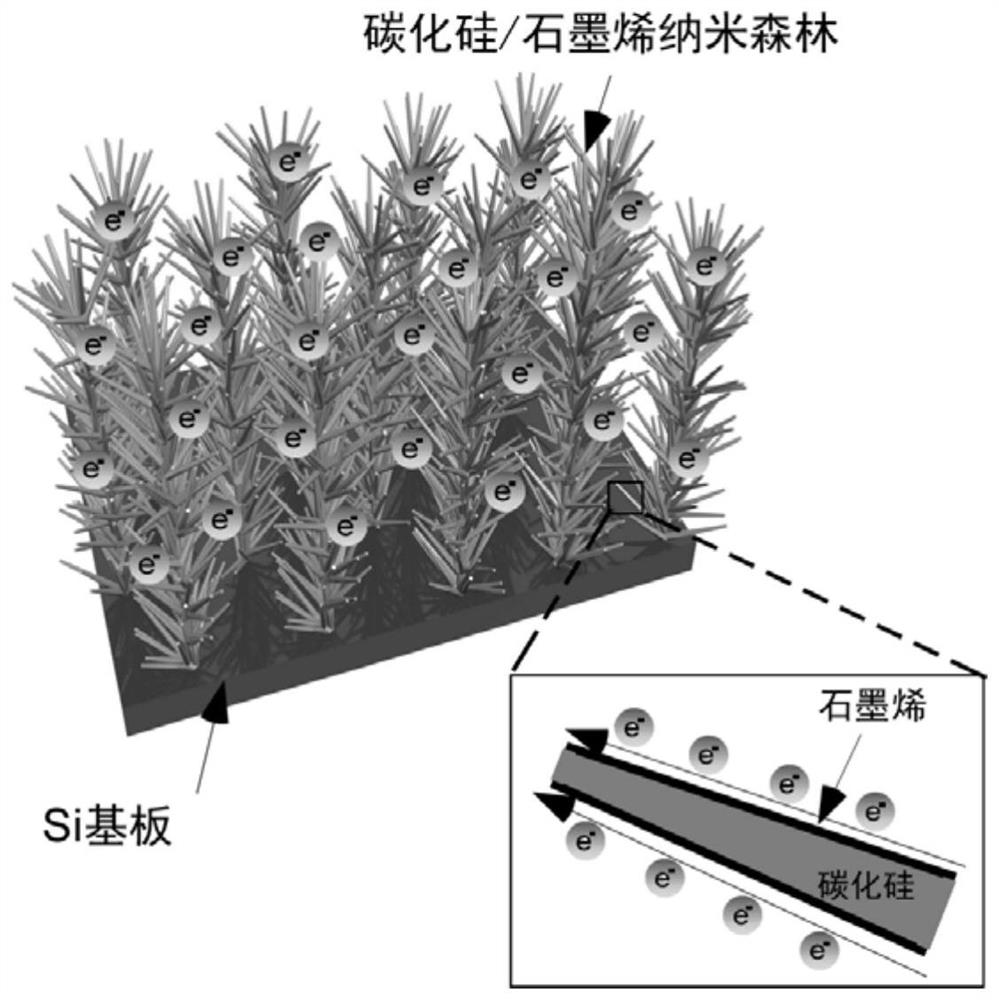

A kind of silicon carbide/graphene composite nano-forest film material and its preparation method and application

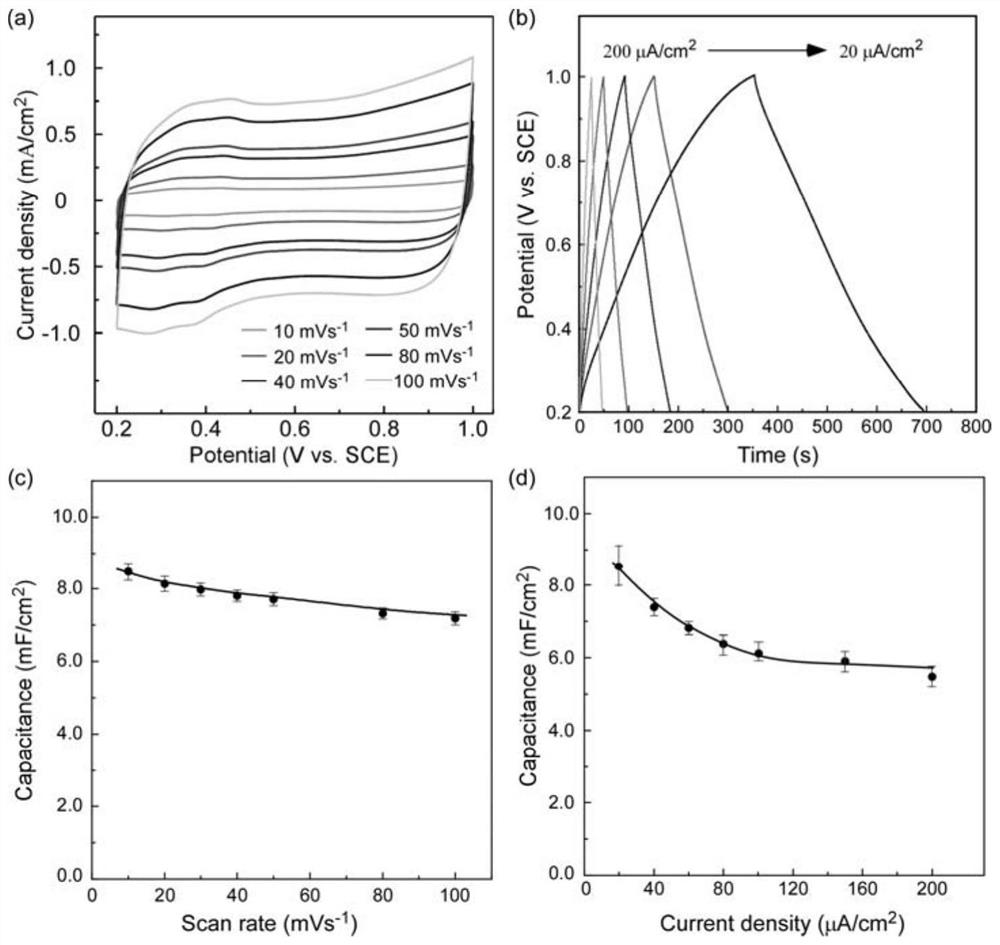

A graphene composite, thin film material technology, applied in the direction of graphene, silicon carbide, carbon compounds, etc., can solve the problems of small electrode, reduced electrical activity, small contact activation area, etc., to achieve high conductivity and reduce internal resistance. , the effect of higher than capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

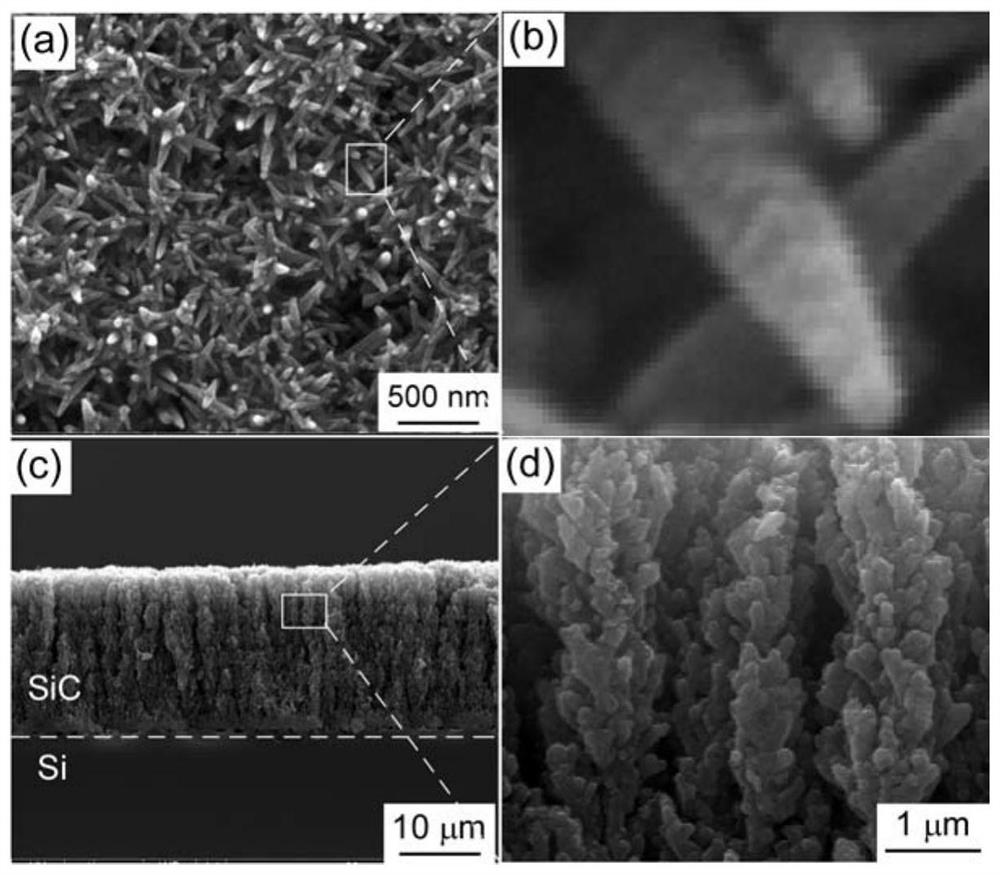

Embodiment 1

[0035] A silicon carbide / graphene composite nano-forest film electrode, the preparation method of which is as follows:

[0036] 1) Lofting: Put the cleaned substrate (single crystal silicon, 4 inches in diameter) into the laser chemical vapor deposition chamber, adjust the position of the substrate so that the laser irradiation covers the entire substrate;

[0037] 2) Vacuumize and introduce gas pressure adjustment: vacuumize the laser chemical vapor deposition chamber to below 10Pa, and introduce dilute gas H 2 , H 2The flow rate is 500 sccm, and the carrier Ar containing the precursor HMDS is introduced, the flow rate of the carrier Ar is 25 sccm, the HMDS flow rate is 6 sccm, and the deposition pressure is adjusted to 400 Pa and stabilized for 5 minutes;

[0038] 3) Deposition: Turn on the laser heating program, adjust the laser power to 290W, laser irradiation output wavelength to 1064nm, set the deposition target temperature to 1250°C, use an infrared thermal imager to m...

Embodiment 2

[0042] A silicon carbide / graphene composite nano-forest film electrode, the preparation method of which is as follows:

[0043] 1) Lofting: put the cleaned substrate (single crystal silicon) into the laser chemical vapor deposition chamber, adjust the position of the substrate so that the laser irradiation covers the entire substrate;

[0044] 2) Vacuumize and introduce gas pressure adjustment: vacuumize the laser chemical vapor deposition chamber to below 10Pa, and introduce dilute gas H 2 , H 2 The flow rate is 500 sccm, and the carrier Ar containing the precursor HMDS is introduced, the flow rate of the carrier Ar is 25 sccm, the HMDS flow rate is 6 sccm, and the deposition pressure is adjusted to 1600 Pa and stabilized for 5 minutes;

[0045] 3) Deposition: Turn on the laser heating program, adjust the power to 260W, laser irradiation output wavelength to 1064nm, set the deposition target temperature to 1200°C, use an infrared thermal imager to monitor the surface tempera...

Embodiment 3

[0049] The preparation method of silicon carbide / graphene composite nano-forest film electrode is as follows:

[0050] 1) Lofting: put the cleaned substrate (single crystal silicon) into the laser chemical vapor deposition chamber, adjust the position of the substrate so that the laser irradiation covers the entire substrate;

[0051] 2) Vacuumize and introduce gas pressure adjustment: vacuumize the laser chemical vapor deposition chamber to below 10Pa, and introduce dilute gas H 2 , H 2 The flow rate is 2000 sccm, and the carrier Ar containing the precursor HMDS is introduced, the flow rate of the carrier Ar is 25 sccm, the HMDS flow rate is 6 sccm, and the deposition pressure is adjusted to 400 Pa and stabilized for 5 minutes;

[0052] 3) Deposition: Turn on the laser heating program, adjust the power to 230W, laser irradiation output wavelength to 1064nm, set the deposition target temperature to 1150°C, use an infrared thermal imager to monitor the surface temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com