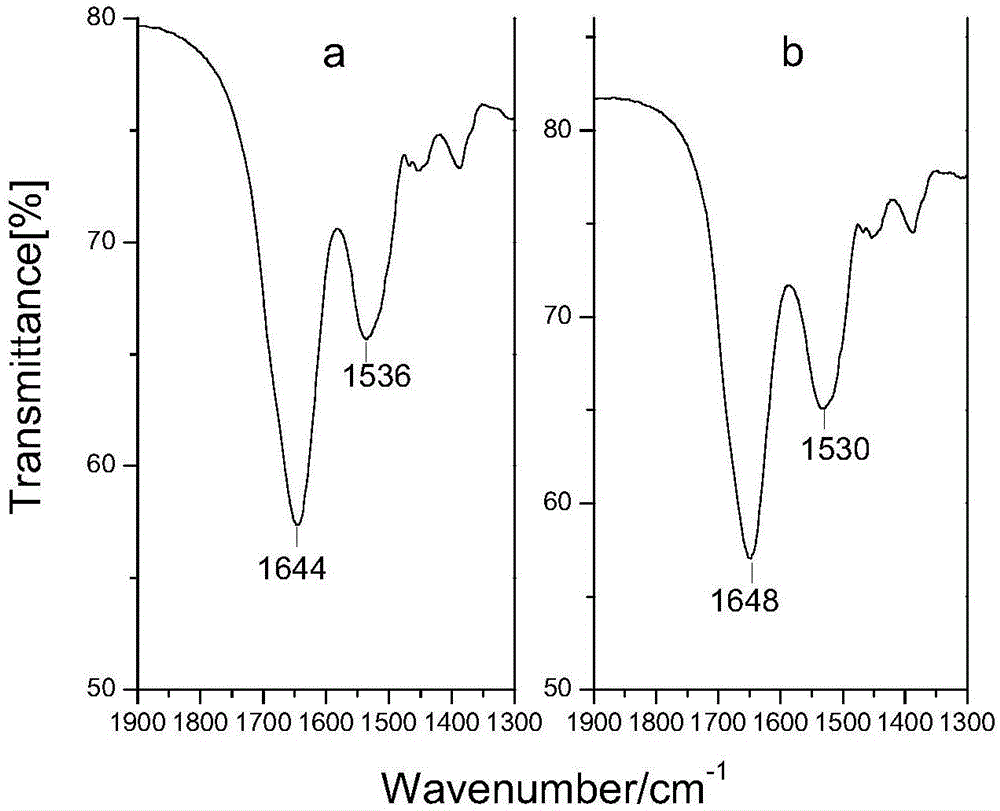

Graphene-hydrotalcite-like sheet-graphite phase carbon nitride composite immobilized protein modified electrode and preparation method and application thereof

InactiveCN104977341BSuppress restackingLarge specific surface areaMaterial analysis by electric/magnetic meansElectrochemical responseChemical reaction

The invention discloses a graphene (GR)-hydrotalcite-like compound (LDH)-graphite phase carbon nitride (g-C3N4) composite material immobilized protein modified electrode, a production method and an application thereof. The method comprises the following steps: compounding an exfoliation hydrotalcite-like compound with negatively charged exfoliation graphene oxide nanosheets, mixing the obtained material with melamine, roasting, and adding water to recover in order to prepare a GR-LDH-g-C3N4 hybrid; and adding a GR-LDH-g-C3N4 and Hb mixed solution to an ionic liquid modified carbon paste electrode in a dropwise manner in order to produce the GR-LDH-g-C3N4 composite material immobilized protein modified electrode. The graphene-hydrotalcite-like compound-graphite phase carbon nitride composite material immobilized protein modified electrode fully displays advantages of a gel method and an integrating, merging and layering method, increases the specific surface area, the conductivity and the biocompatibility of the hybrid material, and inhibits the afresh stacking of GR sheets; and a roasting method allows g-C3N4 to grow on the surface of a GR sheet layer, increases the specific surface area of the hybrid material, and improves the electron transfer rate of an electrochemical reaction process. A constructed CTS / GR-LDH-g-C3N4-Hb composite film-based third-generation trichloroacetic acid sensor has the advantages of low detection limit, wide detection range and small Michaelis constant.

Owner:上海铭煦新材料有限公司

Method and device for spreading, flattening and single-layering tobacco leaves

ActiveCN106690398BAvoid re-stackingAvoid Undetectable DefectsTobacco preparationAcute anglePositive pressure

The invention relates to the field of tobacco processing, and relates to a technology for controlling the shape of tobacco leaves, in particular to a method and equipment for online spreading, flattening, and single-layer transportation of tobacco leaves. Tobacco leaves are accelerated in the material-gas separation air duct, and then the overlapped and wrapped tobacco leaves are unfolded and flattened by the positive pressure and zero pressure conversion of the negative pressure single-layer sieve cylinder, and then transferred to the high-speed belt conveyor, the belt speed of which is greater than or equal to The discharge speed of the sieve cylinder is to prevent the re-stacking of the single-layered tobacco leaves; after the tobacco leaves are transferred to the high-speed belt conveyor, the equal-speed pressure air with an acute angle to the belt running direction is applied to make the tobacco leaves adhere to the high-speed belt surface and follow This method of exposing the sundries, green blocks, and mildew spots in the tobacco leaves to the detection device in an all-round way without dead ends can avoid the sundries, green blocks, and mildew spots in the traditional photoelectric detection when transporting tobacco leaves. Defects that cannot be detected due to the wrapping and overlapping of tobacco leaves.

Owner:KUNMING SHIPBUILDING EQUIP

A kind of graphene molybdenum disulfide composite conductive paste for lithium battery and preparation method thereof

The invention provides graphene-molybdenum disulfide composite conductive paste for lithium battery and a preparation method thereof. The method comprises the following steps of: blending a lithium ion or magnesium ion salt, molybdenum disulfide and graphite particles, heating at a high temperature, so that the lithium ion or magnesium ion is intercalated between the graphite and molybdenum disulfide layers; cooling to room temperature, fusing into a solvent, ultrasonically precrushing, thereby obtaining a mixture; ejecting the mixture through a jet nozzle of a high voltage pulse jet machine, and performing further crushing and stripping on the graphite and molybdenum disulfide by utilizing the mechanical shearing and high-speed collision effects of particles, thereby obtaining the graphene-molybdenum disulfide composite conductive paste. According to the composite conductive paste and the preparation method thereof provided by the invention, nanolayers can be effectively prevented from being stacked again, the surface area utilization rate of the electrode material is improved, and the electrical conductivity of the positive and negative poles of the lithium ion battery is greatly improved.

Owner:张家口龙驰科技有限公司

A kind of graphene-doped metal oxide electrode material and preparation method thereof

ActiveCN108022760BImprove conductivityGood chemical stabilityMaterial nanotechnologyHybrid capacitor electrodesCapacitanceElectrolysis

Owner:XIAMEN UNIV OF TECH

A method for preparing ultra-dispersed graphene by liquid nitrogen quenching

ActiveCN104692364BAvoid re-stackingShorten the cycle time of freeze-drying in situFreeze-dryingGraphite oxide

The invention discloses a method for preparing ultra-dispersed graphene by liquid nitrogen quenching. The invention adopts a chemical method to prepare graphene oxides of different sizes, heats a graphene oxide solution and then quenches it in liquid nitrogen to prepare super-dispersed graphene oxide. Then, the ultra-dispersed graphene oxide is reduced by heating or chemical reduction to prepare the ultra-dispersed graphene. The method has the advantages of low cost, simple process, and can shorten the preparation cycle (mainly shorten the cycle of sample freeze-drying), and is suitable for macro-preparation of ultra-dispersed graphene.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

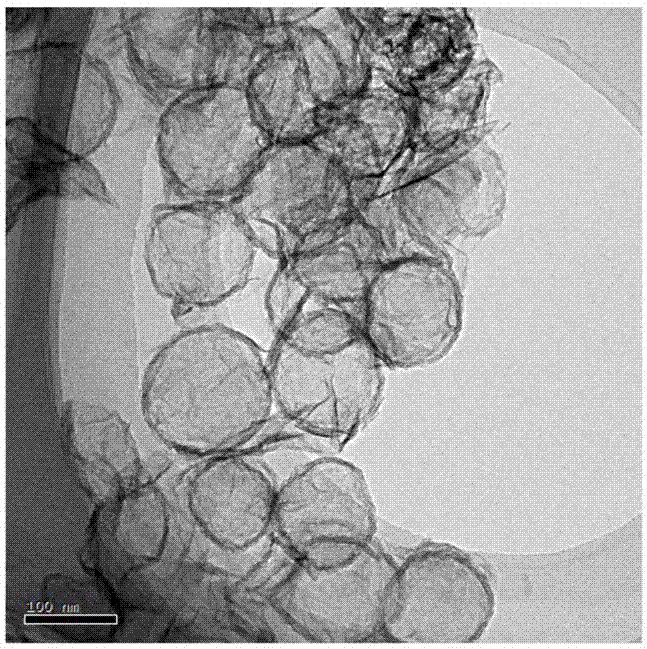

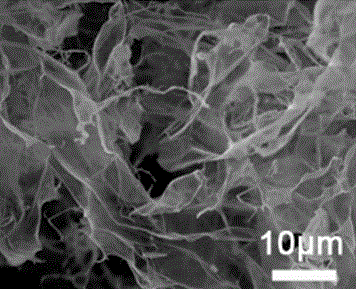

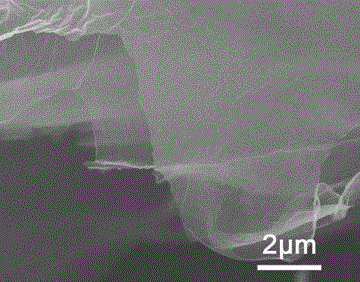

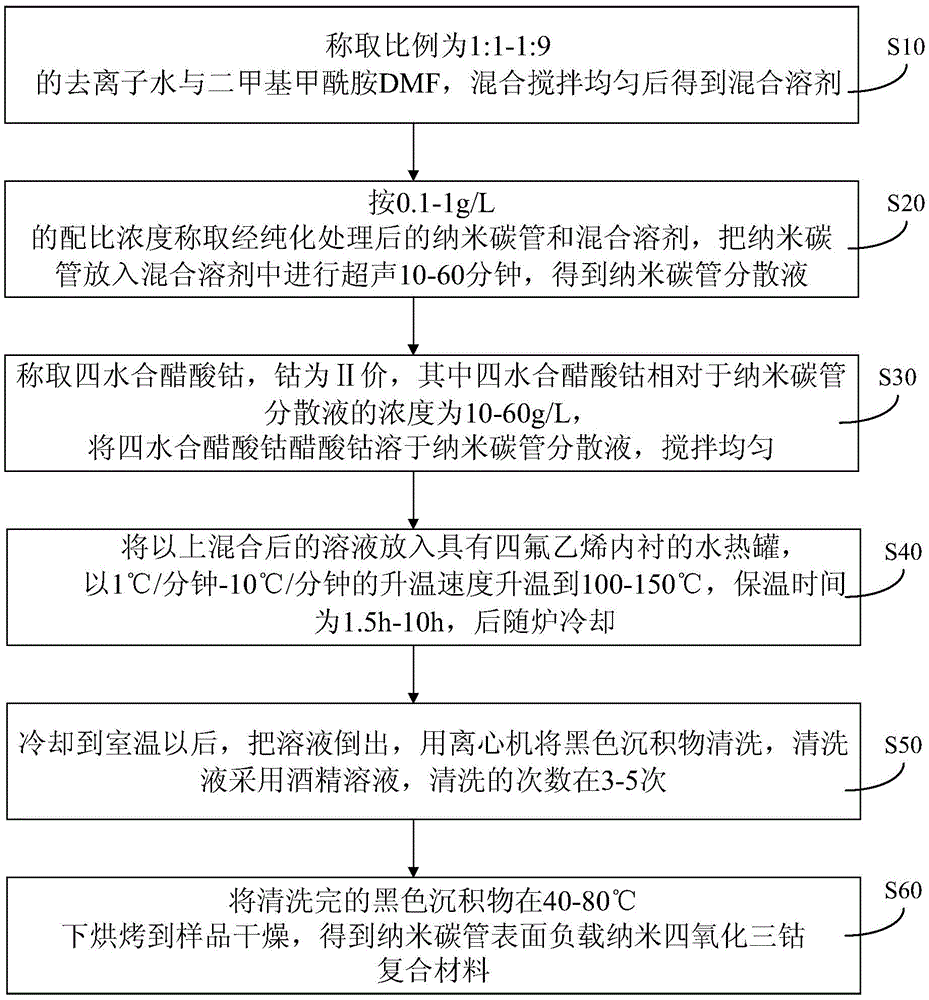

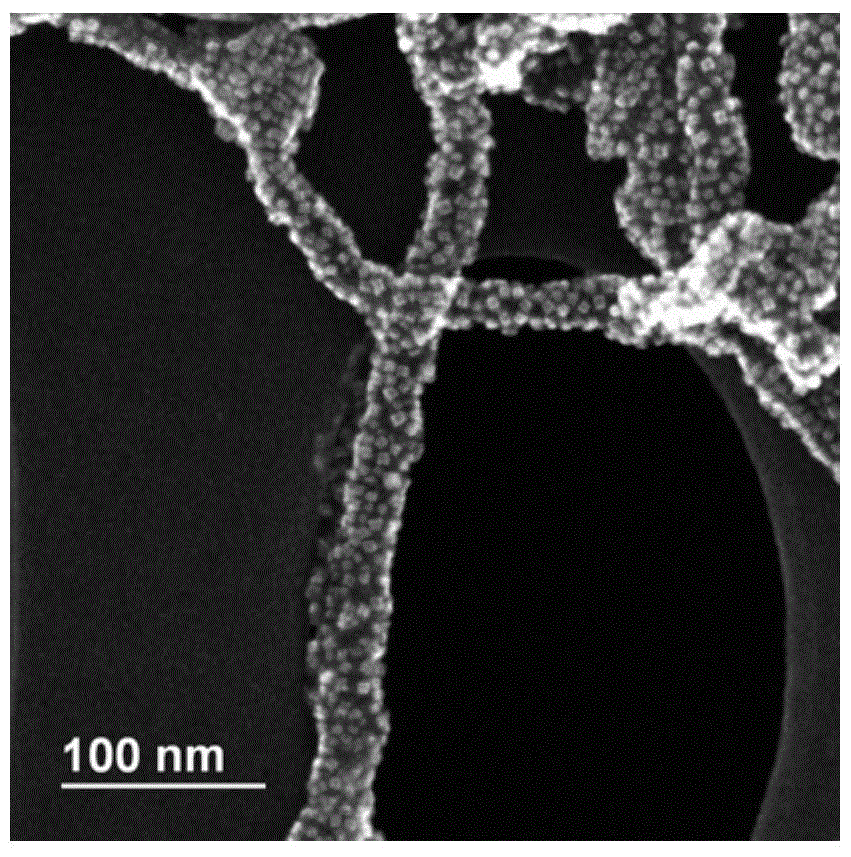

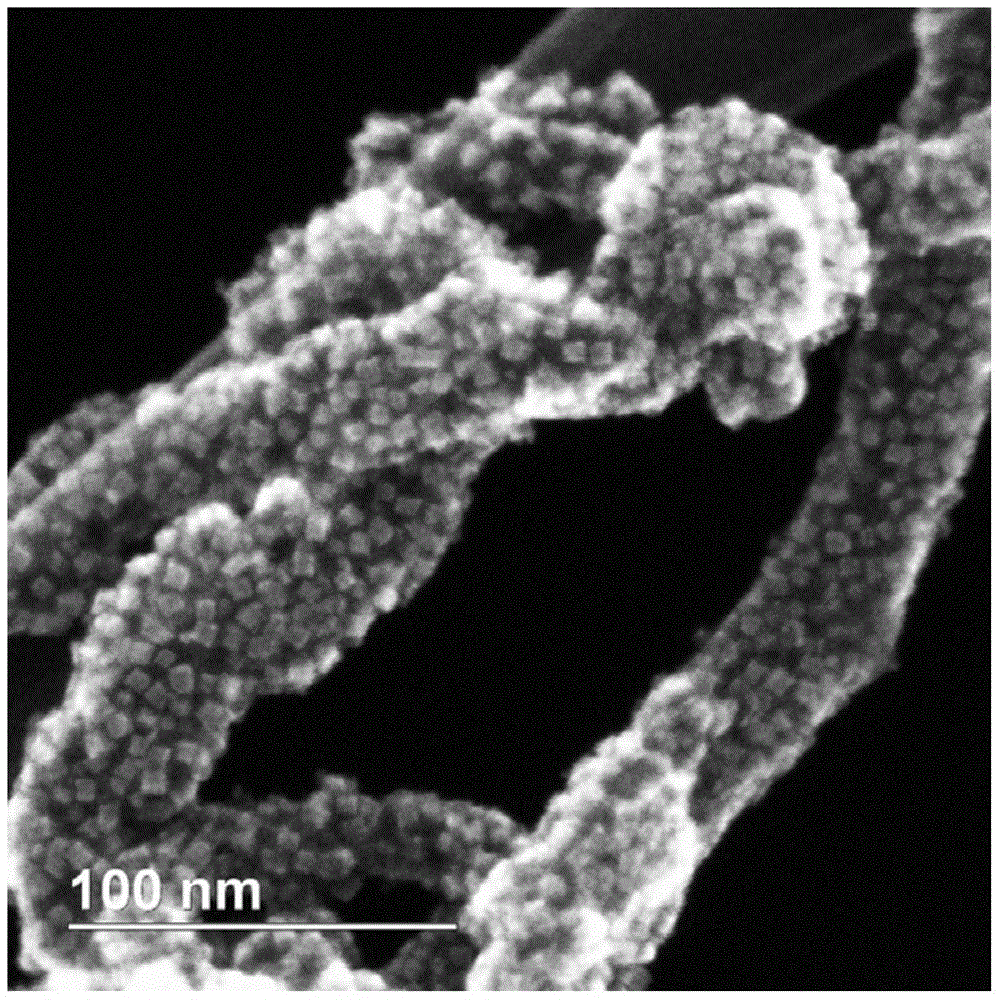

Carbon nanotube surface loaded nano cobalt trioxide composite material and preparation method thereof

ActiveCN104167295BPromote crystallizationEvenly distributedMaterial nanotechnologyHybrid capacitor electrodesTetrafluoroethyleneCobalt(II,III) oxide

The embodiment of the invention discloses a carbon nano tube surface loaded nano cobaltosic oxide composite material and a preparation method thereof. The preparation method comprises the following steps: deionized water and DMF are weighed according to a ratio of 1:1 to 1:9 to obtain a mixed solvent; purified carbon nano tube and the mixed solvent are weighed according to the compounding concentration of 0.1-1g / L, and ultrasonic processing is performed for 10-60min; cobalt(II) acetate tetrahydrate of which the concentration is 10-60g / L relative to carbon nano tube dispersion liquid is weighed, and cobalt(II) acetate tetrahydrate is dispersed in the carbon nano tube dispersion liquid and stirred evenly; the obtained mixed solution is put in a hydrothermal tank with a tetrafluoroethylene liner and then cooled along with a furnace; after the solution is cooled to room temperature, black deposits are cleaned by a centrifuge; and baking is performed until a sample is dried. Co3O4 particles of the carbon nano tube surface loaded nano cobaltosic oxide composite material prepared by the method are cubic and uniform in size, have a side length smaller than 7nm, and are uniformly distributed on the surface of the carbon nano tube.

Owner:杭州中盟智控科技集团有限公司

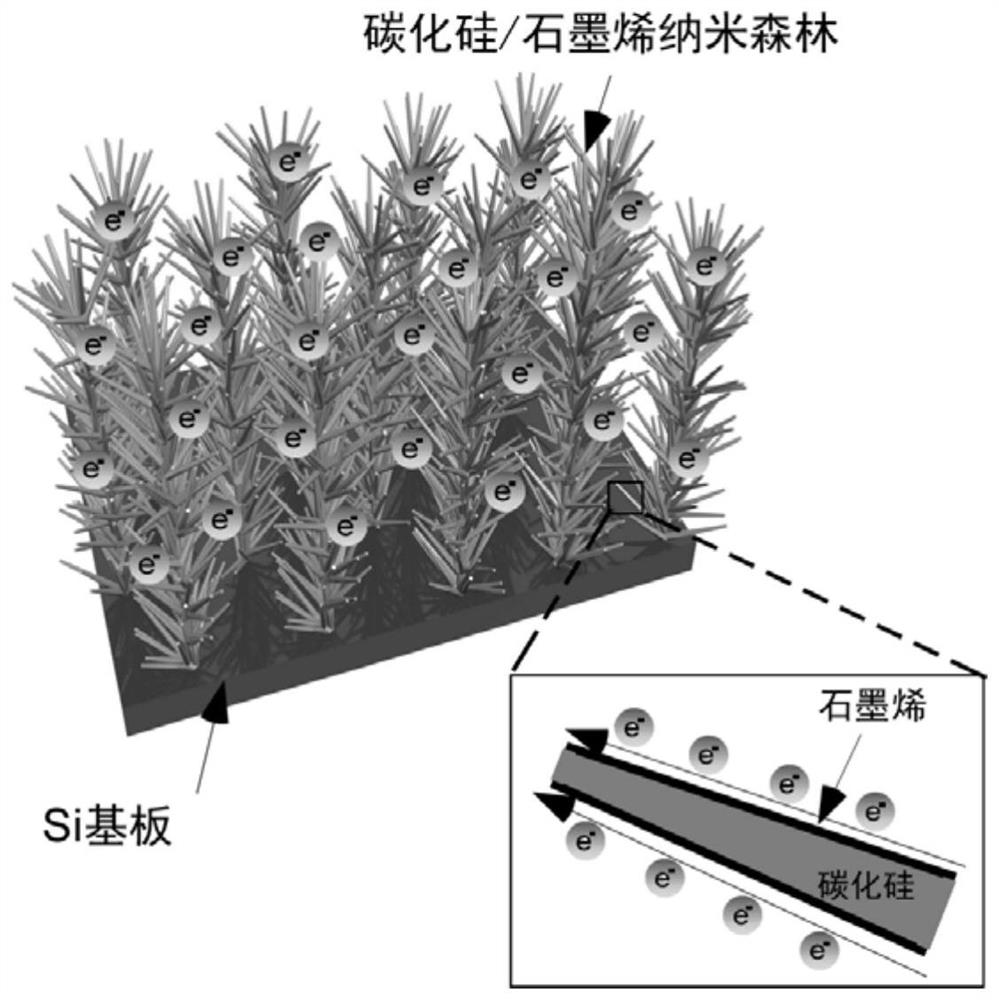

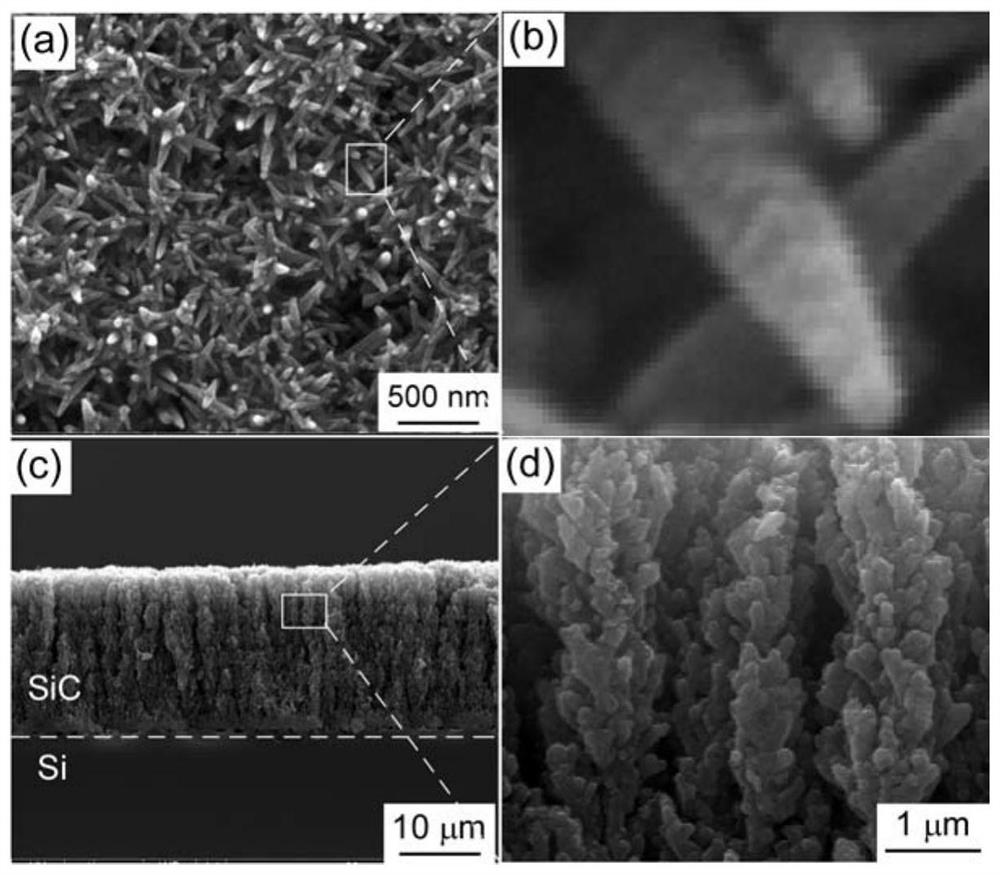

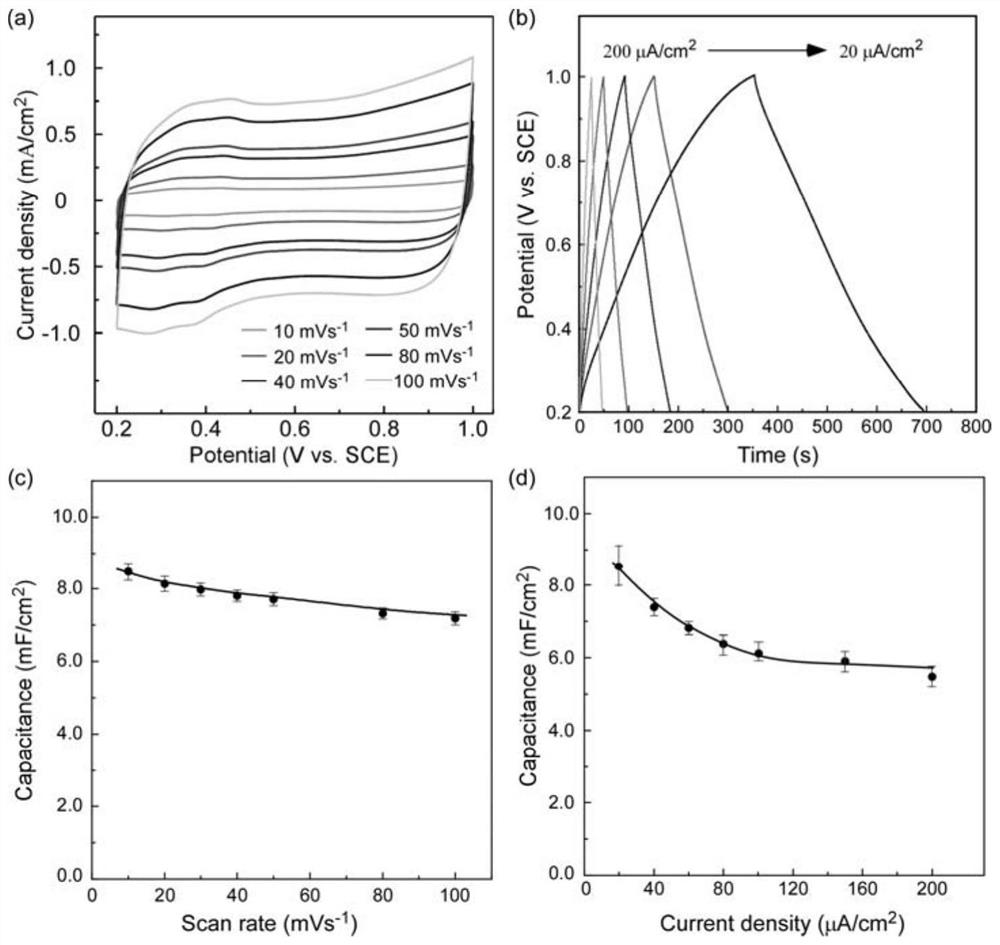

A kind of silicon carbide/graphene composite nano-forest film material and its preparation method and application

ActiveCN110648855BGood electrical conductivityLower internal resistanceHybrid capacitor electrodesGrapheneCapacitanceCarbide silicon

The invention discloses a silicon carbide / graphene composite nano-forest film material and its preparation method and application. The film material is obtained by densely growing silicon carbide / graphene nano-whiskers on the surface of a substrate. The silicon carbide / graphene Graphene nanowhiskers are obtained by the epitaxial growth of graphene with 2 to 3 layers on the surface of silicon carbide whiskers. There is a coherent pore structure between silicon carbide / graphene nanowhiskers, forming a "nano forest" film. Material. The silicon carbide / graphene composite nano-forest film material provided by the invention has the characteristics of high electrical conductivity, large specific surface area, and stable physical and chemical properties, which greatly improves the double-layer capacitance of the negative electrode material, and shows good rate performance and cycle stability. .

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com