Graphene metal compound super capacitor electrode material and preparation method thereof

A technology of supercapacitors and metal composites, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of reducing the specific surface area and specific capacity of graphene, poor conductivity of metal oxides, and unfavorable lithium battery cycles. Achieve the effects of increasing specific capacity and cycle stability, reducing the use of precious metals, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of above-mentioned graphene metal composite supercapacitor electrode material, comprises the steps:

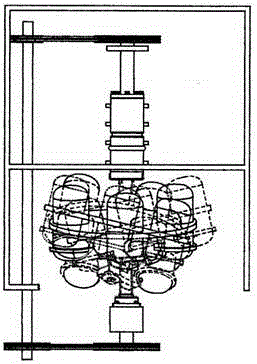

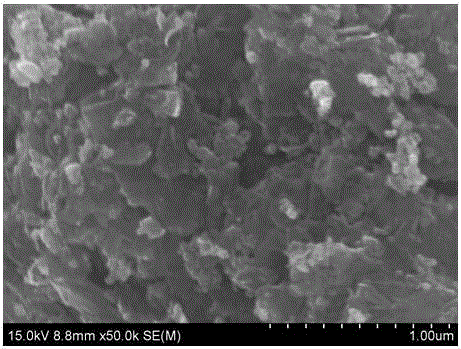

[0026] 1) Add a certain proportion of expanded graphite flakes, metal and / or metal alloys, conductive polymers, and meltable polymers into the graphene peeling machine, and grind together for 10 to 16 hours in a vacuum state to prepare sheet-shaped graphene, sheet Nano-metal and / or sheet-like nano-metal alloy, mixed powder material of granular polymer; the sheet thickness of the sheet-like graphene is less than 100nm; sheet-like nano-metal and / or sheet-like nano-metal alloy The sheet thickness is less than 100nm; the average particle size of the polymer is less than 100nm.

[0027] 2) Pressurize or evacuate the mixed powder material in the reactor, raise the temperature to the melting point of the meltable polymer, keep it warm for 2-4 hours, and then lower it to room temperature to obtain the composite electrode material.

[0028] Wherein, the m...

Embodiment 1

[0033] Step 1: Take 0.25kg of high-purity expanded graphite, 0.25kg of copper powder, 0.1kg of polyaniline, and 0.2kg of polytetrafluoroethylene, put them into the grinding tank of the graphene peeling machine and add 16kg of 201 stainless steel balls, seal, vacuumize, and jacket The temperature of the circulating water is controlled at 35°C, the number of revolutions is 600 times / min, and the ball mill is impacted and rubbed for 12 hours. The grinding tank is removed, the ball material is taken out in a vacuum glove box, and the co-milled powder is obtained by sub-sieving. Wherein the thickness of the metal sheet and the graphene sheet are both below 100 nanometers, and the particle size of the polymer is also below 100 nanometers.

[0034] Step 2: Put the co-milled powder in a vacuum drying oven to vacuumize 0.08~0.1mpa, raise the temperature to 330°C, keep it warm for 2 hours, then stop vacuuming and open the air release valve, you can directly open the drying oven to contac...

Embodiment 2

[0037] Step 1: Take 0.25kg of an alloy powder for soldering (micron grade, containing 5% copper, 3% antimony, 3.5% bismuth, 2% silver, and tin as the balance), and 0.25 kg of high-purity expanded graphite kg, polyaniline 0.1kg, nylon 660.2kg, put into graphene peeling machine grinding tank, add 16kg of 210 stainless steel balls, seal, vacuumize 0.1mpa, jacket circulating water cooling temperature control at about 35 ℃, speed 600 times / min, Impact rubbing and cutting ball milling for 12 hours, remove the grinding tank, take out the ball material in the vacuum glove box, and sieve to obtain co-milled powder. The thickness of the metal sheet and graphene sheet is less than 100 nanometers, and the particle size of the polymer is also less than 100 nanometers.

[0038] Step 2: Put the co-milled powder in a vacuum drying oven, vacuum 0.08~0.1mpa, heat up to 260°C, keep warm for 2 hours, stop vacuuming and open the air release valve, take it out, and get a nanostructured supercapacit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com