Graphene and metallic oxide composite electrode material and preparation method thereof

A technology of composite electrode and graphite electrode, which is applied in the field of electrochemical materials, can solve the problems of easy agglomeration of graphene, reduce the specific surface area and specific capacity of graphene, etc., and achieve the effect of simple preparation method, good market application prospect, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

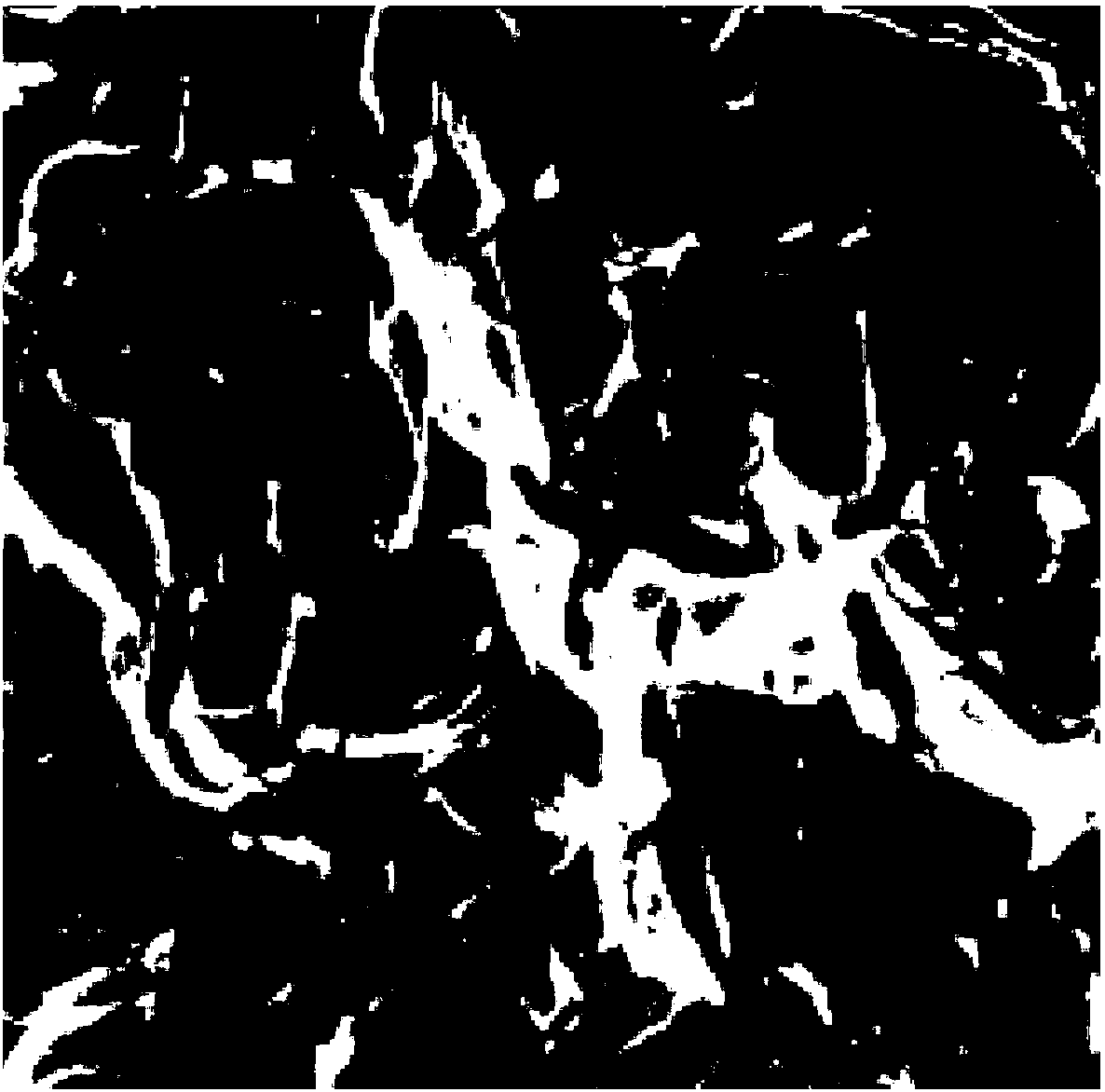

Image

Examples

preparation example Construction

[0023] The embodiment of the present invention provides a kind of preparation method of graphene / metal oxide composite electrode material, comprises the following steps:

[0024] S1, obtaining a pair of graphite electrodes and an electrolyte solution, inserting the pair of graphite electrodes into the electrolyte solution, electrifying and electrolyzing, and obtaining graphene obtained by electrolysis;

[0025] S2, dissolving Ru salt, Mn salt and Co salt in a solvent to obtain a mixed metal salt solution, wherein, in the mixed metal salt solution, the atomic ratio of Ru:Mn:Co is 4:1~4:2~4 ;

[0026] S3, in the mixed metal salt solution, add the graphene, after mixing, dry to obtain the graphene-metal salt precursor;

[0027] S4, calcining the graphene-metal salt precursor at a temperature of 230° C. to 310° C. to obtain a graphene / metal oxide composite electrode material.

[0028] Further, in step S1, the electrolyte solution is a NaCl solution with a concentration of 18-22 ...

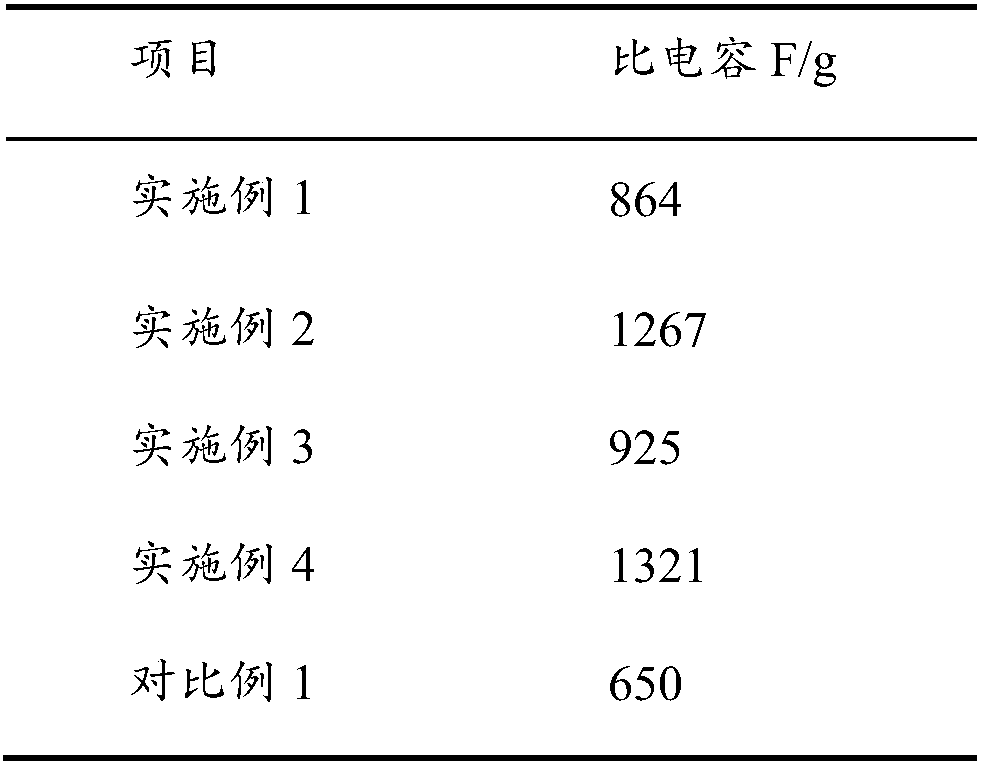

Embodiment 1

[0042] A graphene-doped metal oxide electrode material provided in this embodiment is prepared according to the following steps:

[0043] (1) Insert the paired graphite electrodes into the 20mg / L NaCl electrolyte, energize for electrolysis, the energizing voltage is 10mv, the current is 0.03A, and the energizing time is 24h. After the electrolysis is completed, the extracted powder is cleaned with alcohol and put into a drying box Drying, the drying temperature is 80°C, drying for 0.5h, and the graphene is collected for use;

[0044] (2) dissolving ruthenium trichloride, manganese chloride and cobalt chloride in alcohol according to the atomic ratio of Ru: Mn: Co is 4:3:3 to obtain a mixed metal salt solution;

[0045] (3) in mixed metal salt solution (the total amount of metal salt is 60mg), add 6mg graphene, after mixing, dry to obtain graphene-metal salt precursor;

[0046](4) Keep the graphene-metal salt precursor at 240°C for 10min, raise the temperature to 290°C for 30m...

Embodiment 2

[0048] A graphene-doped metal oxide electrode material provided in this example differs from Example 1 in that the graphene-metal salt precursor is kept at 240°C for 10min, heated to 300°C for 30min, and then The temperature was lowered to 230° C. and kept for 10 minutes to obtain a graphene / metal oxide composite electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com