Carbon nanotube surface loaded nano cobalt trioxide composite material and preparation method thereof

A technology of cobalt tetroxide and carbon nanotubes, which is applied in the fields of nanotechnology, nanotechnology, hybrid/electric double layer capacitor manufacturing, etc., can solve the problems of low distribution density of nanoparticles, uneven distribution of carbon nanotubes, and excessive size of nanoparticles. , to achieve the effects of good controllability and repeatability, favorable for rapid transmission and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

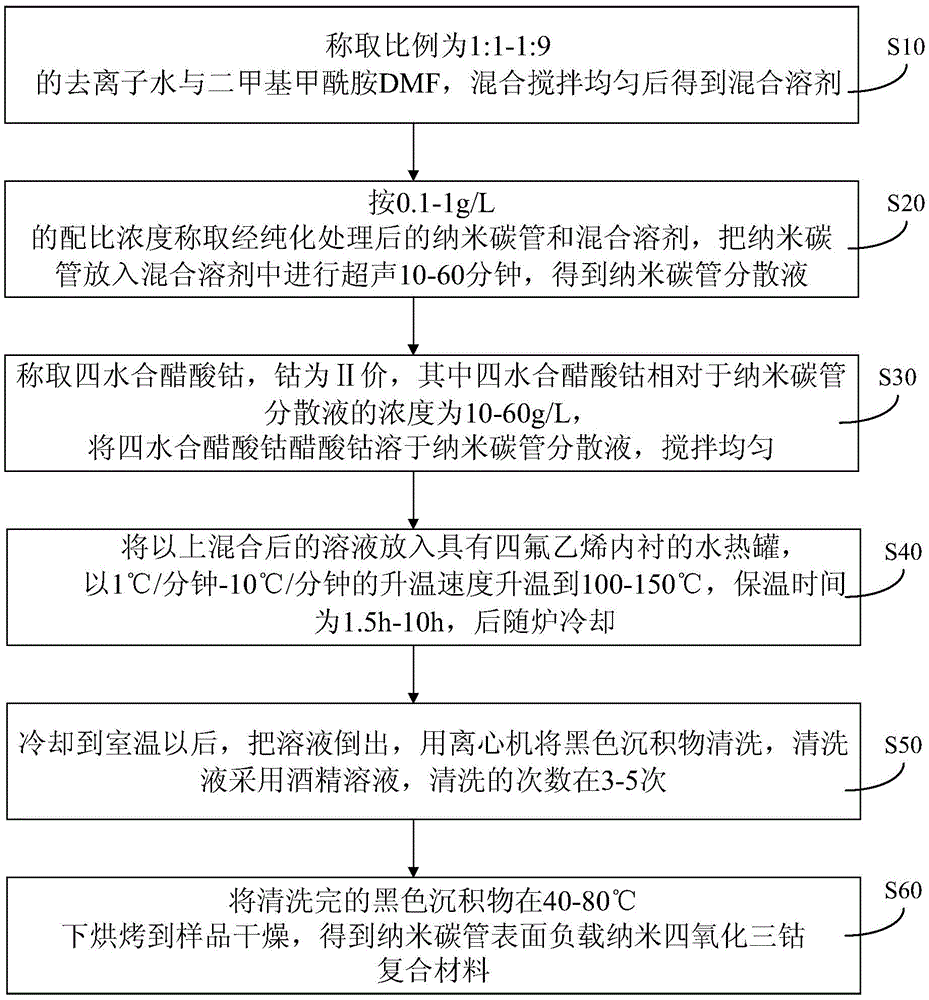

[0028] see figure 1 , which is a flow chart showing the steps of a method for preparing a carbon nanotube surface-supported nano-cobalt tetroxide composite material according to an embodiment of the present invention, which includes the following steps:

[0029] S10, weighing deionized water and dimethylformamide DMF in a ratio of 1:1-1:9, mixing and stirring evenly to obtain a mixed solvent;

[0030] S20, weighing the purified carbon nanotubes and mixed solvent according to the ratio concentration of 0.1-1g / L, putting the carbon nanotubes into the mixed solvent and performing ultrasonication for 10-60 minutes to obtain a carbon nanotube dispersion;

[0031] Among them, in the specific application example, the specific purification treatment steps of carbon nanotubes can be as follows: add 0.5g of carbon nanotubes prepared by chemical vapor deposition CVD method into 100ml of concentrated nitric acid, first ultrasonically disperse for 30min, and then heat and reflux for 4h to ...

Embodiment 1

[0041] Weigh 8ml of DMF and 2ml of deionized water, and stir evenly to obtain a mixed solvent. Weighing 4 mg of the purified carbon nanotubes, putting the carbon nanotubes into a mixed solvent and ultrasonicating for 60 minutes to obtain a carbon nanotube dispersion. Weigh 400 mg of cobalt (II) acetate tetrahydrate, dissolve the cobalt (II) acetate tetrahydrate to obtain a carbon nanotube dispersion, and stir until completely dissolved. Put the above solution into a hydrothermal tank with a tetrafluoroethylene liner and a volume of 20ml. The reaction solution accounts for about 50% of the total volume of the hydrothermal tank, which meets the requirements of the filling volume ratio of the hydrothermal tank. The heating rate is raised to 120°C, the holding time is 1.5h, and then cooled with the furnace. The microparticles are cleaned with a centrifuge, using alcohol solution, and the number of times of cleaning is 5 times. Baking at 40° C. until the sample is dry, the carbon...

Embodiment 2

[0043] Weigh 10ml of DMF and 10ml of deionized water and stir evenly to obtain a solvent. Weigh 2 mg of the purified carbon nanotubes, put the carbon nanotubes into a solvent and perform ultrasonication for 10 minutes to obtain a carbon nanotube dispersion. Weigh 200 mg of cobalt (II) acetate tetrahydrate, dissolve the cobalt (II) acetate tetrahydrate in a mixed solvent, and stir until completely dissolved. Put the above solution into a 50ml hydrothermal tank with a tetrafluoroethylene liner. The reaction solution accounts for about 40% of the total volume of the hydrothermal tank, which meets the requirements of the filling volume ratio of the hydrothermal tank. The heating rate is raised to 150°C, the holding time is 5h, and then cooled with the furnace. The microparticles are cleaned with a centrifuge, using alcohol solution, and the number of times of cleaning is 3 times. Bake at 80°C until the sample is dry to obtain a nano-cobalt tetraoxide composite material supported...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com