Graphene-hydrotalcite-like compound-graphite phase carbon nitride composite material immobilized protein modified electrode, production method and application thereof

A technology of graphite phase carbon nitride and composite materials, which is applied in the analysis of materials, material analysis by electromagnetic means, instruments, etc., can solve the problems of low conductivity, small specific surface area, and limited electrochemical applications, and achieve a larger ratio Effect of surface area and conductivity, low preparation cost, and increased electron transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

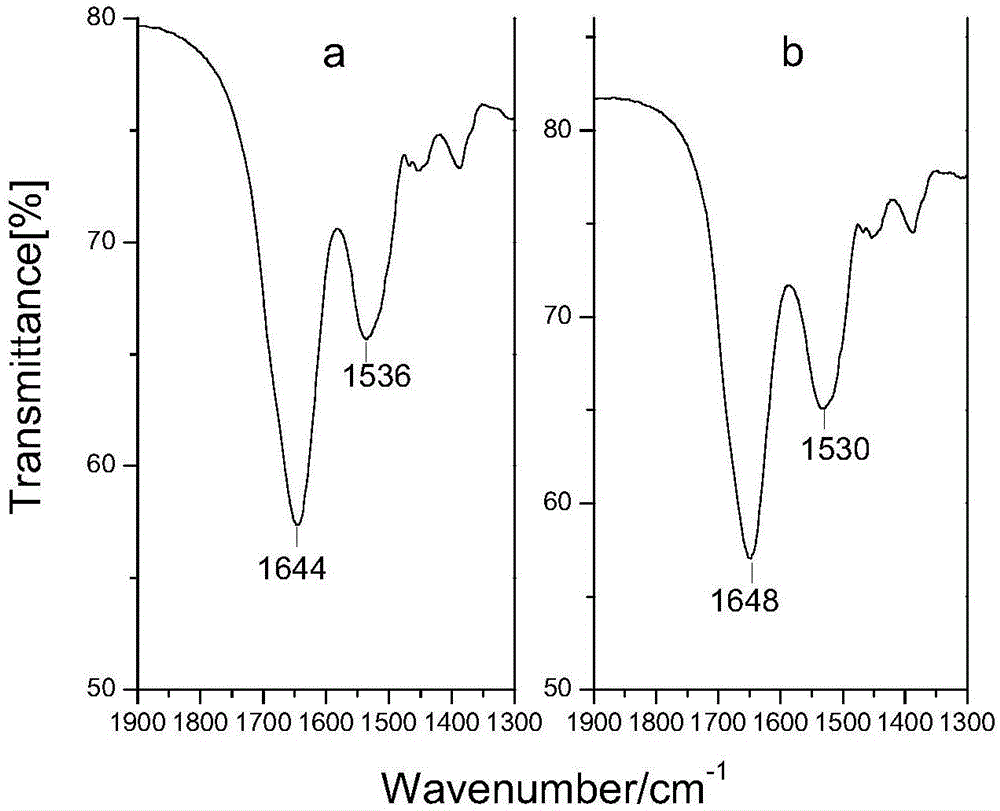

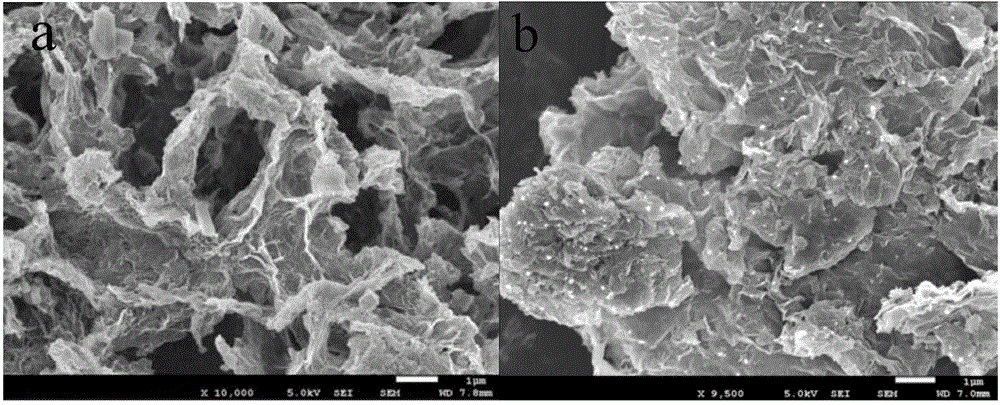

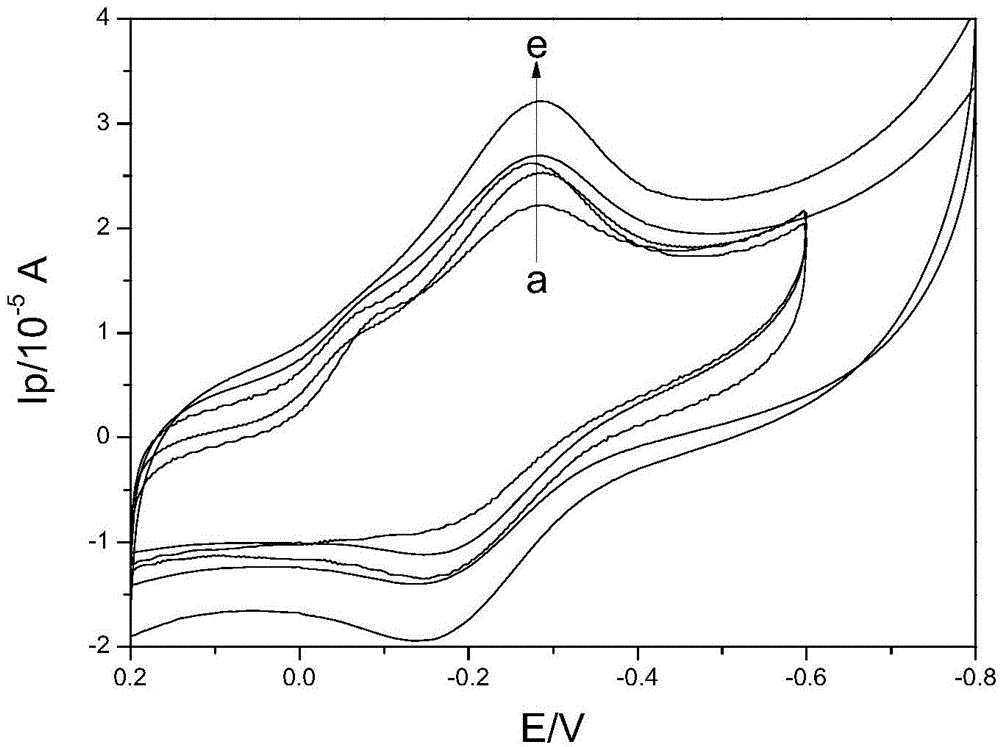

[0039] (a) Preparation of ELDH

[0040] divalent metal salt CoCl 2 ·6H 2 O, trivalent metal salt AlCl 3 ·6H 2 Add O and urea into a round bottom flask with a certain volume of deionized water at a molar ratio of 2:1:7, the total metal ion concentration is 0.15mol / L, stir and reflux at 85°C for 18 hours, and suction filter after the reaction is completed , the filter cake was washed with distilled water for 3 to 5 times, and dried at room temperature for 48 hours to obtain carbonate-intercalated LDH; weigh 100 mg of carbonate-intercalated LDH, and disperse it in NaCl and 3.3 mmol / L concentrations of 1 mol / L and 3.3 mmol / L respectively. mixed aqueous solution of HCl, N 2 Stir under the atmosphere for 12 hours, and dry at room temperature for 12 hours after suction filtration to obtain LDH intercalated with chloride ions; weigh 60 mg of LDH intercalated with chloride ions, and disperse it in 60 mL of NaNO with a concentration of 0.1 mol / L 3in aqueous solution, N 2 Stir unde...

Embodiment 2

[0050] (a) Preparation of ELDH

[0051] divalent metal salt CoCl 2 ·6H 2 O, trivalent metal salt AlCl 3 ·6H 2 Add O and urea into a round bottom flask with a certain volume of deionized water in a molar ratio of 2:1:7, the total metal ion concentration is 0.15mol / L, stir and reflux at 90°C for 24 hours, and suction filter after the reaction is completed , the filter cake was washed with distilled water for 3 to 5 times, and dried at room temperature for 48 hours to obtain carbonate-intercalated LDH; weigh 100 mg of carbonate-intercalated LDH, and disperse it in NaCl and 3.3 mmol / L concentrations of 1 mol / L and 3.3 mmol / L respectively. mixed aqueous solution of HCl, N 2 Stir under the atmosphere for 12 hours, and dry at room temperature for 12 hours after suction filtration to obtain LDH intercalated with chloride ions; weigh 60 mg of LDH intercalated with chloride ions, and disperse it in 60 mL of NaNO with a concentration of 0.1 mol / L 3 in aqueous solution, N 2 Stir und...

Embodiment 3

[0061] (a) Preparation of ELDH

[0062] divalent metal salt CoCl 2 ·6H 2 O, trivalent metal salt AlCl 3 ·6H 2 Add O and urea into a round bottom flask with a certain volume of deionized water in a molar ratio of 2:1:7, the total metal ion concentration is 0.15mol / L, stir and reflux at 95°C for 32 hours, and suction filter after the reaction is completed , the filter cake was washed with distilled water for 3 to 5 times, and dried at room temperature for 48 hours to obtain carbonate-intercalated LDH; weigh 100 mg of carbonate-intercalated LDH, and disperse it in NaCl and 3.3 mmol / L concentrations of 1 mol / L and 3.3 mmol / L respectively. mixed aqueous solution of HCl, N 2 Stir under the atmosphere for 12 hours, and dry at room temperature for 12 hours after suction filtration to obtain LDH intercalated with chloride ions; weigh 60 mg of LDH intercalated with chloride ions, and disperse it in 60 mL of NaNO with a concentration of 0.1 mol / L 3 in aqueous solution, N 2 Stir und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com