Method for preparing ultra-dispersible graphene through liquid nitrogen cold quenching

A graphene and ultra-dispersion technology, which is applied in the field of macro-preparation of ultra-dispersed graphene, can solve the problems of increasing the production cycle of graphene and affecting the quality of prepared graphene, shortening the preparation cycle and shortening the cycle of in-situ freeze-drying , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Graphite oxide was prepared by the modified Hummers method using 32 mesh natural flake graphite. Graphite oxide was prepared from flake graphite at an oxidation temperature of 35 °C and an oxidation time of 2 h. The graphite oxide was dispersed in water, the ultrasonic time was 10 min, and the ultrasonic power was 600 W, and then the visible particles were removed by centrifugation at 3000 rpm , to obtain a graphene oxide solution.

[0022] The graphene oxide solution with a concentration of 0.5 mg / ml was heated to 40 °C and quenched directly in liquid nitrogen until the solution was completely frozen, and then it was freeze-dried in situ. After drying, the ultra-dispersed graphene oxide material was obtained, and then it was reduced under the protection of Ar gas at 900 °C to obtain ultra-dispersed graphene.

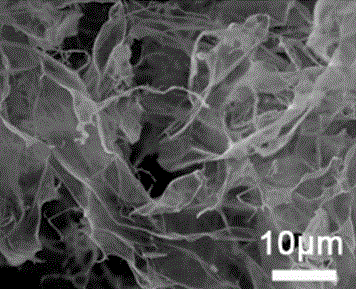

[0023] Electron microscope observation results show that: under such conditions, more than 90% of the graphene sheets in the graphene powder are in a few-layer ...

Embodiment 2

[0025] The preparation method of graphene oxide solution is the same as embodiment 1.

[0026] The graphene oxide solution with a concentration of 2 mg / ml was heated to 40 °C and quenched directly in liquid nitrogen until the solution was completely frozen, and then it was freeze-dried in situ. After drying, the ultra-dispersed graphene oxide material was obtained, and then it was reduced under the protection of Ar gas at 900 °C to obtain ultra-dispersed graphene.

[0027] Electron microscope observation results show that: under such conditions, more than 85% of the graphene sheets in the graphene powder are in a few-layer dispersed state.

Embodiment 3

[0029] The preparation method of graphene oxide solution is the same as embodiment 1.

[0030] The graphene oxide solution with a concentration of 6 mg / ml was heated to 40 °C and quenched directly in liquid nitrogen until the solution was completely frozen, and then it was freeze-dried in situ. After drying, the ultra-dispersed graphene oxide material was obtained, and then it was reduced under the protection of Ar gas at 900 °C to obtain ultra-dispersed graphene.

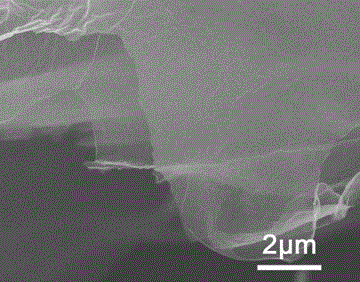

[0031] Electron microscope observation results show that: under such conditions, more than 80% of the graphene sheets in the graphene powder are in a few-layer dispersed state. like figure 2 As shown, the 6 mg / ml graphene oxide solution was directly put into liquid nitrogen and quenched after being heated to 40 °C. It can be seen from the photos of the scanning electron microscope that the high-concentration graphene oxide solution was quenched, and the graphene sheets Layers can also remain thin and hyperdisper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com