Three dimensional graphene/hollow carbon sphere/sulfur composite material, preparation method thereof, and application in lithium-sulfur batteries

A hollow carbon sphere, composite material technology, applied in nanotechnology for materials and surface science, battery electrodes, secondary batteries, etc., can solve the problem that graphene pore structure is not as rich as hollow carbon spheres, and hollow carbon spheres have electronic conductivity. It is not as good as graphene, reducing the battery rate performance of sulfur utilization rate, etc., to achieve the effects of flexible and controllable mechanical flexibility, inhibition of dissolution flying shuttle, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

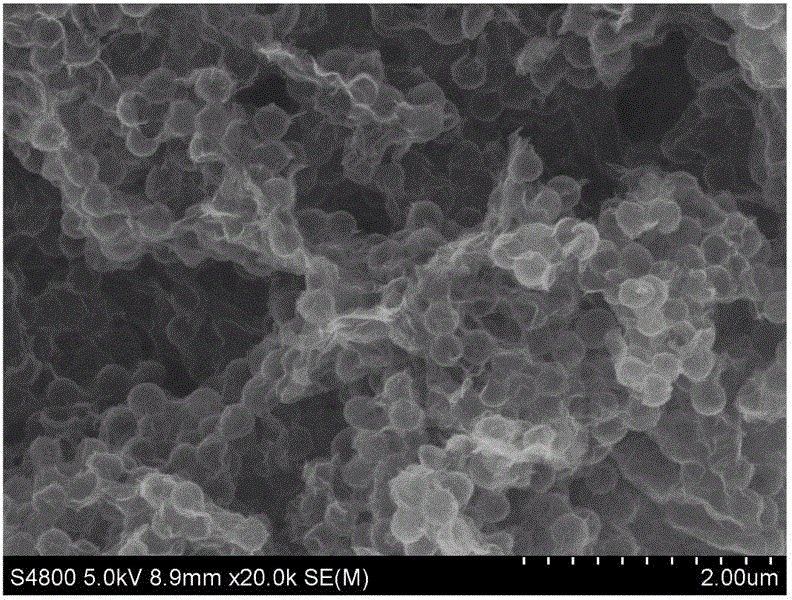

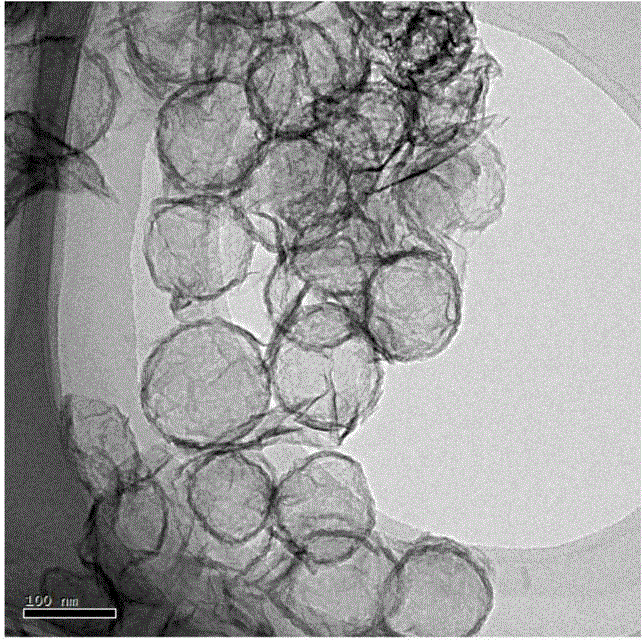

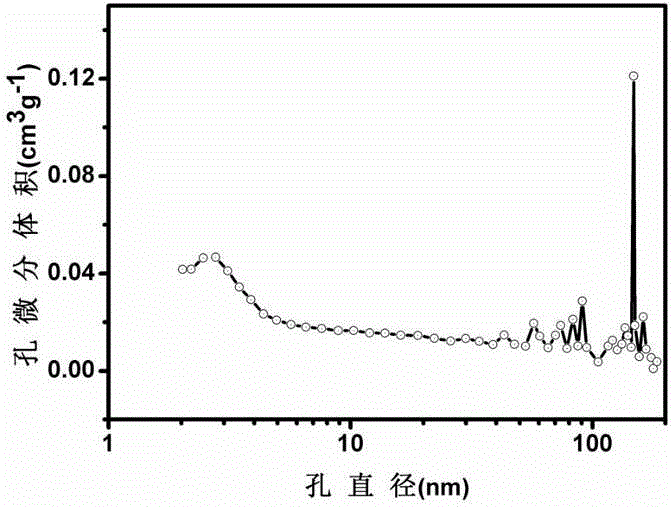

[0043] A three-dimensional graphene-hollow carbon sphere / sulfur composite material of the present invention, the three-dimensional graphene-hollow carbon sphere / sulfur composite material includes nano elemental sulfur and a three-dimensional graphene-hollow carbon sphere nanocomposite, and the nanometer elemental sulfur is evenly distributed In 3D graphene-hollow carbon sphere nanocomposites.

[0044] In the three-dimensional graphene-hollow carbon sphere / sulfur composite material of this embodiment, the three-dimensional graphene-hollow carbon sphere nanocomposite is composed of hollow carbon spheres and graphene, and the hollow carbon spheres are evenly distributed in the three-dimensional network structure formed by graphene middle. The mass ratio of the hollow carbon spheres to the graphene is 7:3, the particle size of the hollow carbon spheres is in the range of 140nm-160nm, and the average particle size is 150nm.

[0045] In the three-dimensional graphene-hollow carbon ...

Embodiment 2

[0062]A three-dimensional graphene-hollow carbon sphere / sulfur composite material of the present invention, the three-dimensional graphene-hollow carbon sphere / sulfur composite material includes nano elemental sulfur and a three-dimensional graphene-hollow carbon sphere nanocomposite, and the nanometer elemental sulfur is evenly distributed In 3D graphene-hollow carbon sphere nanocomposites.

[0063] In the three-dimensional graphene-hollow carbon sphere / sulfur composite material of this embodiment, the three-dimensional graphene-hollow carbon sphere nanocomposite is composed of hollow carbon spheres and graphene, and the hollow carbon spheres are evenly distributed in the three-dimensional network structure formed by graphene middle. The mass ratio of the hollow carbon sphere to the graphene is 8:1, the particle diameter of the hollow carbon sphere is in the range of 140nm-160nm, and the average particle diameter is 150nm.

[0064] In the three-dimensional graphene-hollow ca...

Embodiment 3

[0073] A three-dimensional graphene-hollow carbon sphere / sulfur composite material of the present invention, the three-dimensional graphene-hollow carbon sphere / sulfur composite material includes nano elemental sulfur and a three-dimensional graphene-hollow carbon sphere nanocomposite, and the nanometer elemental sulfur is evenly distributed In 3D graphene-hollow carbon sphere nanocomposites.

[0074] In the three-dimensional graphene-hollow carbon sphere / sulfur composite material of this embodiment, the three-dimensional graphene-hollow carbon sphere nanocomposite is composed of hollow carbon spheres and graphene, and the hollow carbon spheres are evenly distributed in the three-dimensional network structure formed by graphene middle. The mass ratio of the hollow carbon spheres to the graphene is 8:2, the particle diameter of the hollow carbon spheres is in the range of 180nm-220nm, and the average particle diameter is 200nm.

[0075] In the three-dimensional graphene-hollow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com